Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.32 no.3 Bogotá Dec. 2012

A virtual sensor for monitoring excited thermal turbogenerator rotors

Sensor virtual para el monitoreo térmico de rotores de turbogeneradores a partir del estado de excitación

J. R. Gómez1, J. P. Monteagudo2

1 Julio R. Gómez Sarduy. Affiliation: Centro de Estudios de Energía y Medio Ambiente, Universidad de Cienfuegos "Carlos Rafael Rodríguez", Cuba. PhD in Technical Sciences, Electrical Engineer, Universidad Central de Las Villas. Cuba. E-mail: jgomez@ucf.edu.cu

2 José Pedro Monteagudo Yanes. Affiliation: Centro de Estudios de Energía y Medio Ambiente, Universidad de Cienfuegos "Carlos Rafael Rodríguez", Cuba. PhD in Technical Sciences, Mechanical Engineer, Universidad Central de Las Villas. Cuba. E-mail: jpmyanes@ucf.edu.cu

How to cite: J. R. Gómez, J. P. Monteagudo. (2012). A virtual sensor for monitoring excited thermal turbogenerator rotors. Ingeniería e Investigación. Vol. 32, No. 3. December 2012, pp. 5-9.

ABSTRACT

The working temperature of an electric generator's parts is important for its proper operation. The turbogenerator rotor's temperature is of particular interest regarding its protection and maintenance. Because of the difficulty of measuring the temperature of dynamic parts with real and implicitly robust artificial neural network (ANN) sensors it was decided to use a virtual sensor (VS) by which average rotor winding temperature is estimated. Because ANN are characterised by learning through training rather than formal descriptions, this has made them the preferred choice for modelling processes involving complex interrelated variables; some are found in the field of instrumentation, as in this research. This paper presents the development of an ANN-based VS applied to an electricity generating company's 4 MW turbogenerator.

Keywords: virtual sensor, temperature, turbogenerator.

RESUMEN

La temperatura de trabajo de diferentes partes de un generador eléctrico es una magnitud importante para su correcta explotación. La temperatura del rotor del turbogenerador es de particular interés para implementar su protección o para el diagnóstico de mantenimiento. Por la dificultad de hacer las mediciones de temperaturas de partes dinámicas con sensores reales y la robustez implícita en las redes neuronales artificiales (RNA), se ha decidido implementar un sensor virtual (SV) y a través de este método poder estimar la temperatura media del devanado del rotor. Debido a que las RNA se caracterizan por aprender por medio del entrenamiento en lugar de descripciones formales, esto ha hecho que sean la opción preferida para modelar procesos de variables con interrelaciones complejas. Algunos de estos procesos se encuentran en el área de la instrumentación, como es el caso de este trabajo. Aquí se presenta el desarrollo de un SV basado en RNA aplicado a un estudio de caso de un turbogenerador de 4 MW de una empresa cogeneradora.

Palabras clave: Sensor virtual, temperatura, turbogeneradores.

Received: July 18th 2010 Accepted: May 11th 2012

Introduction

Synchronous generators driven by primary motors, particularly steam turbines, have been the main source of generating electricity around the world so far. Cogeneration in many industries makes these machines of primary importance, especially in the sugar industry, where some factories are completely or partially electrified and synchronised to the national grid. These machines are usually robust and reliable; however, failures are costly and usually incur increased energy consumption from the national grid to supply the temporary generating shortfall regarding faulty machine output. Stator winding faults are mainly due to thermal and mechanical stress which leads to deterioration of the isolation. The machines' rotors have a higher failure rate in two pole machines (3,600 rpm). It should also be noted that assembly and disassembly is complicated due to the weight of the parts in-volved and the pertinent rotor alignment and coupling. Several days or weeks are needed in the partial or total repair of a faulty rotor, involving the use of expensive materials and skilled labour. A rotor is dried to ensure high isolation resistance and the suppression of any dynamic imbalances which may arise during winding preparation with locking wedges and tires.

Obviously, the rotors in these machines are subjected to critical operating conditions:

- They are subjected to mechanical stress (shear) stress due to high rotation speed;

- They are subjected to thermal stress due to difficult ventilation conditions; and

- They are subjected to electrical stress, transient variation in load connection and disconnection operation, and automatic voltage regulation.

