1. INTRODUCTION

Starch is one of the most abundant polysaccharides in nature. It is composed mainly of two glucose polymers: amylose and amylopectin [1]. The importance of starch lies in its versatility for both food and non-food applications. It is widely used for its pasting properties, such as gelling agent, swelling agent, water retention agent, among others, which provide texture in many foods [2], [3].

The physicochemical, functional and digestibility properties of native starches will be influenced, among many reasons, by their granular structure, their composition, their botanical source and the extraction method used [3], [4]. Commercial starch comes from different products such as cereals, especially wheat, rice, and corn. The latter is the most widely used industrially and domestically, due to its high extraction yield and availability[5].

Other sources of starch are tubers and roots such as potatoes and cassava [6]. Potato is one of the most consumed agricultural products worldwide, whose origin is established more than 8000 years ago near Lake Titicaca, between Peru and Bolivia.

For the year 2020, Colombia produced about 2.6 million tons of potatoes [7]. Which is concentrated in three departments: Cundinamarca (41 %), Boyacá (27 %) and Nariño (18 %). The cultivation of potatoes is also the main livelihood of farming families in cold climate regions [8]. Among the potato species grown in Colombia, Solanum phureja stands out for presenting the greatest genetic diversity. In Nariño, at least more than 132 varieties of native potatoes are known. However, these varieties are no longer regularly grown due to low demand and short dormancy. This prevents tubers from being stored for long periods of time[9]. Therefore, the variability of this species has been lost over the years. For this reason, it is urgent to search for processing alternatives for varieties of this species that allow them to add value and thus avoid their loss. Thus, the extraction of starch from native potato varieties can be a useful alternative to the problem posed.

Starches from unconventional botanical sources such as native potato may exhibit desirable properties of importance [10]. Authors such as [11] have reported diverse properties among 17 varieties of Creole potato with an amylose content between 14.05 % ( 49.0 % and gelatinization temperatures in a range of 62 °C ( 74 °C. Studies of [9] report an amylose content between 24.82 % and 26.27 %, and a viscosity that varies from 3000 cP to 7000 cP for three varieties of Creole potato (S. phureja). Research results reported by [10] and [12] showed differences in size, crystallinity, thermal and pasting properties between potato starches of native varieties. All the authors mentioned emphasize that the physicochemical, functional and digestibility properties of starch may be due to differences between cultivars.

The comparison of starch from native potato varieties with commercial materials is relevant to establish differences and similarities that may be useful at an industrial level. The research of [3] found several relevant characteristics of commercial starches from different sources. For example, the authors report that potato and root starches exhibit the highest pasting properties, cassava and sweet potato starches show the highest transition temperatures in contrast to wheat starch. The previous results demonstrate that each source of starch can show properties that could be of interest in processes different from each other. The genetic diversity of the potato would also influence the properties of the starch; therefore, the study of its properties is relevant.

So far, there are no reports comparing starches from native potato varieties of Nariño with existing starches on the market. Hence, the objective of this research was to evaluate some physicochemical and technofunctional properties of starch from two native potato varieties: Ratona Blanca and Andina, with commercial potato and corn starches. Therefore, it seeks to determine the potential of these processes as a processing alternative. And thus, the planting of native potato varieties could be stimulated again and prevent their genetic loss.

2. MATERIALS AND METHODS

2.1 Raw Material

Two varieties of native potato (Solanum phureja) grown in the municipality of Gualmatan in the department of Nariño were used. The samples of the Ratona Blanca and Andina varieties were selected, classified, and cleaned for further processing.

2.2 Potato Starch Extraction and Commercial Starches

Starch from native variety potatoes was extracted according to the methodology described by [13]. The potato was washed to remove impurities and was selected. The washed tubers were cut into cubes and submerged in an antioxidant solution of citric acid (C6H8O7) at 1 % w/v. The grinding was carried out in an industrial blender (JAVAR brand, 2HP) at maximum speed for 2 min. The liquid obtained was filtered through muslin, and the bran was washed until the water was clear. The resulting liquid was allowed to settle, the supernatant was discarded, and the washing and sedimentation process was carried out two more times. Finally, the sediment at the bottom of the container was dried at 40 °C, until the humidity of the starch was (10±1) % (dm). Commercial potato and corn starches were purchased from the local market.

