Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

Ingeniería e Investigación

versão impressa ISSN 0120-5609

Ing. Investig. v.31 n.2 Bogotá maio/ago. 2011

The influence of the blast furnace slag replacement on chloride penetration in concrete

Juan Lizarazo Marriaga1, Peter Claisse2

1 Civil Engineer, Specialist and Master, Universidad Nacional de Colombia. Doctor, Coventry University, UK. Assistant Professor, Universidad Nacional de Colombia, Colombia. jmlizarazom@unal.edu.co

2 Physics, University of Oxford. Doctor in Civil Engineering, University of Leeds. Lecturer, Coventry University, UK. p.claisse@coventry.ac.uk

ABSTRACT

Corrosion of steel reinforcement due to chloride penetration is the greatest cause of durability problems in concrete; intense international research has been carried out to understand and avoid this. This paper summarises the results of a theoretical and experimental research programme investigating the influence of blast furnace slag on chloride-related transport properties. The relationship between the apparent chloride diffusion coefficient, electrical resistivity and compressive strength was measured. Chloride, hydroxide, sodium and potassium' s intrinsic diffusion coefficients were obtained by using a computational model and an electrical migration test. The initial hydroxide composition of the pore solution, porosity and chloride binding capacity were also determined from the model. The results showed that blast furnace slag improved chloride penetration resistance, resulting in concrete which was less vulnerable to corrosion.

Keywords: concrete, diffusion, chloride migration, chloride

Received: March 25th 2010

Accepted: July 1th 2011

Introduction

In addition to iron ore or iron pellets, coke and limestone or dolomite fluxes are used during the production of iron in a blast furnace so that the calcium and magnesium from the calcareous fluxes combine with the ore' s aluminates and silicates. This reaction leads to good quality iron being obtained and also a nonmetallic waste, known as slag. If this slag is rapidly cooled, it develops a glassy internal structure and has cementitious activity potential.

Blast furnace slag offers many technical possibilities as cementitious material and may be used to reduce Portland cement consumption. This is particularly beneficial because the cement industry accounts for a large amount of international industrial production of greenhouse gases. From an environmental standpoint, the use of blast furnace slag provides benefits including recycling an industrial by-product and, from an economic standpoint, the costs of processing the slag may be lower than the cost of Portland cement production.

Chloride penetration is the greatest cause of durability problems in concrete because of steel reinforcement corrosion. This paper summarises the results of a theoretical and experimental research programme regarding the influence of blast furnace slag on ion transport properties in concrete. The relationships between the apparent chloride diffusion coefficients, electrical resistivity and compressive strengths were obtained for mixtures using different slag proportions. A computational model and an electrical migration test were used for obtaining the intrinsic diffusion coefficients for chloride, hydroxide, sodium and potassium. The initial hydroxide composition of the pore solution, the porosity, and the chloride binding capacity were also determined from the model.

Theory

Several transport mechanisms can promote ion movement within porous media; diffusion is the flux produced by a difference in chemical potential or concentration, migration is the flux caused by a difference in electric potential and permeability is a measurement of flux when there is a difference in fluid pressure. Capillary suction and sorptivity may create such pressure or concentration gradients.

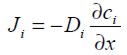

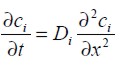

The relationship between flux Ji and concentration ci in a solution is known as Fick' s first law of steady state diffusion (equation 1). Di is the diffusion coefficient, ci is the ion concentration and x is the distance. For non-steady state conditions, when concentrations are changing t, flux is defined by Fick' s second law (equation 2).

| [1] |

| [2] |

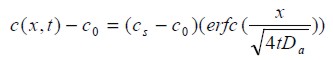

Assuming an ideal situation in which only chloride ions diffuse in homogeneous semi-infinite media, influenced by a constant concentration gradient, an approximate solution of Fick' s second law can be obtained by using equation 3 (Crank, 1976). In this, c (x, t) is defined as chloride concentration for any time and position, co is the initial concentration of chlorides in the pore solution, cs is a constant concentration on the external surface, Da gives the apparent diffusion coefficient and ercf is the Gaussian error function.

| [3] |

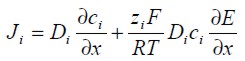

If there is an electric field gradient (which may be caused by concentrations of the migrating ions themselves), the ionic flux can be determined from equation 4 which is known as the Nernst-Planck equation. This describes the flow of any ion species influenced by the action of a concentration gradient and an electric field.

| [5] |

zi is the electrical charge of species i, F is the Faraday constant, R is the gas constant, T absolute temperature and E electrical voltage. The Nearnst-Planck equation is commonly used in electrical migration tests on concrete samples (NTBUILD-492, 1999). An internal electric field is produced in addition to the external applied electric field as a result of free species' ion exchange within the pore solution of concrete during a concrete migration test (Lizarazo-Marriage and Claisse, 2009a). Ions which are free to move (Cl-, OH-, Na+, Ca+ and K+) generate an additional electric potential known as membrane potential which, due to the principle of electro-neutrality, determines ion migration within a porous medium.

