Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Citado por Google

Citado por Google -

Similares en

SciELO

Similares en

SciELO -

Similares en Google

Similares en Google

Compartir

Tecciencia

versión impresa ISSN 1909-3667

Tecciencia vol.10 no.19 Bogotá jul./dic. 2015

https://doi.org/10.18180/tecciencia.2015.19.9

DOI: http://dx.doi.org/10.18180/tecciencia.2015.19.9

Incidence of using chicken fat based biodiesel on the performance of a 13.5 kW compression ignition piston engine for power generation

Incidencia del uso de biodiesel de grasa de pollo en el desempeño de un motor de ignición por compresión de 13.5 kWe empleado para la generación de potencia eléctrica

Fabio Emiro Sierra-Vargas1*, Manuel Antonio Montenegro2, Favio Orlando Narváez Argoty3

1 Universidad Nacional de Colombia, Bogotá, Colombia, fesierrav@unal.edu.co

2 Servicio Nacional de Aprendizaje SENA, Bogotá, Colombia, montenegromanolo@gmail.com

3 Servicio Nacional de Aprendizaje SENA, Bogotá, Colombia, favionarvaeza@yahoo.com

* Corresponding Author. E-mail: fesierrav@unal.edu.co; Tel: 3165000 ext 11130

How to cite: Sierra-Vargas, Fabio E.; Montenegro, Manuel A.; Narvaez A., Favio O.; Incidence of using chicken fat based biodiesel on the performance of a 13.5 kW compression ignition piston engine for power generation TECCIENCIA, Vol. 10 No. 19., 61-72, 2015, DOI: http://dx.doi.org/10.18180/tecciencia.2015.19.9

Received: June 26 2015 Accepted: August 10 2015 Available Online: Sept 7 2015

Abstract

New alternatives and feedstocks have been identified to overcome the impact caused by combustion of fossil fuels; some of them point on the promotion of second, third and fourth generation biofuels resulting from non-edible crops and other raw materials. The lack of information about the performance of engines used for power generation encumbers the use of chicken fat biodiesel in gensets in rural areas or other applications in which power generation is the main purpose. Therefore, this work aims to identify the incidence of using chicken fat biodiesel on the performance of a 13.45kWe internal combustion engine employed for power generation. The biodiesel was synthesized in lab conditions and afterwards fueled in the engine. Parameters such as the total electrical efficiency, heat rate, fuel consumption and the exhaust gas emissions are analyzed. A Lister TR2 diesel engine fixed to a Leroy Soner LSA 38 M/J electrical generator was employed. The chicken fat biodiesel was successfully produced in a lab-scale facility and afterward employed as biofuel blended with commercial biodiesel BPa7. The efficiency of the genset increases up to 38.79% with B22.5 higher than the 35.08% obtained for B0. As a consequence of the fuel reduction and addition of a sustainable biofuel such as chicken-fat biodiesel the carbon footprint was also decreased; the CO2 released decreases about 2.9 kgCO2h-1 when the genset was operating at full capacity fueled with B22.5.

Keywords: Renewable energy, chicken-fat, biodiesel, energy efficiency, carbon footprint.

Resumen

Nuevas alternativas y materias primas han sido identificadas como posibles soluciones a los impactos causados por la combustión de combustibles fósiles; algunas de estas apuntan a la promoción de biocombustibles de segunda, tercera y cuarta generación resultantes de cultivos no comestibles y otras materias primas. La falta de información relacionada con el desempeño de motores empleados para la generación de potencia dificulta el uso de biodiesel hecho a partir de grasa de pollo en generadores instalados en áreas rurales u otras aplicaciones enfocadas en la generación de potencia eléctrica. Por tal motivo, este trabajo busca identificar la incidencia del uso de biodiesel hecho a partir de grasa de pollo en el desempeño de un motogenerador de 13.5kWe. Parámetros tales como la eficiencia eléctrica total, el rendimiento calórico, consumo de combustible y las emisiones de gases de escape fueron analizados. Un motor diésel Lister TR2 acoplado a un generador Leroy Soner LSA 38M/J fue empleado. El biodiesel de grasa de pollo fue producido satisfactoriamente a escala laboratorio y posteriormente empleado como combustible mezclado con biodiesel comercial BPa7. La eficiencia del sistema aumenta hasta 38.79% empleando B22.5; un valor mayor al 35.08% obtenido para B0. Como consecuencia de la reducción en el combustible y la adición de un biocombustible sostenible como el biodiesel de grasa de pollo se estima que la huella de carbono disminuye ; las emisiones de CO2 bajan alrededor de 2.9 kgCO2h-1 empleando el generador a máxima capacidad alimentado con B22.5.

Palabras clave: Energía renovable, grasa de pollo, biodiesel, eficiencia energética, huella de carbono.

1. Introduction

Energy consumption is constantly increasing as a consequence of the industrial development, population growth, humankind lifestyle, among other reasons. Comparing the final world energy consumption of last years is possible to identify that this parameter has risen from 4711 to 6560 Mtoe (Millions of tonnes of oil equivalent) in the 1975-95 period. Meanwhile, the increase in the last 20 years has been even higher, from 6560 to 8979 Mtoe, representing an annual rate of 120.95 Mtoe [1]. Despite most of this energy is based on fossil fuel combustion processes, a minor percentage has been supplied the last 40 years from biofuels and wastes which consumption is rising annually. Thus, the energy produced from this resource increased from 632 to 846 and 1111 Mtoe between 1975, 1995 and 2012, respectively. Some advantages of using biofuels for producing either thermal, mechanical, and electrical energy are related to their availability, variety, employment generation and sustainability. Biodiesel has become a remarkable energy source and an alternative to producing one of these energy types using therefore technologies such as internal combustion engines, stoves or boilers. The increase of first-generation biodiesel has resulted as a consequence of the implementation of several policies promoting the production and extensive utilization of this biofuel. Colombia is not an exception; during last years some policies have promoted the production of palm-oil biodiesel production to supply the transport consumption and implementation of internal combustion engines for power generation. Therefore, the production of palm-oil biodiesel was 489 thousand tons in 2012 [2].