2.3 Physicochemical Properties

Starch was analyzed to determine amylose and phosphorus content with the techniques reported by [14]. An FEI Quanta 200 scanning electron microscope was used to take micrographs of the starch granule size and shape. The parameters used were those reported by [15]: working distance, 7.5 mm; acceleration voltage, 25 kV; condenser lens position, 60 mm. Image processing was carried out with imageJ software. The x-ray diffraction study was carried out with a PANalytical model X'PERT PRO MPD X-ray diffractometer. Data was collected over the range: 2° ≤ 2θ ≤ 45° at 20 θ/min run speed. Relative crystallinity was calculated by the ratio of the crystalline area to the total diffractogram area [16].

2.4 Pasting Properties

Pasting properties of starch were carried with a TA Instruments AR1500 rotational rheometer, following the methodology reported by [17] and [18] with some modifications. Starch suspensions (8 %) with a total mass of 25 g were used and placed in the starch pasting cell. The pasting profile was programmed where samples were first held at 50 °C for 1 min, ramping from 50 °C to 90 °C at 12 °C/min, holding at 90 °C for 2.5 minutes. Then, it was cooled to 50 °C at the same heating rate and again holding at 50 °C for 2 minutes. The following parameters were obtained from the curve: pasting temperature (PT), maximum viscosity (PV), final viscosity (FV), rupture viscosity (BV) and setback viscosity (SV).

2.5 Thermal Properties

Thermal properties were analyzed using a TA Instruments DSC Q20 differential scanning calorimeter, 2 mg of starch was weighed into an aluminum pan and water (1:3 w/w ratio, dry basis) was added. The containers were hermetically sealed. A period of thermal equilibrium was continued for 2 hours before analysis. The samples were gradually heated at 10 °C/min following a temperature ramp from 20 °C to 200 °C. Through the thermograms (DSC) obtained, the initial or start gelatinization temperature (To), peak gelatinization temperature (Tp), final gelatinization or melting temperature (Tc) and the enthalpy of gelatinization (ΔH) were determined.

The TGA analysis was carried out in the Q50 thermogravimetric equipment brand TA Instruments. The starting temperature of starch thermodegradation was obtained with samples of (6 ± 0.50) mg in the presence of a nitrogen atmosphere. A heating of 5 °C/min was carried out, until reaching 600 °C.

2.6 In-vitro Digestibility

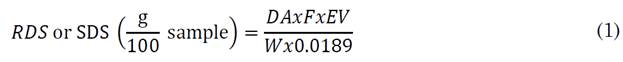

The digestible and resistant fractions of starch were quantified with the enzyme kit from Megazyme (Megazyme International Ireland Ltd. Co. Wicklow, Ireland) K-DSTRS 11/19. Rapidly digestible starch (RDS) and slowly digestible starch (SDS) were calculated with (1). Resistant starch (RS) was calculated with (2).

Where:

DA = absorbance read after 20 minutes (RDS), after 120 minutes (SDS).

F = absorbance conversion to mg.

EV = extraction volume (mL).

W = Weight of the analyzed sample.

Where:

DA = absorbance read against the reagent blank.

F = absorbance conversion to mg

EV = extraction volume. (mL)

FV = aliquots taken from the final volume

W = weight of the analyzed sample in g

2.7 Statistical Analysis

In the experimentation, a totally random experimental design was used. Statistical analysis was carried out using an analysis of variance (ANOVA). For this, a Tukey test at 95 % confidence was used to determine if there were differences between the properties of the studied starches (Andina, Ratona Blanca, commercial potato and corn). Data are reported as the mean of four replicates ± the standard deviation.