Computational model

The computer model used in this research simulated a concrete migration test like that described in ASTM C1202. The code uses a finite difference algorithm to solve the Nearnt-Planck equation, calculating membrane potential throughout the duration of the test, and adjusting the field to achieve electro-neutrality. A more detailed description of the model has been given by Claisse and Beresford (1997) and Claisse et al., (2010).

The purpose of the computational model was to give output for the current passed and membrane potential using the properties of concrete and test conditions as input data. However, in reality, the reverse condition is required; electric current and membrane potential can be measured in the laboratory while measuring other transport properties is highly complex. To solve this problem, the methodology adopted in this research was to use the results from the numerical model to optimise an artificial neural network so that concrete properties were calculated from experimental results. The concrete properties obtained involved intrinsic diffusion for the species involved in the test (Cl-, OH-,Na+ and K+), porosity, chloride binding capacity and pore solution hydroxyl ion concentration. The development of this technique lies beyond the scope of this paper and will not be discussed ; however, it has been fully documented in Lizarazo-Marriaga and Claisse (2009b) and Lizarazo-Marriaga and Claisse (2010).

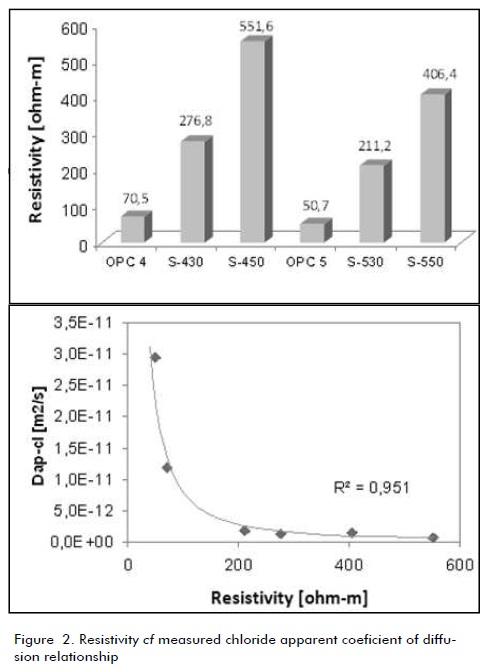

The following conditions were assumed in the model in order to include the complex phenomena which occur during a migration test: (a) the only free species found in the pore solution or external cells would be Cl-, OH-, Na+ and K+; (b) the only ions that interact or react with the cement matrix would be chlorides; and (c) a linear binding capacity isotherm would be established for chlorides. The relationship between the intrinsic diffusion coefficient Din-Cl and the apparent diffusion coefficient Dap-Cl was thus defined by Equation 5, establishing the relationship between porosity (ε) and chloride binding factor (α).

| [5] |

Experiments

Materials

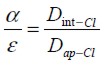

Mixtures of Portland cement and blast furnace slag were prepared at constant 0.4 and 0.5 water to cement ratios. For all mixtures, 400 kg of cementitious material was used per cubic meter of concrete. The replacement levels were 30% and 50% slag. Table 1 shows the mix designs developed and the corresponding nomenclature used in this research. All tests were conducted at ages beyond 120 days, with curing in water tanks.

Tests

Current and membrane potential as in ASTM C1202: The procedure used for measuring electric current was conducted according to standard recommendations. A 100 mm diameter and 50 mm thick concrete cylinder was placed in contact with a chloride and alkaline solution at each end. A 60 V (DC) electric potential difference was applied for 6 hours through the external cells at each end serving as reservoirs and containing metal electrodes. Prior to the test, the samples were fully saturated using a vacuum pump. In addition to the standardised test, membrane potential was measured by adding a salt bridge in the middle of the specimen; using this, the membrane voltage profile was measured during the six hours the test lasted.

