Introduction

Self-compacting concrete (SCC) is a streaming solid blend that can self-unite under its own weight. The profoundly liquid nature of SCC makes installing it under troublesome conditions and in areas with congested reinforcement a reasonable endeavor. The utilization of SCC can likewise limit hearing-related harms on the worksite that are due to the vibration of concrete. Another favorable feature of SCC is that the time required to install enormous segments is significantly diminished. Earlier, in order to increase the strength and durability of the structure, cracks were repaired using epoxy injection or latex treatment or by giving extra reinforcement to the structure during the design phase to ensure that the crack width stayed within permissible limits. The primary motivation to prevent cracks or limit crack width is to upgrade the durability of the structure. Crack propagation can be restricted by including steel fiber into the concrete. Throughout the last three decades, noteworthy research has been conducted to analyze the effect of steel fibers as a fortifying framework on mechanical properties and impact resistance. Steel fibers overcome any issues between the nearby surfaces of existing micro-cracks, defer split development (Siddique et al., 2016), and cut off break spread by diminishing the broken tip opening removal. This component is known as the spanning instrument. The vitality ingestion and the effect on the quality of cement can be furthered by the expansion of steel fiber (Wasim and Ehsan, 2016). Be that as it may, the expansion of steel fiber in high measure has the potential drawback of poor functionality and expanded expense (Ning et al., 2015). Moreover, the use of micro-silica greatly influences and improves the bonding of the transition zone between the cement paste and the total aggregate since it consists of ultra-fine particles (Jeevetha et al., 2014) and increases the bond strength. In addition, the use of silica fume significantly improves the holding said transition zone (Koksal et al., 2008) and expands the bond quality between concrete glue and the total mix by densifying the interfacial zone (WSDOT FOP for ASTM C1621/C1621M). Due to pozzolanic movement, the mechanical qualities of the solid (Tasdemir and Bayramov, 2002) are improved. Another economic strategy could be a process that fixes break in solid and implies self-healing. This would expand the sturdiness of the structure. Microbiologically prompted calcite precipitation (Falguni and Darshika, 2016) is profoundly attractive given the fact that it is common and does not pollute. Appropriate selection of bacteria and dosage (Ghosh et al., 2010; Jonkers et al., 2010) must be ensured. Thus, incorporating these two techniques into steel fiber in concrete to minimize crack propagation (Sivakumar and Santhanam, 2007) would also improve tensile property (Tomaz, 2013; Nuruddin et al., 2014), and, in particular, the technique involving the incorporation of bacteria for crack healing (Naveen and Sivakamasundari, 2016) would improve the overall properties and the durability of SCC. A micro-structure of concrete with an addition of bacteria was visualized by scanning electron microscopy (SEM).

Material properties

In this study, the ingredients of bacteria-enriched steel fiber reinforced SCC, namely Ordinary Portland cement (OPC), and cement-replacement materials acted as binders in the mixes, while manufactured sand was used as the fine aggregate. In addition, a superplasticizer based on polycarboxylate ether (PCE) was used (BASF MasterGlenium ACE 30IT); it is a second-generation superplasticizer for concrete that provides self-compacting abilities. Steel fiber was used in the mixes to give better ductility.

Binders

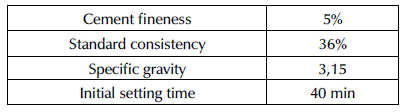

In this experimental work, OPC53 was used. Its main characteristics are shown in Table 1:

Micro-silica is a fine pozzolanic material made out of undefined silica created by electric band heaters as a side-effect of the creation of basic silicon or ferro-silicon amalgams. It consists of spherical particles. Individual micro-silica particles have a diameter of less than 1 urn, which is approximately 1/100 of the size of an average cement particle. Its main field of application is as a pozzolanic material for high-performance concrete. Micro-silica can also be used in a variety of products such as grouts and mortars. The specific gravity of micro-silica is 2,21, its pack density 0,76 gm/cc, and its moisture 0,059%. It also has a white-colored, powdered appearance.

Bacteria

The microscopic organisms Bacillus subtilis, strain no. JC3, a soil bacterium refined in a research facility, was used for this research. An unadulterated culture was gathered from the Department of Agricultural Microbiology, College of Horticulture, Kerala Agricultural University, Vellanikkara, Thrissur. On a supplement agar plate, provinces of strain JC3 were round, raised, smooth, and translucent. The size of a settlement may reach up to 2-3 mm width after 24 h of hatching in dim, oxygen-consuming conditions at 37 °C. The life form delivered a pale blue green color that diffused into the medium. Singular cells of JC3 were Gram-positive, oval to poles, 0,6-0,8 um wide, 2,0 to 3,0 um long, motile, and duplicated by double parting. SEM was performed to recognize the precipitation in concrete.

