Introduction

Greater compaction of ensiled material provides greater specific mass (SM) by expelling air and providing anaerobic conditions for fermentation. This allows better conservation of soluble sugars, minor alteration of structural carbohydrates and reduced proteolysis in the resulting silage, aspects which increase acceptability and consumption by livestock (Velho et al. 2007).

Direct methods are used to evaluate SM of silages, mostly the determination of herbage mass for a known volume of silage, with values being expressed in kg of natural or dry matter per cubic meter. However, these methods involve measuring the volume of the sample, taking it to a suitable facility and drying it for at least 24 hours in an oven. More rapid, indirect methods, which however require sophisticated equipment, aim to facilitate the collection of such data under field conditions, such as: radiometric sensors that present a source and a receptor for gamma waves, a method based on microwave resonance; and the georadar system, also used to estimate SM of soils (Jobim et al. 2007).

However, these indirect methods are still in development and improvement stages and rely on strict calibration to produce reliable data. Among the various invasive tools to determine SM of silages, the penetrometer has specific advantages over other techniques because it requires a simple calibration procedure and can provide reliable data. Sun et al. (2010) suggested that this technique, when properly applied, has the potential to provide good information about silage storage conditions. In an on-station study under controlled conditions, Silva et al. (2011) correlated resistance values provided by maize silage to penetration by a penetrometer with SM values obtained by sampling with the use of a metal cylinder of known volume. Estimates of SM they obtained with this indirect method compared favorably with values obtained with direct measurement, causing them to conclude that the penetrometer could provide reliable estimates under field conditions both quickly and at low cost.

The objective of our study was to measure the SM of maize silage on farms by a direct method (core sampling in the silo panel) and an indirect measurement method (using a penetrometer), and to establish correlations between the estimates obtained, with the aim of establishing the penetrometer as a reliable tool for estimating the degree of compaction of stored forage in the field.

Materials and Methods

Specific mass measurements were made by a direct method in 14 bunker silos (treatments), employing methodologies described by Holmes and Muck (1999) and D'amours and Savoie (2005), in maize silages on dairy farms in Paraná State, Brazil, specifically in the Castro, Carambeí, Arapoti, Piraí do Sul and Ponta Grossa municipalities.

A metal cylinder, 20 cm length and 10 cm diameter, with a serrated cutting edge and attached to a chainsaw, was used, as described by Craig and Roth (2005) (Figure 1) . The cylinder was screwed into the silage panel mechanically through the rotation exerted by the chainsaw. When the sample was withdrawn from the storage panel of the silo, the depth was measured with a rule to calculate the volume of the withdrawn sample. From the cylinder volume and the mass [both natural matter (NM) and dry matter (DM)] of the withdrawn sample, the SM of the silage in the silo was calculated. Whereas NM was the mass of the fresh silage, DM was determined conventionally (weighing after drying NM at 105 °C for 8 h in a forced-air oven).

Silage samples were withdrawn at 5 points (taken as replications) in the silo panel, 3 locations at the top and 2 at the bottom, forming a 'W' like figure. Before the sampling procedure commenced, a slice of silage had been removed manually from each silo panel in order to remove any loose silage from the silage 'face', so that the samples were collected from 'intact' (undisturbed) silage.

To estimate SM through the indirect method, a digital penetrometer (DLG, model PNT-2000-M), which follows the ASAE S313.3 rule that defines penetration resistance as the pressure over the area of a cone with a solid angle of 30°, was used. This equipment is used to determine the penetration resistance in soil compaction studies (Figueiredo et al. 2011; Storck et al. 2016). Penetration resistance was measured at the same time and using the same orientation as in the direct determination with the metal cylinder, with 2 measurements of resistance at each silo panel point, thus giving 10 measurements in each silo. Penetration resistance was measured at points adjacent to the spots where silage samples were taken for the direct measurements, at a distance of approximately 35 cm from those.

For resistance measurements, the penetrometer metal cone was manually pushed into the silage panel horizontally at a constant speed of approximately 2 cm/s up to the end of the cone length, a mandatory procedure according to the instruction manual for the device (Figure 2) Penetration depth into the silo panel was 0.9 m.

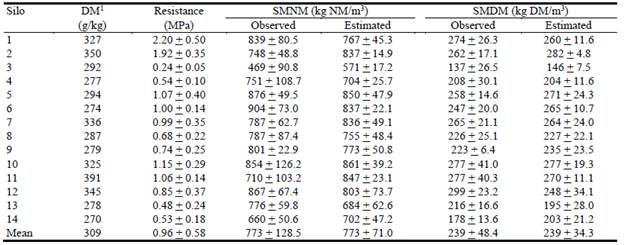

Penetrometer resistance values (in megapascal, MPa) were correlated with the SM values (kg/m3) obtained with use of the cylinder coupled to the chainsaw by a polynomial regression study. The regression equations obtained were used to calculate the values of SM for natural matter (SMNM) and dry matter (SMDM) in each silo (in Table 1: estimated SMNM and estimated SMDM) and these were compared with the values obtained by the direct method (in Table 1: observed SMNM and observed SMDM). Data were not statistically analyzed, considering that there was no replication (silo), since the silos were evaluated on different farms and factors other than the type of assessed silo and silage (maize) may present different characteristics. Therefore, the values obtained for the SMNM and SMDM were descriptively analyzed.

Table 1 Dry matter concentration, resistance by ensiled mass to penetration of the metal cone (± SD), observed and estimated specific mass (natural matter and dry matter basis) (± SD) in 14 farm silos.