Chloride diffusion test: The apparent diffusion coefficients for the mixtures blended with blast furnace slag were obtained using a Gaussian error function (equation 3) which provides a solution to Fick' s second law for the transient condition. After 12 weeks of diffusion, the samples were split into two equal portions along their longitudinal axes and chloride ion penetration was measured using the colorimetric method (Meck and Sirivivatnanon, 2003). It was assumed in this research that the chloride concentration at which the colour would change due to silver nitrate precipitates would be close to 0.07 N (NTBUILD-492, 1999). The diffusion coefficient was determined by the numerical solution of equation 3. It was assumed that the sample would contain no chlorides (c0 = 0) at the start of the test and that the concentration at which the colour changed (cc) would be 0.07 mol / l.

Electrical resistivity: Electrical resistivity has been proposed many times as a measurement of concrete durability (Feldman et al., 1999; Betancourt and Hooton 2004). An AC signal generator with a frequency of 500 Hz was used in this research to measure this property.

Results and discussion

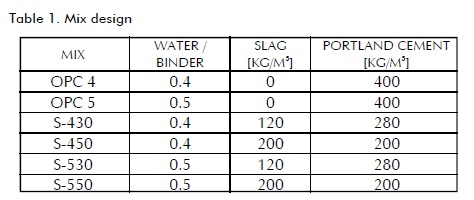

Figure 1 shows the measured apparent diffusion coefficients for chloride which were calculated using equation 3 and the procedure described above. The Figure shows the coefficient for each mixture and the profile described by Fick' s second law after 12 weeks diffusion. The benefits obtained from slag were significant, as has previously been reported by Wang and Lee (2010). Fo mixtures using 0.4 water to cementitious ratio, replacement by slag produced a decrease by a factor of 8 and 19 for mixtures with 30% and 50% replacement, respectively. For mixtures having 0.5 water to cementitious ratio there was a decrease by a factor of 17 and 19 for mixtures with 30% and 50% replacement, respectively. Results reported in the literature (Geisel et al., 1992) similarly found that the addition of blast furnace slag significantly improves the penetration of chlorides. A 50% replacement level showed more benefit than 30% replacement.

One reason why blast furnace slag improves resistance to chloride penetration is the presence of hydration compounds such as calcium silicates attached to aluminium or magnesium chains.

They can bind free chlorides and clog the possible channels through which they move. The pores’ porosity and morphology thus becomes refined due to the slag replacement. Another reason is the abundant presence of tricalcium aluminates in the slag which can bind chlorides, adhering them to the matrix and preventing their movement (Luo et al., 2003).

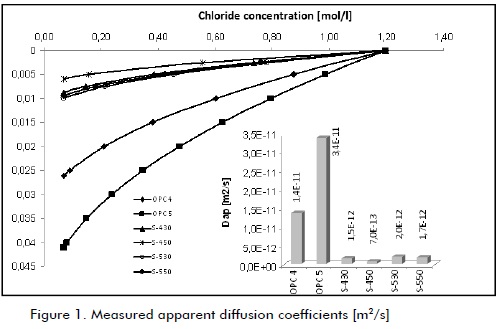

The electrical resistivity of the samples tested is shown in Figure 2 (left-hand side). It was observed that as percentage addition increased, resistivity also increased for both water to cement ratios, this being highest for 50% replacement. The relationship between resistivity and diffusion coefficient is shown in Figure 2 (right-hand side); this shows that data was exponential; "large" increases in resistivity for blended samples yielded to "small" changes in the diffusion coefficient, while for samples without addition, "small" increases in resistivity produced "large" increases in the diffusion coefficients. The increase in resistivity for mixtures using slag increased resistance to corrosion of reinforcement, as has been reported by Song and Saraswathy (2006).

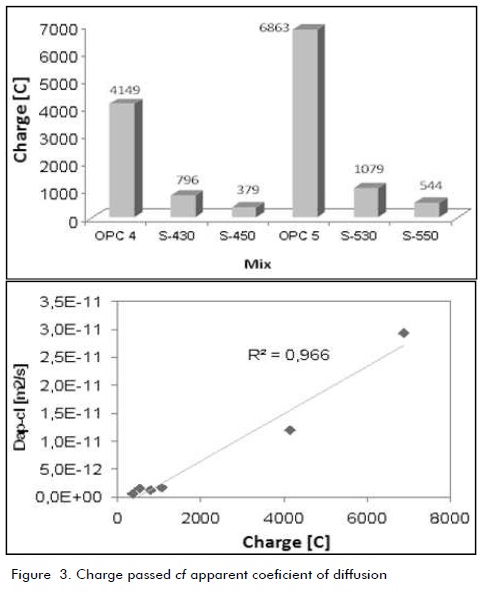

The values of charge passed in coulombs after six hours of the ASTM C1202 test are shown in Figure 3 (left-hand side). There was a decrease in charge passed as the level of slag replacement increased and the water to binder ratio decreased. For both water to binder ratios, the samples without slag showed high chloride ion penetration while the blended samples showed low and very low penetration. Some deficiencies have been identified for this test, such as the Joule effect which causes a temperature rise, the association of all the charge passing with the migration of chlorides (when other species are mobile during the experiment) and measuring electrical conductivity instead of chloride ion penetration. However, Figure 3 (right-hand side) shows that there was acceptable correlation between the measured diffusion coefficient and the charge passing. These results showed that for quality control conditions the ASTM C1202 test could be used reliably in slag blended samples to identify problems with mixes.