Steel fiber

Loose snare finished steel fiber was utilized. It has more significant adaptability with all Portland concretes and admixtures. It additionally gives an even circulation in the blend and improves mechanical jetty, as well as the micro-crack mechanism, impact resistance, flexural strength, and fatigue strength of concrete. 50- and 30-mm length fibers with a diameter of 0,6 mm and tensile strength of 1100 MPa were used (aspect ratio 50). All the fibers were manufactured from high-strength steel. Specimens incorporated with 0,51,5% of steel fiber are shown in Figure 1 by volume fraction.

Calcium lactate

Calcium lactate is a dark or white crystalline salt generated by the activity of lactic corrosive on calcium carbonate. It is used for nourishment (as a fixing in heating powder) and given restoratively. It is made by the response of lactic corrosive to calcium carbonate or calcium hydroxide. The expansion builds the nearness of calcium in concrete. Only the fuse of calcium lactate did not generously influence quality (curation of 3 and 7 days) or even brought about a slight increment (curation of 28 days) in compressive strength values (Henk et al., 2010).

Fine and coarse aggregate

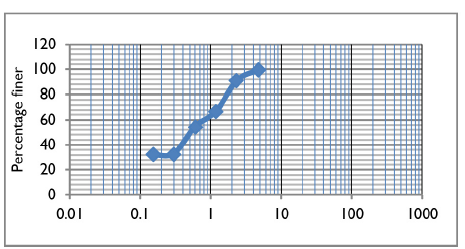

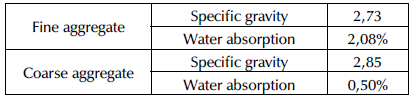

Manufactured sand (M-sand) is a better substitute for river sand because it has no silt or organic impurities and is mostly well graded. It was used in this project to cast the concrete. A fine aggregate of less than 4,75 mm was used. Coarse aggregates are commonly considered to be inert fillers. Their various properties play an important role in the strength, shape and texture, size gradation, moisture content, specific gravity, reactivity, soundness, bulk density, workability, and durability of concrete. Coarse aggregates of 12,5 mm and 6 mm in size were used for casting in a 60:40 ratio. The properties of aggregates used are shown in Table 3 and the sieve curve in Figure 2.

Specimen preparation

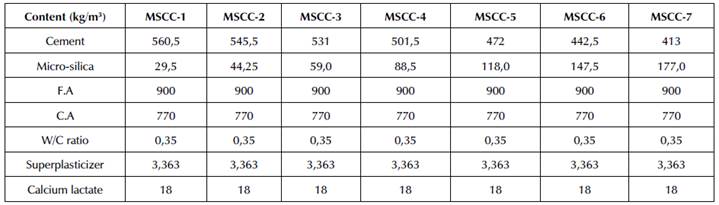

The sizes of the concrete cube and cylinder are 150 x 150 x 150 and 100 x 300 mm, respectively. These two were used to test compressive and split tensile strength. The M40 grade concrete mix design was carried out as per the European standards for SCC (EFNARC, 2002). A W/C ratio of 0,35 was used. The reinforced beam size used for testing flexural strength was 150 x 150 x 700 mm, and advanced shafts of microscopic organisms were thrown. 8 mm reinforcement bars were used for stirrups, distribution, and main bars. Micro-silica was included by swapping the measure of concrete for an ideal fixation from 0 to 30%, with various groupings of steel filaments (0, 0,5, 1, and 1,5% of the total volume). The fortified shafts with microscopic organisms were cast and relieved for 28 days. Miniaturized-scale silica was included by incomplete substitution of concrete at convergences of 0, 5, 7,5, 10, 20, 25, and 30%. The concrete cubes, the cylinders with and without bacteria, and the steel fibers were casted and cured for 28 days.

Mixing procedures

The mixing proportions of SCC reinforced with bacteria-enriched steel fiber are shown in Table 4. An electric concrete mixer was employed, and the binders and sand were mixed for 2 min, followed by pouring 50% of the total mix in water and then mixed again for 3 min. Next, 40% of water and 70% of SP were poured and then mixed for 5 min. Subsequently, the remaining water and SP were added and mixed until a uniform mix was achieved. Finally, the steel fibers were dispersed evenly to prevent fiber balling and mixed for 2 min.

Workability tests

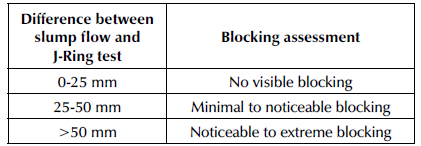

In order to ensure the self-compacting abilities of the mix for on-site quality control, two test methods are sufficient to monitor the production quality. These tests yield results regarding two distinguished properties: flow ability and passing ability. Two workability tests were selected (slump flow and J-Ring) and conducted immediately after the mix was completed. The procedures of the tests were performed in accordance with BS EN 12350:2010 (BSI Standards, 2010). The acceptance criteria of self-compacting abilities in a slump flow test are a minimum diameter of 650 mm and maximum of 800 mm. The blocking assessment was determined using ASTM C1621/C1621M (Okamura and Ouchi, 2003), as shown in in Table 5.