Nonetheless, first generation biofuels face some disadvantages such as the competition with food crops, the water demand for cultivation and the low power density of fuel crops [3]. This results in the food vs. fuel debate that is a key point considered during the design of new policies in some countries. Consequently, new alternatives and feedstock have been identified to overcome these problems; most of them point on the promotion of second, third and fourth generation biofuels resulting from non-edible crops and other raw materials. The production of biodiesel from these non-edible raw materials and their performance in internal combustion engines have been broadly reviewed by some authors worldwide. Ashraful et al. [4] did a valuable review of characteristics and the performance of biodiesel made from non-edible vegetable oils. These authors considered feedstocks such as Karanja, Polanga, Mahua, Rubber seed oil, Cotton seed oil, Jojoba oil, Tobacco oil, Neem, Linseed and Jatorpha. Likewise, Wan Ghazali et al. did a review of the effects of biodiesel from feedstocks different from the above mentioned. In their work, authors included materials such as animal fats like chicken fat, duck tallow, lard, yellow grease and other non-edible feedstocks such as castor, sesame, niger, among others [5].

Chicken fat is a low-cost feedstock extracted from chicken feathers, blood, offal and trims after rendering process. Alptekin et al. [6] demonstrated the feasibility of producing biodiesel from chicken fats considering international standards. Similarly, Shi et al. [7] produced biodiesel from waste chicken fat by an integrated catalytic process of composite membrane and sodium methoxide. They concluded that it was possible to produce this biofuel with a 98.1% conversion of transesterification under optimum conditions. Moreover, Altekin et al. [8] evaluated the performance of such biodiesel in a direct injection diesel engine blended with bioethanol and diesel fuel. The animal fat biodiesel emitted lower CO and total hydrocarbon emissions than diesel fuel. The utilization of biodiesel as an energy source in internal combustion engines is a remarkable area in which several authors have worked the last years; nevertheless, most of the research available in the literature is based on the performance of internal combustion engines employed in the transport sector. A lack of information about the performance of engines used for power generation encumbers the use of chicken fat biodiesel in gensets useful for rural areas or other application in which power generation is the main purpose. Therefore, this work aims to identify the incidence of using chicken fat biodiesel on the performance of a 12kWe internal combustion engine employed for power generation. The biodiesel was synthesized in lab conditions and afterwards fueled in the engine. Parameters such as the total electrical efficiency, heat rate, fuel consumption and the exhaust gas emissions are analyzed.

2. Methods and Materials

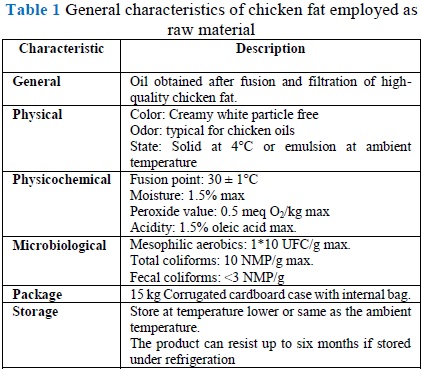

The chicken fat employed as the raw material for the transesterification was supplied by the Industria de Alimentos Procesados INDALPRO LTDA in Bogota, Colombia. It was commercialized in 5kg bags and previously characterized by this industry. Table 1 summarizes some physical and chemical characteristics of the feedstock.

Biodiesel production

The chicken fat was vacuum filtered to obtain a high purity oil without small solid particles. 10 L chicken fat were employed for each test. The oil reacted with methanol following typical transesterification mechanisms. Sodium hydroxide was employed as catalysts, and acetic acid was used in the biodiesel cleaning stage. The process was performed in a batch reactor composed of a double vessel cylinder. The reactor was preheated until reaching 60°C temperature and was constantly agitated using a mechanical mixer. During this process, the oil was fed into the vessel. At the same time, the methanol and the basic catalysts were mixed separately before feeding them into the reactor that contains the oil. When the temperature reached the set point, the alcohol-catalyst mixture was added to the reactor and the systems was hermetically closed. This reaction took place two hours while controlling the temperature.

Afterward, the acetic acid was added to neutralize the catalysts stopping the reaction. During this stage, the reactor was continuously agitated for 10 minutes.

The reactor was cooled down, and the agitator turned off. Hence, the biodiesel was separated from the glycerin due to the differences in their densities. The biodiesel was then water washed to separate any traces of glycerin or catalyst. Then, the biofuel was heated up to 70°C, boiling the traces of water remaining in the mixture; this process was performed two hours, so the sample was stored two days.

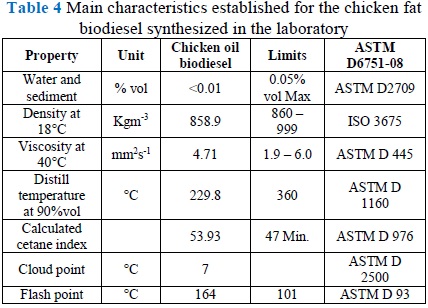

Biodiesel characterization

The biofuel was characterized according to international standards. The quantity of water and sediments were determined by employing a centrifugal separator under the guideline of ASTM D2709 [9]. The density that measures the relationship between the weight and the volume occupied by the sample was established according to ISO 3675 [10]; also, the viscosity was determined based on the ASTM D445 [11].

The distillation temperature at 90% was recorded following the ASTM D 1160 [12] by which a distillation process should be performed.

