Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería y competitividad

Print version ISSN 0123-3033

Ing. compet. vol.17 no.1 Cali Jan./June 2015

Improving construction material and equipment logistics via simulation

Simulación para el mejoramiento de la logística de materiales y equipos en un proyecto de edificación

Adriana Gomez Cabrera*

E-mail: adrianagomez@javeriana.edu.co

María A. Granados-Castillo*

E-mail: mariagranados@javeriana.edu.co

Ivonne K. Pérez-Cendales*

E-mail: ivonne_karime@hotmail.com

* Ingeniería Civil. Pontificia Universidad Javeriana. Bogotá, Colombia.

Eje temático: CIVIL ENGINEERING/INGENIERIA CIVIL

Recibido: junio 16 de 2014

Aceptado: febrero 10 de 2015

Resumen

En este trabajo, se realizó un análisis de los procesos de logística del transporte, distribución y almacenamiento de materiales en actividades de cimentación y estructura, de dos edificaciones en concreto reforzado ubicadas en la ciudad de Bogotá D.C., con el fin de proponer mejoras en los procesos y aumentar la productividad. Lo anterior se desarrolló mediante la realización de modelos de simulación de eventos discretos. El trabajo fue realizado en tres fases, en la primera, se caracterizaron los procesos constructivos y se realizó un trabajo de campo basado en toma de datos, fotografías y videos; en la segunda etapa, se realizaron los modelos de simulación para el escenario real, se identificaron deficiencias y oportunidades de mejora con las cuales se propusieron diferentes escenarios teóricos, los cuales fueron comparados en la tercera fase de la investigación. A partir del análisis de los resultados obtenidos, se concluyó que la simulación de eventos discretos, permite observar la integración y comportamiento de las variables que intervienen en el proceso, logrando así, identificar falencias y proponer mejoras con las cuales se establezca el mejor escenario teniendo en cuenta la relación beneficio- costo.

Palabras Clave: Eventos discretos, logística, productividad, simulación variables.

Abstract

The present project demonstrates a way to improve construction processes, with improvement understood in terms of increased productivity. To achieve this objective, the research presented here relies on discrete event simulation models to analyze transportation logistics, as well as distribution and storage of structure- and foundation-related materials for two reinforced-concrete buildings in Bogota, Colombia. Analysis of the case study can be divided into three phases. In the first, construction processes were characterized, and a field study was conducted via data collection and video/photo recordings. In the second, simulation models were created for the real scenario, with deficiencies and opportunities for model improvement diagnosed and different theoretical scenarios proposed. In the third and final phase, these theoretical scenarios were compared using models to determine their strengths or weaknesses versus the real construction scenario. Based on the comparative study carried out, discrete event simulation allowed for the integration and behavioral observation of all variables affecting the construction process. As a result, deficiencies became conspicuous; in turn, improvements were readily identified in order to establish the best scenario from a cost-benefit perspective.

Key words: Discrete event, logistics, productivity, simulation, variables.

1. Introduction

One of the principal sources of construction losses stems from issues related to resources. Issues of this nature include insufficient material at the construction site, inefficient material distribution and ineffective means of transport; each and every one of these situations generate significant time, and therefore financial, losses during construction projects. Currently, building companies devote considerable effort to controlling their projects; however, they do so without quantifying their results and often end up repeating the same mistakes. Proper time investment during the project planning stage, coupled with proper time spent on the logistics stage, pays dividends in the form of financial savings. As part of planning, it is necessary to delve into transport logistics, distribution and material storage, for mismanagement of any of these factors could provoke field losses. Originally developed in 1993, Arena® is a software tool used for simulating processes by developing models with interactive graphic environments designed to simulate specific areas of the production process, or, in this case, the construction process (Fabregas et al., 2003). A Windows-based application, Arena® is designed to represent all aspects of productive systems; it supports detailed process and resource analysis by means of Flowcharts (graphic depiction) (Gómez, 2010).

