Microwave-assisted extraction is a sought-after procedure applied in industrial and homemade extractions to obtain soluble products via microwave energy. Recently, much attention has been directed to the recovery of bioactive principles from different plant parts considered waste products or of limited competitive significance between man and livestock, such as seeds, leaves, barks, pulp, rind, peels, wood and by-products. Extracts from these substances indicate that the diversity and complexities of phytochemicals constituents and the potency of natural bioactive compounds exist among polyphenols, sterols and alkaloids (secondary metabolites). To obtain sufficient yields of specific phytochemicals for effective protection or regulation of biochemical processes, the need arises for sustainable extraction procedures (Kallel et al. 2014; Aghdase et al. 2017). The reduction in operation time and solvent consumption during microwave heating increases the extraction efficiency as electrical oscillations of microwaves causes repeated rotations of aqueous molecules in the presence of electromagnetic fields that generate heat from the friction of molecules (Rodríguez, 2017; Jimenez et al. 2018). Such updated innovative strategies have resulted in extensive convenient methods of extraction with proven advantages when compared with conventional solid-liquid extraction methods (Olalere et al. 2018a; Zin et al. 2020). Repeated experiments are often conducted to obtain information on constituents of extracts using Gas Chromatography Mass Spectrophotometry (GC-MS), but a wide range of investigations using factorial experiments can be both solvent and time consuming. Limited funds for analysis during such cost-intensive experiments can negatively affect the frequency and integrity of outcomes especially in developing economies. Therefore, a methodology that accommodates these concerns can increase man’s application and utilization of beneficial phytochemicals in black pepper. Response surface methodology (RSM) allows for assessing of the impact of multiple factors and their interactions on one or more response variables (Aydar 2018). This presents a methodology for the possibility of overcoming the challenge of excessive solvent consumption and large sample sizes to produce quality extracts.

Black pepper is a crop of nutritional, medicinal and economic significance commonly sought for its desired biological potency and flavour. Black pepper (Piper nigrum) is a major plant with varied applications in processing industries as products such as black pepper powder, pepper oil, and pepper aqueous are produced in response to increased quality consciousness and preference for natural flavours and medicinal properties. Agbor et al. (2006) reported that black pepper contains not only aromatic compounds but flavonoids, alkaloids, amides and lignans, and some phytochemicals extracted from high-resolution gas chromatography analysis (GC-MS) include δ-cadinol, δ-guaiene, (Z) (E)-farnesol, (E)-β-ocimene and guaiol (Pino et al. 1990). Piper nigrum (family Piperaceae) is a spice widely considered as "The King of spices" for it contains major bioactive phytochemicals and pungent alkaloids like piperine (1-peperoyl piperidine), safrol, pinene, sabinene, limonene, caryophyllene and linalool - compounds that contribute to its overall potency which stimulate beneficial pharmacological actions such as antihypertensive, antioxidant, antitumor, antipyretic, anti-inflammatory, anti-diarrheal, antispasmodic, hepato-protective, antibacterial, antifungal, antiapoptotic and anti-colon toxin (Suvarna and Abdul 2019). Piper nigrum leaves and seeds are applied to indigenous systems of medicine in many rural communities, owing to its multidimensional influence on biological systems. In light of the diverse benefits obtainable from phytochemicals in black pepper, it becomes expedient to explore efficient extraction methods to increase the qualitative yield of black pepper extract.

The use of meat quality and RSM as assessment criteria to optimize extraction efficiency is a novel approach. This approach leverages on the rationale that the more the bioactive compounds extracted, the better the extraction process. Optimization of quality indices such as the physico-chemical and oxidative properties of meat incorporated with extracts (Insani et al. 2008; Sanwo et al. 2019) is an untapped potential for the assessment of qualitative yield generated from microwave extraction. The oxidation of lipid in meat can negatively affect the storability of many multifaceted food products as the nutrient becomes depleted and essential polyunsaturated fatty acids turns rancid as a consequence of hydrolytic and/or oxidative reactions during manufacture, processing, storage and distribution of meat leading to the generation of toxic compounds that are detrimental to consumer health (Böttcher et al. 2015; Keller et al. 2015). On this premise, extracts containing more bioactive principles should minimize the extent of nutrient depletion and subsequent deterioration. This novel approach is notably expedient to overcome the demerits associated with other conventional techniques of extraction, such as higher extraction cost and repetitive trials; lab-intensive and time-consuming extraction, isolation and analysis; high solvent consumption and low extraction yield, which are significant drawbacks to the utilization of natural products by man (Olalere et al. 2017; Zhang et al. 2018). This study is therefore designed to explore a novel approach to improve the quality of black pepper extracts produced from microwave extraction using meat quality assessment optimized by RSM.

MATERIALS AND METHODS

Experimental site

Microwave refluxation and major aspects of meat technological quality assessment were carried out at the Animal Product and Processing Laboratory, Department of Animal Production and Health. Extraction of the aqueous component was determined by Gas Chromatography - Mass Spectrometry (GC - MS) analysis in the Chemistry Department Laboratory, Faculty of Science, University of Lagos. Meat colour values were deduced at the Food Science Laboratory, Department of Food Science and Technology, Federal University of Agriculture, Abeokuta, but the fatty acid and lipid oxidation profile were determined at the Laboratory of Veterinary Medicine, University of Ibadan.

Experimental materials

Dried clarified pepper corms of black pepper sourced from a traditional herb-spice market in Ibadan was pulverized into a finely defined powder using an attrition mill. Black pepper powder was temporarily stored in coloured vials. Ground black pepper was sieved using a mesh and the particles were clarified using an 0.40 mm sieve, then stored in airtight container prior to further analysis. Distilled water was provided at the Feed Quality Laboratory of the Department of Animal Production and Health. Daewood (KOR6N9NC) microwave oven was used for heating aqueous black pepper.

Fresh meat from the breast muscles of carcasses of manually deboned broiler chickens (Cobb strain)weighing between 1.9-2.4 kg was sourced. Before the slaughter of broiler chickens, ethical principles outlined by the Ethical Committee Board of the College of Animal Science and Livestock Production, Federal University of Agriculture, Abeokuta, was adhered to.

