1. Introduction

Upflow gravel filter in layer (UGFL) is a pretreatment process that is being used in tropical countries in multi-stage filtration systems (MSF) which combines dynamic roughing filters (DRF) in combination with different forms of pre-treatment filters (upflow, down flow and horizontal flow gravel filters) and slow sand filtration (SSF). This combination allows the treatment of water with considerably higher levels of contamination than can be treated by SSF alone. Gravel filters have been specified normally to produce an effluent below 10-20 NTU and a level of total suspended solids below 5 mg/l to facilitate the treatment process in the SSF units and increase the operational run time 1. In the UGFL, gravel is placed in layers of different grain sizes, ranging from coarse at the bottom to fine at the top. The water passes through the gravel bed from bottom to top. During this passage impurities are retained in the filter. Upflow filtration has the advantage that the heavier particles are removed first at the bottom of the filter 1, and the system is able to store large amounts of solids at a very low head loss 2.

Numerous studies use mathematical models, applying trajectory theory or phenomenological theory to describe the mechanisms in gravel filtration. Trajectory theory explains the particle transport mechanisms and their behavior in the filter pores, treating them as a single collector. Phenomenological theory uses simple variables such as: the filtration velocity, (vf), filter media size, (d), depth (L) and porosity (ε) to describe the efficiency of the filter.

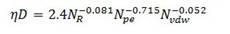

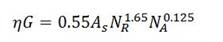

The Trajectory model approach used in this study was developed by Yao et al. 3 distinguishes three dominant processes governing particle transport: diffusion, interception, and sedimentation. Tufenkji & Elimelech 4 refined the Yao model taking into account close range forces (hydrodynamic interactions and universal van der Waals attractive forces). These two models shown in Table 1 indicate that diffusion (ηD) represents the dominant process for small particles (< 1 mm), whereas interception and sedimentation is dominant for larger particles. Diffusion of small particles to the grains is related to the temperature and viscosity of the water along with filtration rate and diameter of the particle and the collector. Interception (ηI) is defined as occurring when a particle following a fluid streamline comes into contact with a collector. Sedimentation (ηG) occurs when a particle is transported out of its fluid streamline onto a collector surface due to gravitational force. The sum of these three processes (Table 1) serves as the basis to calculate the theoretical single collector efficiency (η total), which is the ratio of the rate at which particles strike a collector surface and the rate at which particles flow towards the collector 3.

Table 1 Mathematical model for theoretical filtration analysis.

Where:

K: Boltzmann constant (1.38 x10-23 J/°K);

T: temperature (°K);

Vf: Filtration velocity (m/s, or m/h)

dp: Particle diameter (m)

dc: collector diameter (m)

μ: Viscosity of water (NS/m)

g: gravity (9.81 m/s²)

C: effluent concentration (mg/L

); Co: Influent concentration (mg/L);

L: Filter length (cm)

ε: porosity of the filter media;

η: efficiency of a collector;

α: collision efficiency, probability of adhesion or adhesion factor

δ: specific deposit (g/m3);

t: Time (h). As is the porosity-dependent parameter of Happel’s model;  and

and . Happel’s model is a commonly used approximation for the flow field around spherical collector 14.

. Happel’s model is a commonly used approximation for the flow field around spherical collector 14.  (aspect ratio),

(aspect ratio),  (Peclet number characterizing the ratio of convective to diffusive transport,

(Peclet number characterizing the ratio of convective to diffusive transport,  (van der Waals number characterizing the ratio of van der Waals interaction energy to the particle’s thermal energy; A is the Hamaker constant of the interacting media, i.e. 10-20 (5,

(van der Waals number characterizing the ratio of van der Waals interaction energy to the particle’s thermal energy; A is the Hamaker constant of the interacting media, i.e. 10-20 (5,  (attraction number; combined influence of van der Waals attraction forces and fluid velocity on particle deposition by interception), and

(attraction number; combined influence of van der Waals attraction forces and fluid velocity on particle deposition by interception), and  (gravity number; ratio of Stokes particle settling velocity to approach velocity of fluid).

