INTRODUCTION

In recent years, there has been a growing global interest in promoting a balanced and healthy diet to reduce the problems associated with obesity, diabetes, and cancer; for this reason, the food industry continuously seeks to develop products with nutritional quality and health promoters (Jafari et al., 2021). Also, changes in the modern lifestyle have shifted consumer preferences towards instant and easy-to-prepare foods (Przybył et al., 2018). Dehydrated fruit juices could meet the increased demand for healthy foods (Bannikova et al., 2020). Bioactive components of fruits provide functional properties and help control specific physiological functions for disease prevention and health improvement (Igual et al., 2021). Fruit powders have the potential as healthy products that can be easily reconstituted or as a natural ingredient of high nutritional value for new food formulations (Shishir & Chen, 2017).

Lulo (Solanum quitoense Lam.) is an exotic fruit characterized by an acid flavor and intense aroma, which gives it important potential for entering new international markets and developing new products (Forero et al., 2015). Lulo is a significant source of carotenoids, phenolic compounds, vitamins (E, C, B1, B2, B3, B6 and pro-vitamin A), minerals (iron, calcium, phosphorus, potassium, and nitrogen), carbohydrates, fiber, and proteins (Ramírez et al., 2018). Lulo has demonstrated antihypertensive properties due to the presence of hesperidin (Indira et al., 2021). Lulo is usually consumed fresh but is also used to make juice, jellies, desserts, frozen concentrated pulp, tea, and wine (Indira et al., 2020). However, due to its high perfectibility, postharvest handling is critical; the shelf life of lulo under ambient conditions is 3 to 5 days, with losses that can reach up to 50% of production (Escobar et al., 2023). The main strategies used for its preservation are refrigeration and modified atmospheres (Reyes et al., 2024).

Spray drying is a widely used method for preserving food and has great potential for producing functional products (Acosta et al., 2023). This technique consists of atomizing a liquid through a gaseous medium at high temperatures, which produces rapid dehydration, decreases the degradation of thermosensitive compounds, and results in a high-quality powder (Wang et al., 2021). However, spray drying of fruits has some problems associated with stickiness, hygroscopicity, and low yield caused by the glass transition temperature of low molecular weight compounds, such as sugars and organic acids (Shrivastava et al., 2021). To reduce these problems, some high-molecular-weight biopolymers, called carrier agents, are needed (Tontul & Topuz, 2017).

Maltodextrin is the most commonly used carrier agent due to its high availability, low cost, low viscosity, high solubility, and good retention of volatile compounds (Pant et al., 2022). However, high concentrations of maltodextrin can reduce product quality and affect taste, the same as consumer/market acceptance (Moghbeli et al., 2019). Whey proteins are another type of carrier agent widely used due to their ability to improve spray drying performance at lower concentrations than maltodextrin through preferential migration of protein to the drop-air interface and rapid film formation on the particle surface (Tontul & Topuz, 2017). Recently, some researchers have suggested a favorable synergistic effect between both carrier agents in spray drying (Kumar et al., 2021; Meena et al., 2021; Bannikova et al., 2020).

There is considerable scientific literature that has demonstrated the successful implementation of various spray-dried fruit juices (Shishir & Chen, 2017). However, there is very little information about the spray-drying conditions of lulo. Forero et al. (2015) and Forero et al. (2014) published two research articles studying the effects of four different drying methods, such as hot air drying, ultrasound-assisted hot air-drying, freeze-drying, and spray-drying, on morphological, thermal, functional properties, and sensory and chemical changes in lulo. According to their results, the best preservation method was freeze-drying, followed by spray-drying; however, they mention that spray-drying has important advantages such as higher yields and the possibility of greater industrial scaling. It is important to mention that these authors worked under fixed conditions and did not optimize the drying process.

Mousavi & Ghandiha (2022) mentioned that it is essential to know how process variables affect the physicochemical and functional characteristics of powders to obtain a high process yield and superior quality in fruit powder. For these reasons, this study aimed to optimize spray drying conditions for lulo pulp by evaluating the effect of maltodextrin and whey protein concentrated (WPC) mixtures and inlet air temperature on the process yield, physicochemical properties, and particle morphology of the lulo powders.