Additionally, a Pearson correlation analysis was performed on some of the variables studied to determine the statistical relationship between them. All analyzes performed were run using RStudio software.

3. RESULTS AND DISCUSSION

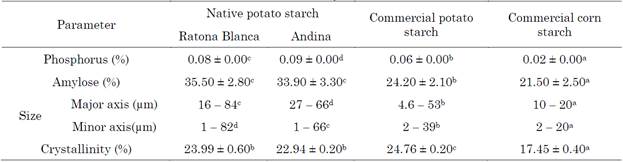

The results of the physicochemical parameters evaluated for potato starch varieties Ratona Blanca and Andina in comparison to commercial potato and corn starch are shown inTable 1.

Table 1 Chemical parameters of potato starch (S. phureja and S. tuberosum) and corn (Zea mays)*

*Data (mean ± SD) in the same row with different superscript letters were significantly different (P ≤ 0.05). n=4.

Source: Created by the authors.

3.1 Phosphorus and Amylose Content

The phosphorus content is higher in the starch of the two potato varieties compared to commercial potato and corn starch. There were statistically significant differences between the sources evaluated (P<0.05). The potato starch variety Ratona Blanca presented higher values of phosphorus (0.08 %), only slightly surpassed by Andina (0.09 %). Several authors have reported a phosphorus content in potato starch of up to 0.06 % and a maximum content in corn starch of 0.03 % [6].

Amylose content in the two potato varieties was higher than that found for commercial potato and corn starch, with significant differences between these two botanical sources (P<0.05). Starch from the Ratona Blanca variety had a higher amylose content, while corn starch had the lowest content among all the starches studied. The values found are close to the normal content of amylose in starch of different potato cultivars (20 % to 35 %) reported by [9] and [13].

The results found in the present investigation are greater than those reported by [9]. The authors found an average content between 25 % and 27 % amylose in three varieties of Creole potato (S. phureja). Studies of [15] obtained a wider range from 24 % to 32 % amylose for Andean potato varieties. These differences can be attributed to the enzymatic reactions involved in the biosynthesis of linear or branched components within the granule [19]. Likewise, it may be due to the different cultivation conditions that influence the characteristics of the starch [2], [11], [20].

3.2 Scanning Electron Microscopy (SEM)

Figure 1 shows the micrographs of the starch granules evaluated. It was observed that the size and shape distribution of the potato starch granule is not uniform. The varieties studied exhibit large and oval granules and smaller spherical granules (Figure 1(a), 1(b)). What was found coincides with [13] and [18] who report a bimodal distribution in potato starch granules. The corn starch granules presented a polygonal shape with a more uniform size (Figure 1(c)). Commercial potato starch (Figure 1(d)) exhibited large granules with oval shapes and smooth surface. It also exhibited small granules with a truncated spherical shape and polygonal edges with a tendency to agglomerate like corn starch. This latter form is unusual for potato starch. Authors such as [21] have reported these characteristics in cassava starch granules. Therefore, it could be inferred that the commercial potato starch studied could be a combination of potato and cassava starch.

Source: Created by the authors.

Figure 1 SEM-Micrographs of potato and corn starch. (a) Ratona Blanca starch. (b) Andina starch. (c) Commercial potato starch. (d) Commercial corn starch

As seen in Table 1, the Ratona Blanca variety presented a larger size compared to the Andina variety and to commercial potato and corn starches. The diameters obtained for the two native potato varieties were higher than those reported by [20] (18 µm -31 µm) and smaller than the sizes exhibited in the studies by [6] (5 µm - 100 µm).

The variation in size and shape of the starch granules are attributed, among other reasons, to the botanical source [19], [22]. Especially between potato cultivars, the morphological and size variability in the granule is higher compared to other plant products [2]. The biochemistry of the chloroplast or amyloplast, the physiology of the plant, as well as the physical characteristics of the plastids, are determinants in the development of the shape and final size of the starch granule [19], [22].