Experimental design

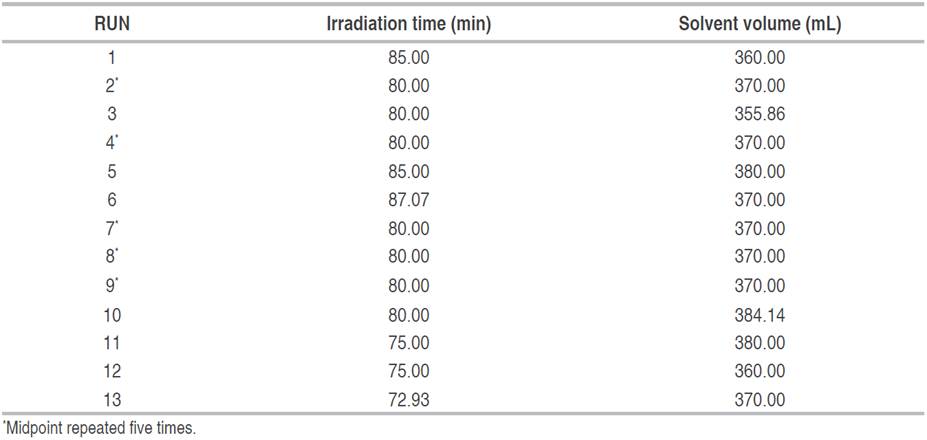

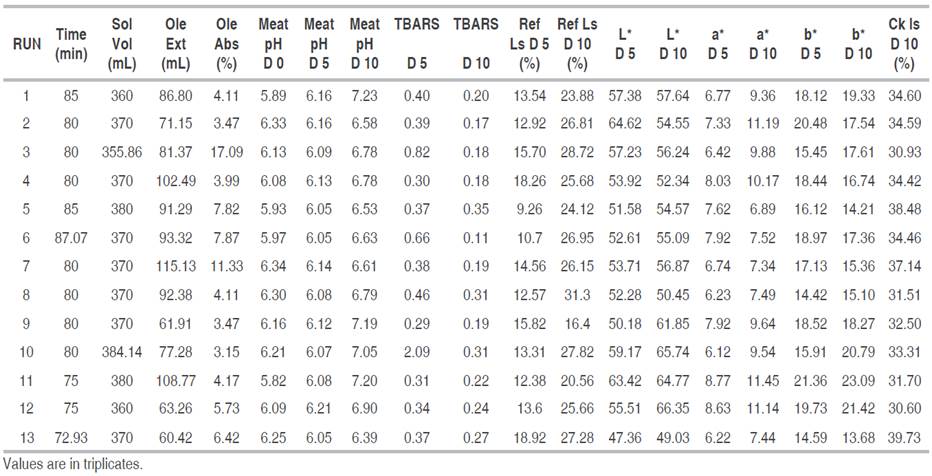

Central composite design (CCD) as defined by Anderson and Whitcomb (2016) was used for the experiment (process analysis and optimization procedure). 13 experimental runs were generated with 5 repetitions as the central point. Operational factors and ranges were generated from adjustments to the study of Olalere et al. (2018a). Two variable factors - irradiation time (75-85 min) and solvent volume (360-380 mL) were applied while two fixed factors - microwave power and particle size were held constant at 320 W and 0.40 mm. Afterwards, data obtained from a qualitative assessment of extracts via meat quality assessment was optimized using response surface methodology.

Microwave refluxation procedure and extract yield calculation

13 experimental runs were generated using Design Expert software with 5 repetitions generated as central points (Table 1). 8 g of ground black pepper was mixed with 360-380 mL of distilled water per experimental run. Soaking and stirring of dissolved pepper prior to loading was carried out to achieve homogeneity and uniform hydration of the mixture placed in an irradiation-tolerant container before placement in the microwave cavity. Microwave power was fixed at 320 W. Before extraction, pre-heating was performed for 10 min at 160 W - a slight modification to the procedure established by Olalere et al. (2017). Subsequently, the loading and unloading of the mixture and extracts from the cavity were carried out according to the procedure established by previous studies (Olalere et al. 2017; 2018b).

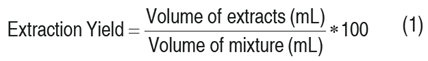

Extracts obtained were cooled and placed in coloured vials prior to the soaking of chicken meat. The extraction yield was calculated by using Equation (1).

Experimental birds

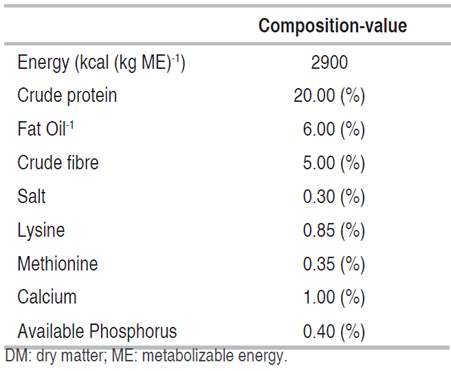

20 (4-weeks old) broiler (Cobb strain) chickens reared under an intensive deep litter management system were sourced, then further reared for four weeks. Commercial diet fed is presented in Table 2. Birds were subjected to uniform management, thereafter, birds were sacrificed and breast muscles extracted, then, weighed before soaking prior to subsequent meat quality analysis.

Determination of microwave extraction temperature

The internal temperature of the microwave was measured for 5 min post-extraction, and temperature ranged between 37±2 °C.

Determination of meat extract uptake

20 g of raw meat from the breast muscles were weighed in triplicates and labelled; then 20 mL of extract was added to each sample and left for 30 min. The samples were subsequently removed and reweighed. The increase in weight of samples indicate the volume of extract absorbed.

Extract quality assessment

Each meat sample soaked in each extract was drained for 5 min prior to qualitative (pH, colour, refrigeration and cooking loss) investigations.

Meat pH and colour evaluation

Meat pH was measured using an Orion 230A pH meter (Thermo Fisher Scientific, Waltham, MA). Chicken meat colour was measured with a CR-400 Chroma Meter instrument (Minolta Co., Osaka, Japan) via CIE L* (lightness), CIE a* (redness), and CIE b* (yellowness) according to specification by Kralik et al. (2017).

Determination of malondialdehyde content in meat

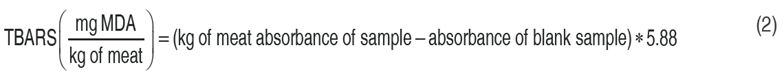

Lipid peroxidation was determined by measuring the formation of thiobarbituric acid reactive substances (TBARS). The preparatory procedure for absorbance: blank was set up following the procedure documented by Adeleye et al. (2021). Lipid oxidation was reported as milligrams of malondialdehyde per kilogram of meat, using Equation (2) (Kim et al. 2020).

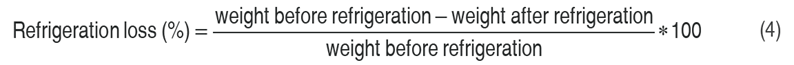

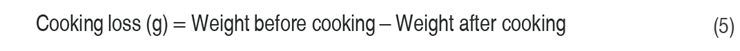

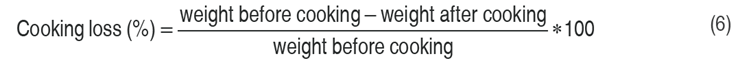

Meat refrigeration loss

Meat samples soaked in aqueous extracts were refrigerated to determine the refrigeration loss. Each sample was weighed prior to refrigeration, then re-weighed on day 0, 5 and 10. Refrigeration loss and loss percentages were calculated using Equations (3) and (4), respectively:

Evaluation of cooking loss

Cook loss percentages were calculated on day 10, post-refrigeration. Meat samples were allowed to drain, then weighed, wrapped in separate air-tight polythene bags and cooked in a water bath at 70 °C for 20 min, applying slight modifications to the procedure stated by Sanwo et al. (2012).

Cooking loss was determined using Equations (5) and (6):

Gas Chromatography Mass Spectrometry of aqueous black pepper extract

Spectrometry [Gas Chromatography Mass Spectrometry (GCMS)] analysis of extract generated from the highest and best desirability was carried out. GC (Agilent 7890, USA) and MS (Agilent 5975 model, USA) had 30 mm tubular column diameter, 0.32 mm internal diameter and 0.25 µm thickness. The oven initial temperature hold was operated at 80 °C for 2 min at 12 °C min-1 to a temperature of 240 °C held for 6 min. The interface temperature between GC and MS is 250 °C. A small portion of the supernatant solution was filtered using the 0.45 µm micro filter and diluted with analytical grade acetone to 1:10. One microliter of the diluted solution was then injected into the gas chromatography column at 280 °C at a helium gas velocity of 1 mL min-1. The scan ranges between 50 and 500 with a spitless mode of analysis. Filtered extracts (1 µL) were diluted using analytical standard grade acetone extract 1:10 injected into the GC-MS for components identification as described by Olalere et al. (2018a), while the bioactive components present were identified in relation to the peak area fragmentation fingerprints.

