INTRODUCTION

The banana tree belongs to the Musaceae family and is considered one of the main crops of economic interest in the fruit market. Also, banana is the second most traded fruit in the world (Perrier et al., 2011) and is grown in 80 tropical countries, with a production of 106 million tons. India, China, the Philippines and Brazil are the largest producers. The largest exporting countries are Costa Rica and Ecuador, with Ecuador accounting for 30% of world trade (FAO, 2017).

Since it is a highly appreciated fruit, innovations and technologies have appeared to optimize the productive process in recent years, mainly related to the improvement of fruit quality.

However, research on the quality aspects of banana fruits is of extreme importance because they are mainly destined for direct consumption.

Considered an ecological practice, fruit bagging is a very effective and old technique for protecting fruits from attack by pests and diseases (Teixeira et al., 2011). In banana cultures, in addition to phytosanitary factors, studies have indicated that bagging can improve fruit quality. Thus, in temperate areas, it is common to cover. The fruits, while they are growing, improve yield and fruit quality. However, this technique is also used in warmer countries during the coldest seasons to protect fruits (Sakai, 2015).

Although it is an expensive technique, it protects the bunches from physical damage, such as wind action, low temperatures, fruit contact with the leaves, diseases and hail (Alves et al., 1999; Rodrigues et al., 2001; Costa et al., 2002; Silva Filho and Moreira, 2005; Moreira, 2008; Euleuterio et al., 2010; Sakai, 2015).

The method of bagging fruits is a cultural practice adopted by large-scale banana growers. Questions that have not been resolved refer to the existence of differences in the types of materials used for bagging bunches, along with bag color here are differences between fruit bagging recommendations around the world, based on preferences for color and material (Surajit et al, 2016; Santos et al., 2017).

There is a need for studies on bagging materials (Azevedo et al., 2016; Coelho et al., 2008) information and on how to perform bagging in different situations (Costa et al., 2002). Sarkar et al. (2016), in an experiment in India, evaluated the use of polypropylene bags and found that bagged fruits presented less insect damage and higher mass. However, Kutinyu (2014), in a study with different cluster protection materials, found that bagging did not provide significant results for fruit weight in Grande Naine. Sakai (2015) obtained similar results, evaluating the physical protection of 'Nanicão' bunches, and observed that the bunch mass, second bunch mass, fruit density and pulp pH were not influenced by bagging.

Therefore, studies that evaluate the effect of color of the plastic used to cover banana bunches are crucial since they can subsidize information for the productive sector to demystify and elucidate the role of this method in the production and quality of fruits. This study aimed to assess the influence of plastic bag colors on the production and quality of banana 'BRS Conquista'.

MATERIAL AND METHODS

The current study took place at the Sao Paulo State University (Unesp), School of Agriculture, Botucatu, São Paulo, Brazil. According to the Köppen classification, mesothermic temperate type (Cfa) was the predominant climate in the region, that is, humid and with a mean temperature of the hottest month close to 22°C (Cunha and Martins, 2009). The soil of the experimental area was classified as Red Nitosol (Santos et al., 2018).

Prior to the experiment installation, a soil analysis was performed with soil samples at depths of 0-20 cm and 20-40 cm. Based on this analysis, liming and fertilization were performed according to Raij et al. (1999), i.e. using 1.89 t ha-1 of dolomitic limestone, 300 g/plant of urea and 241.5 g/plant of potassium chloride. During the experiment, other cultural treatments were carried out in the orchard according to the technical recommendations for the crop.

Two-year-old banana 'BRS Conquista' plants were spaced at 2 x 2.5 m and evaluated in an agricultural cycle in 2017.

The treatments consisted of polypropylene bags with different colors (i.e. white, black, red and blue), plus a control (non-bagged bunches). The bag dimensions were 150x75 cm, open at the ends, with lateral perforations of 0.5 cm to allow gas exchange between the fruits and the outside air. The experiment design used randomized blocks, with five treatments, four replications and four plants per plot, totalling 80 plants.