(gravity number; ratio of Stokes particle settling velocity to approach velocity of fluid).

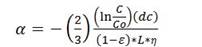

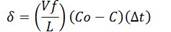

The filter performance can be related to the single collector efficiency and the attachment factor for a given particle size by Eq. 9 3. Attachment is a factor to estimate the collision between a particle and the collector.

Lin et al. 7 and Collins et al. 8 have analyzed filter performance and the attachment factor adopting the trajectory model of Yao et al. 3 using a mix of tap water and kaolinite clay suspensions in their experience. I am not aware however of studies applying this model with natural surface water as is done in this research using water from the Cauca river. This paper presents the results of this experiment exploring the performance of a pilot upflow gravel filter in layers fed with natural water (surface source) operating with three vf and take applying the trajectory theory model approach.

2. Materials and methods

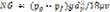

The study was conducted on a circular filter with a diameter of 1.93 m filled with four gravel layers. Gravel sizes and thickness of each layer were defined according to the investigations of Galvis 1. The layer with the coarsest gravel was put at the bottom and the layer with the smallest gravel on the top of the filter. The thickness of each layer was 0.25 m resulting in a total length of 1.0 m filter medium (Fig. 1). The UGFL was fed with natural water from the Cauca River. To reduce the entrance of turbidity or TSS selected in the pilot filter a dynamic roughing filter, DyRF, unit was installed before the UGFL. Flow control was carried out in a channel with a triangular weir. Table 2 summarizes the characteristics of the pilot filter and the media sizes used in this study. The gravel was washed with clean water and a grain size analysis was performed to confirm the grain size for each layer to estimate the uniformity coefficient, U c (d 60 /d 10 ) (Table 2); the porosity (ε o ) of the filter material was determined following the procedure defined by Ives 9.

Figure 1 Pilot filter scheme used in the study with marked sampling points S1-S5 and respective piezometers.

Table 2 Characteristics of pilot filter.

| Characteristic | Value |

|---|---|

| Filter material | Ferrocement |

| Form | Circular |

| Diameter | 1.93 m |

| Gravel media used in the study | |

| Layer 1 (bottom) | Thickness: 0.25 m; media size: 25.4 - 19 mm; *U c 1.3; Porosity: 0.52 |

| Layer 2 | Thickness: 0.25 m; media size: 19 - 12.7 mm; U c 1.28; Porosity: 0.45 |

| Layer 3 | Thickness: 0.25 m; media size: 12.7 - 6.35 mm; U c 1.46 Porosity: 0.39 |

| Layer 4 (surface) | Thickness: 0.25 m; media size: 6.35- 3.17 mm; U c 1.5 Porosity: 0.34 |

* Uc= d60/d10

Piezometers and sampling points were installed in each gravel layer to allow taking measurements of head loss (hf) and water quality samples during the filter run. Hydraulic behavior was verified for a clean bed using tracer tests following the methodology described by Sánchez et al. 10. Tracer test results were analyzed with the mathematical model Wolf-Resnick and the model of completely mixed reactors in series (CMRS).

Tree filtration velocities, v f , were analyzed (0.5, 0.75 and 1.0 m/h), and the first filter runs were carried out at v f 0.5 m/h. For each velocity two filter runs were analyzed, one with filter material that was washed outside the filter and one after a normal filter cleaning procedure by drainage. Two criteria were considered to ending the filter run as suggested by Galvis 1: Drop in the removal efficiency for turbidity or TSS (filter breakthrough) and the maximum permissible head loss (hf maximum) of 15 cm 1. One parallel unit was conditioned without gravel to check the effect of no media for each filter bed height; the experiment was conducted for vf 0.5 m/h.