Statistical design

Data obtained from responses were analyzed using Design Expert version 13.0.5.0 (Design Expert, 2021).Mean separation at 5% level of significance was carried out according to the regression coefficients examined that were subjected to analysis of variance (ANOVA) to derive response surface and contour plots together with the coefficient of determination (R2) for each response. Numerical optimization was performed to determine the level of desirability.

RESULTS AND DISCUSSION

Quality characteristics of chicken meat soaked in black pepper aqueous extracts prepared from designed extraction combinations

Optimization of aqueous extract using chicken meat soaked in aqueous black pepper extract subjected to irradiation time and solvent volume is presented in Table 3. Extract volume ranged between 60.42-115.13 mL, while aqueous extract uptake was between 3.15 and 17.09%. Meat pH ranged from 5.82-6.33, 6.05-6.21 and 6.39-7.23 on days 0, 5 and 10 of refrigeration storage, respectively. Meat TBARs value ranged between 0.286-2.088 and 0.11-0.351 on days 5 and 10 of storage, respectively. Loss resulting from refrigeration storage of meat samples soaked in extracts on days 5 and 10 were 9.26-18.92% and 16.4-28.72% while cook loss ranged between 30.6 and 39.73% on day 10. Meat colour parameter (L*, a* and b*) ranged between 47.36-64.62, 6.12-8.77 and 14.42-21.36 respectively on day 5; 49.03-66.35, 6.86-11.45 and 13.68-23.09 respectively on day 10.

Response surface and contour plots of extraction conditions optimized via meat quality assessment

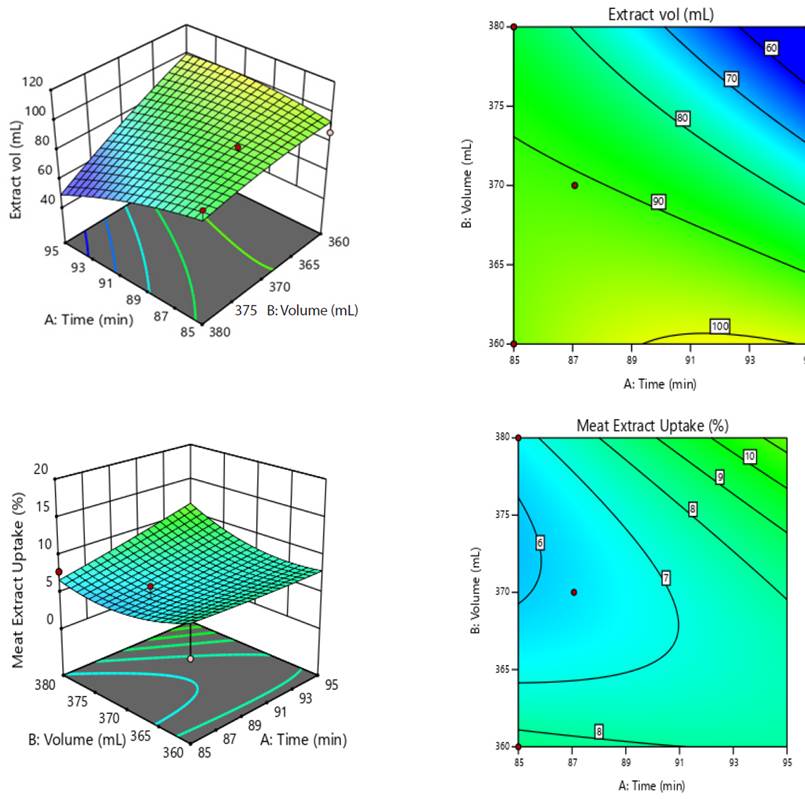

The response surface and contour plots showing the interaction of irradiation time and solvent volume (variable factors) on quality indices of extracts derived is detailed in Figure 1-7. Figure 1 shows the response surface and contour plots in relation to the extract yield and solvent absorbed in meat. Volume of extract obtained was at its peak in at 338.5 mL of distilled water and 90 min of irradiation. Oleoresin uptake (%) increases as irradiation time and solvent volume increased. Extraction method employed increased bioactive compounds harvested. Notably, the temperature of operation impacted extraction efficiency. Microwave power at 320 W which is sandwiched between the 300 and 350 W employed by Olalere et al. (2018a) complemented other extraction factors with more bioactive compounds extracted. Optimal microwave irradiation energy at 320 W likely enhance molecular movement of the electromagnetic field and the substance within the cavity, thereby, positively influencing molecular seeping of solvent into the dissolved matrix and increasing the dissolution and recovery of phytochemical compounds (Zin et al. 2020). Teo et al. (2009) expressed benefits derived from the use of closed vessel system operation. With little evaporation experienced, solvent volume is slightly sustained compared to extraction via open systems where solvent volume increases as extraction duration extends. Furthermore, dielectric conduction and refluxation of microwave cavity at lower temperature further facilitate the extraction of bioactive compounds. Such extraction method identified as green extraction method minimizes solvent consumption and operates an environmentally friendly procedure (Flórez et al. 2015). The solute: solvent ratio likewise affects microwave solvent extraction processes. Tatke and Jaiswal (2011) stressed the limitations solubility or mass transfer impose. Additionally, the quantity of black pepper dissolved in distilled water for this study positively affect the extraction yield. Beyond 8 g, a possibility exists that an optimal value would not be attained nor additional benefits derived, possibly resulting in diluted extracts, with limited solute potency. The capacity for water to absorb energy and refluxation, thereby facilitating the uniform distribution and microwaves exposures likely aided the extraction of functional compounds in this study (Veggi et al. 2013). Similar effects results in expected extraction outcomes as irradiation from specialized microwave allows for easier and proper control of operation with operation at lower cost than pressurized extraction protocols. The effect of ratios of water to raw material can likewise affect the solute extract yield and the number of compounds obtained. In a study conducted by Passos and Coimbra (2013), rescued liquid to solid ratios did not result in higher recovery of polysaccharide but monosaccharides implying solvent volume is critical to extraction yield. Findings confirm this, as revealed by the quantity of oleoresin extracted from white and black pepper that increase as solvent increased (Olalere et al. 2017, 2018a). In this study, however, more solvent volume was used at 360-380 mL than the 120 mL reported by authors previously cited. Significant outcome may be attributed to extraction system (closed system) employed in this study. Extracts can be applied to improve shelf stability of raw products. Also, functional compounds can be isolated for medicinal or therapeutic uses. The quantity of compounds harvested using this methodology exceeds the 55 compounds found in Piper nigrum by Mohammed et al. (2016), attesting to the efficiency of extraction method employed.

Figure 1 Response surface and contour plots of extract yield and uptake (%) of chicken meat soaked in black pepper extract.