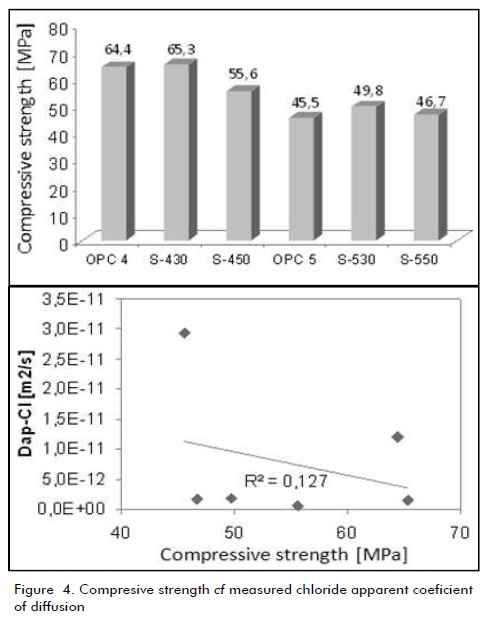

Figure 4 (left-hand side) shows the results for compressive strength for all mixtures tested. It may be noted that maximum strength was reached when slag replacement was 30% for both water to binder ratios. Although there were no significant increases in strength, the values obtained did not decrease, thus indicating that blast furnace slag blends can be used as structural material in similar conditions to Portland cement. Figure 4 (righthand side) shows that there was no clear relationship between compressive strength and diffusion coefficient. This result was significant because compressive strength is the most popular test in concrete technology and tends to be used as correlation for estimating other properties.

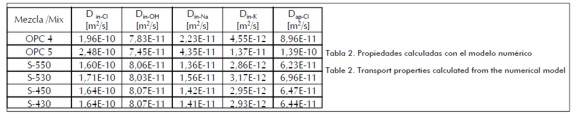

The electrical test was used for measuring electric current and membrane potential. The neural network was then used to calculate ion transport-related properties. Table 2 shows the results of the simulation which produced results for the intrinsic diffusion coefficients for chloride (Din-Cl ), hydroxyl (Din-OH ), sodium (Din-Na ) and potassium (Din-K ). It also shows the simulated apparent diffusion coefficient calculated using equation 5.

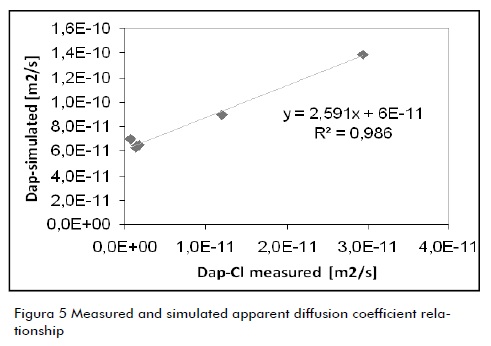

Figure 5 shows the relationship between apparent diffusion coefficient measured and calculated; it can be observed that the parameters had good correlation. The determination coefficient R2 obtained was 0.986, which showed linear dependence between these variables. The differences between the numerical values were due to the basic equations used to calculate the coefficients. Fick' s second law was used for diffusion and the Nearnst Planck equation was used for electromigration coupled to diffusion.

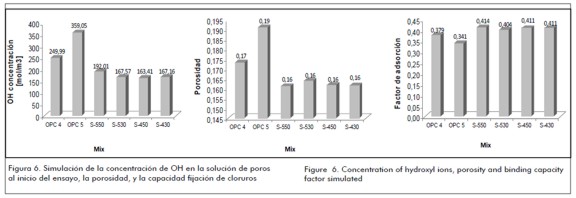

The initial hydroxyl ion concentration, porosity and binding capacity factor for chlorides are shown in Figure 6. It can be observed that alkalinity, measured as OH- ion concentration, decreased as the percentage of slag replacement increased. This was because the alkalis (Na+ and K+) in slag pore solution were consumed by complex hydration reactions resulting in decreased pH. This decrease affected pore solution conductivity and mobile species' diffusion-migration due to changes in ion potential. The numerical results for the OH- concentration generally agreed with results published previously by Bertolini et al., (2004).