Mechanical tests

Two mechanical tests were conducted to compare the control mix and the DSCC mixes with various cement-replacement materials. Compressive strength tests were performed at 7 and 28 days, while flexural quality tests were conducted at 28 days. The testing methods of both the compressive and flexural quality tests are in accordance with IS 516:1959 (Reaffirmed 2004) (Bureau of Indian Standards, 2004).

Ultra-sonic pulse velocity

The methodology includes estimating the time it takes for an ultrasonic heartbeat to go through the solid under study. A relatively higher speed is acquired when the solid quality is acceptable in terms of thickness, consistency, and homogeneity, among others. The values for the beams were taken before and after the flexural test. The velocity was also measured 28 days after the flexural testing, which gave an idea about the healing.

Results and discussion

Micro-silica-based SCC

The mineral admixture micro-silica was employed as the concrete substitution material. Small-scale silica gives a progressively uniform dissemination and a more prominent volume of hydration items. As a channel, it diminishes the normal size of pores in the concrete glue. Smaller-scale silica is an exceptionally fine material with less explicit gravity than concrete, so it does not increase the density of concrete.

Workability

A slump flow test was conducted to evaluate the flat free stream without impediments. It is the most generally utilized test, and it gives a decent appraisal of the filling capacity. It gives no sign of the solid's ability to go between support without blocking, but it may give some sign of protection from isolation. The passing capabilities of SCC are measured by utilizing the J-Ring test in a mix with a droop cone form. The test strategy is restricted to concrete with a total size of 25 mm at most.

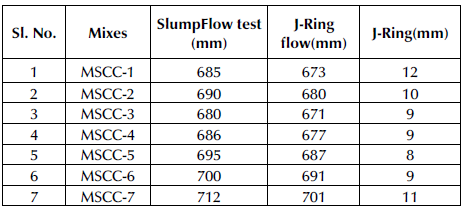

A highly flowable concrete does not simply have to do with prime point compacting, since SCC ought to stream under its own load as well as filling the whole frame and accomplishing a uniform consolidation without segregation. The superplasticizer content is kept constant as the binder content remains constant. The workability is determined using standard tests such as flow table testing and the J-Ring test, which are shown in Figure 3. The results are shown in Table 6.

The obtained results fall under the range of 650 to 800 mm, which is recommended by EFNARC (2002). A visual inspection showed that the SCC had a good cohesion, so, from the workability results and the aforementioned inspection, the mix can be said to be an SCC. The results show that the increase in the addition of micro-silica causes the increase in the slump value. The circular molded particles of micro-silica go about as a smaller-than-expected metal roller inside the SCC blend, which prompts the improvement of the functionality of cement.

Miniaturized-scale silica also fundamentally lessens draining, given that the free water is spent in wetting the enormous micro-silica surface. Therefore, the free water left in the blend for draining was unexpectedly depleted. The expansion of smaller-scale silica in a blend modifies the concrete glue structure. The resulting paste contains a greater amount of the solid calcium-silicate hydrates and less of the feeble and effectively solvent calcium hydroxides than the common concrete glues. The miniaturized-scale silica particles are very little, and they scatter to cause the partition of the concrete particles. The upside of utilizing miniaturized-scale silica is that it very well may be considered to diminish the warm splitting brought about by the warmth of concrete hydration. It also results in the improvement of durability.

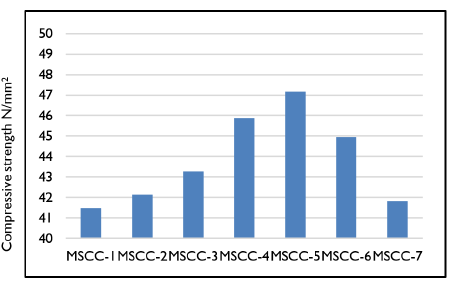

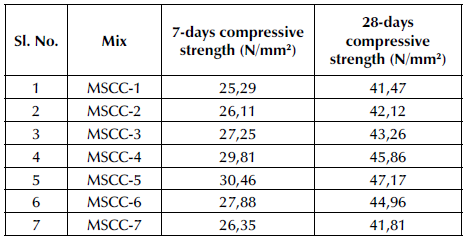

Compressive strength

A compressive strength test was conducted on concrete specimens, cubes of Mix40 SCC, with micro-silica as a fractional substitution of cement. 150 mm cubes were used for the testing. Since it is a pozzolanic material, micro-silica improves the complete paste bond and enhances the bonding properties at the interface between the fiber and the network with a thick C-S-H gel in the strengthened self-compacting mixtures. The acquired outcomes are shown in Table 7, and a graphical representation is given in Figure 4.