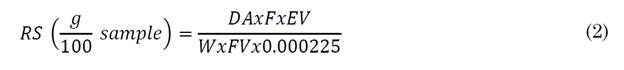

3.3 X-ray diffraction

Figure 2 shows the X-ray diffraction patterns of potato and corn starches. The starch of the two potato varieties and the commercial potato starch presented a B-type crystalline structure. Corn starch presented a type A diffraction pattern with a doublet around 17.15° and 18.06° of 2θ. It also exhibited strong diffraction peaks around 15.11° and 23.03° of 2θ.

Potato starch from native varieties showed higher intensity peaks at 17° of 2θ (Figure 2). Likewise, they presented a peak at 5° of 2θ which has been reported as characteristic of starches with type B crystallinity [12]. On the other hand, commercial potato starch presented a higher intensity peak at 17° of 2θ and a characteristic peak at 5° of 2θ as native potato starches. For this starch, three phases were identified, two of which coincide with potato; and a third identified as cassava starch according to the pattern reported by [23]. This coincides with the granules of characteristic cassava starch morphology found in the micrographs.

The analyzed starches presented differences between the potato varieties with the commercial starches (P<0.05). Commercial potato starch presented the highest crystallinity with approximately 25 % (Table 1). While corn starch presented the lowest crystallinity with an approximate value of 17 %. These results are in agreement with [24], who report that crystallinity generally varies from 15 % ( 45 % and depends on botanical sources, granule population and starch composition.

Type B crystallinity starch are longer and are grouped in a hexagonal cell [25]. Probably for this reason, all potato starches exhibited higher crystallinity, due to the degree of polymerization and length of their amylopectin chains [4], [25]. Therefore, potato starch may have greater crystallinity despite its amylose content.

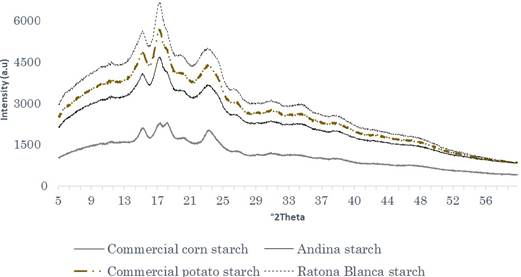

3.4 Pasting Properties

The pasting parameters were different among all the starches evaluated (P<0.05). As shown in Figure 3, the Andina variety exhibited the highest peak viscosity (PV), with (8714 ± 166) cP. While corn starch exhibited the lowest result (1241 ± 79) cP. For its part, potato starch variety Ratona Blanca presented a higher PV (6148 ± 153) cP than corn starch and commercial potato starch (5346 ± 129) cP.

Pasting temperature (PT) was higher for corn starch, followed by Ratona Blanca, with values close to 75 °C and 64 °C, respectively. While the commercial potato starch and the Andina variety presented PT of 63 °C and 62.2 °C, respectively. A higher PT refers to a higher internal organization of the starch granule [18]. This is related to the breakdown viscosity (BV), which represents the stability of the granules against shear and temperature; higher values of this parameter indicate less stability. Corn starch presented the lowest BV values (318 cP) followed by Ratona Blanca potato starch (1491 cP).

The lowest values of setback viscosity (SV) were again for corn starch and potato variety Ratona Blanca with 104 cP and 310 cP respectively. On the other hand, the highest final viscosity (FV) was exhibited by Ratona Blanca starch (5838 cP), while the lowest value was for corn starch (1137 cP). The setback viscosity (SV) is related to the ability of starch to retrograde (syneresis) and the final viscosity (FV) refers to the ability of starch to form viscous pastes [18]. Several investigations have reported different results in potato varieties in both S. phureja and S. tuberosum species. Studies of [10] informed a PV between 14000 cP-16000 cP for starch from ten native potato varieties (S. phureja).

On the other hand, authors of [12] reported lower PV values of up to 556 cP for starch from Andean potato varieties. The research of [9] obtained PV between 3700 cP and 7200 cP for three varieties of Creole potato. Pasting characteristics vary greatly according to the botanical source of the starch. Especially in potatoes, where there is a great genetic diversity and where the growing conditions have a notable influence on the composition of the product.