Turbidity measurements were performed using a Hach 2100P turbidimeter. TSS were measured according to Standard Methods 2540 B 11, using Whatman paper filter of 1.2 µm and particle size distributions were measured using the equipment Mastersizer 2000 (vers. 5.6), laser diffraction particle size in the range of 0.02µm to 2000µm, following the procedures described in the operating manual .

2.1 Attachment factor determination using colloid filtration theory (CFT)

A theoretical single collector efficiency SCE was calculated for different particle sizes using Eq. (4) and Eq. (8) (defined by the median particle diameter) for the respective filter design variables in each gravel layer to check the effect of hydrodynamic and Van der Waals attractive forces. The attachment factor was calculated using Eq. (9) and following the procedure of Lin et al. 7 for which the particle size distribution of the TSS concentration of the influent and the effluent for each gravel layer was analyzed; weighted according to the particle size distributions (PSD) and matched to the respective SCE value. The attachment factor (Eq 9) was verified by trial and error until it matches the sum of colloid filtration theory modeled (CFTm) be close to the measured for TSS concentrations for each particle size distribution of the influent and effluent and the correlation (r2) was verified for CFTm and actual CFT (measured). Attachment factors over the filter length were calculated by comparing the TSS concentration and PSD results of the initial influent and effluent from each gravel layer.

3. Results and discussion

3.1 Operation behavior of UGFL

The analysis of the hydraulic performance of the UGF showed a plug flow fraction of 80% and a mixed flow of 20%. The results of the CMRS model indicated n= 10 reactors in series, which shows good hydraulic conditions for the experiment. The filter was operated with influent turbidity between 15-70 UNT and the maximum removal efficiency of 70% was obtained for influent values of 50 NTU. Turbidity is caused by suspended particles or colloidal matter that obstructs light transmission through the water 12. As the turbidity does not directly measure the solids concentration, in this study the TSS were measured by their relation with particle size. Taking into account that the system was fed with natural water for each vf where two runs were carried out with TSS influent being: median TSS 9.6 mg/l for vf 0.5 m/h; 10.7 mg/l for vf 0.75 m/h and 8.6 mg/l for vf 1.0 m/h.

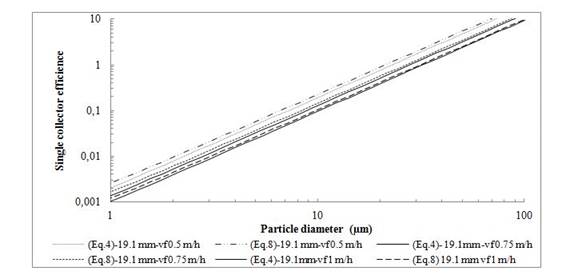

3.2 Theoretical single collector efficiency

The theoretical SCEs calculated using Eqs. (4) and (8) for the different filtration velocities and gravel layer size of UGFL as a function of particle size are shown in Fig. 2. Results indicated that sedimentation represents the main particle removal mechanism in UGFL which is in accordance with the research of Wegelin et al. 13, Boller 2, Collins et al. 8 and Lin et al. 7. Fig 3 shows that single collector efficiency calculated by Eq 4 and Eq 8 was almost the same as the value calculated for a constant gravel size. This suggests that the effect of hydrodynamic interactions and universal van der Waals attractive forces is of low significance in the UGFL according to Tufenkji & Elimelech 4 in Eq 8. For smaller filtration velocity (vf 0.5 m/h) the highest value of single collector efficiency was obtained (both Eqs). This higher efficiency can be explained because hydrodynamic forces are smaller at low velocities and this can promote sedimentation rates of particles in the grains.