MATERIAL AND METHODS

Raw material. Lulo was procured from a local market in Pasto (southwestern Colombia). We selected fruits at maturity stage 4, following the guidelines outlined in the Colombian Technical Standard NTC 5093 (ICONTEC - Instituto Colombiano de Normas Técnicas y Certificación, 2002). The fruits were processed immediately upon arrival at the laboratory with a pulper (FPSTJE317R, Oster®, EE. UU). The seeds were removed, and the lulo pulp was kept in a freezer (-24°C). The lulo pulp had 12.6 ± 0.8% total solids, 10.5 ± 0.25 °Bx value, 2.9 ± 0.2% citric acid content, and a pH of 3.03 ± 0.01. Maltodextrin (DE 20) and whey protein concentrate (WPC) were obtained from Tecnas S.A., Colombia.

Preparation of lulo powders. Frozen lulo pulp and carrier agents were mixed for 10 min with a multi-tool (3000, Dremel, EE. UU) until homogeneity was achieved. Batches of 200 g of suspension were prepared. The feed was maintained with constant agitation on a heating plate with a magnetic stirrer (Hot Plate 1224Q73, Thomas Scientific, USA) at 400 rpm and a constant temperature of 25°C. Drying conditions were adjusted according to the experimental design derived from the Box-Behnken design (Table 1). Dried fruit pulp powders were obtained using a lab spray dryer (6000Y, Shanghai Bilon Instrument Co., China). The solid was packed in low-density polyethylene (LDPE) pouches and stored until physical and chemical characterization.

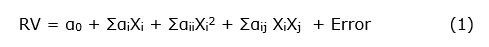

Statistical analysis. Response surface methodology (RSM) was used for process optimization using a Box-Behnken design. Experimental data were analyzed with the software Statgraphics Centurion XVI.II (Statgraphics Technologies, Inc., EE. UU). The independent variables were: inlet air temperature (T) (160 - 220 °C), maltodextrin (MD) concentration (15 - 35%), and whey protein concentrate (WPC) concentration (1 - 5%). The feed flow and air flow rate were kept constant at 4 mL/min and 9 m/s, respectively. The levels of the factors of the drying process evaluated were optimized according to the following response variables: powder yield (Y), moisture content (MC), bulk density (BD), solubility (S), and ascorbic acid content (AC).

An analysis of variance (ANOVA) was used to estimate the statistical parameters, and a regression surface analysis was realized according to Shrivastava et al. (2021) with a second-order polynomial Equation 1 to express the relationship between the predicted response and independent variables:

Where RV is the predicted response value, α0 is the intercept term, αi is a linear term, αii is the squared term, αij is the interaction term, Xi and Xj are the coded levels of independent variables and Error is a component due to the experimental error.

Powder yield

The process yield was computed as the ratio of the mass of solids content in the collected powders to the mass of initial total solids in the feed solution after spray drying (Gawalek, 2021).

Moisture content. The moisture content was evaluated by a moisture analyzer (XM 60, Sartorius, Germany) at 105°C to a constant weight (Moghbeli et al., 2019).

Bulk density. Powder bulk density was determined according to the method used by Souza et al. (2020). 2 g of sample were weighed and placed into a graduated 10 mL cylinder. The cylinder was manually hit on a table from a height of approximately 10 cm, and the bulk density was calculated as the ratio between the mass of powder contained in the cylinder and the volume occupied.

Solubility. Solubility was determined according to the method proposed by Tomsone et al. (2020), with some modifications. The powder sample (1 g) was added to 100 mL of distilled water and blended using mixer V1-plus (Boeco, Germany) for 5 min before centrifugation at 3000 rpm for 5 min (Dynamic Scientific, United Kingdom). An aliquot (25 mL) of each supernatant was removed, transferred to porcelain dishes, and dried to a constant weight in an oven at 105°C. The solubility index (%) was calculated as the ratio of the dried supernatant weight to the amount of the original weight of the sample (1 g).

