Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

DYNA

versão impressa ISSN 0012-7353

Dyna rev.fac.nac.minas vol.80 no.182 Medellín nov./dez. 2013

A METHODOLOGY FOR KNOWLEDGE MODELING OF FAULT DIAGNOSIS BASED ON PETRI NETS

UNA METODOLOGÍA PARA MODELAR EL CONOCIMIENTO DEL DIAGNÓSTICO DE FALLAS BASADA EN LAS REDES DE PETRI

JUAN PALACIO BETANCUR

M.Sc., National University of Colombia Medellín Campus, jepalaciob@unal.edu.co

GERMÁN ZAPATA MADRIGAL

PhD. Profesor Asociado, National University of Colombia Medellín Campus, gdzapata@unal.edu.co

LUIS MARÍN GÓMEZ

P.Eng., EMGESA S.A. ESP Electric Division, Colombia. lmarin@endesacolombia.com.co

JOSE IVÁN VELÁSQUEZ

P.Eng., EMGESA S.A. ESP Electric Division, Colombia. jvelazqu@endesacolombia.com.co

Received for review August 5th, 2012, accepted July 6th, 2013, final version August, 8th, 2013

ABSTRACT: This paper presents a methodology for knowledge survey and modeling. The methodology aims to make an expert system for fault diagnosis and solution. The methodology comprises a plant system definition, information and knowledge sources, and knowledge models. This is done to guide the operators' behavior and the plant personnel in contingency situations.

KEYWORDS: fault clearing, fault diagnosis, knowledge modeling, expert systems, Petri nets.

RESUMEN: Se presenta una metodología para el levantamiento y modelado del conocimiento con el fin de realizar un sistema experto para el diagnóstico y despeje de fallas. Esta consta de la definición de los sistemas de la planta, las fuentes de información y conocimiento, y finalmente los modelos del conocimiento. Todo con el fin de guiar el comportamiento de los operadores y el personal de la planta en situaciones de contingencia.

PALABRAS CLAVE: Despeje de fallas, diagnóstico de fallas, modelamiento del conocimiento, sistemas expertos, redes de Petri.

1. INTRODUCTION

In highly complex systems, due to their scope or the many signals required to control and supervise the processes that the systems perform, faults that cause the plant to operate in a degraded state or force it to shut down are common. If the necessary knowledge were available in an organized and timely manner, the operating and maintenance personnel could quickly and safely solve the problem, avoiding penalties and other inconveniences for the company, including machine shut downs or damages that could have been prevented with timely intervention.

A tool is thus necessary that gives the personnel at these plants access to a guide for diagnosing and restoring faults that can be treated quickly.

This problem is solved by implementing an expert system for fault diagnosis, in which the plant's personnel could change the rules as new knowledge is acquired or equipment is replaced. To make an expert system, it is necessary to create a knowledge collecting and modeling process, which is used in an inference engine.

This knowledge collection and modeling process is the objective of this article, which presents a methodology based on Petri nets that allows knowledge modeling for diagnosing and solution of faults. This methodology arises from the experience obtained creating the diagnostic system for the El Paraíso hydraulic power plant owned by EMGESA S.A. E.S.P.

This work first shows the theoretical framework that shows the rationale for creating the proposed expert system. Marked Petri nets, which are the formal modeling tools considered, are then presented. Next, the methodology is presented with model examples. And finally, a validation case is presented.

2. THEORETICAL FRAMEWORK

According to Peña [1] expert systems (ES), also called knowledge-based systems, are used to replace tasks that only expert personnel could previously perform. A previous study from Uraikul [2] indicates that the expert systems are software systems that can capture human experience to provide support for decision-making or for recording using a symbolic representation, such as graphs, neural networks, rules, among others [3]. The most common expert system application in control processes is for fault diagnosis.

Mora [4] affirms that when handling knowledge-based systems, it is important to exploit all possible information sources, as they can have errors or inconsistencies. Using the available models is thus recommended rather than creating a system completely based on knowledge.