The SCC mixes made with micro-silica showed a strength above 40 N/mm2, which may suggest a medium-quality cement. According to the results, the ideal measure of micro-silica that can be utilized as a concrete substitution in SCC is 20%. The improvement in mechanical properties improves the roots from the expansion of fine micro-silica to the concrete solid lattice, as well as the pozzolanic responses between the micro-silica and the free calcium hydroxide in the concrete matrix.

The compressive strength is improved as the average size of pores in the concrete matrix decreases due to the fineness of micro-silica. Hence, further studies should be carried out with this optimum amount of micro-silica.

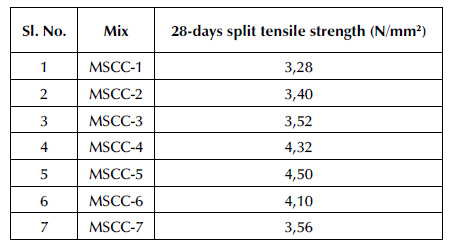

Split tensile strength

The tensile strength of concrete is one of its essential and most significant properties. The solid is exceptionally frail under tractable power given its fragile nature, and it is not made to oppose immediate pressure. Concrete breaks when exposed to malleable powers. Thus, it is important to decide the tensile strength of concrete in order to determine the heap at which concrete members may crack.

The inclusion of micro-silica as a replacement of cement shows a slight increase in the split tensile strength throughout the variation in a definitive manner. However, there is no significant reduction in strength with an increase in the micro-silica content of up to MSCC-5 and a 20% addition of micro-silica. Beyond 20%, there is a decrease in split tensile strength.

The test results regarding compressive strength, split tensile strength, and workability show that the optimum micro silica content is observed to be 20%, i.e., MSCC-5. Further studies should focus on SCC specimens with this optimum content of micro-silica. The split tensile strengths of different micro-silica-based SCCs are shown in Table 8.

Bacteria-enriched self-compacting concrete

The MSCC-5 showed better workability and strength parameters. Self-healing of concrete is achieved by incorporating Bacillus subtilis in SCC. Microcracks of up to 0,2mm wide are autogenously recuperated because of the hydration of non-responded concrete particles present in the grid, which interact with entering water. The mending process based on microscopic organisms has been found to feasibly recuperate up to 0,5 mm. A control mix was made with micro-silica (20% cement), a constant amount of Bacillus subtilis, and a constant amount of calcium lactate. Steel fiber and a constant amount of bacteria were added to the SCC containing a replacement of 20% cement with micro-silica.

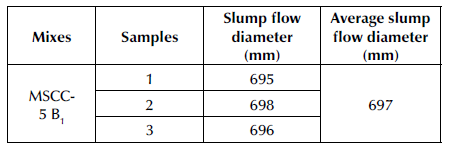

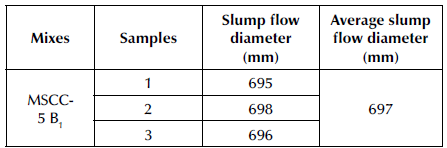

A constant amount of Bacillus subtilis, 105 cells per mL of water, was added into the mix containing an optimum quantity of micro-silica, MSCC-5. The mix was labeled as MSCC-5 B1, which is the SCC mix containing 20% micro-silica as cement replacement and 105 cells per mL of water. Workability and mechanical strength tests were carried out. The SCC mix MSCC-5 B1 was taken as the control mix for further comparative studies.

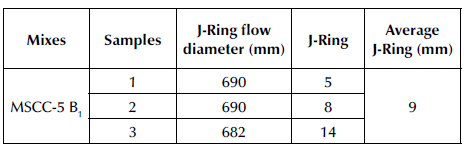

Workability

Workability tests on bacteria-enriched SCC were carried out as per BS EN 12350:2010 (BSI Standards, 2010). Acceptance criteria regarding self-compacting abilities in the slump flow test were a minimum diameter of 650 mm and a maximum of 800 mm. The blocking assessment was performed using ASTM C1621/C1621M-17 (ASTM International, 2017). Flow table and J-Ring tests showed no significant changes compared to MSCC-5. The MSCC-5 B1 mix is a cohesive mix with less resistance to passing through the J-Ring. As the mix contains 20% of micro-silica, the effect of bleeding is reduced due to the large surface area. Hence, the bacteria seem to have no significant effect on the flow characteristics of SCC. The results are shown in Tables 9 and 10.