When 90% of the sample has boiled, the temperature shall be registered. Meanwhile, the flash point and the cloud point were identified according to the ASTM D2500 [13] and ASTM D93 [14], respectively. Finally, the Cetane index was calculated using the ASTM D976 [15] and the results of the distillation curve.

Tests on the internal combustion engine

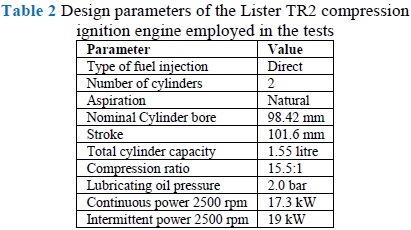

The internal combustion engine employed for this analysis was a Lister TR2 diesel engine. The characteristics of this engine are summarized as follows (Table 2) [16].

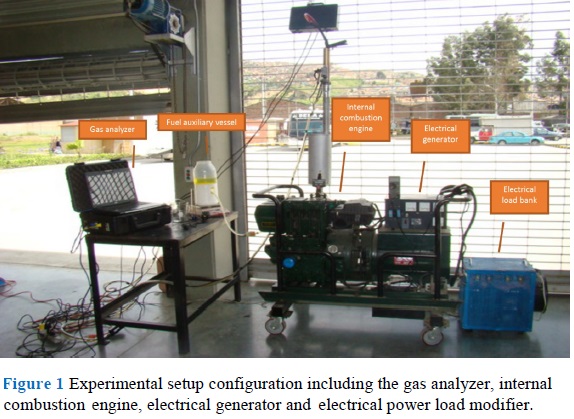

The engine was fixed to an electrical generator capable of transforming the max mechanical power of the internal combustion engine into electrical power with an efficiency equivalent to 90%. The electrical generator was a Leroy Soner LSA 38 M/ J % generator, 220V and 13.45 kW max outlet (Figure 1). Likewise, a bank of electrical resistances was designed to change the load in the generator. Hence, it was possible to vary the power by varying the electrical current.

As a consequence of the variation of the electrical power produced in the generator, the fuel consumption changes and these differences were recorded measuring the weight of the cylinders in which the chicken-oil was stored. Analyzing the relationship between the fuel consumption and the power generated was possible moving the electrical power in the range of 2-17 kWe. Eight different power loads were established to measure the electrical current and the fuel consumption. Measurements were recorded when current was 0, 5.3, 11.8, 17.4, 25.2, 30.9, 38.4 and 44.1 Amp. Power was then calculated using the following equation that relates the current, voltage, and the power factor.

Where, P [kW] corresponds to the electrical power supplied by the genset, I [Amp] is the current measured with the clamp multimeter, and pf is the power factor. Likewise, five mixtures between traditional diesel and chicken fat biodiesel were employed to identify the incidence of the mass fraction on the fuel consumption, efficiency, and heat rate. The commercial biodiesel was bought at a fuel station located in Bogota, Colombia; this fuel is made of 7%vol. Palm oil biodiesel and 93% pure diesel (BPa7) according to the Colombian national policies.

The mixtures were labeled in accordance with the volumetric fraction of chicken oil biodiesel in the blend, i.e. B0 corresponds to pure BPa7, whereas B-22.5 corresponds to 22.5% chicken oil biodiesel and 77.5% BPa7. The assortments defined were B0, B7.5, B12.5, B17.5, and B22.5. The procedure followed for each test was the same. The engine was initially preheated and operated with BPa7 during five minutes. Simultaneously, an auxiliary 1100 cm3 vessel was fed with the mixture chosen for the corresponding test

The initial weight of the vessel was recorded; the engine runs 10 minutes without any electrical load to guarantee that the equipment was filled with the mixture. Afterward, the electrical load was set in the resistance bank. Each test took some minutes while three measurements of the vessel weight were recorded. Meanwhile, each test was performed three times to guarantee repeatability increasing the confidence and accuracy of the results.

Fuel consumption was calculated as the ratio between the difference of the weight in the vessel and the time each measurement was made. The average of the fuel consumption was reported and employed to identify the thermal power supplied by the fuel. This parameter was reckoned as the product of fuel mass rate and the mixture heating value. The heating value of the BPa7 was assumed as 43567 kJ/kg in accordance with Forero et al. [17] and the heating value of chicken oil biodiesel considered equals to 40173 kJ/kg as stated by Alpteki et al. [6]. The heating value of the assortment was also determined as the weighted average of heating values and mass fraction.

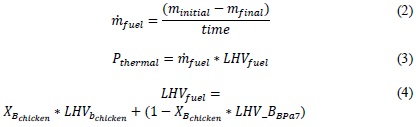

Where, mfuel [kgs-1] is the fuel consumption, nwiai [kg] the initial weight of the sample in the auxiliary vessel, minitial [kg] the final weight at the corresponding time when the measurement was recorded. Pthermal [kWth] is the thermal power supplied by the fuel, LHVfuel [kJkg-1] is the lower heating value of the mixture, XB_chicken represents the mass fraction of the chicken fat biodiesel in the mix, LHVB_chicken [kJkg-1] corresponds to the lower heating value of the chicken fat biodiesel and LHVB_BPa7 [kJkg-1] the heating value of the commercial biodiesel.

Likewise, the energy efficiency and heat rate were identified. The electrical efficiency was calculated as the ratio of the electrical power supplied by the system and the thermal power provided by the fuel.

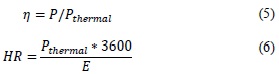

The heat rate is a similar measurement that relates the performance of the genset; it is worldwide employed to analyze the heat needed to produce one kWh electrical energy. These parameters were calculated based on the following equations where n [%] is the electrical efficiency, P [kWe] is the electrical power determined previously, Pthermal [kW] corresponds to the thermal power, HR [kJkWh-1] represents the heat rate and E [kWh] is the electrical energy supplied by the genset during one hour.

