INTRODUCTION

Currently, urban drainage systems are often overwhelmed by the hydraulic load of rain, lack of maintenance, and, in some cases, poor projection, causing numerous problems, such as floods, public health problems, and a decrease in the flow speed of the roads, directly influencing the traffic and transport of society. In this sense, sustainable drainage systems are gaining importance, among which are permeable pavements, which provide an immediate response to the correct management of surface runoff caused by rainfall [1] [4].

One of the most widespread pervious pavements is pervious concrete (PC), which is composed of Portland Cement, coarse aggregates, and water (potable) and, in some cases, may have small proportions of fine aggregates (sand) to increase its mechanical strength (without damaging its hydraulic performance) [5]. Commonly the PC has an aggregate-cement (α/c) ratio varying from 4:1 to 6:1 (which guarantees its high porosity) and a w/c ratio varying from 0,26 to 0,45). Lower ratios implement additives to ensure the workability of the material [6], [7].

These mix proportion recommendations lead to the production of PCS with a maximum unit weight of 2000 kg/m3, varying porosity of 15-35 %, permeability > 1 mm/s, and proper mechanical behavior depending on their final request (walkway or low-traffic pavement) [5].

The material has been extensively studied in the laboratory (hydraulic and mechanical performance). However, few studies have evaluated its behavior in experimental fields, considering clogging and maintenance [3]. Nevertheless, comparing these two types of evaluation is essential to understanding the material's performance. In this sense, the present work aims to evaluate the performance of PC in the field and laboratory and to verify the main differences between these two types of analysis, considering four types of aggregate granulometry (coarse) and three procedures of compacting to fulfill the standard requirements to be considered as PC.

MATERIALS AND METHODS

Materials

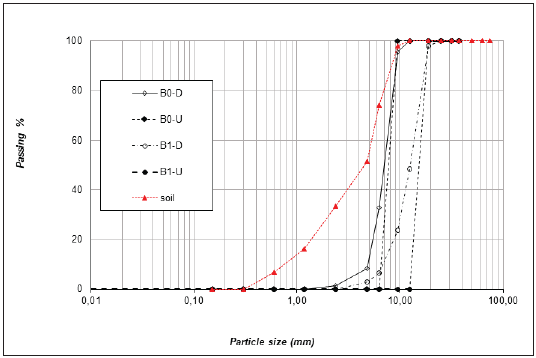

Pervious concrete (PC) was produced using Portland Cement Type II (CP II-Z-32 Brazilian denomination), four different types of coarse aggregates (of basaltic origin, considering two maximum sizes and continuous and discontinuous granulometry), and drinking water. The granulometric curves of the aggregates and sediment (soil) used are shown in Figure 1. The tests were carried out according to the Brazilian Standard ABNT NBR 7211 [8].

METHODS

-PC Production

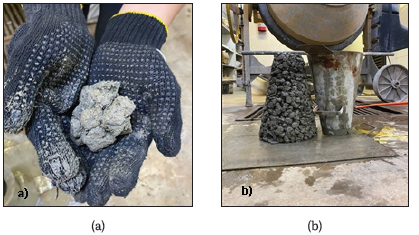

To produce the pc, a mix proportion of 1:3,26 (cement: coarse aggregate) was used (taken from [9], contemplating a w/c ratio of 0,34 (fixed in all mixtures) to obtain a zero slump [10] and a suitable consistency as recommended by [5] as shown in Figure 2. The mix was carried out in a concrete mixer with a capacity of 450 liters and a total mixture time of five minutes.

Experimental Fields Construction

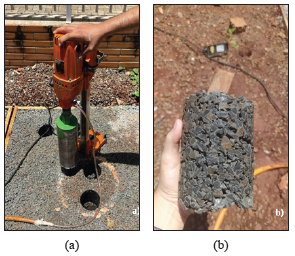

Four experimental fields were built, considering a total water infiltration system, a base layer with a coarse aggregate of 25 mm, and a variation of the surface course of PC of 10 cm in height. The experimental field construction followed the next steps: First, the soil excavation was carried out (Figure 3a); second, a 30 cm layer of granular base (25 mm) was placed (Figure 3b) without compaction to guarantee the total infiltration of water in the soil; third, after leveling the base layer, the wooden forms were positioned to ensure an area of 1 m2 per slab and a height of the surface layer of 10 cm, as recommended by the Brazilian Standard ABNT NBR 16416 [11]. Finally, the PC was placed in the forms (Figure 3c), leveled, and compacted with a metal roller (1 m long and 67 kg in weight). The PC 10 roll passes were used to compact, as recommended by [12].