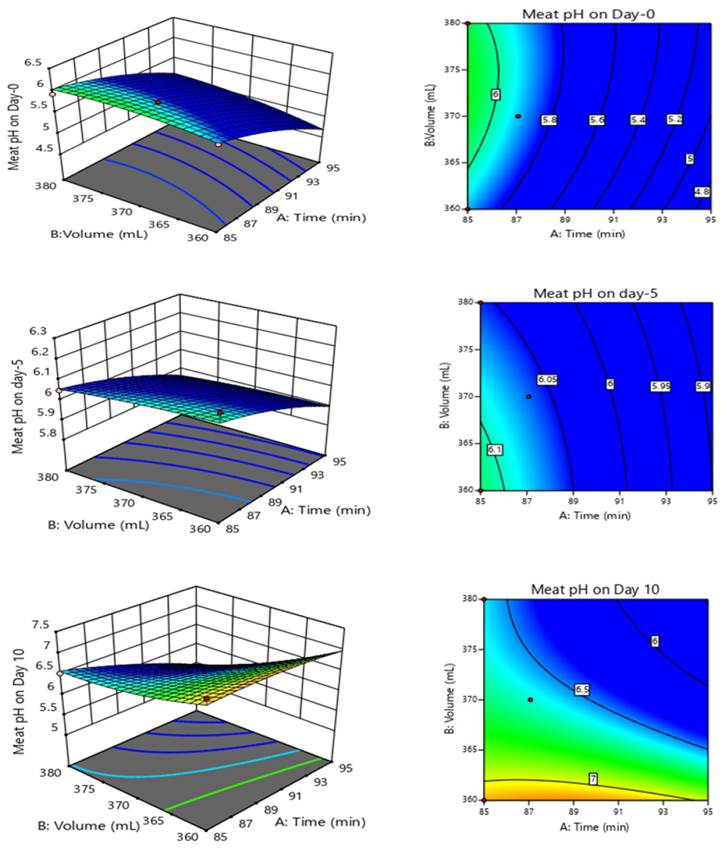

Figure 2 shows the response surface and contour plots of the pH of meat soaked in extracts on days 0, 5 and 10 of refrigeration storage. Meat pH on day 0 decreased as irradiation time of extracts is extended and the solvent volume is lowered while generating extracts; while on day 5, meat pH reduced among samples soaked in extracts formed from higher irradiation time and 372 mL of distilled water. On day-10, meat pH decreased among samples soaked in aqueous extracts generated from increased irradiation time and solvent volume combination. Extraction process of black pepper reveal solvent volume affects meat pH. Experiment conducted affirms that meat pH is critical to quality of extract obtained. Plant molecules can absorb microwave energy causing cell disruption by internal superheating, leading to desorption of phytochemicals and release of chemical compounds in extracts. An oscillating electric field or refluxation causes vibrations of polar molecules along with molecular friction that extends to volumetric heating, thereby causing water evaporation within cells and subsequent increased pressure that result in cell disruption (Balasubramanian et al. 2011; Tan and Muhamad 2017) and pH of resultant extract.

Figure 2 Response surface and contour plots of pH of meat soaked in black pepper aqueous extracts on day-0, 5 and 10 of refrigeration storage.

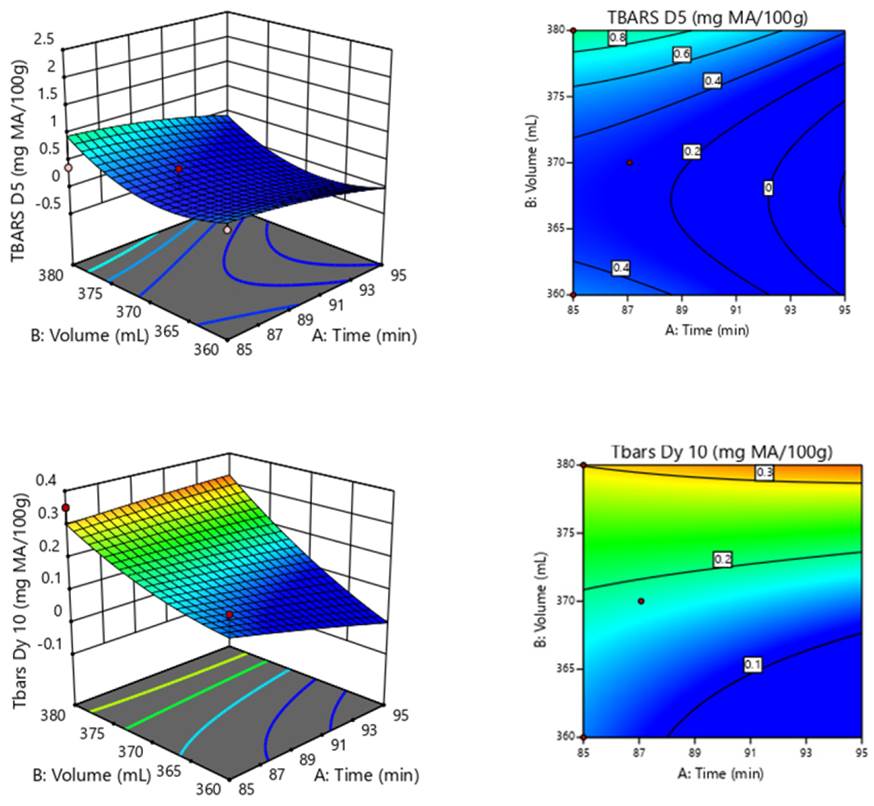

As seen from Figure 3, the response surface and contour plots of 2-thiobarbituric acid reactive substance count of broiler chicken meat soaked in black pepper extracts, then preserved for 5 and 10 days respectively is presented. The higher the solvent volume used for extraction, the higher the meat 2-thiobarbituric acid reactive substance (TBARs) count, especially at 371 mL in combination with 87 min of irradiation time, but on day-10, stored meat had lowered malondialdehyde value, especially when soaked in extract generated from lower solvent volume. Least meat TBARs value was recorded at 88 min of irradiation time and 367 mL of solvent volume. Extract quality affecting meat TBARs value reveal higher solvent volume increases meat TBARs (malondialdehyde) value. Though Tatke and Jaiswal (2011) explained that higher proportion of solvent volume to solid matrix resulted in higher extraction yields, however, higher moisture content and degree of unsaturation of meat lipid facilitated generation of pro-oxidants. Thus, lower solvent volume corresponds with higher extract concentration as well as generation of phenolic compounds.

Figure 3 Response surface and contour plots of 2-thiobarbituric acid reactive substance (MDA) in meat of broiler chickens soaked in black pepper aqueous extract stored for 5 and 10 of refrigeration.