1DM - dry matter; NM -natural matter; Resistance - resistance to penetration of the metal cone; SMNM - specific mass of natural matter; SMDM - specific mass of dry matter.

Results

The average DM concentration found in the silages evaluated was 309 g DM/kg, ranging from 270 to 391 g DM/kg (Table 1). Density of silage as determined by the direct method ('observed') ranged from 469 to 904 kg/m3 (mean 773 ± 129 kg/m3) for NM and from 137 to 299 kg/m3 (mean 239 ± 48.4 kg/m3) for DM. The density measurements were compared with the range in penetration resistance in the silos, which varied from 0.24 to 2.20 MPa (mean 0.96 ± 0.58 MPa). The results for this comparison are shown in Figures 3 and 4.

Figure 3 Relationship between SMNM (specific mass based on natural matter), expressed in kg/rrf and resistance to penetrometer metallic cone, expressed in MPa.

Discussion

The values observed for DM concentration of the silages evaluated are consistent with the recommendation of Nussio et al. (2001) that the optimal DM concentration of maize plants at ensiling should be 300-350 g DM/kg. According to these authors, DM concentrations below 300 g DM/kg are associated with lower DM yield, losses by leaching and low silage quality, factors that may lead to reduced intake by animals. The quality of silages was evidenced by parameters such as neutral detergent fiber, starch content and pH, which presented mean values of 46.35 ± 4.8 %, 33.28 ± 4.62 % and 3.81 ± 0.07, respectively (A.M. Krüger unpublished data).

The values obtained using the direct method indicated that there was considerable variation in how well the material was compacted in the silos, which can be related to the method of compaction used, the stage of growth of the forage when ensiled, the moisture content of the forage at ensiling, etc. According to Jobim et al. (2007), although there is no optimal value for silage density, values in the range of 550-850 kg NM/m3 are most suitable, and these are obtained only under favorable conditions. Typically, appropriate compression for desirable fermentative characteristics and minimal losses in maize silage is obtained with minimum SMDM around 225 kg DM/m3. The majority of the silages sampled were above this minimum level. One might expect that the nutritional value and acceptability of the silage to livestock would also vary markedly.

The penetration resistance observed when employing the indirect method indicates that, while there was marked variation in density of the silage as measured directly, there was much greater variation in resistance as measured by the penetrometer. If one assumes that the density measurements were accurate, one might question the accuracy of the penetrometer readings for the same silages.

In an experiment in which 18 penetrometer measures were performed in one silage sample kept under controlled conditions in an experimental station, Silva et al. (2011) found a mean penetrometer resistance of 1.09 ± 0.23 MPa and specific mass observed based on dry matter of 170 ± 36.5 kg DM/m3. As in the present study, resistance values obtained were compared with direct measurements as well.

The results obtained for SM (Table 1) observed (direct method) and estimated (indirect method), both for NM and DM, are consistent with those typically observed in farm silos and the values found by the indirect method presented a smaller range of variation when compared with the direct method, because regression equations determine the middle pathway and reduce the effect of outlying values. There was a positive relationship between the SM of silage and penetration resistance to the metal cone (Figures 3 and 4). This was a curvilinear relationship with silage SM increasing as the resistance to the cone penetration increased to a peak of about 900 kg NM/m3 or 300 kg DM/m3.

Silva et al. (2011) observed a positive linear relationship between the SM of maize silage and penetration resistance to the metal cone in 2 experiments. However, in 1 of the experiments, the adjusted linear equation had a low coefficient of determination, explaining only 33% of the observed variation. This low coefficient was attributed to surface conformations of silos used in the second experiment, since they provided lower compression of the ensiled material, and altered the physical correlation of mass and volume, which may have influenced the relationship between SM of silage and penetration resistance to the metal cone. In order to correct this, they developed equations based on the stratum in which each measurement was taken.

Those authors observed that the SM estimation with the penetrometer had greater accuracy when expressed as SMNM rather than as SMDM, while in our study the SM estimated with the indirect method showed greater accuracy when expressed as SMDM (R2 = 0.80) rather than as SMNM (R2 = 0.57). The differences between the studies may be attributed to the range of uncontrolled factors that may affect silage in silos on different farms (the study of Silva et al. 2011 was conducted under controlled conditions on an experimental station); also, the penetrometer used in the above-mentioned study was a different model from the one we used.

After corrections considering silage stratum, Silva et al. (2011) found R2 = 0.86 between the observed and estimated SMNM and R2 = 0.82 between observed and estimated SMDM. Both Silva et al. (2011) and Vissers et al. (2007) concluded that the penetrometer is a reliable indirect method for determining the SM of maize silage.

Our work confirms this conclusion and in addition corroborates that the penetrometer method is a simple tool that can be used on farm. The regression equation y = -82.109x2 + 257.9x + 89.182 (R2 = 0.80) we developed for estimating SMDM using this penetrometer provided good (80%) estimates of compaction of maize silage. However, how well this regression relates to other penetrometers and silage types needs further testing. Our data suggest that penetrometer measurements above 1.0 MPa in maize silage indicate compaction above 250 kg DM/m3. However, more testing would be needed to confirm this rule of thumb. It was of interest that all silages with SMDM above 260 kg DM/m3 had DM % inthe range 325-391 g DM/kg. All silages with penetro-meter readings below 0.75 MPa had DM % below 300 g DM/kg and SMDM below 230 kg DM/m3. The relationship between DM in silage and reliability of the machine needs to be investigated further to confirm these findings.