Ascorbic acid content. Ascorbic acid content was determined according to the method proposed by Aguirre et al. (2019), with some modifications. 1g of powder was dissolved in 5 mL of distilled water using a vortex stirrer V1-plus (Boeco, Germany). An aliquot of 10 μL of freshly prepared 2- nitroaniline (0.16%) and 20 μL of sodium nitrite (0.08%) was taken; then, 380 μL of 96% ethanol, 50 μL of the sample (extract), and 50 μL of 0.15% oxalic acid were added, mixed, and allowed to stand for 5 min. Subsequently, 120 μL of 10% NaOH and 380 μL of distilled water were added. Finally, the mixture was read in a spectrophotometer (Genesys 10S UV-Vis, Thermo Scientific, USA) at an absorbance of 540 nm and compared with an ascorbic acid calibration curve (R2>0.99). For the blank, a 50 μL aliquot of oxalic acid was taken as a sample during the experiment.

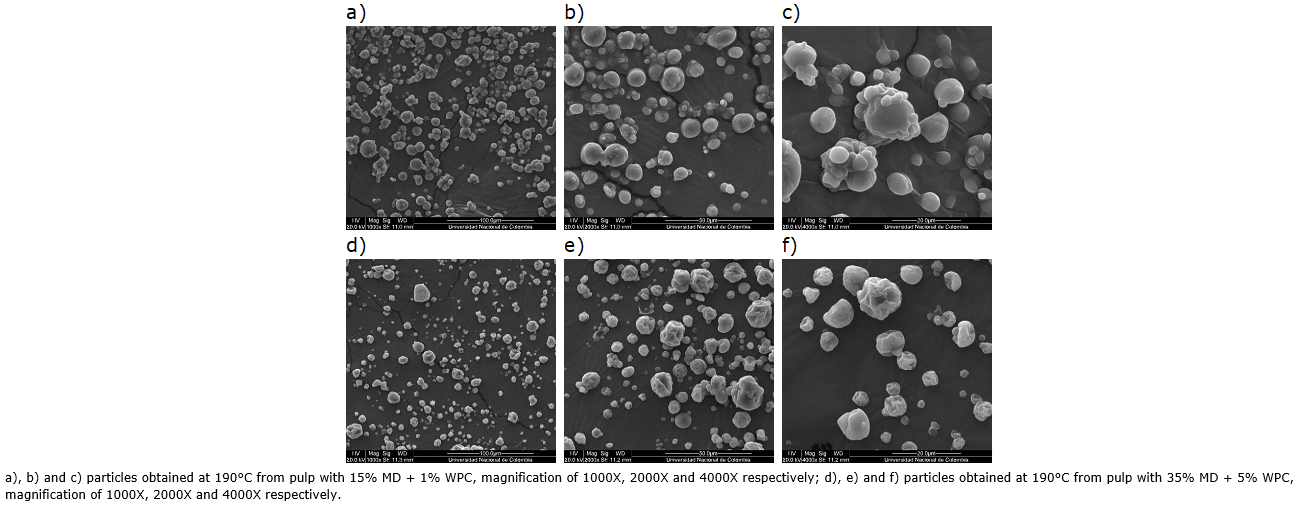

Scanning electron microscopy (SEM). A scanning electron microscope (FEI Quanta 200 FEG, Netherlands) was used to examine the dried lulo powders’ microstructure. 1 cm2 of the samples was prepared, positioned on an SEM stub, and then sputter-coated with gold (Quorum Q150R ES sputter coater). All samples were examined under high vacuum conditions at an accelerating voltage of 20 kV. Photographs of powder particles were obtained at magnifications of 1000, 2000, and 4000X.

RESULTS AND DISCUSSION

Table 1 displays the results obtained from Matrix of the Box-Behnken design and experimental data obtained for the response variables studied.