The bagging was done shortly after the inflorescence issued, before the opening of the bracts. The bags were tied at the top.

Starting with the second cycle, cluster emission is not simultaneous among plants; therefore, fruit development occurs under different conditions between plants. To standardize the harvest point, the bunches were harvested when they reached the thermal accumulation degree-days of 3,200.33°C after inflorescence emission. To assess this thermal accumulation pattern, non-useful plants in the area were previously selected, and the thermal accumulation between inflorescence emission and harvest was calculated; the basal temperature was lower than 15°C and higher than 37°C, according to Figueiredo et al. (2006).

The evaluations of plant productive performance was done right after harvesting, when the fruits presented a completely green peel (PBMH and PIF, 2006). The variables included production or bunch mass (kg), rachis mass (kg), fruit total mass (kg) and mean cluster mass (kg), which were measured in scale; number of fruits per bunch and per cluster; and yield (t ha-1), for which the cluster mass was considered with a stand of 2,000 plants/ha.

The evaluations of yield performance considered five fruits from the second cluster of the bunch. The following variables were evaluated: fruit number per length and length (cm) and diameter (mm) of the fruits; the latter was measured using a digital caliper for evaluations of the physical and physicochemical characteristics of the ripe fruits. The leaves were kept on shelves at room temperature until they were completely yellow (PBMH and PIF, 2006). The following variables were evaluated: fruit number per cluster; fruit length (cm) and fruit diameter (mm); the latter was measured using a digital calliper.

For the physical and physicochemical characteristics of the ripe fruits, clusters were kept on shelves at room temperature until they were completely yellow (PBMH and PIF, 2006). The following evaluations were carried out on the five fruits of the second ripen cluster: pulp/peel ratio, with the fruits and peels weighed on a semi-analytical balance. The fruit mass was determined with the peel divided by peel mass; the values were expressed in grams. The titratable acidity (TA) was obtained according to the analytical standards of Instituto Adolfo Lutz (Lutz, 2005), titrated with sodium hydroxide (NaOH) to 0.1 N, using 5 g of homogenized pulp, diluted in 100 mL of distilled water and 0.3 mL of phenolphthalein. The content of soluble solids (SS) was measured with the aid of a digital refractometer (Atago 3405 PR-32a Palette), expressed in °Brix. The maturation index (SS/ TA) was calculated with the ratio of the soluble solids and the titratable acidity.

The data were submitted to analysis of variance, and, when there was significance, the means were compared with the Scott-Knot test at 5% probability level. All analyses were performed in the program SISVAR 5.0 - Program of Statistical Analysis and Planning of Experiments of the Federal University of Lavras (Ferreira, 2011).

RESULTS AND DISCUSSION

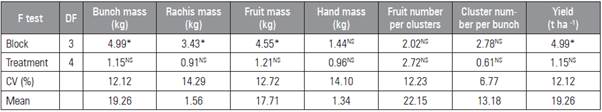

In terms of productive performance, the analysis of variance did not detect any significant effect of treatments on the variables (Tab. 1).

Table 1. Values of the F test, degrees of freedom (DF), coefficients of variation (CV) and mean bunch, rachis mass, fruit mass, hand mass, number of fruits per clusters and number of clusters per bunch of banana 'BRS Conquista' in Botucatu, State of Sao Paulo, 2018.

NS = not significant; * = significant at P≤0.05.

The fact that there was no difference between the color of the polypropylene bags for bunch mass indirectly resulted in the absence of effect on the rachis and fruits mass since bunch mass is composed of rachis and fruit mass. Moreira (2008) evaluated banana bunch mass in the presence and absence of bagging in the State of Amazonia and did not found any significance in the variation of the treatments for cultivars Prata Zulu, FHIA 18, Nanicão 2001 and Thap Maeo.

In an experiment using blue plastic bags to cover banana bunches, cv. Williams did not present any significant effect on bunch mass, according to Muchui et al. (2010). Also, Sakai (2015) evaluated bagging in two fruit development seasons (i.e. summer and winter) and did not notice any statistical difference for bunch mass.