3.5 Thermal Properties

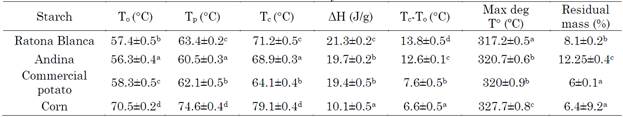

The gelatinization parameters of the starches analyzed by DSC are shown in Table 2. The initial temperature (To) of potato starches was lower compared to corn starch, indicating that more energy is required to initiate gelatinization [3]. On the other hand, the enthalpy was higher in potato starches (19 J/g ( 21 J/g) than in corn starch. Gelatinization enthalpy is the energy required to break the ordered helical structure in starch granules [26].

Table 2 Gelatinization and thermogravimetric properties of potato and corn starches*

*Data (mean ± SD) in the same column with different superscript letters were significantly different (P ≤ 0.05), n=4. To: initial temperature; Tp: peak temperature; Tc: final temperature; ΔH: gelatinization enthalpy; Máx deg T°: maximum degradation temperature.

Source: Created by the authors.

Comparatively, potato starch needs the most energy to alter the semi-crystalline structure of the granules. This agrees with the crystallinity exhibited by potato starches compared to corn starch. Especially Ratona Blanca potato starch exhibits higher ΔH, possibly due to its crystallinity and internal structure. The gelatinization range (Tc ( To) was narrower for corn starch, while it was wider for the Ratona Blanca variety. The small range of gelatinization may be due to the presence of less thermally stable crystallites within the starch granules[22]. Or also to the high heterogeneity of the size of starch granules and possibly to the arrangement of amylose and amylopectin within the granule [10]. The results found are close to the values of To, Tp and Tc found by [1], [9] and [11]. Unlike the previous authors, the reported enthalpy values are lower than those found in the present investigation for potato starches.

The TGA results of the potato and corn starches are presented in Table 2. The weight loss was generated in two stages, the first one occurred around 100 °C and corresponds to the elimination of water in the sample. The second stage occurred between 250 °C ( 370 °C, which was attributed to starch decomposition. The degradation start temperatures were close among all the starches evaluated. Ratona Blanca variety presented a maximum degradation temperature lower than the other starches. This means that the variety mentioned is thermally stable at temperatures below 317 ºC where the process of thermal degradation begins. Regarding the residues, after the thermal process, the starch of the Andina variety was the one with the highest residual percentage.

The residue corresponds to the inorganic components of starch [10], in the case of Andina, it is probably associated with its higher mineral content like phosphorus.

Different authors such as [22] and by [5] show a similar behavior in potato starches and other botanical sources. Where, during the second stage of the analysis, approximately 70 % of the initial sample is degraded. The authors affirm that the percentages of loss are quite similar between starches without being directly related to the crystallinity of the polysaccharide. Authors like [27] suggest that it could be more related to its proximal composition. This could be confirmed in the present investigation, where the potato starches with higher crystallinity presented lower degradation temperatures.

The thermal degradation of starch is a relevant aspect when processing foods and starch-based materials, especially in processes associated with high temperatures [27]. In this case, potato starches presented lower degradation temperatures, with which it can be concluded that they could be more useful in thermal processes where greater stability is not required.

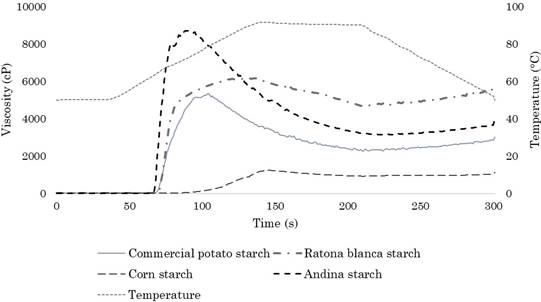

3.6 In-vitro Digestibility

Figure 4 shows the results for the digestibility parameters evaluated: Rapidly digestible starch (RDS), slowly digestible starch (SDS) and resistant starch (RS). Highly significant differences (P<0.001) were found between the starches studied, in all digestibility fractions analyzed, except for slowly digestible starch (SDS). The RDS was significantly lower in potato starch from native varieties compared to commercial starches. With values of (71.47±0.76) % and (67.8±0.8) % for commercial corn and potato starches, respectively. On the other hand, potato starch varieties Andina and Ratona Blanca presented contents of (57.7±0.2) % and (52.6±1) %, respectively.