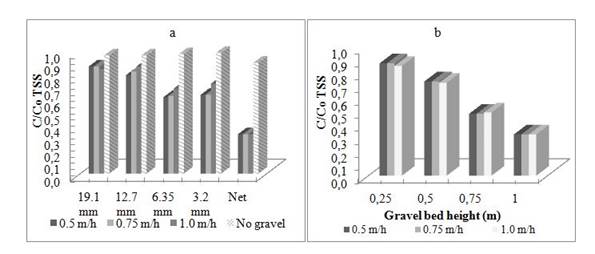

3.3 Total suspended solids and particle size behavior in the gravel layers

Figure 3a shows the removal efficiency of the TSS in each gravel layer for the three vf. Results indicate that the removal efficiency improved with reduction of gravel grain size, but little difference in the removal efficiency was noticed between different vf. This result also was confirmed by a review of the incremental removal efficiency of TSS over the gravel bed height. However, the removal efficiency of TSS increases with filter depth bed reaching maximum efficiency in the last two gravel layers of 6.35 and 3.2 mm (Fig. 3b). The test in the unit without gravel reveals that, even in the absence of any media, some removal of TSS is obtained due to sedimentation, but the removal is low (C/Co between 0.02 to 0.04) (Fig 3a).

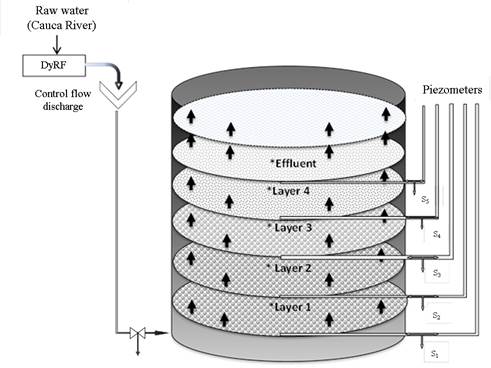

The particle size distribution in samples collected at the end of each gravel layer indicates that the particle removal pattern changed with filter run time. The overall particle removal efficiency can be influenced by change in the effluent of each gravel layer as stated by Kim & Lawler 14. Figure 4 shows the results of particle size distribution from two representative samples of the same UGFL operating at vf 0.5 m/h one after 30 days (Fig 4a) and one after 53 days (Fig 4b). Low particle removal was obtained after 30 days but improved considerably over time indicating a conditioning process of the filter media that becomes better at capturing particles. With increasing filter operation time the pattern of reduction of particles along the filter depth bed changes (Fig 4b) with the total gravel bed becoming more efficient in particle removal 6. Progressive reduction of particles along the filter height (Fig 4b) is an indication of deep-bed filtration, Lin et al. 7.

Figure 4 Particle size distributions by gravel media: (a) run time 30 days- vf 0.5 m/h, influent TSS 37.4 mg/L and (b) run time 53 days, vf 0.5 m/h, influent TSS 22.4 mg/L.

Figure 5 shows the net removal efficiency of particles in the UGFL for each vf. The result indicates that the removal efficiency is similar for the three flow velocities for particles larger than 5 µm. Particles larger than 80 µm were removed totally, however for particles in the range of 10-80 µm removal efficiencies were about 90%, for particle sizes in the range of 2-10 µm removal efficiency descended with significant differences for each vf and it was difficult to remove particles less than 2 µm, this result was consistent with Lin et al. 7. The results also show that vf has an effect on removal of particles smaller than 5 µm, demonstrating a better removal for the lowest vf (0.5 m/h).