Table 2 presents a summary of the analysis of variance (ANOVA) with main and interaction effects, assessed as linear, quadratic, and interaction terms of independent variables from the experimental design:

Table 2 Analysis of variance for lulo pulp spray drying process (ANOVA).

| Response variables | Independent variables and linear effects | Quadratic effects | Interaction effects | ||||||

|---|---|---|---|---|---|---|---|---|---|

| T | MD | W | TT | MM | WW | TM | TW | MW | |

| P-value | P- value | P- value | P- value | P- value | P- value | P- value | P-value | P- value | |

| Powder yield (Y) | 0.0004 | 0.0001 | 0.0824 | 0.2161 | 0.5998 | 0.2854 | 0.3693 | 0.1534 | 0.3363 |

| Moisture content (MC) | 0.0005 | 0.0010 | 0.0734 | 0.6724 | 0.2108 | 0.1861 | 0.0537 | 0.6342 | 0.8195 |

| Bulk density (B) | 0.0000 | 0.0048 | 0.4240 | 0.6133 | 0.9124 | 0.6406 | 0.5916 | 0.9825 | 0.9825 |

| Solubility (S) | 0.0023 | 0.0015 | 0.2700 | 0.0239 | 0.3045 | 0.9518 | 0.2141 | 0.6934 | 0.2447 |

| Ascorbic acid content (AC) | 0.0000 | 0.0009 | 0.6616 | 0.0000 | 0.9382 | 0.9144 | 0.0189 | 0.0843 | 0.9247 |

T = inlet air temperature (°C), MD = maltodextrin concentration (g/100 g pulp), W = whey protein concentration (g/100 g pulp).

Powder yield. The powder yield varied between 35.4% and 66.6%. Tontul & Topuz (2017) stated that spray drying is successful when the product yield exceeds 50%. Gawalek (2021) mentions that to obtain a drying yield >90% at the industrial scale, process conditions should be selected to get a minimum yield of 50% at the laboratory scale. For this reason, the results obtained on lulo are considered satisfactory. The ANOVA analysis (Table 2) showed a significant effect (p < 0.05) of the inlet air temperature and maltodextrin concentration on powder yield.

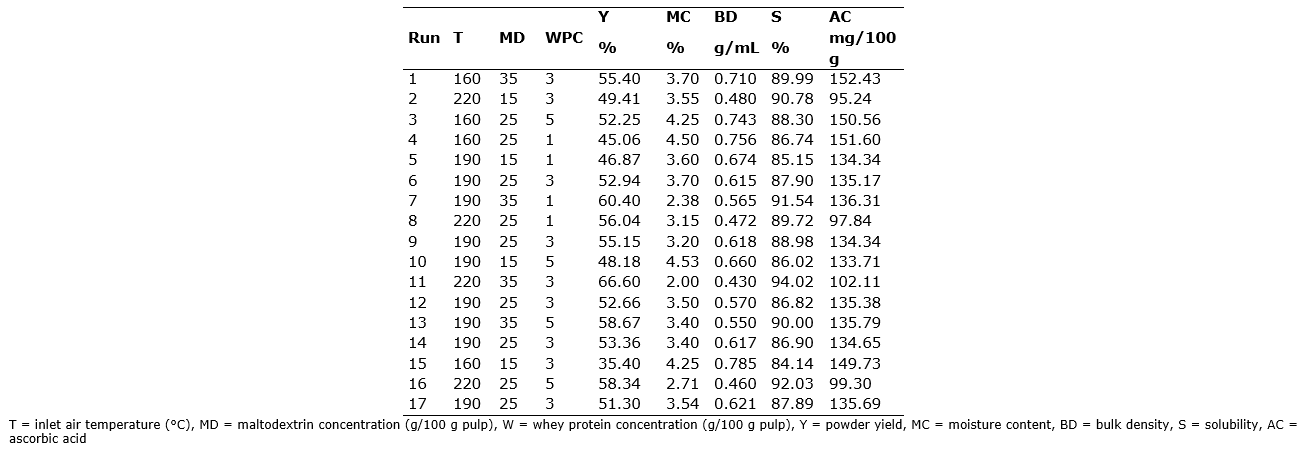

The main effects diagram indicates that inlet air temperature had a positive effect on the powder yield (Figure 1a). Shishir & Chen (2017) mention that an increase in the temperature gradient between the feed stream and the hot air improves heat processes, increases the drying rate, and promotes the formation of dry particles with low humidity and hygroscopicity, which have little adhesion inside the drying chamber and can be easily collected at the end of the process. Similar results were reported on the spray drying of pineapple-mint juice (Braga et al., 2020) and blackberry pulp (Ferreira et al., 2018).