If a condition-based maintenance (CBM) programme is used for a turbogenerator, then this requires paying special attention to rotor condition, monitoring being the initial step in this type of maintenance (Mamikonyants, 2005; Ahmad, 2012). CBM consists of nothing more than regularly measuring one or more variables associated with the machine and interpreting the results to ascertain its present state. Automatisation maintenance is initiated following CBM, its fundamental purpose is to automate meas-urement where inference sensors (called virtual sensors (VS) or software sensors) are sometimes necessary. In the case of stators and other stationary parts, temperature is detected with the aid of thermocouples or resistance thermometers which allow the temperature to be measured at different parts, for example, the temperature of copper, steel, cooling agent flow (water and oil) and the temperature at supporting points. Obviously, using these sensors is extremely difficult when interest lies in measuring the temperature of a moving winding rotor during machine operation. Where measurement concerns a difficult area for introducing measuring instruments or is very costly, then the information regarding such variable must be estimated. In many cases, immeasurable information about the variable of interest can be inferred from another magnitude, as in the case of an electrical machine's rotor winding temperature, where the winding's ohmic resistance is proportional to its average temperature.

Software sensors (estimators) have been developed, also known as smart sensors, soft-sensors or VS, through which a variable is inferred by taking existing information regarding another variable into account. To make the inference, such software is based on a mathematical model in a heuristic or "smart" model (Leal and Herrera, 2008).

An intelligent model relies on artificial neural networks (ANN); an ANN is a set of adaptable computing elements simulating a biological neuron's behaviour. This paper describes developing a VS for estimating turbogenerator rotor winding average temperature, selected as a base case. The rotor's average temperature was constructed from the variables so measured in a circuit involving an ANN inferential model.

The characteristics of the supervised equipment

This study was carried out using a turbine installed in a generating plant; it has the following specifications:

Primary motor:

Back pressure turbine

Direct steam pressure: 18 kg/cm2 Direct steam temperature: 310°C

Back pressure: 2 kg/cm2

Generator:

Power: 5,000 kVA

Power factor: 0.8

Voltage: 6,300 V, current: 459 A

Connection and polarity: 2 pole

Rotor resistance: 0.35199 Ω at 32°C

Reference model

VS requires a model and its accuracy is critical for obtaining reliable results. VS accuracy thus depends on the model's accuracy and the actual accuracy of the sensors used.

The reference model for the proposed application was defined by means of an equation calculating the winding's average temperature, using its electrical resistance. The actual data for train ing the ANN was obtained and organised with this model.

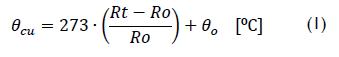

The average temperature of copper wound machines can be determined by knowing the value of internal resistance (Ro) measured at a specific temperature (θo). Internal resistance was measured each time there was a heating test and average winding temperature of was calculated using Equation (1):

where:

Rt - hot winding resistance at working temperature θcu in Ω

Ro - winding resistance temperature in θo in Ω.

If interest lies in continuous monitoring of resistance without stopping the machine, then the average temperature of the rotor must be constantly calculated, measuring voltage and current excitation, as:

Iexc Vexc being current and voltage excitation whose measurements are available from the power plant's instrument panels.

However, the resistance value obtained with these measurements includes a component making the actual value differ from the rotor winding's internal resistance due to the brushes' contact resistance which must be taken into account and corrected. The actual resistance is thus calculated as:

where:

Re is the value of the brushes' contact resistance, in Ω.

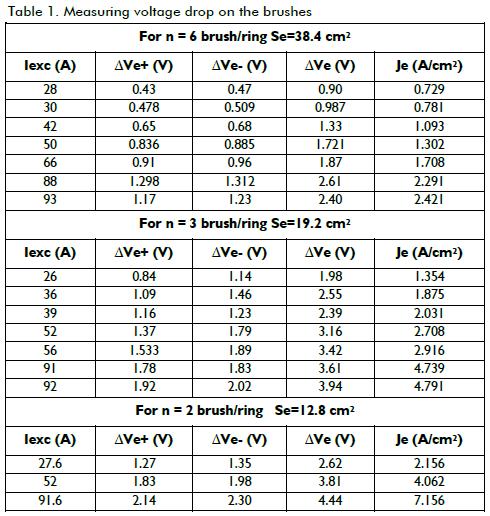

Due to the complex nature of brush contact (Kostenko and Piotrosvki, 1979; Voldek, 1985), its resistance is not constant but depends on the current. The brushes' voltamperic nature represents voltage drop ΔVe in the brushes' contact layer, the brushes' average current density being Je in A/cm2:

This can be experimentally determined by varying the current through the field, Iexc, and the number of blades per ring, so as to vary the brushes' total area, Se, and current density, Je. Vary-ing the brushes' current density, positive brush voltage drop was measured at the generator ring (ΔVe +) and the other at the negative brush (ΔVe-), obtaining fall (ΔVe) by summing them. Table 1 gives the measurement results.