Source: Created by the authors.

Figure 4 Content of rapidly digestible starch (RDS), slowly digestible starch (SDS), resistant starch (RS) in native potato starch, commercial potato, and corn starch. Data (mean ± SD) on the same component with different letters were significantly different (P ≤ 0.05)

Potato starches presented SDS values close to 12 % for all starches with the exception of corn starch, which presented values close to (7.5±0.3) %. The content of resistant starch (RS) was higher in starches from the Ratona Blanca and Andina varieties, with (33.14±0.8) % and (28.9±0.7) %, respectively.

While commercial potato starch only obtained a content of (22.5±0.7) % and (11.8±0.5) % for corn. The results found were similar to the RS values reported by [21]. On the other hand, [28] exhibited higher SDS contents (65.71±0.37) % compared to the results found in this research and lower RS contents with (20.28±4.74) %.The nutritional interest of starch lies in its speed and degree of digestion and absorption in the small intestine. For this reason, the content of SDS and RS is of special interest at a technological and nutritional level. The starch of the potato varieties studied exhibited high amounts of RS and significant amounts of SDS. This determines the lower digestibility of these starches compared to commercial ones.

3.7 Correlation and Comparison Between Physicochemical and Functional Properties of Potato and Corn Starches

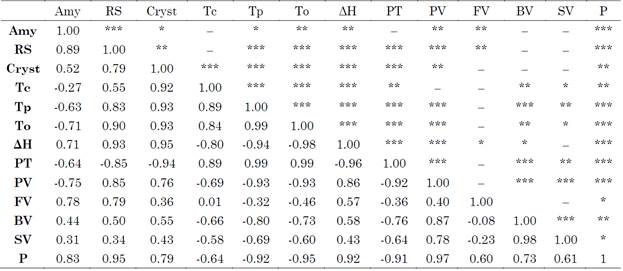

Table 3 shows the correlation coefficients. Variables that did not show correlation or that were represented by other variables such as TGA parameters and granule size were excluded.

Table 3 Pearson correlation coefficients between physicochemical and functional variables of potato and corn starches.

*Significant correlation (P<0.05), **Significant correlation (P<0.01), ***Highly significant correlation (P<0.001). Amy: Amylose content; RS: Resistant starch; Cryst: Crystallinity; Tc: conclusion temperature; To: start temperature; Tp: peak temperature; ΔH: gelatinization enthalpy; PT: Pasting temperature; PV: Peak viscosity; FV: Final viscosity; BV: Breakdown viscosity; SV: Setback viscosity; P: Phosphorus content.

Source: Created by the authors.

Amylose content had a positive correlation with resistant starch, crystallinity, phosphorus, ΔH and FV. While it also presented negative correlations with variables such as Tp, To and PV. Starch resistance has often been associated with amylose content. The denser structure of amylose in relation to amylopectin makes it less susceptible to enzymatic attacks[29].

Similarly, the crystallinity that in most cases is negatively affected by amylose; in the present investigation it exhibits a positive relationship, possibly due to its length and disposition. In general, starches with higher crystallinity can become more resistant. In this study, there was a positive correlation between these two variables (r: 0.79; P<0.01).

This is evidenced by the higher RS content of potato starches, which in turn presented higher crystallinity. However, it has been determined that the starch resistance does not always depend on the degree of crystallinity [4]. Today it is known that digestibility is also due to multiple factors. These include granule shape and size, granule pores, amylose chain length, amylopectin linearization, and association with other compounds such as phosphorus and lipids [4], [18]. As evidenced in Table 3, phosphorus shows a high correlation with RS (r:0.95, P<0.001) and crystallinity (r: 0.79, P<0.01); which could corroborate the above information.