The incorporation of maltodextrin had a positive and linear effect on powder yield (Figure 1 a). Igual et al. (2014) report that lulo has low molecular weight compounds that give it a low glass transition temperature, which makes it impossible to recover powders due to the sticky and viscoelastic behavior during spray drying. Tontul & Topuz (2017) mention that encapsulating agents are generally added to fruit juices to improve the glass transition temperature and powder yield. WPC concentration had no significant effect on yield. This could be attributed to the low level of WPC used because higher concentrations had an impact on the viscosity of the feed suspension, which did not allow for drying. Yousefi & Abbasi (2022) mention that protein solubility is affected, among many other factors, by pH. According to these authors, there is a pH region in which protein solubility is minimal as they approach the isoelectric point, resulting in the formation of a protein-protein bond and, eventually, coagulation. Shang et al. (2023) state that in beverages based on whey protein, pH < 3.5 presents problems related to denaturation or aggregation due to their proximity to the isoelectric point. Ho et al. (2021) reported a reduction in solubility and foaming of WPC solutions adjusted to pH close to 3 in the spray drying of WPC. The pH value of lulo pulp in this investigation was 3.03 ± 0.01, which could cause poor dispersion of the encapsulant. The isoelectric point of whey proteins could be another possible cause of WPC concentration not having a significant effect on yield.

Moisture content. According to Tontul & Topuz (2017), to be considered microbiologically safe and to be stored for long periods fruit powders should have a moisture content of less than 5%. Moisture values of the lulo powder obtained were 2-4.5% (Table 1). Forero et al. (2015) and Igual et al. (2014) obtained a moisture content of 3.8% and between 0.9 and 5% in spray-dried lulo pulp powders. The inlet air temperature had a significant effect on lulo powders' moisture. An increase in temperature decreased the moisture content of the lulo powders (Figure 1b). This behavior can be attributed to higher efficiency in the heat transfer and water evaporation processes (Gawałek, 2022).

The moisture content of the powders decreases with increasing maltodextrin concentration (Figure 1 b). According to Braga et al. (2020), maltodextrin increased feed total solids concentration, which reduced the amount of available water that must be evaporated, resulting in a decrease in the final moisture content of pineapple-mint juice. In addition, Khalifa et al. (2019) observed that incorporating encapsulating agents decreases hygroscopicity, which allowed for obtaining mulberry powders with better moisture content. WPC content had no significant effect on the moisture content of the lulo powders (Table 2). Ruano et al. (2018) reported that adding WPC to sugarcane juice had a negative effect on the moisture content of the powders due to water retention of the proteins in their amorphous state, as also mentioned by Tontul & Topuz (2017). The low concentration of WPC was probably not sufficient to affect the moisture content of the lulo powders.

Bulk density. The bulk density values of the lulo powders were between 0.4 to 0.8 g/mL (Table 1). Similar results of 0.295 - 0.810 g/mL were obtained for custard apple pulp powder (Shrivastava et al., 2021), for orange juice (0.35 - 0.65 g/mL) (Igual et al., 2021), and for cranberry juice (0.39 - 0.67) (Michalska et al., 2020).

According to analysis of variance, inlet air temperature had a statistically significant effect on bulk density (p < 0.05) (Table 2). The increase in inlet air temperature caused a significant decrease in the bulk density of lulo powders (Figure 1 c). Fazaeli et al. (2012) state that when fruit juice is subjected to lower drying temperatures, water steam accumulates inside the particle, which cannot escape and condenses as it passes through the cooler regions of the dryer, causing the particles to shrink, reduce in size, and have higher humidity and density. In addition, Michalska et al. (2020) found a correlation between high moisture content and high bulk density in cranberry powders. According to results in Table 1, lulo powders obtained in runs 4 and 15 at the lowest temperature (160 °C) had the highest moisture content (4.5 and 4.2 %, respectively) and a higher bulk density (0.8 g/mL).