The need for re-evaluating production management strategies in the construction process has been demonstrated by Botero (2005); strategies that fit the bill would need to include employment of new measuring systems that focus on new project planning and control techniques.

To put this type of research into context, it is worthwhile to outline its status both within Colombia and around the globe. One such area is the digital simulation of constructive processes to handle risk and uncertainty in decision making. Echeverry et al (2008) did exactly that: the Arena® digital simulation processes was used to model wall and slab structures. Additionally, work done by Céspedes (2010) laid out a related methodology based on field data and time-lapse videos, which facilitated digital simulation in Arena®. Another relevant study was conducted by Gómez (2010), wherein a case study served as the foundation for the simulation of discrete events with Arena® as a tool for the planning, reengineering and analysis of construction projects. Gómez and Correa (2011) turned to digital simulation to represent and examine construction material transportation and distribution processes for mining companies. Gómez et al (2012) propose value engineering for construction projects that integrates digital simulation and the Lean Construction philosophy. For their part, Ruiz et al (2011) evince the importance of digital models in which simulation is presented in real terms and without manipulations, thereby paving the way for significant productivity gains.

Furthermore, studies which depend on other tools (i.e. non-Arena® tools) have been developed, e.g. López (1996) and Ballesteros (1998). Both studies are grounded in the Micro Cyclone© tool (created by D. Halpin; Halpin and Riggs, 1992). In addition to Micro Cyclone, research done by Navarro (2001) utilized Stroboscope (developed by Martínez, 1996).

Shifting our attention to the international scene, there are a number of digital simulation studies in Japan. For example, the studies carried out by Li et al (2009) and Li et al (2012) used virtual prototypes to optimize construction planning programs by analyzing resource assignment, planning schedules and site design plans, among other facets. confirm that virtual prototypes increase work force efficiency and reduce risk; in short, the analysis and improvement of resource allocation, work routes and equipment and material location, among other factors, proves to be a worthwhile endeavor.

Regarding the state of the art countries outside of Japan and Colombia, Labban et al (2013) argue that despite the fact that research into simulation in the construction industry is advancing within academia, its application in the construction sector has so far been limited. The authors bolstered their thesis with the following argument: the construction sector is traditionally slow to adopt innovations and keeps working with traditional techniques frequently shown to be insufficient. They suggest illustrating the benefits of discrete event simulation in Civil Engineering using case studies to change the tide in the construction sector, expounding the need for further investigation into the implementation of these methodologies in the real world.

On balance, as a result of the aforementioned investigations, project planners have been armed with the tools required to thoroughly evaluate different scenarios in probabilistic terms. In other words, this type of research enhances decision-making processes in the face of uncertain conditions.

2. Project description

The present case study revolves around two construction projects in the Colombian capital, Bogota. The first project (P1) is a nine-story building with a basement. Designed to house educational facilities, its total constructed area is 11,400 m2. With regards to P1, analysis revolved around material transportation process logistics for the construction of caissons. The second project (P2) is an eight-story building with two basements destined for office use (total constructed area comes in at 11, 528 m2). For P2, simulation was used to study the logistics of the material transportation processes for the building of the structure and floor slabs and columns.

3. Methodology

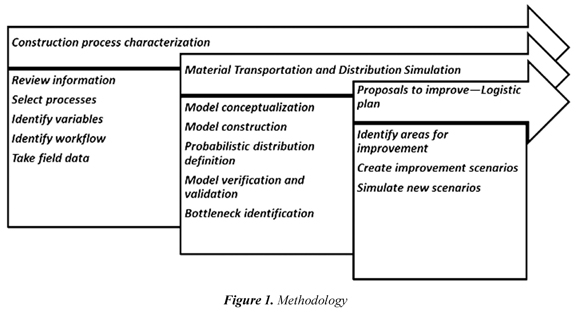

This research was divided into three phases: (i) construction process characterization; (ii) discrete event simulation; (iii) proposed points of improvement. See Figure 1 for the methodology behind this tripartite division.