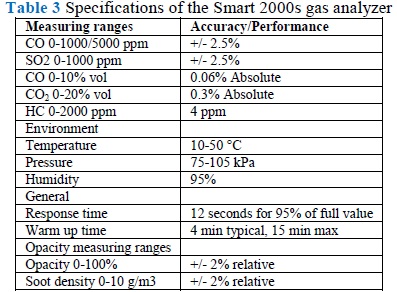

Finally, emissions were analyzed employing a portable SMART 2000s gas analyzer. This is a fully computerized, NDIR analyzer and advanced optical opacity meter integrated. Some specifications of this equipment were summarized in the Table 3.

This equipment records the data and exports it to any standard data analysis software like Microsoft Excel; more specification of the equipment are available in Galio [18]. For each test, measurements of O2, CO2, CO, HC, NO and NO2 were recorded, they were statistically analyzed to calculate the average value. Likewise, opacity and particulate matter were sensed.

The addition of chicken fat biodiesel into the mixture mitigates the environmental impact in terms of the carbon footprint; at the end of the manuscript, a brief analysis of the CO2 reduction based on the addition of the chicken fat biodiesel to the blend; it was performed using for that a Diesel BPa7 emission index equals to 73920 kgCO2/TJ [19].

3. Results and analysis

Biodiesel characterization

After producing chicken fat biodiesel under the operational conditions mentioned before, it was characterized, and parameters like water and sediments, density, viscosity, cetane index, cloud point, among others were identified. Table 4 summarized the main characteristics identified for a sample of chicken fat biodiesel.

It is observable that sample is properly dried, so water content is smaller than the maximum allowed. Meanwhile, the viscosity is in the range between 860 and 999 kgm-3. This parameter is so valuable when working with liquid biofuels because it is strongly related to the capability that the fluid will have to flow in the system. High viscosity biofuels will require more powerful pumps to make it flow and could also cause blocking problems in the tubes when ambient temperature decreases considerably. Meanwhile, high viscosity causes a poor flow of fuel in the engine combustion chamber during intake stroke taking a long time to mix the air. On the other hand, a low viscosity could cause leakage in the fuel system [20].

The distillation temperature at 90% vol is lower than the maximum that represents the temperature at which the sample will boil. This parameter will also have an effect on the combustion because if higher temperatures are needed, the fuel will take long and waste more energy on heating before boiling. Likewise, the higher the temperature, the less volatile the biofuel is which decreases the efficiency of the fuel-air mixture in the cylinder.

Calculated Cetane index is 14.7% greater than the minimum defined in standard D976. The cetane index is a parameter that provides insights about the detonation capability of the biofuel; lower cetane indexes could result in detonation problems in the internal combustion engines, decreasing the thermal efficiency, increasing heat rate, causing incomplete combustion of the fuel, and releasing more particulate matter with the exhaust gases. In Also, high cetane number allows compressive ignition engines to run smoothly and with less noise [21].

Flashpoint is 62.38% greater than admissible by the standard; this parameter indicates the minimum temperature at which the biofuel will ignite as a result of exposure to a flame.

Therefore, a high value exhibits safe conditions of storage and operation with chicken fat biodiesel as an energy source.

Cloud point is another significant parameter that always need to be analyzed. Despite the fact that Colombia is a country where there are not such big differences of the ambient temperature, some places have low temperatures. The cloud point determines the temperature at which some crystals are observable in the biofuel. The higher the temperature, the more probabilities exist of having blocking problems and detonation problems. Some biofuels have higher cloud points in comparison with fossil diesel. For instance, Moser [22], Vyas et al. [23], and Wan Ghazali et al. [5] reported properties from biodiesel from different feedstocks; in most of the cases, the cloud point was higher than 0°C.

Fuel consumption, energy efficiency and heat rate

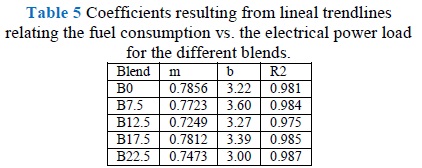

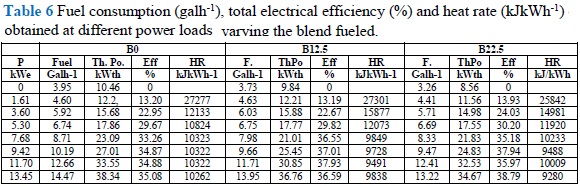

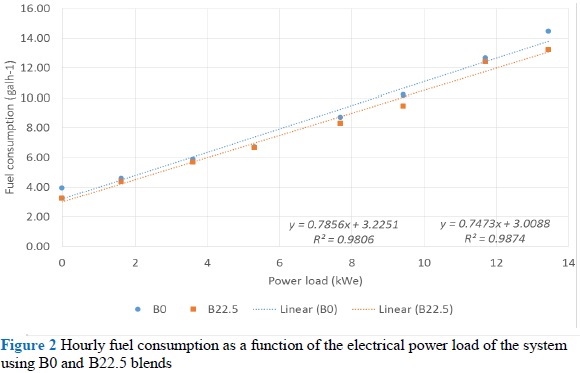

The results of the fuel consumption, energy efficiency and heat rate of B0, B12.5 and B22.5 blends are gathered in Table 6 The power load varied between 0 and 13.45 kWe and measurements were recorded at 0%, 12%, 27%, 39%, 57%, 70%, 87% and 100% electrical load capacity. The fuel consumption was exhibited in galh-1 because despite it is not an international system unit, it is the traditional unit by which managers and engineers buy the fuel in Colombia. The fuel consumption has a direct relationship with the power load; the more electrical power is delivered by the genset, the more fuel is required. However, it is interesting to highlight that the power produced and the fuel consumption raise up proportionally fitting a linear trendline with a coefficient of determination (R2) near 0.99 (Figure 2).