In the electric power system, the decisions made in contingencies are based not only on the plant manuals and drawings but also on the experiences of the people in charge taken into account. In other study Feng [5] suggests that diagnosing faults in power systems can be resolved using knowledge-based systems or ES.

Angeli [6] affirms that expert systems have great relevance in fault diagnosis because they can simulate human reasoning when handling a problem and can solve problems using heuristic rules.

It is necessary to consider that errors are inherently human according to Reason [7]. From the human perspective, unsafe actions occur for two reasons: errors and procedural violations. To reduce these errors, the natural thing is thus to reduce the variability in human behavior. Starting from the perspective that human conditions (e.g., negligence, forgetfulness, lack of knowledge) cannot be changed, however, it is possible to change the conditions under which humans work.

The above, added to the necessity of solving the present problem in the plant as quickly as possible during contingencies, promotes implementing expert systems that help guide and supervise the safe solution of faults.

This work presents a methodology for creating knowledge and modeling based on Petri nets to build an application that serves as a guide for operators of large production plants.

In this proposal, Petri nets (PNs) are used as modeling tools that are the most complete knowledge modeling tools according to Tavana [8] and Chaudhury [9]. Other tools like knowledge trees do not allow modeling the dynamic characteristics of sequential systems, conflicts, concurrences, synchronisms, or place fusions. PNs can also be used as a single tool to host the knowledge base and inference engine, facilitating their validation and any required changes.

3. MARKED PETRI NETS

The tasks that the maintenance and operation personnel perform in a plant can be seen as a set of discrete event systems (DES). PN systems, which are mathematical and graphical tools that allow us to model, simulate, and control discrete events, are thus used. The PNs represent a modeling tool independent of any technology and are clear, easy to use, and unambiguous according to Silva [10]

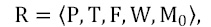

A PN can be presented as a tuple with the form  Where:

Where:

Set of system places.

Set of system places. Set of all transitions.

Set of all transitions. Set of arcs.

Set of arcs. Function of weight of arcs.

Function of weight of arcs. Function of initial marking. In addition,

Function of initial marking. In addition,  represents the number of tokens in place.

represents the number of tokens in place.  .

.

The evolution (dynamic behavior) of an independent PN depends on the transition enabling. A transition t is enabled, i.e., it can be fired, if before t:

Marking after firing transition tj is determined by the equation:

4. METHODOLOGY

To create an ES in a plant with all kinds of personnel, including some with experience, others with less experience, personnel with different types of knowledge, some who are reluctant towards automation, and all with little time, it is necessary to organize the work using a methodology that drives the project to completion.

We next present the methodology to generate an expert system for fault diagnosis and reducing human diagnostic errors. This has been implemented to create an ES for the company EMGESA S.A. ESP and helped the fault diagnosis process in a hydroelectric power plant. The steps discussed include the following: define the system, understand the system, define information sources, define knowledge sources, plan and perform interviews of multiple system users and controllers, contrast the knowledge with information sources, and knowledge modeling, as shown in fig. 1.

If the plant is already divided into systems when a severity analysis is performed, it is possible to begin with the critical systems. If such an analysis is not available, the plant experts' judgment should be used because it is important to first aim for the system with the greatest impact.

A clear and complete division is important because the knowledge model clarity depends on clear system delimitations.

4.1. Understand the system

To intervene, it is necessary to have a vast knowledge of the system in question. This includes the function of the system within the production plant and the components and their functions. It is also necessary to clarify the principles that determine their behavior.

Part of the knowledge can be from the statistics about fault causes and the elements with more susceptibility to wear. The ones with the highest failure rates are those for which the ES should specialize and for which the operation and maintenance personnel should receive additional training.

4.2. Define information Sources

The information sources are software, measurement, control and protection equipment, and other digital resources that can help make real-time decisions.