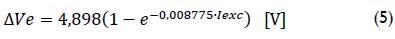

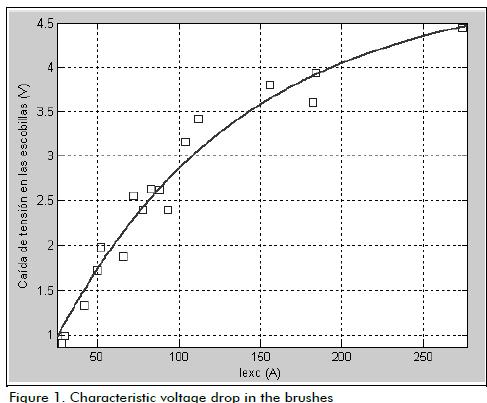

The value of the excitation current was calculated from experimental data (Je) corresponding to this current density with six working brushes per ring and voltage drop curve (ΔVe) was obtained depending on current Iexc, as shown in Figure 1, and adjusted with R2 = 0.9615 correlation to equation (5):

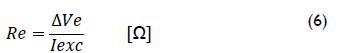

Contact resistance was expressed as:

Using equations (2), (3), (5), (6) and substituting into equation (1), thus obtaining Equation (7):

Expression (7) constituted the reference model or a numeric prototype for generating the data used to train the ANN, considering the case analysed (Ro=0.35199 Ω and θo=32ºC).

Case study: ANN-based virtual sensor (VS) development

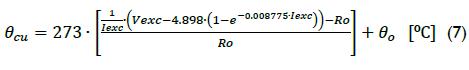

The available measurements were excitation voltage (Vexc) and excitation current (Iexc). The windings' average temperature was calculated from these measurements and the use of expression (7), creating a database for developing an ANN-based VS, giving its output temperature (T) in °C (see Figure 2). This network was designed and trained using Matlab 7.8.0 neural network toolbox (R2009a).

Single neurons are combined in a neuronal model to build a network whose architecture can be quite varied. An ANN is characterised by its topology, the nodes and learning rules or training. The technical literature suggests a multilayer feed-forward network as being the most suitable for these applications (Halpin and Burch, 1997).

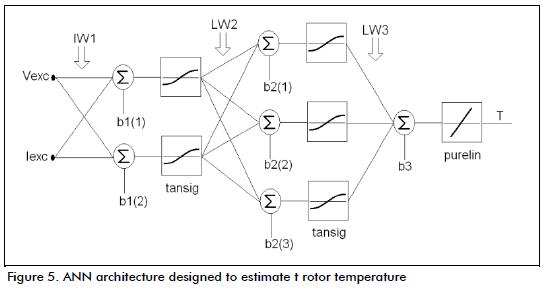

This is a network where the set of neurons is arranged in levels so that the links are established from neurons at level i to neurons at level j (i <j), so that information flows unidirectionally from the input units to the output units. Typically there is a layer of sensor units, one or more hidden layers of neurons and a layer of neurons for output. The network architecture used in this paper contained a first layer with input neurons, an intermediate layer with hidden neurons and an output neuron for the last layer. Although multiple hidden layer architecture can be used, it has been shown that a single hidden layer is usually enough (Halpin and Burch, 1997). The input vector (Vexc, Iexc) comprised voltage and excitation current. The rotor's average temperature was estimated from such magnitudes (i.e. ANN output). The function used in the hidden layer's neurons was a sigmoidal hyperbolic tangent function (tansig) and the output neuron function was linear (purelin) (Halpin and Burch, 1997).

The network was trained with 297 experimental data sets of voltage and current excitation and the corresponding average temperature calculated by expression (7). Each input and output variable in the data set was normalised using the maximum value

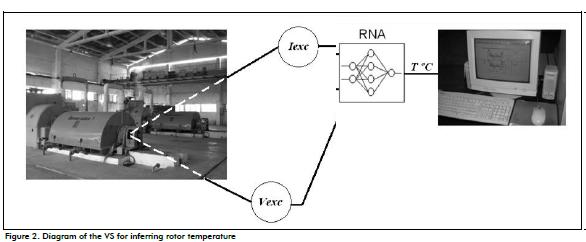

of the variable, as recommended in the pertinent literature (Hal-pin and Burch, 1997; Gomez, 2008). 60% of the data was used for training, 20% for validating and 20% for testing. Learning and convergence were satisfactory (see Figure 3), in which the Matlab window showed mean square error (MSE) evolution in training data sets for validating, testing and training.

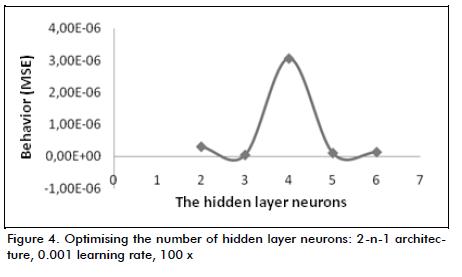

Regarding entries and departures, the network had two input and one output neurons. Selecting the appropriate number of hidden neurons was important, so the network was trained by varying their number and keeping all other parameters constant, resulting in three neurons in the hidden layer; network performance was better (see Figure 4). 2-3-1 architecture was thus chosen, as shown in Figure 5.