Compressive strength

The compressive strength of microorganism-enhanced SCC was evaluated by pounding to the decimation of the test shapes using methods for compression testing machines in accordance with IS 516:1959 (Reaffirmed 2004) (Bureau of Indian Standards, 2004). The observed results are shown in Table 11.

The results show that by the addition of Bacillus subtilis to MSCC-5 yields an increase of about 3,5% in compressive strength. Direct incorporation of bacteria also showed an increase in the compressive strength of concrete. This is due to the reduction in micropores by the calcite deposition of bacteria, which makes the concrete matrix more compact. The bacteria converts the calcium lactate into calcium carbonate crystals, which are not soluble in water. As the micro-silica takes up most of the micro pores due to its extreme fineness, there is only a slight increase in compressive strength due to the addition of Bacillus subtilis.

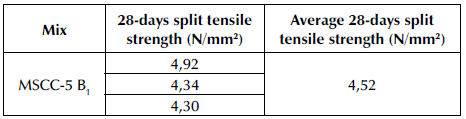

Split tensile strength

Split tensile strength testing was carried out on bacteria-enriched SCC. From the results shown in Table 12, only a very slight increase in the tensile strength of MSCC-5 was observed. Therefore, in general, it can be concluded that there is no significant variation in tensile strength from the parenting mix, MSCC-5. The results suggest that Bacillus subtilis has no effect on improvement or any adverse effect in the tensile strength of mix.

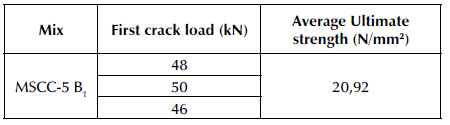

Flexural strength

The flexural strength test was carried out in accordance with IS 516:1959 (Reaffirmed 2004) (Bureau of Indian Standards, 2004) on 700 mm long concrete beams with a 150 x 150 mm cross-section. During testing, the first crack loads were noted. It was observed that the crack width was wider (greater than 2 mm). Multiple cracks were more rarely noticed. MSCC-5 B1 mixes possess a good flexural strength. The results show that bacteria enriched self-compacting concrete, as shown in Table 13 and Figure 5.

Bacteria-enriched SFRSCC

Bacteria-enriched SCC satisfies the requirements and has good mechanical properties. The crack width observed during the flexural strength testing highlights the need for limiting. The healing of SCC with the help of calcite-precipitating bacteria is effective up to 0,5 mm. The crack propagation and formation can be limited by incorporating fibers into SCC. In further experimental study, hook-ended steel fibers shall be incorporated into SCC enriched with bacteria. Steel fiber bridges the gap between surfaces, thus reducing crack width and ensuring an effective healing of SCC. The presence of steel fiber can affect the workability of the mix, even though it improves the split tensile strength, flexural strength, and ductile behavior of concrete.

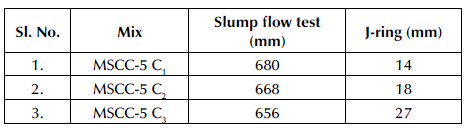

Workability

The workability of bacteria-enriched steel fiber reinforced self-compacting concrete (SFRSCC) was tested regarding passing capabilities and flowability. Different volumes of steel fibers were added to SCC containing the aforementioned optimum amount of micro silica. The SCC mixes MSCC-5 C1, MSCC-5 C2, and MSCC-5 C3 contain 0,5, 1, and 1,5% volumes of steel fiber, respectively. Workability is affected by the presence of steel fiber and micro silica. In essence, the spherical shape of micro silica improves the workability of SCC, but the presence of steel fiber hinders it. The J-Ring test results on bacteria-enriched SFRSCC shows that the MSCC-5 C1 and MSCC-5 C2 mixes have no visible blocking, as they were within the range of 0-25 mm. However, MSCC-5 C3 showed minimal to noticeable blocking, as it was above 25 mm. Table 14 shows the workability of bacteria-enriched SFRSCC.

Hook-end steel fibers cause sticking of the solid lattice all through the stream, which is dependent on steel fiber volume. As the volume of steel fibre increases, workability decreases. The filling ability of bacteria-enriched SFRSCC decreases with an increase in the concentration of steel fibre. The passing capabilities test also showed an impact caused by the increase in steel fibers. Bacteria-enriched SFRSCC mixes with lower steel fiber content are suitable to be used as self-compacting concrete.

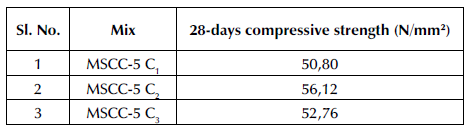

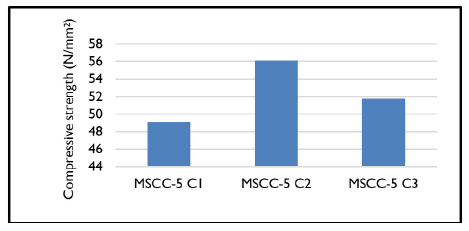

Compressive strength

Compressive strength testing was conducted on SFRSCC, and the obtained results are shown in Table 15. Graphical representation of compressive strength is shown in Figure 6.