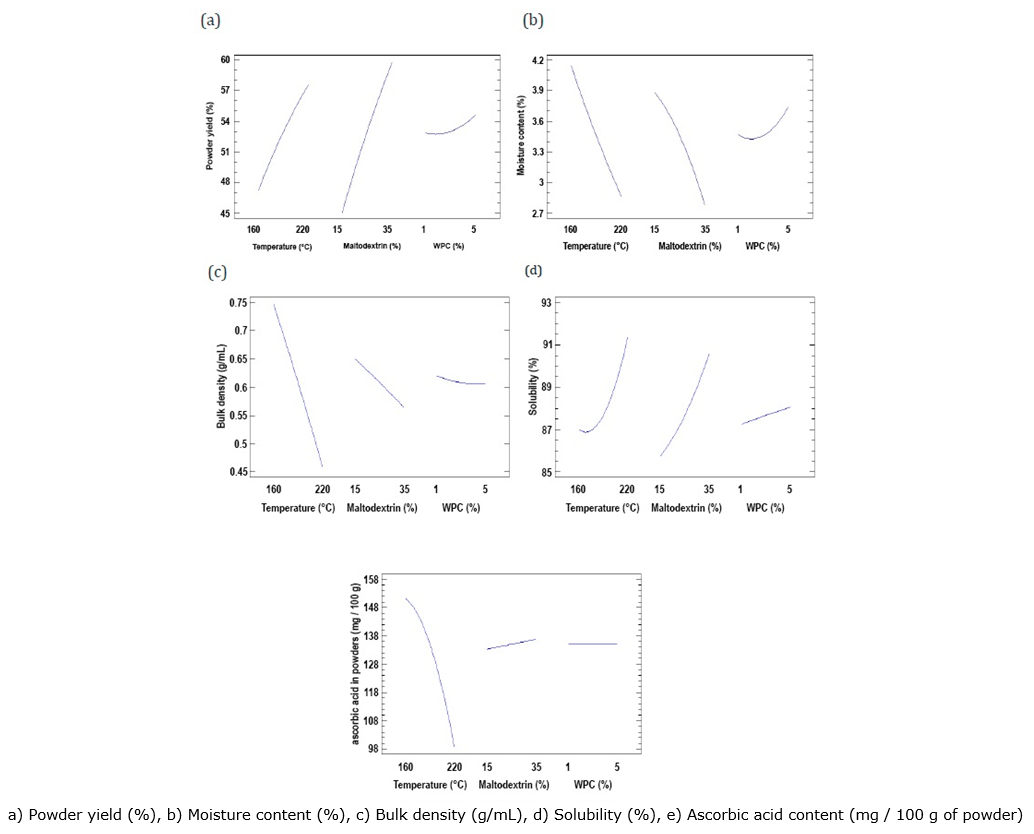

Ferreira et al. (2018) mention that spray drying at high inlet air temperatures resulted in larger particles that maintained their shape due to the accelerated formation of a rigid and porous cortex caused by rapid evaporation and diffusion of water. As can be seen in SEM images Figure 2, lulo powders obtained at 160°C were generally smaller than lulo powders obtained at 220°C and showed wrinkled surfaces and signs of particle shrinkage. On the other hand, lulo powders obtained at 220°C were more spherical and larger; individual particles with smooth surfaces and micropores can be observed; therefore, they possess a larger volume and lower weight, which could justify a lower bulk density at higher inlet air temperatures.

A higher amount of maltodextrin resulted in powders with lower bulk density (Figure 1c). Moghaddam et al. (2017) obtained similar results in cherry juice: the higher the maltodextrin concentration, the lower the bulk density; these authors attributed this to the effect of the encapsulants on the final moisture content in the powders. Tontul & Topuz (2017) further suggest that incorporating an encapsulating agent prevents powder sticking and agglomerations.