The inverse correlation presented between amylose and PT was also reported by [20]. There were also positive correlations between phosphorus and FV, unlike the previous authors, who showed a negative correlation. For potato starch, a higher content of amylose is associated with a lower content of phosphate groups, and for corn it represents a higher content of phospholipids. The differences found between the studied starches can be attributed to their composition, morphology and structural conformation [1]. Tuber starches such as potatoes exhibit higher viscosities due to their high content of phosphate groups. The charges of the phosphate groups are known to cause repulsion between the amylose and amylopectin chains, leading to increased swelling, water absorption, and viscosity [12].

The higher viscosity of the Andina variety starch can be attributed to factors such as its higher content of amylopectin and phosphorus, or a possible higher proportion of larger granules [12]. On the other hand, the lower values of PV in corn starch are due to its higher content of phospholipids. Which restrict granular swelling because they form complexes with amylose. This contributes to the maintenance of granule integrity and in turn decreases the viscosity exhibited by corn starch [30].

Studies reported by [31] suggested that leached starch molecules reorganize faster and are responsible for higher SV and lower FV. However, authors such as [32] showed that amylose content and starch recrystallization do not always correlate. Other minor components such as phosphates, lipids and proteins also influence this process, which generally affects the functional properties of starch [33]. In the present investigation, the Ratona Blanca potato starch with the highest amylose content had the lowest SV and highest FV. This could be due to its composition and/or due to structural differences between amylose and amylopectin. The higher PV of native potato varieties makes them especially useful materials as thickeners in products such as instant soups, compotes, and sauces. On the other hand, the lower SV of Ratona Blanca and corn starch can be useful in products with homogeneous phases such as beverages. Or it could also be used in bakery products, where the greatest retrogradation is associated with the greatest aging of the crumb.

Enthalpy (ΔH) was positively correlated with amylose content, RS, and crystallinity. Authors such as [33] showed that more amylose tended to entangle the other starch molecules and bind the granules; which increases thermal stability. This can also explain the correlation between crystallinity and RS with the thermal and pasting variables. A higher ΔH and higher gelatinization temperatures are associated with a higher degree of internal organization of the granule. Studies carried out by [12] show that the internal structure of amylopectin and amylose affects the functionalities of starch. A greater internal organization, especially of native potato starches, may be of interest for applications where thermal processes at high temperatures are required, such as baking or pasteurization.

The variation of the composition and conformation at the molecular level has a significant impact on the functionality of the starch. These are given among other reasons at the botanical source of origin. According to [2], the physicochemical variation between species is high. Therefore, starches from different sources exhibit different properties. This not only depends on the relative proportions of amylose and amylopectin, but also on components such as lipids, proteins and phosphate groups [2], [3]. This explains the similarities and differences between the potato starches studied, as with respect to commercial starches. Native potato starches presented characteristics that are of potential industrial use in different production processes.

4. CONCLUSIONS

The Ratona Blanca variety potato starch exhibits physicochemical and functional characteristics similar to the Andina variety starch but differs in most parameters with commercial potato and corn starches. Potato starches from both native varieties and commercial starch presented the largest granule size higher value in pasting properties, higher crystallinity, higher resistant starch content and higher phosphorus content. On the other hand, corn starch, despite its lower amylose content, presented lower crystallinity, which is associated with its higher digestibility compared to potato starches.

The properties of commercial potato starch were intermediate between Ratona Blanca and Andina potato starches. The latter exhibited superiority in resistant starch content, higher peak viscosity and higher enthalpy. The properties mentioned presented a positive correlation with each other, which could be related to its composition (phosphorus content) and its structure at the molecular level (length and arrangement of amylose and amylopectin chains). These exhibited differential properties can be useful in different fields, such as nutrition and the food industry.