Due to its metabolic activity, Bacillus subtilis converts calcium lactate into calcium carbonates. The fine calcite also fills up the pores and densifies the SFRSCC, which in turn increases the compressive strength. The results of the compressive strength and workability tests show that MSCC-5 C2 becomes progressively better in comparison with different blends with various rates of steel fiber expansion. This improvement is a direct result of the nearness of calcite creating microbes in the blend. This calcium carbonate constantly produced by the microbes and calcium lactate as an organic nutrient makes the interior structure of solid progressively conservative, which brings about an improvement in compressive strength.

From the results, it can be noted that the compressive strength values declined beyond MSCC-5 C2 (1% of steel fiber), and that a further increase in steel content reduces the compressive strength. Steel fiber overcomes any barrier between adjoining surfaces of existing microcracks, thus causing imprisonment in the network. This builds up the break shutting powers, which invigorates an expansion of the compressive strength. The presence of pozzolanic material also results in a significant improvement for SFRSCC. There is a decrease in the strength of SCC made with 1,5% steel fiber (MSCC-5 C3), which is due to the increase in the entrapped air in the concrete, which decreases the compressive strength. An increase in the steel fiber volume increases the porosity, as the distribution is not uniform and the matrix contains regions of only fiber.

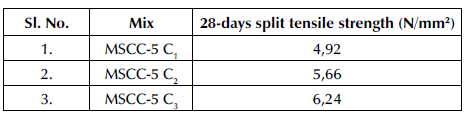

Split tensile strength

The tensile strength is one of the basic and most important properties to be improved in concrete. Table 16 shows the results of split tensile strength testing.

The addition of steel fiber resulted in an increase in split tensile strength. Because of the bridging action of steel fibers, the increase in the fiber content in the reinforced SCC mixtures showed improved results.

The spanning activity of reused steel fiber captured the split from further opening, and numerous breaks were thus shaped in the samples. Prior research likewise reported an increased rigidity in fortified SCC brought about by steel fibers.

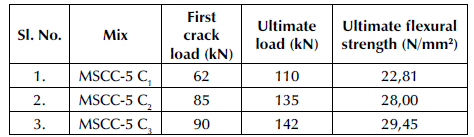

Flexural strength

Two-points flexural strength testing of the self-compacting concrete mixes was conducted at 28 days. The reinforced beams containing steel fiber were coated with a whitewash to facilitate the identification of cracks during loading. During testing, the load at which the first crack visible was noted. The flexural strength test was carried out in accordance with IS 516:1959 (Reaffirmed 2004) (Bureau of Indian Standards, 2004) on concrete beams 700 mm long and with a 150 x 150 mm cross-section. The results are shown in Table 17.

As seen in Table 17, bacteria-enriched SFRSCC shows an enhanced flexural strength with an increased percentage of steel fiber volume by total volume. However, increasing the fiber content decreases the flexural stiffness, while the ultimate load carrying capacity and its corresponding deflection increases. The maximum flexural strength was 29,45 N/mm2 (142 kN) for 1,5% of steel fiber (MSCC-5 C3), which represents a 40% increase compared to the MSCC-5 B1 mix. By comparing the results with bacteria-enriched SCC (MSCC-5 B1), it is seen that the improvement in flexural behavior is due to the presence to steel fiber.

The flexural strength of concrete depends on the steel fiber volume and the aspect ratio of the fiber. With the increase in aspect ratio and volume of steel fiber, the flexural strength was improved. The bond between fiber and concrete, obtained by using hooked-end steel fibers, increased the flexural strength. The random distribution of steel fiber into self-compacting concrete, which controls the cracks and bridges them, resulted in an increased load carrying capacity for the beam. However, on considering the results of bacteria-enriched SFRSCC specimens in fresh and hardened state, MSCC-5 C2 shows good workability and higher compressive strength than other mixes. MSCC-5 C2 showed a 19% increase in compressive strength than MSCC-5 and a 15% increase compared to MSCC-5 B1.

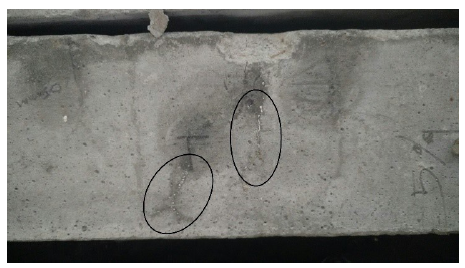

Visual inspection and discussion

By closely observing the beams after 28 days, the fact that the cracks were measured at less than 0,5 mm in width shows proper sealing of the cracks. Beyond 0,5 mm, the healing of concrete was rarer, even though white precipitates were seen on the inner surfaces. The majority of cracks between 0,1 and 0,2 mm wide were sealed off with calcium precipitate. The beams can take up more loads without forming many cracks because of the steel fiber content. A 10% increase over the first cracks showed more crack width, which were therefore not easy to heal. The first crack load and its 10% increment showed less crack width, thus facilitating healing (Figure 7).