The permeability (in field) was measured according to ASTM C1701 [13]. During the test setup, the perimeter of the infiltration ring was sealed directly with the PC surface with silicone (Figure 3d) to restrict water loss. After verifying the permeability, the clogging phenomenon was simulated using a dry soil mix (clay and sand) (Figure 3e), following the procedure suggested by [12]. For the mechanical tests of the experimental field, cylindrical specimens (10x10 cm) were extracted according to the age of the studied test as Shown in Figure 4a and Figure 4b.

Laboratory-produced pc

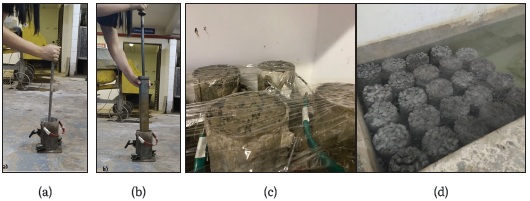

To evaluate PC performance in the laboratory and compare it with the specimens extracted from the experimental fields, cylindrical specimens (10 cm x 20 cm) were molded. As there is no standardization and/or consensus in the literature for compacting [3], two compaction procedures were used: steel bar (Figure 5a) with 12 blows per layer with three layers [14]three aggregates from civil construction waste and one basalt aggregate (reference and 2,5 kg Proctor's hammer (Figure 5b) with ten blows per layer with two layers [12]. These procedures were chosen because they are the most common in the literature to keep the PC produced within the standard parameters (unit weight) [15]. All specimens produced were cured and immersed in water until the test age (Figure 5c and Figure 5d).

Performance Verification (laboratory and field test)

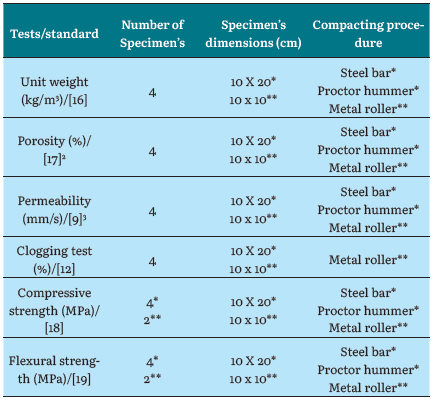

Figure 6 and Table 2 presents the hydraulic and mechanical tests, the number, dimensions, and compaction of the specimens analyzed at 28 days of curing, produced with the coarse aggregates selected.

TABLE 1 EXPERIMENTAL PROGRAM

Source: Own elaboration.

*Laboratory-produced pc

**Extracted field specimens

***The hydraulic test and compressive strength were carried out drawing on the same specimen

For each PC mixture, a nomenclature was adopted according to the coarse aggregate used (Granulometry: B0-U, B0-D, B1-U, B1-D), the compaction procedure for the specimens molded in the laboratory (steel bar-H and Proctor of 2,5 kg-P), and for the specimens extracted from the experimental fields-T (metal roller). For example, the PC "B0-U-T" was made with 9,5 mm coarse aggregate, uniform granulometry, and is an extracted specimen, while "B1-D-H" was made with 19 mm coarse aggregate, discontinuous granulometry, and compacted with a steel bar.