VS simulation

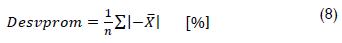

The results obtained from the VS were statistically validated using average deviation expressed as a percentage. This gave the data points' average absolute deviation, i.e.:

where:

n was the number of observations

X was individual deviation, expressed as a percentage

X- was the average value of all individual deviations ex-pressed as a percentage.

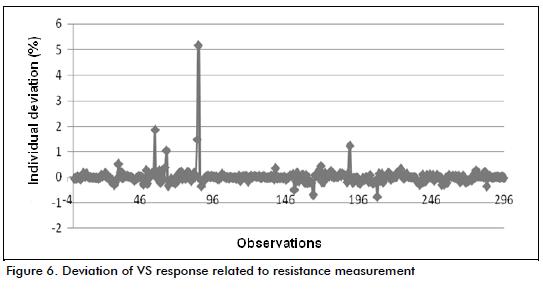

The entire experimental data universe was used in the analysis and the ANN model was used to simulate energy consumption; individual deviation was determined using the temperature given by the neuronal model in relation to the actual temperature data and applying expression (8). The average deviation was expressed as a percentage and standard variable led to better quality visualisation of the model's fit.

The mean deviation defined by equation (8) was 0.14% the maximum deviation 5.15%. Individual deviation in 95% of the data was less than 0.74% and previous data variance was 0.14%. Figure 6 gives the individual deviation pattern, showing the model's excellent response.

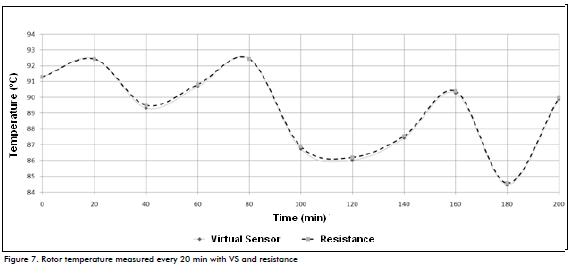

The results of the rotor's temperature, estimated by both methods, are shown to compare ANN response related to the resistance method, observing that the results practically coincided throughout the sampled interval (Figure 7).

Conclusions

An ANN-based virtual sensor was developed for estimating the mean temperature of synchronous machines' excited rotor winding, which could be used immediately due to the ease in operating it as only voltage and excitation current were considered as input variables.

Good correlation was shown between VS results and the method serving as reference for electrical winding resistance. VS average deviation was 0.14% and 95% of the cases showed less than 0.74% individual deviation, which also demonstrated the quality of the modelling.

These sensors work on-line with the plant, being integrated with any monitoring system, thereby improving plant instrumentation, facilitating control and management and also adding new variables, alarms and functions.

The proposed method did not involve additional costs, as it used the plant's conventional monitoring equipment in its operation.

References

Ahmad, R and Kamaruddin, S. An overview of time-based and condition-based maintenance in industrial application. Computers & Industrial Engineering, Volume 63, Issue 1, August 2012, pp 135-149. [ Links ]

Boccaletti, C., Cerri, G. and Seyedan, B., A neural network simulator of gas turbine with a waste heat recovery section. Journal of Engineering for Gas Turbines and Power. April ,2001, Vol. 123, pp. 371-376. [ Links ]

Gómez, J. R., et al., Artificial intelligence applied to the charge distribution in a cogeneration system. Energy Magazine, No. 39, July, 2008. [ Links ]

Halpin, S. M. and Burch, R. F., Applicability of neural networks to industrial and commercial power systems: A tutorial overview, IEEE Transactions on Industry Applications, Vol. 33, NO. 5, Sept., 1997, pp 1355-1361. [ Links ]

Kostenko, M. P. and Piotrosvki, L. M., Electrical Machines. Volume I, MIR Publisher, Moscow, 1979. [ Links ]

Leal, R. R. and Herrera E., Virtual sensors using artificial neural networks. Two case studies in biotechnology., Iteso.mx / - rleal / files / conielec.pdf. (vi: 2008). [ Links ]

Mamikonyants, L. G., et al., Concept of transfer to repair of power plant turbogenerators according to their technical state. Power Technology and Engineering (formerly Hydrotechnical Construction) Volume 39, Number 6 (2005), pp. 359-363 [ Links ]

Voldek, A. I., Electrical Machines. Volume I. Editorial People and Education, Havana, 1985. [ Links ]