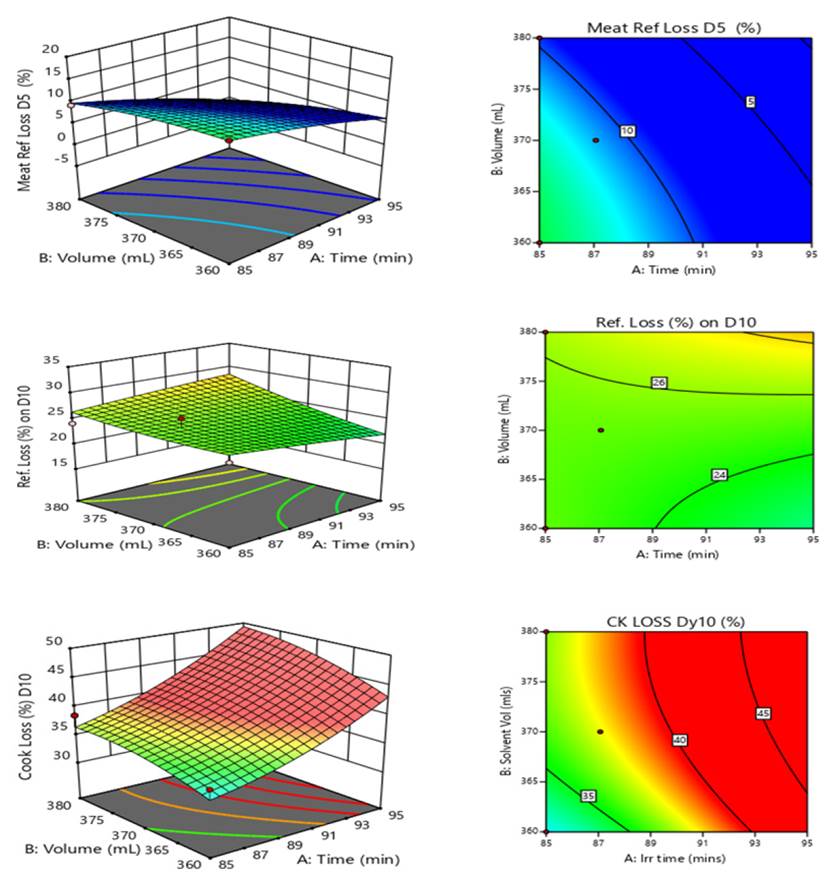

Response surface and contour plots of refrigeration and cooking loss percentages obtained after soaking chicken meat in black pepper extract, stored for 5 and 10 days is shown in Figure 4. Meat refrigeration loss was suppressed for extracts generated from lower irradiation time and higher solvent volume, while on day-10, refrigeration loss was minimized at 89 min of irradiation exposure and 367 mL of solvent volume. Cooking loss of meat on day-10 post-refrigeration resulted in higher moisture loss as the irradiation time and solvent volume increased. Meat refrigeration loss was lowered among extracts generated from lower irradiation time and higher solvent volume. On the other hand, loss (%) from cooking meat incorporated with aqueous extracts on day-10 post-refrigeration had more moisture loss as the irradiation time and solvent volume increased. According to USDA (2013), the percentage of naturally occurring water in meat varies with the type of muscle and the pH of the meat. Hence, moisture movement in and out of pore spaces of muscle cells affect the eventual moisture content of meat incorporated with extracts. Aqueous extracts contain acidic compounds that interacts with meat interstitial fat by maintaining a fairly acidic environment (pH) that fairly regulates muscle cell properties and layering, yielding meat with minimal moisture loss. Refrigeration loss of meat was fairly stabilized by aqueous extracts generated at lower irradiation time and solvent volume. Compositional analysis of black pepper by Clery et al. (2006) and Jeleń (2015) reveal black pepper contain terpenes, nitrogen-containing compounds, limonene, α- and β-pinene, methyl propanal, myrcene, 2- and 3-methylbutanal, α-phellandrene, linalool, butyric acid and 3-methylbutyric acid, altering the internal environment within meat, suppressing loose movement of water, water soluble sarcoplasmic proteins, vitamins and enzymes from interstitial spaces and muscle cells (Sanwo et al. 2019). This explains why the moisture loss was higher in meat preserved with extracts generated from higher extraction (irradiation and time) values post-cooking as the quality of bioactive principles in pepper is possibly suppressed.

Figure 4 Response surface and contour plots of refrigeration and cook loss percentage of chicken meat soaked in black pepper aqueous extract stored for 5 and 10 days.

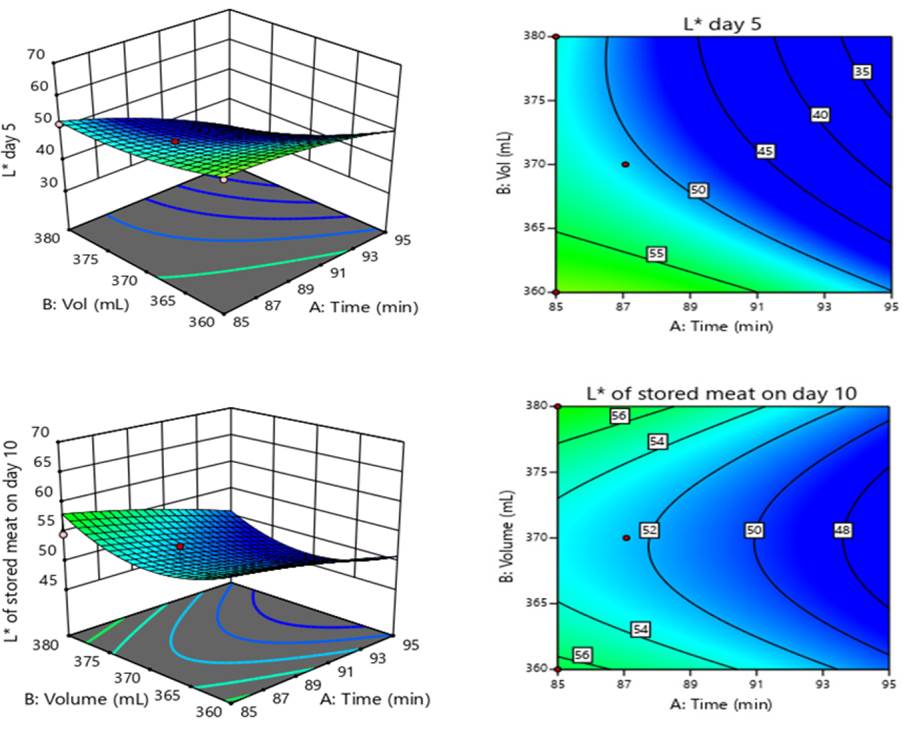

The response surface and contour plots for meat lightness (L*) of samples soaked in black pepper extract on day 5 and 10 of refrigeration storage is presented in Figure 5. Meat L* value increased as the irradiation time and solvent volume applied to extract decreased after soaking then storing meat for 5 days; however, on day-10, higher L* values were recorded as extraction conditions were sandwiched between 85-87 min and 361-379 mL of irradiation time and solvent volume respectively. The trend of activity of black pepper extracts on meat L* values as storage progresses contradicts the report of Ramamoorthi et al. (2010) that storage decreased meat L* and a* values, possibly pointing to the effectiveness of extraction process in releasing bioactive compounds in pepper, however, that meat lightness increased with decreasing irradiation time and solvent volume indicates minimal dosage of antioxidant application favors extension of meat lightness. Falowo et al. (2014) supports this by stating that higher concentrations of antioxidants may alter expected effects through pro-oxidative action. Notably, from this study, extraction conditions sandwiched between 85-87 min and 361-379 mL of irradiation time and solvent volume respectively in tandem with fixed extraction factors favours the preservation of meat lightness using black pepper extract.

Figure 5 Response surface and contour plots of lightness value of meat soaked in black pepper aqueous extract on days 5 and 10 of refrigeration storage.