The equations of each trendline are summarized in Table 5, where m corresponds to the slope, b is the y-axis and the coefficient of determination. Similarly, as stated before, the decrease in the b-values with the addition of chicken fat biodiesel in the blend is a valuable result of the test.This reduction indicates that the genset requires less fuel during operation at idle mode. This can be ascribed to a better combustion in the cylinders resulting from higher oxygen content and lower carbon content in the chicken fat biodiesel chemical structure in comparison with the traditional BPa7 structure. When the genset must provide more electricity, it will require more fuel increasing the consumption about 3.6 times approximately.

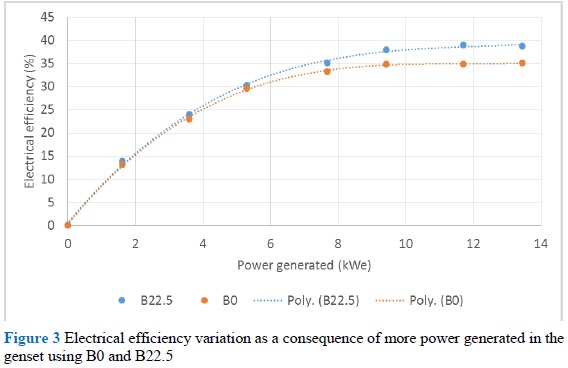

Meanwhile, the fuel consumption is directly related to the thermal power provided by the combustion in the genset. With all blends, the efficiency of the genset similarly varied when increasing the power load. This parameter that relates the electrical power produced by the genset and the thermal power supplied by the fuel increases fitting a third-grade polynomic trendline (Figure 3).

The efficiency rapidly moves up when power load varied from 0 to 50% of the maximum capacity. Afterward, it maintains almost constant. As mentioned before, the addition of chicken fat biodiesel to the blend decreases the fuel consumption and the heating value of the mixture; nevertheless, the electrical efficiency growths as a result of a better combustion in the cylinder. When B0, B7.5, B12.5 B17.5 and B22.5 blends were used, the max efficiency was 35.08, 35.69, 36.59, 37.71 and 38.79%, respectively. It means that the maximum efficiency is enhanced about 10.6% of the initial value when B22.5 is employed.

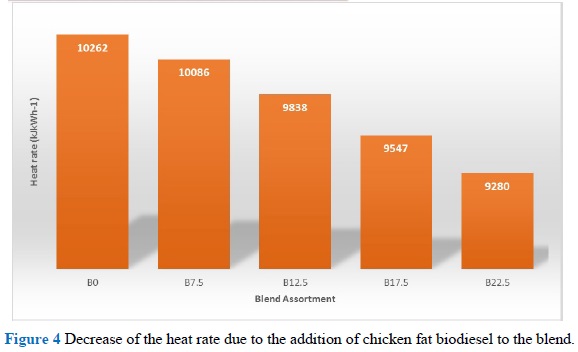

The heat rate is a valuable parameter employed when producing electricity in an internal combustion engine because it relates the heat required for the electrical energy produced. This variable is close-related to the electrical efficiency but provides insights of the thermal energy that could be employed afterwards in a heat recovery equipment for cogeneration systems.

The heat rate decreases when the power load is about the 50% of the maximum capacity. The behavior of this parameter is opposite to the trend presented in the Figure 4; the more electrical power produced the lower the heat rate. When analyzing a typical reciprocating engine to generate electrical energy, the heat rate becomes a mandatory parameter. According to RETScreen product database [24], the heat rate of commercialized engines such as Caterpillar engines are in the range of 8300 to 10500 kJkWh-1 for capacities between 150 to 5000 kW; likewise, heat rate of Waukesha and Wartsila engines are about 11500 and 7600 kJkWh-1, respectively.

Similarly, other authors have analyzed the heat rate and electrical efficiency of internal combustion engines fueled with diesel, natural gas, gasoline, and biofuels; most of them indicate typical values in the range of 8000 to 10000 kJ/kWh and 30-40%, respectively [17] [3] [25].

Environmental impact

The addition of chicken fat biodiesel has a direct effect on the final exhaust gas composition. First of all, a reduction in the Oxygen content was identified as a consequence of a higher power load. In all cases, the decrease was notorious, for instance, the oxygen content moved downwards from 15.24% to 6.03% for the B0 blend.

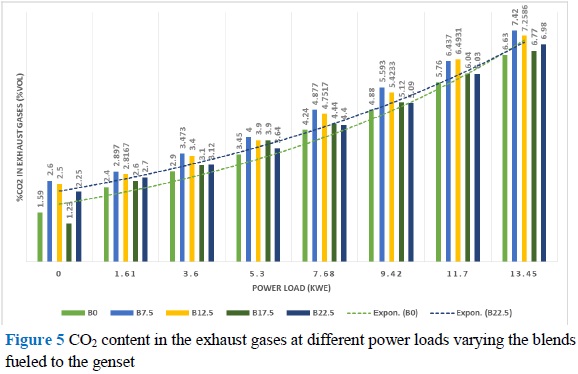

Similarly, this behavior occurred with B17.5 and B22.5 blends; the values reduced from 18.52 to 5.69% and from 16.09 to 5.44% respectively. This trend is associated with the higher consumption of oxygen and fuel in the combustion after an increase of the power delivered by the genset. Otherwise, the %CO2 in the exhaust gases exhibited an opposite trend. The more power produced by the engine, the more %CO2 in the exhaust gases. When running the engine in an idle mode the average %CO2 observed was about 2.034% lower than the 7.01% obtained at full capacity. Figure 5 shows the variation of the %CO2 in the exhaust gases as a function of the power load for the different chicken fat biodiesel/biodiesel BPa7 blends employed in the tests. In all cases, there was an increase ascribed to the reduction of the oxygen content in the gases and a more complete combustion of more fuel in the cylinders.