In Figure 3, SEM images of lulo powder obtained at 190°C with different concentrations of maltodextrin and WPC can be observed. In lulo powders with the highest concentration of encapsulants (35% MD + 5% WPC) (Figures 3 d, e, f), individual particles with few agglomerations are observed, whereas, lower concentration of encapsulant (15% MD + 1% WPC) resulted in particles with higher agglomeration (Figures 3 a, b and c), indicating visco-elastic and hygroscopic behavior, which increases the weight of the particles and bulk density.

In general terms, high bulk density is desirable because, as Pant et al. (2022) described, higher bulk density is related to better characteristics of powders during packaging, storage, and transport. However, when analyzing the results of the lulo powders, those with a higher bulk density have more agglomerations and moisture content and, in general terms, a lower quality. For this reason, during the optimization of multiple responses, it was taken as part of the desirability of lulo powder to minimize this response variable.

Solubility. Determining the solubility properties of fruit powders is essential to establish their reconstitution properties (Lekshmi et al., 2021). The solubility values of the lulo powders ranged from 84.1 - 94 %, similar to those reported in other fruit spray drying studies of 75.4 to 92.1% in custard apple (Shrivastava et al., 2021); 95 - 99% in pineapple-mint juice (Braga et al., 2020); 58.39 - 79.37% in blackberry (Ferreira et al., 2018); 70.7 - 80.0% in sour cherry (Moghaddam et al., 2017); and 96.7 - 98.06% in cape gooseberry (Cortés et al., 2017).

According to Figure 1 d, an increase in inlet air temperature improved the solubility of lulo powder. This behavior could be caused by the effect of temperature on particle porosity. Similar results were reported by Castañón et al. (2020), who obtained an improvement in solubility in orange powders with higher inlet air temperatures. These authors attributed these results to the fact that the rapid elimination of water in the form of vapor resulted in a porous particle with lower humidity, which facilitates its solubilization.

Inlet air temperature had a quadratic effect (Table 1), and according to Figure 1 d, the increase in inlet air temperature initially had a slightly negative effect on solubility. Pant et al. (2022) reported that temperature may have a negative effect on solubility due to the formation of an impenetrable surface layer that does not allow water diffusion through the particle and hinders its solubilization. Probably, during the spray drying of lulo, the low initial temperatures formed a hard crust, and the steam inside the particle did not have enough pressure to generate micropores, which promoted the shrinkage of the particle due to the condensation of the steam in the cooler areas of the dryer, as confirmed in the section on bulk density.

An increase in maltodextrin improved solubility (Figure 1 d). This positive effect could be caused by the impact on the moisture content of the powders and the reduction of viscoelastic behavior in agglomerations, which allows a larger area to come into contact with water, thus improving solubility (Braga et al., 2020). Moghaddam et al. (2017) mentioned that maltodextrin solubility is higher than that of fruit solids; therefore, increasing its concentration improved powder solubility. Lekshmi et al. (2021) reported an improvement in solubility; these authors attribute this to the hydrophilic nature of maltodextrin.

Ascorbic acid content. Vitamins are nutrients that play a very important role in the immune system and the health of consumers; however, their high thermal sensitivity and instability lead to the loss of their biological function; therefore, their preservation during spray drying is indispensable (Akbarbaglu et al., 2021). The results of the ascorbic acid content of the lulo powders are shown in Table 1, which ranged from 95.2 to 152.4 mg ascorbic acid /100 g powder. Similar results were obtained by Igual et al. (2014) in the spray drying of lulo (31 - 243 mg/100 g powder).

As expected, the increase in drying temperature produced a decrease in the ascorbic acid content in the lulo powders (Figure 1 e). The content of heat-sensitive compounds decreases with increasing temperature due to thermal degradation (Shishir & Chen, 2017).

Maltodextrin concentration had a significant effect on preserving ascorbic acid concentration (Figure 1 e). Souza et al. (2020) obtained good retention of ascorbic acid and carotenoids in acerola - ciriguela mixed juice powders. These authors attributed it to the effectiveness of maltodextrin as a coating that protects sensitive compounds. Cortés et al. (2017) stated that ascorbic acid has a high molecular affinity with maltodextrin due to the -OH molecules they have in common, which allows this encapsulant to protect it during spray drying and decrease its degradation.