Regarding porosity, the results showed a decrease as water to binder ratio decreased and this was more significant as the amount of replacement increased. It should be noted that porosity was defined according to interconnected void volume related by the tortuosity of the concrete' s pore system. The same Figure shows the cement matrix (a)chloride binding capacity. As described above, slag replacement promoted chloride binding due to an increase in products capable of reacting with them, especially due to the alumina content of the slag.

Conclusions

Several conclusions drawn in this research paper are summarised below.

- Blast furnace slag can be used to produce concrete with compressive strength and chloride penetration similar or superior to that obtained with just Portland cement. However, it is necessary to evaluate which percentage of replacement produces optimum results;

- When compressive strength, electrical resistivity and charge passed in accordance with ASTM C1202 were measured in mixtures blended with blast furnace slag, as an indirect measurement of chloride ion penetration, each technique’s characteristics and limitations should be considered;

- Replacement with blast furnace slag significantly increased the resistance of concrete to chloride penetration; diffusion coefficients measured experimentally decreased over 8 times when mixtures were blended;

- The proposed numerical modelling method for evaluating ion transport in concrete offered the possibility of finding reliable values for the properties while avoiding high costs involved in equipment and time. For the mixtures tested, the results agreed with expected values from references and other experiments ; and

- The methodology presented in this paper opens the way forward for investigating the transport properties of several new cementitious materials for construction.

References

Bertolini, L., Elsener, B., Pedeferri, P., Polder, R.B., Corrosion of Steel in Concrete: Prevention, Diagnosis and Repair., Wiley, First edition, London, 2004, pp.155-195. [ Links ]

Betancourt, J., Hooton, R.D., Study of the Joule effect on rapid chloride permeability values and evaluation of related electrical properties of concretes., Cement and Concrete Research, Vol. 34, 2004, pp. 1007-1015. [ Links ]

Claisse, P.A., Beresford T.W., Obtaining More From the Electrical Chloride Test., ACI - SP170-57, Vol. 170, 1997, pp. 1119-1132. [ Links ]

Claisse, P., Elsayad, H. Ganjian, E., Modelling the rapid chloride permeability test., Cement and Concrete Research, Vol. 40, 2010, pp. 405-409. [ Links ]

Crank, J., The Mathematics of Diffusion., Oxford University Press, Second Edition, Oxford, 1976, pp. 1-44. [ Links ]

Feldman, R., Prudencio, L.R., Chan, G., Rapid chloride permeability test on blended cement and other concretes: correlations between charge, initial current and conductivity., Construction and Building Materials, Vol.13, 1999, pp. 149-154. [ Links ] [ Links ]

Lizarazo-Marriaga, J., Claisse, P., Effect of the non-linear membrane potential on the migration of ionic species in concrete., Elecrochemica Acta, Vol. 54, 2009a, pp. 2761-276. [ Links ]

Lizarazo-Marriaga, J., Claisse, P., Determination of the concrete chloride diffusion coefficient based on an electrochemical test and an optimization model., Materials Chemistry and Physics, Vol. 117, 2009b, pp. 536-543. [ Links ]

Lizarazo-Marriaga, J., Claisse P., Determination of the transport properties of a blended concrete from its electrical properties measured during a migration test., Magazine of Concrete Research, Vol. 62, 2010, pp. 163-175. [ Links ]

Luo, R., Cai, Y., Wang, C., Huang, X., Study of chloride binding and diffusion in GGBS concrete., Cement and Concrete Research, Vol. 33, 2003, pp. 1-7. [ Links ]

NTBUILD-492., Nordtest method: concrete, mortar and cementbased repair materials: chloride migration coefficient from non-steady-state migration experiments., Nordic Council Ministers, 1999. [ Links ]

Meck, E., Sirivivatnanon, V., Field indicator of chloride penetration depth., Cement and Concrete Research, Vol. 33, 2003, pp. 1113-1117. [ Links ]

Song, H., Saraswathy, V., Studies on the corrosion resistance of reinforced steel in concrete with ground granulated blastfurnace slag-An overview., Journal of Hazardous Materials, 2006, Vol. 138, pp. 226-233. [ Links ]

Wang, X., Lee, H., Modeling the hydration of concrete incorporating fly ash or slag., Cement and Concrete Research, 2010, Vol. 40, pp. 984-996. [ Links ]

texto em

texto em