3.1 Fieldwork

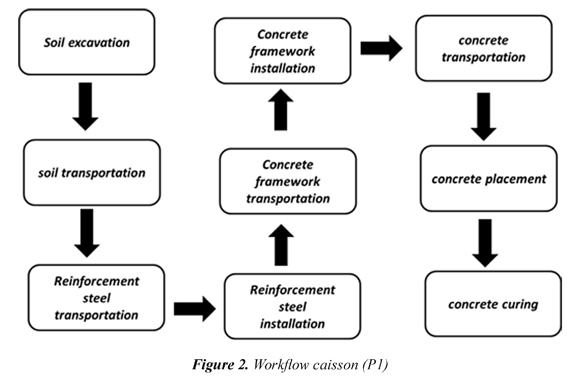

As dictated by the needs concomitant to the processes studied, this research examined activities related to the logistics of material transportation and that of construction process equipment. These activities were expressed graphically as workflows, which are displayed in Figure 2. Once the pertinent activities were established, the next step consisted of plant layout analysis and the identification of collection and storage points in addition to material transportation routes. Having done this, research proceeded to field data, for which fifty (50) duration data samples were taken, along with cataloging human resources, equipment and/or tools at each of the sites studied.

3.2 Model development

3.2.1 Data analysis for model input

Input Analyzer, a valuable tool, was brought to bear on times measured in the field, producing the probability function that best fit each one of the data series taken in the field. This secondary fit was achieved by virtue of goodness and fit tests (Chi-square or Kolmogorov-Smirnov).

3.2.2 Simulation

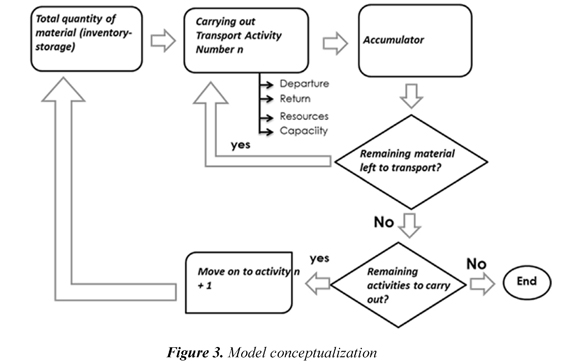

Based on Arena® software generated workflows for each transport and installation activity comprising the caisson and structure construction processes (P1 and P2, respectively), simulation models representing the real scenarios of the two processes were created. Simulation models for comparison were developed with input data, i.e. information obtained from fieldwork. These samples include: workflow, time, resources, quantity takeoff equipment and tool capacities. Restrictions-e.g. work schedules, employee breaks and time required for concrete curing-were also taken into account. Figure 3 indicates the conceptualization of simulation models, and a screenshot of part of the Arena® modelling software can be observed in Figure 4.

3.2.3 Verification

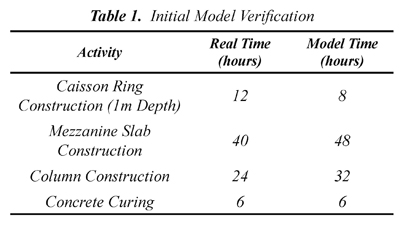

Model verification consists of comparing a simulated scenario's performance to that of the real scenario for each project. For the present study, model verification confirmed a suitable configuration of the decision elements in the model was achieved. This meant that entity paths matched up with the work plan and each activity's predecessor and successor are appropriate. A joint review of the models, done with researchers and the parties responsible for the projects, was conducted, and the conclusion reached was that the model accurately represented each one of the construction processes studied (results depicted in Table 1).