The mean cluster mass was also unaffected by fruit bagging, regardless of color (Tab. 1). These results corroborate with those found by Rodrigues et al. (2001), who aimed to verify the influence of bagging banana bunches on the production of cv. 'Prata-anã' and did not verify statistical differences for cluster mass, fruit mass and number of clusters. Sakai (2015) evaluated bagging bananas in two fruit development seasons (i.e. Summer and Winter) did not report any statistical difference for cluster mass.

It was evident that the environmental conditions of Botucatu, State of Sao Paulo, the microclimate of the treatments, did not impact the productive aspects.

Fruit bagging only changes the amount of radiation, humidity and temperature within the cluster area. All other parts of the plants, i.e. leaves, are still exposed to environmental conditions and variations. Nevertheless, it is worth emphasizing that leaves are the main photosynthetic organs that produce carbohydrates that will later be translocated to fruits; also, photosynthesis is not efficient enough in green fruits. Thus, these traits may have resulted in the absence of effects of bagging bunches on the productive factors.

However, Costa et al. (2002) studied bagged bunches during winter, summer and autumn seasons and reported an increase in bunch mass of cv. Grand Naine bagged in the summer. Soto (2015) verified an increase in bunch yield, as a function of bagging in the summer. The highest yield of the bunches was attributed to the increase in temperature inside the bags, which created a more uniform microclimate (Alves, 1999). Another relevant aspect is the banana's ability to emit leaves more frequently in the summer, which leads to a greater photosynthetically active area and, consequently, greater production.

For the number of fruits, cluster and yield, the color of the polypropylene bags showed no differences, indicating that any of the evaluated colors could be recommended for bagging banana bunches in the field. Costa et al. (2002) did not find any significant difference for the yield of bagged and non-bagged bunches in a study on cv. Prata-anã and Grande Naine.

In an experiment on banana bunches covered with polyethylene bags, Moreira (2008) found that the bags did not affect the number of fruits or clusters; also, the differences were only observed in the cultivars. Plant behaviour related to the number of fruits and clusters and the productive capacity is mainly due to genetic and edaphoclimatic factors.

Another important factor is the moment of floral differentiation since any disturbances, such as unfavorable climatic conditions, may reflect on bunch formation and development (Karamura et al., 2011).

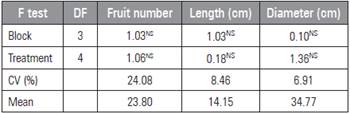

When the physical characteristics were evaluated in the second cluster with green fruits, no significant difference was observed for the number, length and diameter of the fruits (Tab. 2).

Table 2. Values of F test, degrees of freedom (DF), coefficients of variation (CV) and mean fruit number, length and diameter of fruits of the second cluster of banana 'BRS Conquista' in Botucatu, State of Sao Paulo, 2018.

NS = not significant at P<0.01 and P≤0.05 by F test.

The values found for fruit length and diameter were similar to those found by Rodrigues et al. (2001).

Likewise, similar values were found by Aquino et al. (2017), who observed length and diameter values of approximately 14.00 and 38 cm in plants of the 'Prata' group, respectively. An experiment in Kenya evaluated the effect of blue-colored polyethylene bags and of non-bagging on cv. Williams, Muchui et al. (2010) and did not find any significant differences for length. Rodrigues et al. (2001) also did not obtain statistical difference for fruit length and diameter for bagged bunches in cv. Prata anã.

According to the classification proposed for cv. Prata by Abanorte by the Fruit Growers' Central Association of North Minas Gerais - (MI et al., 2000), the fruits from 'BRS Conquista' fit the best quality type since they presented values higher than 14 cm in length and larger than 32 mm in diameter. Independent of the bag color, the fruits presented within the stated size range for 'Prata' in the current study. Therefore, the bunch bagging method did not impair fruit development.