These can include monitoring systems, event logs, protection systems, and supervisory systems. To include these systems, it is necessary to verify that they are trustworthy and instrumentable.

4.3. Define knowledge sources

The knowledge sources are people or documents that can be used to create the knowledge base.

Starting from the knowledge sources, the process PNs should be created. It is thus important to have enough knowledge sources to be able to contrast the data.

The sources can include process engineers, operators, maintenance personnel, and procedure manuals.

4.4. Plan and perform interviews with multiple system users and controllers

Knowledge from the plant personnel is distributed among multiple people, i.e., the operation personnel have global and sequential knowledge. They know when the equipment can start functioning. In these interviews, one must be balanced; although the users and controllers coexist with the plant, they can also lack knowledge about transient states. When these interviews are developed, one should end up with a basic knowledge of the system being examined. The purpose is to obtain a basic group of failure modes.

Knowledge that is more specific exists; the technical maintenance personnel own this knowledge. There should be two restrictions to the information provided in these interviews. First, due to the technical maintenance personnel knowledge, they may perform non-standard operations, e.g., leaving equipment unprotected. Second, these personnel have generally spent a long time in the plant, so their knowledge is based on experience. Also it can be difficult for them to give up valuable information. With the information obtained from these interviews, the information already possessed should be specialized and filtered. The number of failure modes should increase, and the solutions to each failure mode should expand.

The plant engineers also possess knowledge. This knowledge is not specific but rather more analytical, as they are more likely to consult manuals and plans. It is thus necessary to compare the information previously obtained to the reality at the plant. This is the last group of interviews, and they should provide full knowledge of the plant and failure modes as well as the solution for each mode.

4.5. Contrasting knowledge and information sources

At this moment, a lot of information on the failure modes and their solution is available, though there can always be contradictions between multiple knowledge sources. It is thus necessary to go to manuals, plans, and maintenance plans where different resolutions can be found.

4.6. Knowledge modeling

With clear information, the knowledge should be systematized as Tecuci [11] and Queck [12] say. This work is based on the PNs described above because fault diagnosis and its clearing during the operation are sequences of discrete events. This topic is elaborated below. This is the last step and becomes the source material for the computing tool that reads the nets and guides the personnel to clear the fault in the system.

5. KNOWLEDGE MODELING

As mentioned in the theoretical framework, a PN is the most complete knowledge modeling tool and is thus used in this work.

The PN-Editor has been designed to work with PNs and give the flexibility needed so future experts can modify or add rules to models [13].

PN places contain elements of user or information source interactions: there are messages to the users, buttons that the tool has, signals to be acquired, and diagnosis results. At the same time, the transition marks the evolution of the net using the markings in the places. The arc thus shows the information flux between the different steps and actors in the diagnosis.

For model clarity and to facilitate the automation process, it is necessary to label places because they can have multiple interpretations. The labels seek to represent the element with which each place interacts, as in Table 1.

The nets of the models should start from the most general and progress to the most specific. In the diagnostic process in the hydroelectric plant, the trigger of the fault model is a signal from the fault announcer, which aggregates many faults. With the help of the event logger and other instrumented signals, it also investigates the problem until it detects the fault.

A diagnosis path case of a stator and a transformer in a hydropower plant is shown in Fig. 2. The place descriptions are found in Table 2.

This is the knowledge model for identifying if a fault was caused by: an internal damage to the power transformer, or a single phase ground fault. These represent only a few alternatives within this failure mode, and all options are not presented for purposes of illustration and good understanding of the model.

In some cases, it is not possible to have instrumentation. Buttons are used in such cases to allow the possibility of a user deciding the route. Fig. 3 shows this example, in which the Verify tension is presented at the Show place, and the user must report what was found.

6. VALIDATION CASE

This methodology was applied in a plant from company EMGESA, and the validation test and the results are presented below.

6.1. Validation test

Models for different functional faults were made. These were added to software that was developed in the same context of this methodology, as presented by Arboleda and others in [14].