3.2.4 Validation

To validate the models, the Confidence Interval (CI) method proposed by Banks (2005) was used. This method enjoyed a confidence of 100 (1-α)% via the length of the confidence interval obtained. That being said, to ensure a desired error level of ± 1 day, 30 and 20 replicas are required for P1 and P 2, respectively (95% confidence).

3.2.5 Proposals for improvement

Analysis of the simulated results highlighted shortcomings occasioned by delays in the transportation of excavation byproduct (dirt accumulated after digging) for P1. In general (i.e. for both models), these problems were connected to the use of unsuitable equipment and tools, under-utilization of equipment and tools, as well as transportation hindrances. The real scenario for P1 can be observed in Figure 5 and the real scenario for P2 in Figure 6.

In light of the aforementioned situation, options aimed improving the processes development and increasing productivity were proposed. These options strove to: a) boost equipment capacity and capability versus those already available on the construction site; b) introduce different equipment; c) increase human resources; d) define work logistics encompassing set material storage, distribution and collection points, not to mention fixed transportation routes.

3.2.6 Scenarios

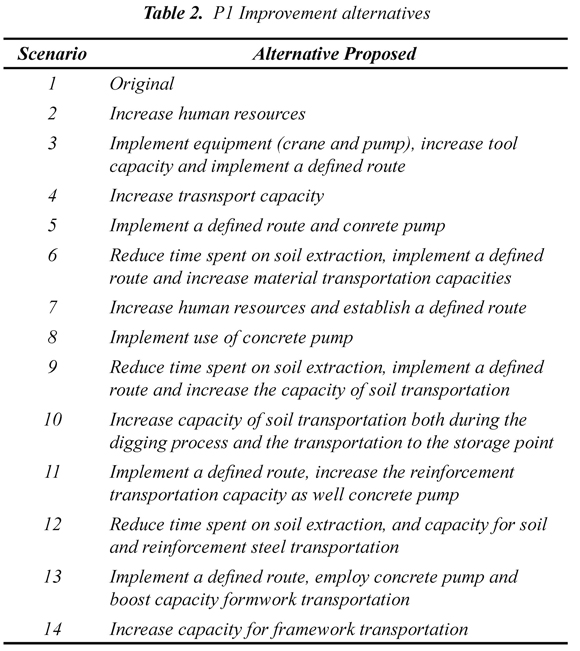

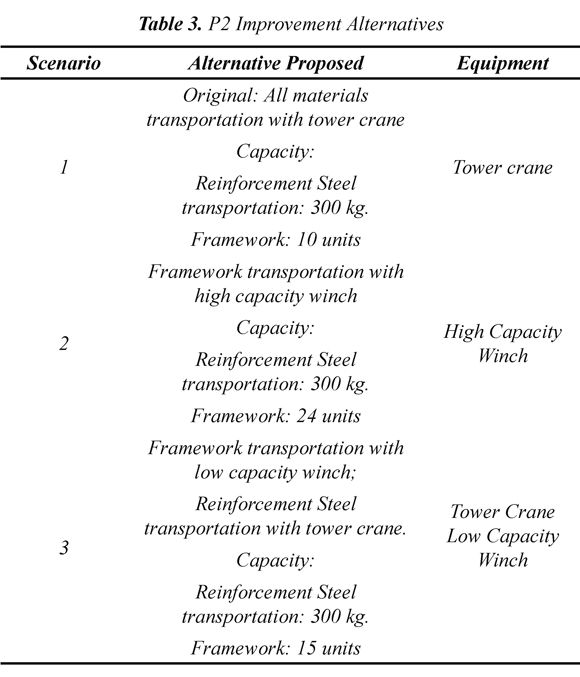

Theoretical scenarios were matched to improvement options identified for each model. That is to say, for P1, scenarios looked to increase human resources, implement new equipment, create a clear distribution for plant layout analysis and maximize tool/equipment transportation capacity. Moreover, these alternatives were combined to give rise to a total of thirteen (13) theoretical scenarios, which are depicted in Table 2. For P2, seeing as scenario's objective was to increase vertical material transportation capacity, cargo winches (with different characteristics) were suggested (see Table 3).