Next, the structure of calcium carbonate-based minerals after the bacterial metabolic transformation of calcium lactate is presented, as indicated by the accompanying response:

The yield of calcium carbonate-based minerals increases when CO2 molecules react with portlandite (Ca(OH)2) minerals, which are quantitatively huge hydration aftereffects of solid particles:

The last response is homologous to carbonation, a moderate procedure that normally happens in concrete because of the internal dissemination of environmental carbon dioxide, whose rate is considerably increased by the metabolic transformation of calcium lactate. Microscopic organisms in addition to calcium lactate intervene in the creation of plentiful measures of 20-80 um-sized mineral-like accelerates on break surfaces of young, 7-days cured concrete stone specimens (Henk et al., 2010).

Ultrasonic pulse velocity

An ultrasonic pulse velocity (UPV) test was conducted on the beams containing 0,5, 1 and 1,5% of steel fibers before and after being loaded for cracking, as well as after 56 days. The results gave an idea of the porosity of the concrete specimens. Cracked concrete specimens showed that waves took longer to travel than in the same concrete specimens before cracking. It was seen that, with the irregular distribution of steel fibers, the velocity of the SCC blends diminished due to more voids in the blends with steel strands than in the control blend. This reduction may be due to the fact that the steel fibers are arranged arbitrarily, and, when the waves go through the fibers, they do not travel in a straight line forward to the opposite end. The concrete specimen after 28 days showed less time for the passage of waves in comparison with the cracked beam before 56 days. ASTM C597-16 (ASTM International, 2016a) and IS 13311(part 1)-1992 (Bureau of Indian Standards, 1992) categorize the results as excellent, good, doubtful, poor, and very poor for >4,5, 3,5-4,5, 3-3,5, 2-3, and <2 km/s, respectively. All the specimens under study fell under the good and excellent categories.

The UPV test results suggest that, at the age of 28 days, the bacteria-enriched SFRSCC shows traces of healing. Nevertheless, the uncracked areas in concrete were found to be much stronger than cracked parts. Even the white deposits in the cracks can be seen, as shown in Figure 5, and cracks below 0,5 mm wide are being sealed. Thus, the steel fibers take up more load and delay the formation, propagation, and width of cracks, which implies good conditions for bacteria-based healing.

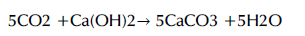

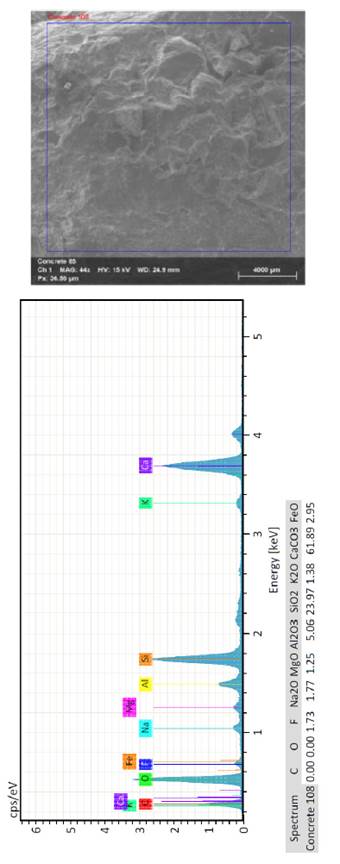

SEM and EDS

Scanning electron microscopy (SEM) was used to recognize the morphology of the materials inside the breaks. Figure 8 shows the SEM analysis of a bacteria-enriched concrete specimen.

These tests are generally conducted at a micro-scale in order to identify and characterize the materials deposited within the concrete cracks after self-healing. SEM analysis is carried out as per the guidelines of ASTM C1723-16 (ASTM International, 2016b) for examination of hardened concrete using SEM. This maximizes the reliability of the results obtained. The SEM shows the magnified image of calcite precipitation in concrete. The white color seen in Figures 8a and b is due to the lighting effect, which causes charging current. Those Figures are the magnified images of the powdered specimen. Figures 8c and d show the calcite precipitation in a solid specimen less than 1 x 1 x 0,5 cm in size.

EDS is directly related to SEM; it shows the elements and chemicals present in the sample. The EDS was studied as per the guidelines of ASTM E1508-12a (ASTM International, 2019). The SEM images shown in Figure 9 correspond to the area of the specimen where the EDS was studied. The EDS test was conducted to determine the presence of calcite and silicate in the solid specimen. The EDS results shown in Table 8 show the elemental presence of silicon and calcium.