Depending on the chemical structure of the methyl ester employed, the air-fuel ratio, the viscosity of the blend, the operational conditions, among other parameters, the CO2 in the internal combustion engine can increase or decrease. Variations of the CO2 content has been reported when using biodiesel blends produced with feedstocks such as Jatropha oil [26], waste cooking oil [27], Tobacco oil [28], Apricot Seed kernel oil [29], Jojoba oil [30], corn oil [31], and cashew

nut sheel liquid [32]. When CO2 increases it can be ascribed to the more complete combustion and a higher conversion of CO into CO2; otherwise, a reduction of CO2 can be associated with the lower carbon to hydrogen ratio of biodiesel in comparison to the ratio of traditional fuel [5]. In general terms, the results exhibit an increase of the CO2 in the exhaust gas as a consequence of the addition of chicken fat biodiesel. In most of the tests performed, the CO2 was slightly higher regardless the power load, i.e. the CO2 moved up from 5.76% to 6.4 and 6.0% with B12.5 and B22.5, respectively at 11.7 kWe power load.

CO in the exhaust gases exhibited non-conclusive results. All tests presented a maximum decrease of the CO embedded in the mixture when power load moved up to7.68 kWe; afterwards the values moved up again as a result of higher power loads. When B0 was employed the CO changes from 413.33 to 300 and 785 ppm at 0, 7.68 and 11.7 kWe, respectively. The CO also varies from 593.3 to 265.5 and 782 ppm at 0, 7.68 and 11.7 kWe with B12.5. Moreover, this parameter moves from 541.3 to 200 and 431 ppm at same power loads with B22.5. The partial decrease in this parameter can be associated with a proper combustion reaction between the fuel and oxygen in the engine.

However, the increase in the power load and the consequent increase of the fuel consumption results in a slight decrease in the quality of the combustion produced by the reduction of the oxygen as stated above. Likewise, it is remarkable to highlight that addition of chicken fat biodiesel has a slight reduction of the CO in the exhaust gases when comparing the CO content of exhaust gases for different blends at same power load.

The decrease of the CO in the flue gases is a so frequent result reported by several authors worldwide after blending biomass-based biodiesel with traditional diesel [33] [34] [35] [36]. Frequently, the decrease of this parameter in the exhaust gasses is ascribed to the oxygen content of the blends and the higher oxygen content of the chicken-fat methyl ester [5]. NOx emissions increase in all cases as a consequence of the higher power loads and more air intake to the engine. At high temperatures, the Nitrogen embedded in the air oxidizes to produce NOx undergoing the Zeldovich mechanism; the addition of chicken fat biodiesel does not exhibit conclusive results that let us determine if there is a direct incidence on these emissions.

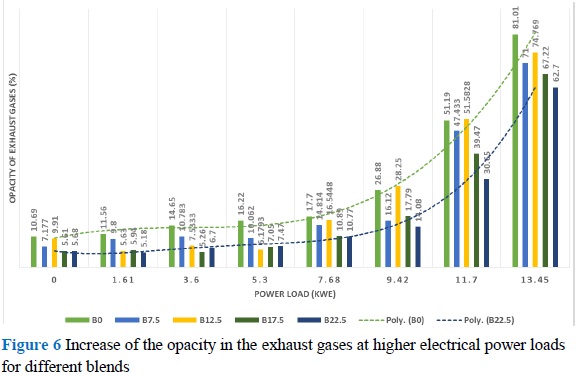

The opacity is a measurement strongly associated with the particulate matter mass concentration in the flue gas that was measured with the opacimeter. An increase in the opacity means a higher emission of particulate matter frequently caused by an incomplete combustion. Figure 6 exhibits the variation of this parameter for the different blends at various power loads. There is an observable increase in this variable as a function of higher power loads in the genset; it is also produced by a fuel-rich premixed ignition of carbon fuel which is quenched due to lack of sufficient oxygen to burn the fuel completely [25].

However, the utilization of chicken fat biodiesel enhances the combustion reaction reducing the soot formation, particulate matter emission and consequently the opacity in the exhaust gases. For instance, at 13.45 kW power load, this parameter is reduced about 23% with the addition of 22.5%vol chicken fat biodiesel to the blend (B22.5).

Oxygenated fuels reduce the chances of producing soot precursors such as polycyclic aromatic hydrocarbons and acetylene; it also decreases the synthesis of particulate matter as a result of the combustion of the carbon atoms bonded to oxygen [37].

The addition of non-edible biodiesel to liquid fuels employed by the internal combustion engine is an alternative employed worldwide with the idea of promoting sustainable processes and mitigate the environmental impact that results from fossil fuel combustion. It is considered that CO2 reduction and carbon footprint decrease is possible as a consequence of the process by which biomass is produced due to photosynthesis reactions. Despite CO2 is produced from biomass combustion, the CO2 released could be associated to that absorbed during the plants growth.

Therefore, the carbon footprint variation was determined taking into account the Colombian diesel greenhouse emission index and the thermal energy required to produce a particular power load. Utilization of chicken fat biodiesel in the fuel not only increases the electrical efficiency of the system as above mentioned but also decreases the Carbon footprint of the process; the more chicken-fat biodiesel in the blend, the less CO2 is released. A great reduction was observable at higher power loads due to the increase in the fuel consumption and, therefore, an intensification in the energy produced by the chicken fat biodiesel. At the maximum power load, the decrease in the carbon footprint varies about 8.6, 15.3, 22.2, and 28.7% when using B7.5, B12.5, B17.5 and B22.5, respectively. The mean decrease of CO2 emissions for B22.5 blend was 27.4% approximately calculated as the average of partial reduction at the different power loads employed in the tests. At full capacity, the decrease of the CO2 emissions was about 0.9, 1.6, 2.3, and 2.9 kgCO2h-1 at B7.5, B12.5, B17.5 and B22.5. Hence, the environmental impact of using B22.5 could be described as the annual reduction of 12.63, 20.21, 25.26 tonCO2 when considering 50, 80 and 100% availability of the genset.