4. Analysis and discussion

Final analysis encompassed a comparison of total cost and total time spent on each of the theoretical scenarios proposed to the same aspects for the real scenario. Figure 7 displays this information. For reader clarity, the real scenario refers to how the project was actually carried out. Scenario comparison translated into identification of the use of a boom crane? to tackle soil buildup created by digging; doing so generated a time and cost optimization of 33% (time) and 26% (cost) between simulated and real scenarios for P1. Employing a pump for concrete transportation not only decreased amount of resources needed, but also lowered costs by 15% on average. However, personnel increases did not see parallel significant reductions in time; instead, it led to cost increases of approximately 26%. In the same way, factors such as increasing equipment and tool capacity for transportation, and implementing a defined route for the these items, contributed a roughly 20% time reduction, yet, in some cases, the increased resources and implementation of a footbridge as a new route saw costs jump approximately 17%. In sum, the cost of their integration into the construction process outweighs the time reduction they proffer.

For P2, Figure 8 displays the results obtained for the proposed scenarios (with scenario 1 the original scenario, i.e. how the project was developed). In this graphic, a reduction in time is observed, but it was accompanied by higher costs. As a form of complementary analysis, a comprehensive scenario comparison was performed, with results showing that turning to winches for vertical cargo transportation reduced the time variable by 25% on average. However, this equipment cannot be used to transport steel given safety regulations. Thus, on account of the fact that rental costs in this case would skyrocket around 33%, this option should not be considered an efficient alternative.

5. Conclusions

Taken together, a workflow based on the characterization of the processes studied and field data collection afforded the identification of the different variables within the workflow itself, in addition to the interrelation of these variables within the overall process.

The use of data observed in situ for discrete event simulation models has an advantage over other planning methods insofar as the real data enhance reliability (compared to data obtained from commercial databases).

Discrete event simulation allows for visual analysis of the behavior presented by all variables affecting the material transportation process. Thus, it facilitates the identification of losses, such as inefficient means of transportation, route interference and ill-conceived routes, insufficient human resources and under-utilized tools and/or equipment.

With the analysis of theoretical scenarios, assets and drawbacks of results obtained via simulation can be compared to the real scenario. Conducting this type of analysis means decision makers are furnished with the information necessary to identify the best "cost-benefit" scenario.

For concrete and excavation by product transportation (shown in scenarios 3 and 9 for the caisson construction model (P1)-the use of a boom crane and pump leads to improvements evidenced by 33% and 16% savings in cost and time, respectively.

The proposed personnel increase for the caisson construction model (P1) represents the greatest jump in costs, compared to the rest of the proposed scenarios (37% increase for personnel versus 5% for other improvement proposal). More than anything, this evinces that human resources are the variable exercising the greatest influence on costs.

After evaluating cost and duration (time) in the proposed scenarios, for P2 (the structure), the real scenario turns out to be the best scenario (material transportation is carried out by means of a tower crane). For P1 (caisson), scenario 3 proves ideal; said scenario involves the introduction of new equipment, expansion of existing equipment capacity and definition of transportation routes.

The adoption of tools such as simulation in the planning stage of construction projects entails greater initial investment and prolonged planning duration. However, these factors allow responsible parties to reap rewards such as increased productivity. In other industries, benefits of this nature have been shown to outweigh incurring higher initial investment costs. In this particular case study, scenario analysis could lead to savings approaching 30%, which is a representative of savings to be had in the construction sector.