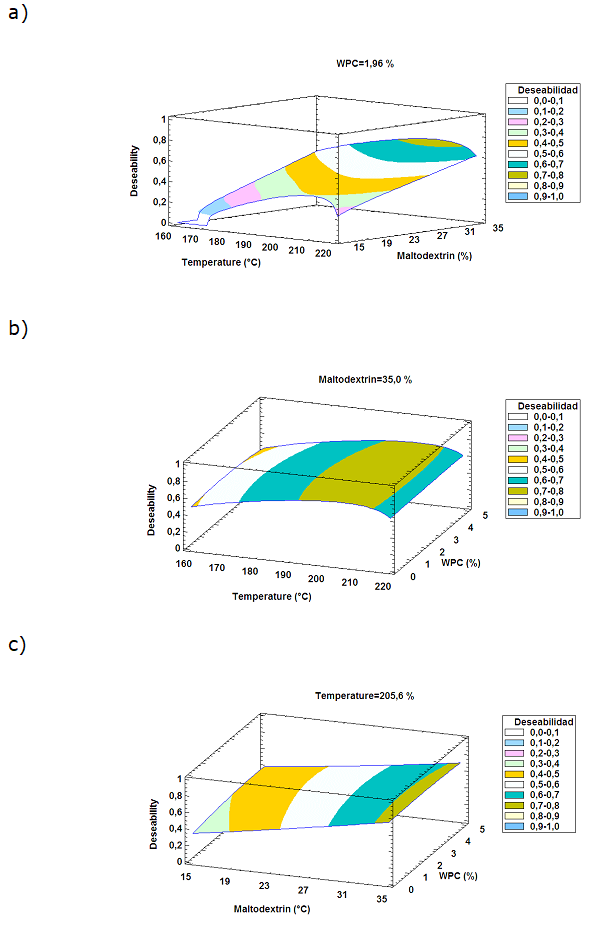

Multiple response optimization. For the selection of the optimum spray drying process factors, the maximum values of powder yield, solubility, and ascorbic acid content and the minimum values of moisture content and bulk density were taken into consideration according to the results and analysis obtained for each response variable.

As can be seen in the response surface plots for inlet temperature and maltodextrin concentration (Figure 4 a), the highest desirability values (60 - 70%) were found at temperatures between 200 to 210°C and a concentration of 35% maltodextrin, probably because these factors had a favorable effect on the moisture content and hygroscopicity of the powders, which improves the overall desirability of the powders. Higher temperatures may result in thermal degradation of sensitive compounds such as ascorbic acid. The response surface plot for inlet temperature and WPC concentration confirms that the best results are obtained at moderate temperatures. Figure 4 c indicates that higher maltodextrin content improved the overall desirability of the powder.

The multiple response optimization yielded the following optimal values for the process factors: drying temperature of 205.6°C, maltodextrin concentration of 35%, and WPC concentration of 1.96%. Under these conditions, the mathematical model estimated a powder yield of 62.82 %, a moisture content of 2.27 %, a bulk density of 0.49 g/mL, a solubility of 91.88 %, and an ascorbic acid content of 120.8 mg/100 g powder.

CONCLUSIONS

Seventeen different runs according to the Box-Behnken design were used to study the spray drying yield and quality parameters of lulo powder at various levels of temperature (T), maltodextrin (MD), and whey protein concentrate (WPC). T and MD had a significant effect on all of the response variables, while WPC had no significant effect on any of them, maybe due to the low concentration used in this study. The results of the optimization allow for obtaining a powdered product with an acceptable yield of more than 50%, good physical characteristics, and high retention of ascorbic acid. Scanning electron microscopy (SEM) showed the effect of temperature and carrier agent concentration on particle size and morphology, which affect variables such as bulk density and solubility. It is recommended that future research include a sensory evaluation, especially when there is interest in evaluating lulo powders as an ingredient in novelty food products.