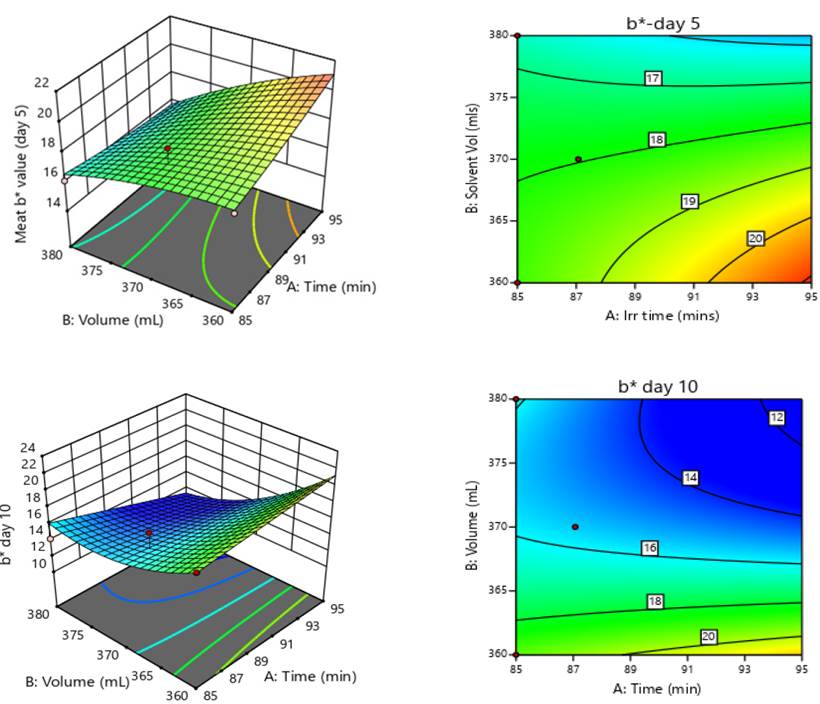

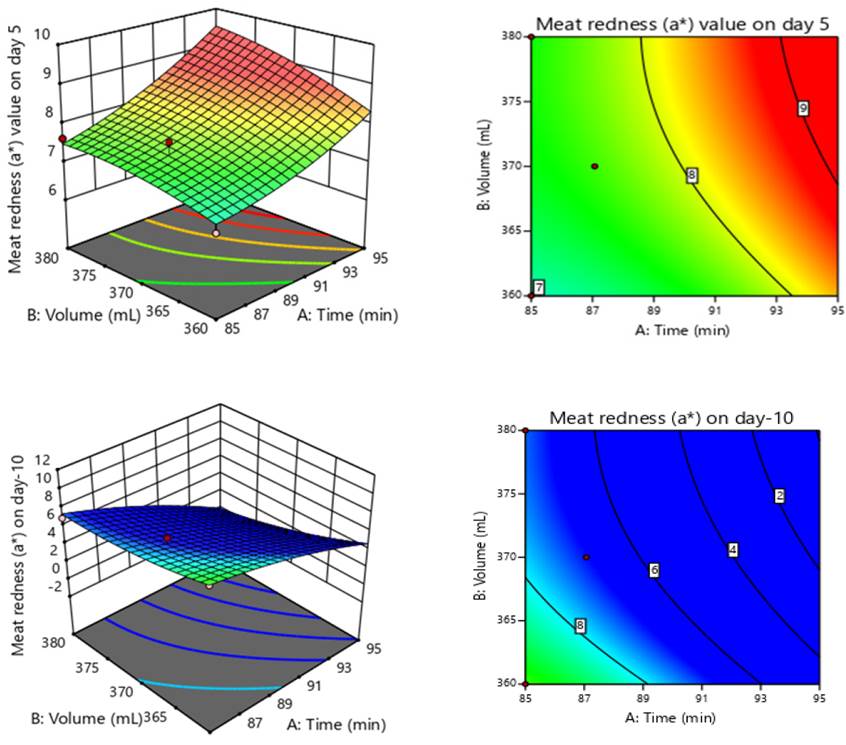

Response surface and contour plots of redness (a*) and yellowness (b*) values after soaking chicken meat in black pepper extract stored in the refrigerator for 5 and 10 days is presented in Figure 6 and 7, respectively. Meat a* value increased as irradiation time and solvent volume increased; but on day-10, as irradiation time and solvent volume lowered, meat a* value reduced. On the other hand, meat yellowness (b*) values were elevated for meat soaked in extracts derived from increased irradiation time and solvent volume on day-5 of storage, but on day-10, meat b* values increased in extracts generated from lower solvent volume and fairly-constant irradiation time (91.50 min). According to Leal (2019), meat redness is perceived by consumers as an indicator of freshness and superior product quality that can further be enhanced by highly oxidizing compounds or additives. Oxidizing principles were extracted from black pepper. The antioxidant components abounded with higher irradiation time and solvent volume, though within defined set-up. The change observed on D 10 may be attributed to the kind of storage employed (refrigeration storage). Extension of the preservative potency of extracts may be achieved if storage at temperatures lower than 4 °C is employed in tandem with other preservation methodologies (active packaging) for better storage. Outcome of this study agrees with Ramamoorthi et al. (2010), whose study reveal all antioxidants increased L* value by two units (lighter), but the irradiation dose had no effect.

Figure 6 Response surface and contour plots of redness values of chicken meat soaked in black pepper aqueous extract on days 5 and 10 of refrigeration storage.

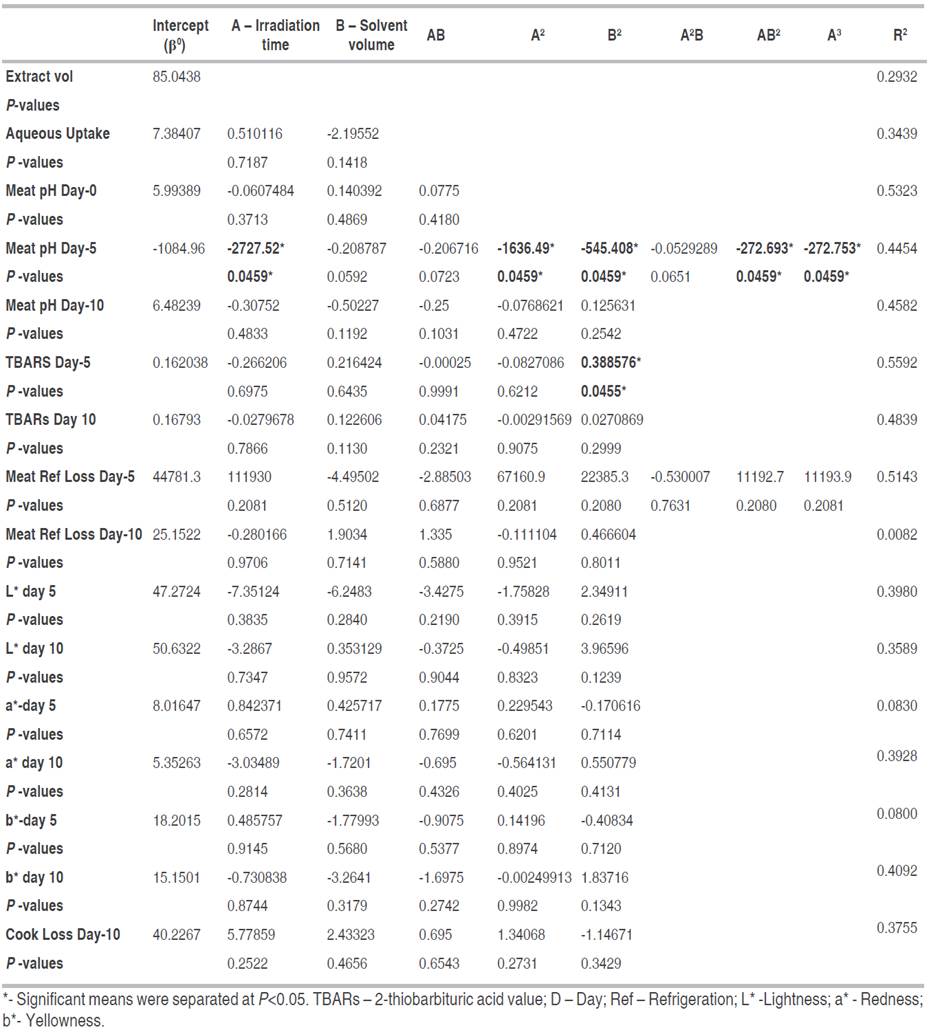

Regression coefficient of responses (aqueous extract volume, meat absorption percentage, colour, loss percentage and 2-thiobarbituric acid value) as a function of the independent variables

Model regression coefficient applied for the optimization of white pepper aqueous extracts is shown in Table 4. Linear irradiation time for pH (-2727.52) on day-5; quadratic model for irradiation time and solvent volume for pH on day-5 (-1636.49 and -545.408); as well as cubic model for solvent volume were significant (P<0.05) among models and coefficients assessed.