RESULTS

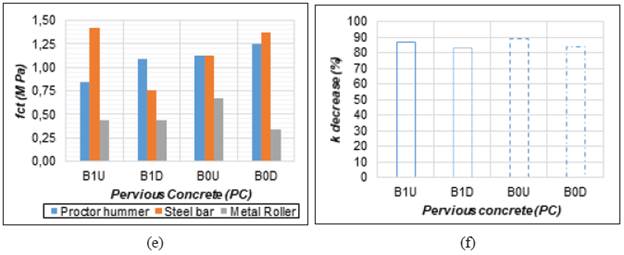

Figure 3 presents the performance results (hydraulic and mechanical) evaluated on the specimens molded in the laboratory and the specimens extracted from the experimental fields. Unit weight (p) results are initially shown (Figure 7a), followed by porosity ( ) (Figure 7b), permeability (k) (Figure 7c), compressive strength (f'c) (Figure 7d), flexural strength (fct) (Figure 7e), and finally clogging (Figure 7f).

Source: Own elaboration.

*The results presented correspond to an average of the number of specimens presented in Table 2 for each specific compacting procedure.

FIGURE 7 PERFORMANCE RESULTS.

The unit weight results (Figure 7a) vary from 1855 to 2523 kg/m3, being generally PC with discontinuous granulometry aggregate presenting the highest values. This is justified by the diversity of sizes that leads to a better arrangement of the grains after compaction [20]. The behavior of the unit weight (Figure 7a) shows a great difference between laboratory and field conditions, and in the latter, a greater magnitude is reached depending on the best distribution of compaction energy and the final arrangement of the grains [21].

The porosity varies from 22 % to 35 %, and all the concrete is produced in the acceptable range for PC according to the standard parameters [22], the discontinuous granulometry being the one that reached the lowest values in all cases associated with better grain rearrangement (variable sizes) [23]. The porosity (Figure 7b) also shows an inverse behavior to the unit weight, i.e., in the experimental fields, it resulted in a lower magnitude of the porosity, justified by the high unit weight obtained and the better arrangement of the grains [21].

The permeability varies from 3,8 to 9,26 mm/s, fulfilling the concretes produced with the minimum standard (>1 mm/s) [22]. In the case of permeability behavior (Figure 7c), the same porosity trend was not maintained, and in almost all cases (B1U, B1D and B0U), the highest permeability was reached in the experimental fields. two reasons can explain this fact: first, the hydraulic principle of the test used in the field, but in the laboratory (constant), because there is no unidirectional flow restriction, and in the laboratory, there such a restriction exists; second, this hydraulic property depends not only on the porosity but also on the interconnection of the pores, which was guaranteed in the field by the type of compaction used, while in the laboratory, the type of compaction used reduced the pore connection, justifying the lower permeability results [14].

The mechanical results (Figures 7d and 7e) were more associated with the grain size than with the compacting method and the material's porosity, with the steel bar being the most efficient in terms of compaction in terms of strength. The concretes produced with B0 are the ones that reached the highest resistance values, associated with the highest points of contact between the grains and the best stress distribution, agreeing with the results obtained by [24].

Finally, the clogging results (permeability loss) showed that CPs produced with a smaller grain size lose (B0) more permeability when compared to those of a larger size and that the magnitude of the permeability loss was associated with the type of sediment used (a mix of clay and sand) and the amount of it, which simulates 20 years of service in the material [12].

CONCLUSIONS

The PC produced in the laboratory and field fulfills the minimal requirements to be considered a pervious material according to the standard limits. First in field, the applied compaction was shown to be more efficient due to a better arrangement of the grains, resulting in higher unit weight. On the other hand, the porosity is directly associated with unit weight, with the heaviest PCS being the least porous and the lightest PCS being the most porous; therefore, the compacting procedure is a control parameter to ensure an adequate porosity. Nevertheless, the permeability showed a different behavior than expected in the literature. Such a difference is associated with the flow restrictions, which the laboratory test has compared to the field test, and a better interconnection of the pores given by the compaction method used. The mechanical performance of the evaluated PCS was more associated with the grain size than with the compaction used, where smaller sizes present smaller pores than a greater stress distribution, meaning greater resistance. Finally, the permeability loss found with the clogging simulation was associated with the type of sediment used (mix of soils). In this case, to guarantee greater hydraulic durability, it is recommended to use aggregates larger than 10 mm (agreeing to the literature).