4. Conclusions

The analysis of the incidence of using chicken fat biodiesel on the performance of a 13.45kWe compression ignition engine for power generation was done. The chicken-fat biodiesel was successfully produced in a lab-scale facility and afterward employed as biofuel blended with commercial biodiesel BPa7. The efficiency of the genset increases up to 38.79% with B22.5 higher than the 35.08% obtained for B0. Meanwhile, the heat rate at full capacity mode moved down to 9280 kJkWh-1. As a consequence of the fuel reduction and addition of a sustainable biofuel such as chicken fat biodiesel the carbon footprint was also decreased; the CO2 released decreases about 2.9 kgCO2h-1 when the genset was operating at full capacity fueled with B22.5. This reduction of the carbon footprint could be associated with the reduction of 12.6, 20.2 and 25.2 tortXhyr-1 when considering 50, 80 and 100% availability of the genset. Chicken fat biodiesel exhibited to be a feasible raw material for biodiesel synthesizing; nevertheless, more research needs to be carried out to identify the availability and location of this feedstock. Likewise, it is pertinent to analyze the recent energy policies and execute a Life-cycle cost analysis (LCCA) aiming to study the economic feasibility of producing and commercializing such biofuel in the Colombian energy market.

Acknowledgements

Authors kindly acknowledged the support of staff of the Clean Development Mechanisms and Energy Management (MDL&GE) research group from Universidad Nacional de Colombia

References

[I] International Energy Agency, "World energy flow," IEA, 2015. [Online]. Available: http://www.iea.org/Sankey/#?c=World&s=Finalconsumption. [Accessed 05 08 2015] [ Links ].

[2] PROEXPORT, "Biofuels investment in Colombia," Mincomercio, 2015. [Online]. Available: http://www.investincolombia.com.co/sectors/agribusiness/biofuels.html. [Accessed 07 08 2015] [ Links ].

[3] F. Millo, B. K. Debnath, T. Vlachos, C. Ciaravino, L. Postrioti and G. Buitoni, "Effects of different biofuels blends on performance and emissions of an automotive disel engine," Fuel, vol. 159, pp. 614-627, 2015. [ Links ]

[4] A. Ashraful, H. Masjuki, M. Kalam, I. Rizwanul Fattah, S. Imtenan, S. Shahir and H. Mobarak, "Production and comparison of fuel properties, engine performance, and emission characteristics of biodiesel from various non-edible vegetable oils: A review," Energy Conversion and Management, vol. 80, pp. 202-228, 2014. [ Links ]

[5] W. N. M. Wan Ghazali, R. Mamat, H. Masjuki and G. Najafi, "Effects of biodiesel from different feedstocks on engine performance and emissions: A review," Renewable and Sustainable Energy Reviews, vol. 51, pp. 585-602, 2015. [ Links ]

[6] E. Alptekin, M. Canakci and H. Sanli, "Biodiesel production from vegetable oil and waste animal fats in a pilot plant," Waste Management, vol. 34, no. 11, pp. 2146-2154, 2014. [ Links ]

[7] W. Shin, J. Li, B. He, F. Yan, Z. Cui, K. Wu, L. Lin, X. Qian and Y. Cheng, "Biodiesel production from wsate chicken fat with low free fatty acids by an integrated catalytic process of composite membrane and sodium methoxide," Bioresource Technology, vol. 139, pp. 316-322, 2013. [ Links ]

[8] E. Alptekin, M. Canakci, A. Necati Ozsezen, A. Turkcan and H. Sanli, "Using waste animal fat based biodiesels-bioethanol-diesel fuel blends in a DI diesel engine,"Fuel, vol. 157, pp. 245-254, 2015. [ Links ]

[9] American Society for Testing and Materials, "ASTM D2709 Standard Test Method for Water and Sediment in Middle Distillate Fuels by Centrifuge," West Conshohcken, 2014. [ Links ]

[10] ISO, "ISO 3675:1998 Crude Petroleum and liquid petroleum products -- Laboratory determination of density -- Hydrometer method," 1998. [Online]. Available: http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detai l.htm?csnumber=26326. [Accessed 12 06 2015] [ Links ].

[11] American Society for Testing and Materiales, "D445-15 Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)," 2015. [Online]. Available: http://www.astm.org/Standards/D445.htm. [Accessed 20 05 2015] [ Links ].

[12] American Society for Testing and Materials, "D1160-15 Standard Test Method for Distillation of Petroleum Products at Reduced Pressure," 2015. [Online]. Available: http://www.astm.org/Standards/D1160.htm. [Accessed 26 03 2015] [ Links ].

[13] American Society for Testing and Materials, "D2500 Standard Test Method for Cloud Point of Petroleum Products," 2011. [Online]. Available: http://www.astm.org/Standards/D2500.htm. [Accessed 17 03 2015] [ Links ].

[14] American Society for Testing and Materials, "D93 Standard Test Methods for Flash Point by Pensky-Marten Closed Cup Tester," 2015. [Online]. Available: http://www.astm.org/Standards/D93.htm. [Accessed 10 02 2015] [ Links ].

[15] American Society for Testing and Materials, "D976 Standard Test Method for Calculated Cetane Index for Distillate Fuels," 2015. [Online]. Available: http://www.astm.org/Standards/D976.htm. [Accessed 15 04 2015] [ Links ].

[16] Lister Petter, "TR2," 2015. [Online]. Available: http://www.lister-petter.com/p/power-water-solutions/4/lp-range/1/engines/58/tr2. [Accessed 20 06 2015] [ Links ].