6. References

Abourizk, S., Haddad, Z., & Elsersy, A. (2013). A discrete event simulation model of asphalt paving operations. In, Winter Simulation Conference 2013 (pp. 3215-3224). Washington, USA. [ Links ]

Ballesteros, L. (1998). Estudios de productividad basados en tecnologias de disgnostico y simulación digital. Tesis de Magister, Departamento de Ingenieria Civil y Ambiental, Universidad de los Andes, Bogotá D.C., Colombia. [ Links ]

Banks, J. (2005). Discrete Event Simulation (4 ed.) New Jersey, USA: Pearson Prentice Hall. [ Links ]

Botero, L. F. (2005). Construcción sin pérdidas (2 ed.) Bogotá, Colombia: Legis. [ Links ]

Céspedes, J. D. (2010). Mejoramiento de la Productividad en Construcción: Time-Lapse y Simulación Digital como Herramientas de Análisis. Tesis de Maestría, Departamento de Ingeniería Civil y Ambiental, Universidad de los Andes, Bogotá D.C., Colombia. [ Links ]

Echeverry, D., Páez, H., & Mesa, H. (2008). Simulación digital de procesos de construcción de estructura en concreto: casos de estudio práctico en Bogotá. Revista Ingeniería de Construcción, 23 (2), 64-71. [ Links ]

Fabregas, A., Wadnipar, R., Paternina, C., Mancilla, A. (2003). Simulación de sistemas productivos con Arena. Barranquilla, Colombia: Ediciones Uninorte. [ Links ]

Gómez, A. (2010). Simulación de Procesos Constructivos. Revista Ingeniería de Construcción, 25 (1), 121-141. [ Links ]

Gómez, A., Echeverry, J., Giraldo, M., Otalora, C., & Cano, M. (2012). Mejoramiento de procesos constructivos a partir de un módulo programable de captura de imágenes y simulación digital. Revista Ingeniería de Construcción, 27 (2), 35-53. [ Links ]

Gómez, M. R., & Correa, E. A. (2011). Análisis del transporte y distribución de materiales de construcción utilizando simulación discreta en 3D. Boletín Ciencias de la Tierra, 1 (30), 39-52. [ Links ]

Halpin, D., & Riggs, L. (1992). Planning and analysis of construction operations. New York, USA: Wiley. [ Links ]

Labban, R., Li, H., Chan, N., Huang, T., Guo, H.L, Lu, W., & Skitmore, M. (2009). Optimizing construction planning schedules by virtual prototyping enabled resource analysis. Automation in construction, 18 (7), 912-918. [ Links ]

Li, H., Chan, N., Huang, T., Skitmore, M., & Yang, J. (2012). Virtual prototyping for planning bridge construction. Automation in construction, 27 (1), 1-10. [ Links ]

López, J. (1996). Control integral de calidad del concreto compactado con rodillo. Tesis de Magíster, Maestría en Ingeniería Civil, Departamento de Ingeniería Civil, Universidad de los Andes, Bogotá D.C., Colombia. [ Links ]

Martínez, J. (1996). STROBOSCOPE State and Resource Based Simulation of Construction Processes. 15/05/2015 http://www.cem.umich.edu/ [ Links ]

Navarro, L. (2001). Simulación Digital de Procesos Constructivos. Tesis de Magíster, Maestría en Ingeniería Civil, Departamento de Ingeniería Civil y Ambiental, Universidad de los Andes, Bogotá D.C., Colombia. [ Links ]

Ruiz, H., González, E., Martínez-Álvarez, F., & Monroy-Alvarado, G. (2011). Simulación: Conceptos y Evolución. XV Congreso Internacional de Investigación en Ciencias Administrativas (pp. 1-17). Veracruz, México: Universidad Veracruzana. [ Links ]

Revista Ingeniería y Competitividad por Universidad del Valle se encuentra bajo una licencia Creative Commons Reconocimiento - Debe reconocer adecuadamente la autoría, proporcionar un enlace a la licencia e indicar si se han realizado cambios. Puede hacerlo de cualquier manera razonable, pero no de una manera que sugiera que tiene el apoyo del licenciador o lo recibe por el uso que hace.