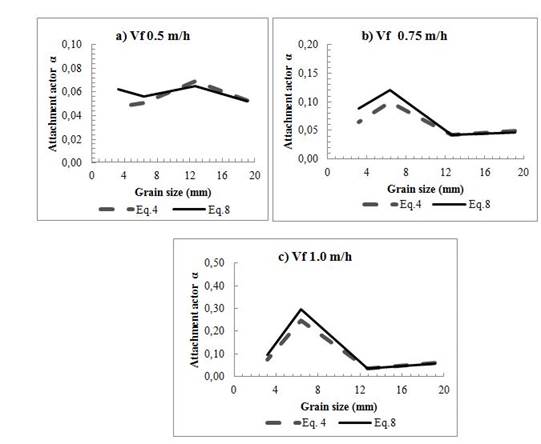

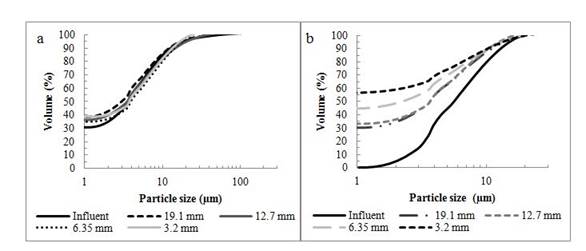

3.4 Attachment factor behavior

Taking into account particle size distribution in each gravel layer for different filtration velocities and the theoretical SCEs derived from Eqs. (4) and (9) the attachment factors were calculated for each grain size in the UGFL according with the model of Eq. 9. Figure 6 shows a typical result for the attachment factor (α) verified by trial and error until it matched the sum of colloid filtration theory modeled (CFTm) TSS concentrations for each particle size to the actual TSS concentration (measured by particle size distribution test) of the effluent en each gravel layer and the respective correlation (r2).

Figure 6 Attachment factor (α) obtained by trial and error between CFTm (calculated) and CFT act (measured by particle size test) for different gravel layer size (vf= 0,5 m/h).

Attachment factors for each grain size obtained in the UGFL are shown in Figure 7. The calculated attachment factor in the two models was highest for gravel sizes of 6.4 mm both for vf 0.75 and 1.0 m/h. The figure also shows the difference between the two models indicating that the inclusion of hydrodynamic and attractive van der Waals forces (Eq. 8) results in an increased estimation of attachment factor (7-15%) for small size grain. For vf 0.5 m/h the attachment factor was similar for the different gravel sizes (Fig 7a).

These results are in harmony with reports of Lin et al. 7 who observed increasing removal efficiency and attachment factor for gravel size of 7.55 mm with vf in the range of 0.5 -1.5 m/h. The results also show that the deposition of particles in a UGFL not only is the result of sedimentation but also of attachment. The attachment factor is the ratio between the particles adhering to the collector and the particles contacting collector 8. However, Bradford et al. 15 have reported that attachment of colloids to the solid-water interface is not a significant mechanism of deposition. Attachment is affected by London-van der Waals forces, surface chemical interactions, electrostatic forces, hydration, hydrophobic interactions, or steric interactions 16-18. When this factor is close to 1, there is complete destabilization and particles will be readily removed in the filter. When α=0, the particles are completely stabilized and their removal will be difficult. The important effect of the attachment factor implies that it may be expected that the removal efficiency of a UGFL can be improved by destabilizing particles that is for example by adding a coagulant 19.

4. Conclusions

This paper analyzes the attachment factor in upflow gravel filter in layers in a pilot filter fed with natural water (surface source) operating with three vf and applying the trajectory theory model approach looking at total suspended solids and particle size removal. In a UGFL sedimentation represents the main particle removal mechanism but the findings clearly show that attachment and flow velocities also have a significant role. Progressive reduction of smaller particles with small media size along the filter height was observed indicating deep-bed filtration process. The attachment factor was calculated taking into account total suspended solids and particle size distribution adopting the model of Yao et al. (3) and the theoretical single collector efficiencies. Single collector efficiencies increased with decreasing vf. Attachment factors for each gravel size calculated by the model were highest for gravel size of 6.4 mm for vf 0.75 and 1.0 m/h. The difference in vf on the overall removal efficiency was only observed for particles smaller than 5 µm which were better removed at vf of 0.5 m/h.

Removal efficiency of particles smaller than 10 µm was basically obtained in gravel bed layers of 6.35 mm and 3.2 mm. Particles sizes larger than 80 µm were totally removed and it was difficult to remove particles less than 2 µm.

The results of the research suggest that it would be useful if future research explores in detail the effect of destabilization of particles by coagulation in UGFL.