[17] C. A. Forero-Núnez, J. E. Arango and F. E. Sierra-Vargas, "Evaluación energética de un sistema de generación de 400 kWe en modo diesel-gas licuado de petróleo," Ingeniería Mecánica, vol. 17, no. 3, pp. 205-215, 2014. [ Links ]

[18] GALIO indutrial develoment, "Model - SMART 200s," 2015. [Online]. Available: http://galio.com/smart-series/smart-2000x/. [Accessed 5 07 2015] [ Links ].

[19] UPME, "Factores de emisión para los combustibles colombianos," 2003. [Online]. Available: https://www.google.com.co/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&cad=rja&uact=8&ved=0CBwQFjAAahUKEwjh06-Hk8PIAhUGJh4KHR0nCik&url=http%3A%2F%2Fwww.siame.g ov.co%2FPortals%2F0%2FFECOCupme.xls&usg=AFQjCNFTh M9IcnWNHxi4bootAEliXy_CoQ. [Accessed 4 8 2015] [ Links ].

[20] A. Ashraful, H. Masjuki, M. Kalam, I. Rizwanul Fattah, S. Imtenan, S. Shahir and H. Mobarak, "Production and comparison of fuel properties, engine performance, and emission characteristics of biodiesel from various non-edible vegetable oil: A review," Energy Conversion and Management, vol. 80, pp. 202-228, 2014. [ Links ]

[21] E. Alptekin and M. Canakci, "Characterization of the key fuel properties of methyl ester-diesel fuel blends.," Fuel, vol. 88, no. 1, pp. 75-80, 2009. [ Links ]

[22] B. R. Moser, "Influence of blending canola, palm, soybean, and sunflower oil methyl ester on fuel properties of biodiesel," Energy & fuels, vol. 22, no. 6, pp. 4301-4306, 2008. [ Links ]

[23] A. P. Vyas, N. Subrahmanyam and P. A. Patel, "Production of biodiesel through transesterification of Jathropha oil using KNO3/Al2O3 solid catalyst," Fuel, vol. 88, no. 4, pp. 625-628, 2009. [ Links ]

[24] Natural Resources Canada, "RETScreen International product database," 2015. [Online]. Available: http://www.retscreen.net/ang/d_data_p.php. [Accessed 10 08 2015] [ Links ].

[25] S. Lee and T. Y. Kim, "Feasibility study of using wood pyrolysis oil-ethanol blended fuel with diesel pilot injection in a diesel engine," Fuel, vol. 162, pp. 65-73, 2015. [ Links ]

[26] H. C. Ong, H. Masjuki, H. Mahlia, A. Silitonga, W. Chong and T. Yusaf, "Engine performance and emissions using Jatroha curcas, ceiba pentandra and Calophyllum inophyllum biodiesel in a CI diesel engine," Energy, vol. 69, pp. 427-445, 2014. [ Links ]

[27] H. An, W. Yang, S. Chou and K. Chua, "Combustion and emissions characteristics of diesel engine fueled by biodiesel at partial load conditions," Applied Energy, vol. 99, pp. 363-371, 2012. [ Links ]

[28] A. Parlak, V. Ayhan, I. Cesur and G. Kõkkülünk, "Investigation of the effects of steam injection on performance and emissions of a diesel engine fuelled with tobacco seed oil methyl ester," Fuel Processing Technology, vol. 116, pp. 101-109, 2013. [ Links ]

[29] M. Gumus and S. Kasifoglu, "Performance and emissions evaluation of a compression ignition engine using biodiesel (apricot seed kernel oil methyl ester) and its blends with diesel fuel," Biomass and bioenergy, vol. 34, no. 1, pp. 134-139, 2010. [ Links ]

[30] H. Saleh, "Effect of exhaust gas recirculation on diesle engine nitrogen oxide reduction operating with jojoba methyl ester," Renewable Energy, vol. 34, no. 10, pp. 2178-2186, 2009. [ Links ]

[31] D. Rakopoulos, C. Rakopoulos, E. Giakoumis, A. Dimaratos and M. Founti, "Comparative environmental behavior of bus engine operating on blends of diesel fuel with four straight vegetable oild of Greek origin: Sunflower, cottonseed, conr and olive," Fuel, vol. 90, no. 11, pp. 3439-3446, 2011. [ Links ]

[32] S. Vedharaj, R. Vallinayagam, W. Yang, S. Chou, K. Chua and P. Lee, "Experimental and finite element analysis of a coated diesel engine fueled by cashew nut shell liquid biodiesel," Experimental Thermal and Fluid Science, vol. 53, pp. 259-268, 2014. [ Links ]

[33] A. Dhar, R. Kevin and A. K. Agarwal, "Production of biodiesel from high-FFA neem oil and its performance, emission and combustion characterization in a single cylinder DICI engine," Fuel Processing Technology, vol. 97, pp. 118-129, 2012. [ Links ]

[34] A. Ramadhas, C. Muraleedharan and S. Jayaraj, "Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil," Renewable Energy, vol. 30, no. 12, pp. 1789-1800, 2005. [ Links ]

[35] G. Tuccar, T. Ozgur and K. Aydin, "Effect of disel-microalgae biiodiesel-butanol blends on performance and emission of diesel engine," Fuel, vol. 132, pp. 47-52, 2014. [ Links ]

[36] R. Behcet, "Performance and emission study of waste anchovy fish biodiesel in a disel engine," Fuel Processing Technology, vol. 92, no. 6, pp. 1187-1194, 2011. [ Links ]

[37] C. Westbrook, W. J. Plitz and H. J. Curran, "Chemical kinetic modeling study of th eeffects of oxygenated hydrocarbons on Soot Emissions from Diesel Engines," The journal ofphysical chemistry A, vol. 110, no. 21, pp. 6912-6922, 2006. [ Links ]