Table 4 Regression coefficient of response parameters of black pepper aqueous extract applied as a function of independent variable.

An overview of the significant models from the regression coefficient table signifies aspects extract properties affected meat quality values presented in Table 3. On D 5, as irradiation time increases, solvent volume at 372 mL of distilled water was optimal. Since pH is a fundamental quality index for storage, it can be deduced that decline in potency of extracts corresponds with tendency for meat pH to shift from acidity to basicity. Changes in meat pH and colour result from post mortem glycolysis and glycogen conversion into lactic acid (Honkavaara et al. 2003; Abubakar et al. 2021) and the extent of variation influences the properties of meat. Meat soaked in acidic medium affects its hydrogen ion balance, therefore, significant changes on D 5, implies meat post-mortem changes was affected by extract properties on D 5 than D 0 and 10. Piper nigrum contain acidic compounds such as 2-Ethylbenzotriazole and (R)-(-)-14-Methyl-8-hexadecyn-1-ol, but overall, proportions of hydrocarbons in extracts possibly resulted in tissue alterations due to changes in muscle glycolysis with resultant decline in meat pH. Report on spices and herbs reveal these organic substances often contain high concentrations of phenolic components with an extreme H-donating activity by Falowo et al. (2014) further highlight the power of extracts. Hence, pronounced influence from variations among extracts on D 5 signify operational extraction conditions impacted extract quality and acidity with variations in acidic strength and tissue modification on D 5. Further implications and deductions from this study indicate that generally, extraction yield increases proportionally with power, solvent volume, irradiation time and particle size until the increase becomes insignificant or the yield declines (Xiao et al. 2008).

The quadratic model for the influence of solvent volume on 2-thiobarbituric acid (TBARs) value (0.3886) on day-5. Meat TBARs value was influenced (P<0.05) at 0.389 on day-5 of refrigeration storage. Linear model (irradiation time and solvent volume) values ranged between -7.483 and 5.788; -14.983 and 2.433 for extract volume and cook loss percentage respectively. Similarly, 2FI model and quadratic model were between -10.255 and 0.695 as well as -3.51 to 1.34 for aqueous extract volume and cook loss percentage respectively; while the quadratic model for solvent volume varied from -2.28 to 3.97 for extract volume and meat lightness respectively. Regression coefficient (R2) ranged between 0.0830 and 0.5592 for meat lightness and malondialdehyde values on day (D) 5 of refrigeration storage. Drosou et al. (2015) explained that the use of water as solvent under microwave extraction significantly increased the yield of polyphenols in red grape, however, this study has demonstrated that increasing solvent volume enhances extraction efficiency up till a limit and beyond this, further release of bioactive principles cannot be achieved. Therefore, increasing extraction criteria values beyond the limit will not positively enhance the extraction of polyphenols in aqueous black pepper extracts, which acts as antioxidants for quenching free radicals progressively generated beyond day 5, as meat is subjected to refrigeration storage.

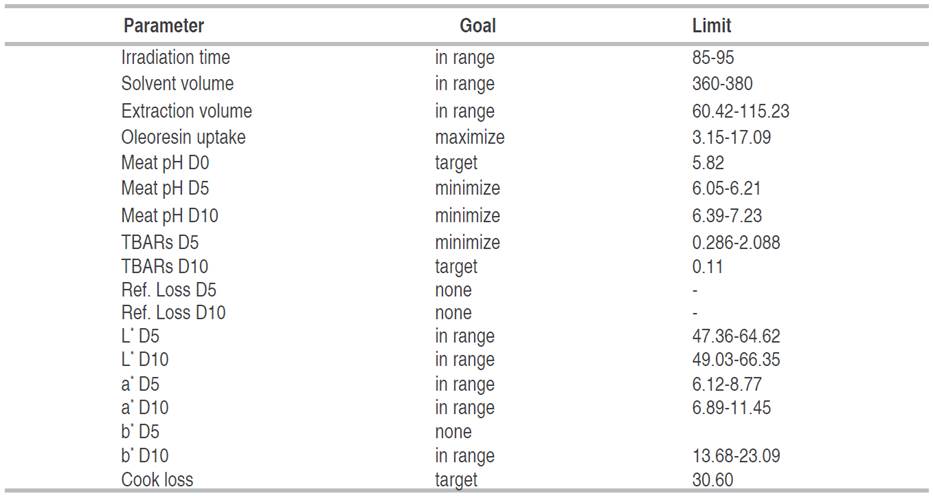

Criteria for optimization of production of black pepper aqueous extracts is presented in Table 5. The time for extract exposure to microwave irradiation was fixed between 85-95 min and the solvent volume was likewise fixed between 360 and 380 mL. Volume of extract to be obtained ranged between 60.42 and 115.23 mL, while extract soaked-u by meat was set to be maximized between 3.15 and 17.09. Meat pH of 5.82 was targeted for D 0 but meat pH for D 5 and 10 were minimized, ranging between 6.05-6.21 and 6.39-7.23 respectively. Meat malondialdehyde value range for D 5 was fixed between 0.286-2.088 but targeted at 0.11 for D 10. Meat lightness and redness on D 5 and 10 respectively were varied between 47.36-64.62, 49.03-66.35; 6.12-8.77 and 6.89-11.45, while cook loss of 30.60% was targeted. Refrigeration loss (%) in meat for D 5 and 10 and meat yellowness on D5 were not factored to obtain optimization outcomes.