It is noteworthy that length, diameter and fruit number are not only related to the bunch bagging method but also to abiotic factors during floral differentiation to bunch harvest and to cultivar genetic characteristics.

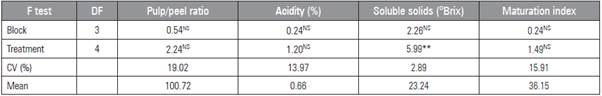

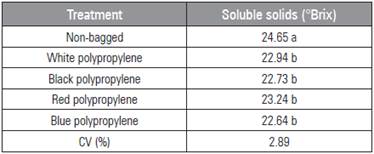

For the post-harvest characteristics of the ripe fruits, there was no statistical difference between the treatments for pulp/peel ratio, acidity, and maturation index time (Tab. 3), but there was a significant effect for soluble solids (Tab. 4).

Table 3. Values of F test, degrees of freedom (DF), coefficients of variation (CV) and means of pulp/peel ratio, acidity, soluble solids and maturation index of 'BRS Conquista' in Botucatu, State of Sao Paulo, 2018.

NS = not significant; ** = significant at P<0.01 by F test.

Table 4. Soluble solids values of the second cluster of the bunch of 'BRS Conquista' submitted to different polypropylene bag colors in Botucatu, State of Sao Paulo, 2018.

Means with different letters indicate significant differences according to the Scott-Knot test (P≤0.05).

The pulp/peel ratio is linked to the genetic characteristics of the cultivar and fruit ripening phase; therefore, during the maturation process, there was an increase in pulp mass and, consequently, a decrease in peel mass because of the osmotic transfer of moisture from the peel to the pulp and water loss from the peel to the environment. Thus, there are two factors that may interfere in the pulp/peel ratio that did not occur in the current study (Payasi and Sanwl, 2005).

Silva Filho and Moreira (2005) also verified that bagged or non-bagged bunches in different types of cultivars did not alter the pulp/peel ratio. Muchui et al. (2010) did not find any significant relationship between the pulp/peel ratio of cv. Williams in an experiment with different bag colors and perforation sizes.

These authors also found no statistical differences for titratable acidity in fruits, as observed by Silva Filho and Moreira (2005) in an experiment with several varieties using the bunch bagging method in the State of Amazonia.

For the fruit maturation index, there was no significant difference between the treatments. The maturation index is the most widely used method to evaluate fruit flavor, which is the most representative isolated measurement of acidity and sugars (Chitarra and Chitarra, 2005). A ripe banana is a great example of a high SS/TA ratio because it has high levels of sugar and a low acid content.

There was a difference in the content of soluble solids in the fruits. The non-bagged fruits presented the highest average, 24.65° Brix (Tab. 4). Green bananas have high levels of starch; however, as a fruit ripens, starch is broken down into sugars to be used in the respiratory process, consequently increasing the soluble solid contents in the pulp (Chitarra and Chitarra, 2005). This result can be related to the fact that the non-bagged fruits were more exposed to radiation, which, even in small proportions, may have allowed greater photosynthesis and sugar production.

The non-bagged fruits may have presented a lower respiration rate than the bagged ones because, inside the bags, the mean temperature was much higher that outside, which in turn promoted an increased respiratory rate and, therefore, an increased sugar consumption.

During the respiratory process, substrates are consumed but mainly organic acids, sugars and starch are consumed (Chitarra and Chitarra, 2005), so the lower the respiration rate, the lower the substance consumption, causing higher soluble solids contents, as observed in the non-bagged fruits. Costa et al. (2002) observed a low soluble solids content in bagged bunches in cv. Nanicão, in Tietê, State of Sao Paulo. Likewise, Silva Filho and Moreira (2005) found higher soluble solids in non-bagged bunches than in bagged ones.

CONCLUSIONS

Regardless of the bag color, the banana bunch bagging method for 'BRS Conquista' did not promote changes in the plant productive performance.

The non-bagged fruits presented a higher soluble solids content than the bagged ones although the maturation index and the other physicochemical traits were not affected.