The presence of silicon indicates that the specimen contains silicate (SiO2) which proves the presence of micro-silica and cement. The presence of calcium is an indication of calcite compounds. The quantification of chemical compounds in the sample using EDS showed that the presence of calcite is about 61,89%. The silicate compound contained in the specimen was about 23,97%. Hence, on combining the SEM and EDS results, the presence of calcite is confirmed, so bacteria-based healing in self-compacting concrete is practical and effective.

Conclusions

This study showed that the mineral admixture and self-healing agent added to SCC resulted in a considerable increase in compressive strength. Next, some concluding remarks are presented:

SCC with partial replacement material of cement has a slump in the range of 650-800 mm. Workability increases with the increase in micro-silica, which is due to the spherical nature of micro-silica particles. A visual examination of the mix proves that it has good cohesion. Thus, the mix satisfies all criteria for a SCC.

The quantity of micro-silica added to SCC varied from 5 to 30% of cement weight. All seven mixes showed good workability and were within the permissible range. The compressive strength of all mixes was above 41 N/ mm2. The improvement in strength is clearly due to the fineness and the pozzolanic behavior of micro-silica. As micro-silica is the 1/100th size of cement, the average pore size is minimized, as it fills the pores and makes the SCC more compact.

SCC with 20% micro-silica replacement of cement showed better workability and strength. The MSCC-5 mix is therefore taken as the optimum mix.

The bacteria-enriched self-compacting concrete mixes fulfilled the SCC requirements. MSCC-5 B1 showed a good workability of 697 mm (the range is 650-800 mm). MSCC-5 B1 did not show a significant change in the values of the slump flow and J-Ring tests. Hence, it can be concluded that the bacteria have no significant effect in the workability of SCC. The visual observation of mixes shows the mix has good cohesion.

Bacteria contribute to increasing the compressive strength of SCC. There was a 3,6% increase in the compressive strength of bacteria-enriched SCC in comparison with MSCC-5.

The bacteria-enriched SFRSCC mixes fulfilled the requirements of self-compacting concrete while showing a good workability, but the increase in steel fiber content caused the workability to decrease. The MSCC-5 C3 mix showed little blocking, and its J-Ring value was 27 mm. This shows that the passing ability of bacteria-enriched SFRSCC is affected by adding 1,5% of steel fiber.

As the steel fiber content increases in bacteria-enriched SFRSCC, the porosity increases. The increase in compressive strength is also due to calcite precipitation in the pores of fresh mixes, which densifies the matrix.

MSCC-5 C2 has an effective performance, a compressive strength of 56,12 N/mm2, and an ultimate strength of 28 N/mm2. When the fiber content increases beyond 1%, it has more and more entrapped air. In other words, the porosity increases, which, in turn, affects the strength.

The flexural strength increases with the increase of steel fiber content. A maximum value of 29,45 N/mm2 was recorded for 1,5% of steel fiber content, which is 40% more than MSCC-5 B1. Flexural strength depends on the fiber content and the aspect ratio of the fiber. The increase is due to the bonding between aggregate-paste and fiber-matrix. Micro-silica enhances the interface of aggregate-paste.

The UPV results show an increase in the time value for the cracked SFRSCC, which is due to the increase in the gap and the reflection effect by steel fiber. The UPV results after water curing the cracked specimens suggest that the crack is healed upon aging.

Visual examination showed white deposits over cracks even at the age of 28 days (calcite crystals are white-colored). After 56 days, the specimens loaded with an initial crack load and 10 and 20% increments showed evidence of crack healing. Cracks less than 1 mm wide are effectively healed.

As bacteria-based healing is more effective up to 0,5 mm. The bacteria enriched SCC shows wider cracks, which delays the healing process, whereas bacteria-containing SFRSCC has less crack width because of the bridging action of steel fiber. The first cracks and those due to the 10% load increment are effectively healed. As the first crack load of bacteria-enriched SFRSCC is far more than that of bacteria-enriched SCC, the former is better in terms of durability and ductile property.

SEM images showed the presence of calcite crystals in the specimens. Similar images are seen in the literature. The presence of calcite compounds was confirmed by the EDS test results, which showed calcium and silicon ions.

Bacteria-enriched SFRSCC is more efficient than normal self-compacting and self-healing concrete, as steel fiber helps in taking up more load without much cracking, thus favoring an effective environment for bacteria-based healing.

Bacteria-enriched SCC and steel fiber reinforced SCC are practical in its concepts, with good strength and workability compared to normal SCC. Bacteria-enriched SFRSCC has better strength and healing characteristics than bacteria enriched SCC.