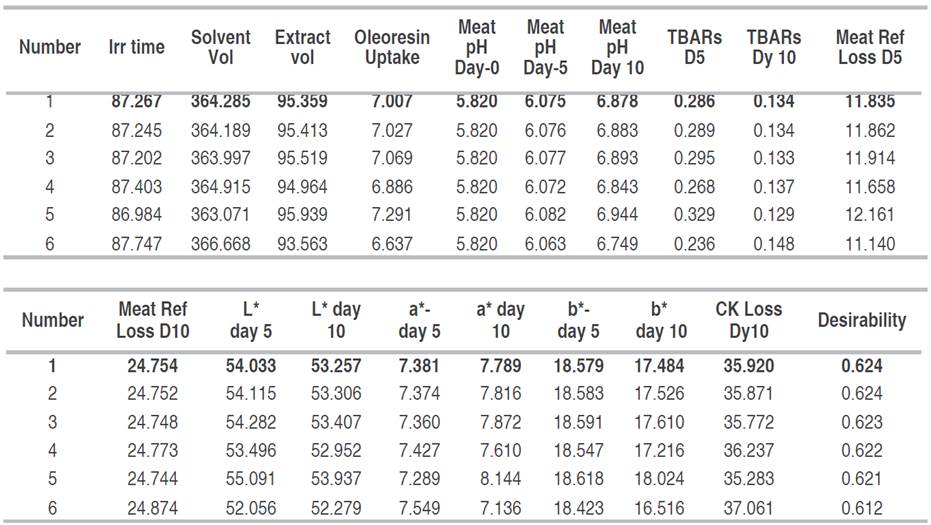

From the suggested solutions in Table 6, six solutions were proffered. An irradiation time of 87.267 min and 364.285 mL of distilled water would result in best desirability level of 0.624, while holding solvent volume and microwave power constant, however, a similar combination of 87.245 min and 364.189 mL of distilled water can be combined as variable factors to achieve a similar effect. Other suggested solutions have desirability values of 0.623, 0.622, 0.621 and 0.612 respectively. This study has shown that irradiation time and solvent volume are critical factors that can affect the extraction of functional compounds in black pepper. Also, while the change in irradiation time of solutions suggested was close, the solvent volume affected the desirability than the irradiation time. This agrees with the findings of Jeyaratnam et al. (2016) that with increased solvent volume for extraction, a lower heat and by extension the irradiation time reduces for actual extraction as the energy requirement for vaporization increases. Also, from this study, the upper and lower limit for irradiation time and the extraction of white pepper with optimal desirability is between 87.245 and 87.267 min and further increment in irradiation time will not significantly increase extraction yield of bioactive compounds (Mustapa et al. 2015).

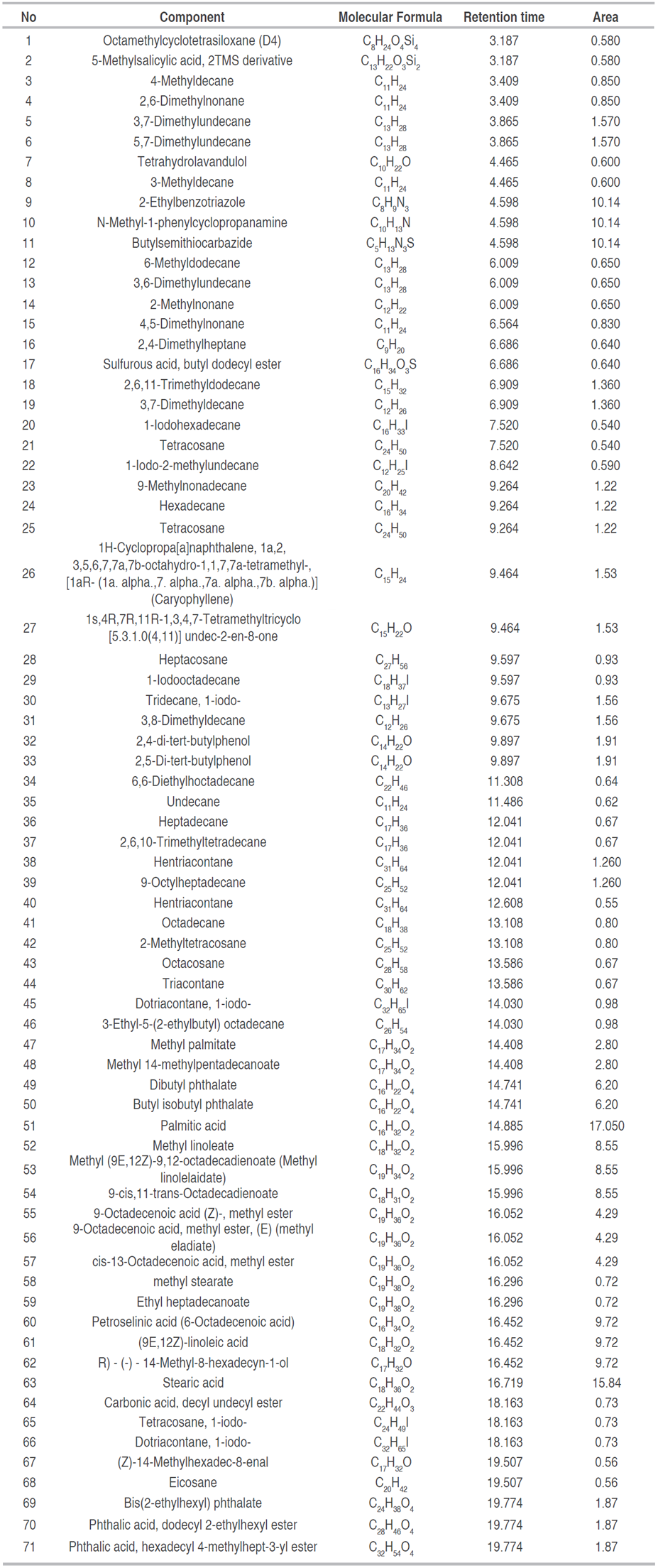

Bioactive compounds gotten from black pepper extract via optimized criteria is presented in Table 7. A total of 71 compounds were identified with a diverse range of element-based compounds such as silicon, nitrogen, sulphur and iodine. Two silicon, and nitrogen-based compounds as well as one sulphur and nitrogen-sulphur based compound were obtained, while seven iodine-based compounds were found. Palmitic acid was the major abundant component (17.05%), followed by Stearic acid (15.84%), 2-Ethylbenzotriazole (10.14%), N-Methyl-1-phenylcyclopropanamine (10.14%) and butylsemithiocarbazide (10.14%). Linoleic acid, petroselenic acid and (R)-(-)-14-Methyl-8-hexadecyn-1-ol were 9.72 % respectively, while methyl linoleate, methyl linolelaidate and 9-cis, 11-trans-octadecadienoate were 8.55% respectively. Slightly lower yield was dibutyl phthalate and butyl isobutyl phthalate. Notably, Bis (2-ethylhexyl) phthalate content of 8.55% was present in aqueous extract. The GC-MS result for optimized black pepper extract contradicts the reports of Zhang and Xu (2015) and Olalere et al. (2018a) that white pepper contains more bioactive compounds than black pepper, thus indicating that the method of extraction employed have a strong impact on the qualitative yield of bioactive components.

CONCLUSIONS

Meat quality is a major criterion for purchase that drives consumer preference and decision. This study has demonstrated that the number of compounds extracted correspond with extraction efficiency, evidenced by the influence of extracts on meat pH and MDA count on D 5; meat lightness and eventual number of compounds extracted. Extraction conditions sandwiched between 85-87 min and 361-379 mL of irradiation time and solvent volume respectively, in tandem with other fixed extraction operational factors favors the preservation of lightness in meat, while the least meat TBARs value was recorded at 88 min of irradiation time and 367 mL of solvent volume. After optimization was performed, a total of six solutions were suggested for the extraction of aqueous black pepper, and the recommended extraction criteria had desirability level of 0.624 was for two solutions. With irradiation power and particle size fixed at 320 W and 8 g respectively, alongside 0.40 mm particle size; 87.268 min of irradiation time and 364.285 mL of solvent volume was suggested as the recommended variable extraction values, while an irradiation time of 87.245 min and 364.189 mL can be applied as effective alternative. Applying the suggested extraction conditions in a closed system, a total of 71 compounds were found which is a remarkable improvement in the extraction yield and efficiency.