The software is called SIDIF (from the Spanish "Software de diagnóstico de fallas"). It works like the knowledge engine and graphical interface with operator. Its functions are shown in Fig. 4.

Then, using SIDIF a methodology validation plan was structured, in which it was necessary to simulate fault conditions in power plant. For it two tools were used. The first was the induction of fault signals from the fault source, i.e. if fault signal is from a relay; output contacts are shorted to simulate the short. The second was by connecting an OPC which could simulate the system signals that for reasons of safety and operation of the plant, it was not possible to induce. The outline of this assembly is the one shown in Fig. 5.

SIDIF and the methodology were tested by means of contrasting fault diagnosis results with and without system. Metrics that were proposed were: Completion time and accurate diagnosis (yes/no).

Three tests were designed in which the fault had to been found and isolated by the operation group. Each test was more complicated than the previous. The experiment was accomplished under controlled conditions of locked rotor to avoid emergency stop due to induced signals. The operation group were given the entire tools and conditions they would have in case of a contingency.

6.2. Results

Test results without SIDIF are presented in Table 3 and Table 4 corresponds to the other case.

Considering progressive complexity level between tests, the results can be interpreted as follows:

- In the development of fault diagnostics which require basic knowledge, usage of the knowledge model is unnecessary as the personnel has the required capacity for finding the fault cause quickly. The time difference between the two tests scenarios are due to delays implicit in using a software tool.

- As tests increase in complexity, operator knowledge begins to be insufficient to resolve the contingencies. It is in these cases where the use of the tool that interprets knowledge models is important to get the right analysis and fault diagnosis.

7. CONCLUSIONS

This paper presents a methodology to obtain models of an expert system for diagnosing faults using Petri nets. Using Petri nets allows one to have a single tool for the knowledge base and inference engine.

For finding fault causes, the methodology is based on deterministic rules. For this reason, emphasis is placed on making a complete survey of all branches within the fault modes in order to not cause uncertainties in the diagnosis process. A future work may be the inclusion of indeterministic tools such as stochastic Petri nets and fuzzy logic in order to cover the branches not taken into account during the process of obtaining knowledge.

The implementation of a system such SIDIF, that is based on the methodology presented in this paper, implies an improvement in the personnel capability to react to failures, giving flexibility and accuracy in decision-making in high pressure moments.

In the search for references in the development of the work, information was found on modeling tools and their possibility of use for fault diagnosis. However, there were no developments found such as the one presented in this paper.

When knowledge is available for diagnosing faults and modeled using a formal tool like Petri nets, the fear that people in an organization will leave and take their knowledge with them can be reduced. This methodology can be used for topics like diagnosis, but it can also be used for any other need that occurs in the company, e.g., a plant procedure guide.

8. ACKNOWLEDGEMENTS

The content of this work is a product of the research activities developed by EMGESA. S.A. E.S.P and the National University of Colombia - Medellin Campus, in the framework of the research project "Automatic diagnosis of faults in EMGESA's hydroelectric power plants", a project financed by COLCIENCIAS. We thank these entities for their support in developing this project.

REFERENCES

[1] Peña-Ayala, A., Sistemas basados en Conocimiento: Una Base para su Concepción y Desarrollo [PhD Thesis]. México: Instituto Politécnico Nacional, 2006. [ Links ]

[2] Uraikul, V., Chan,C. W. and Tontiwachwuthikul, P., Artificial intelligence for monitoring and supervisory control of process systems, Engineering Applications of Artificial Intelligence, vol. 20(2), pp. 115-131, 2007. [ Links ]

[3] Gutiérrez, S. A. and Branch, J. W., A Comparison Between Expert Systems and Autonomic Computing Plus Mobile Agent Approaches for Fault Management., Dyna, vol. 78 (168), pp. 173-181, 2011. [ Links ]

[4] Mora, J. J., Localización de faltas en sistemas de distribución de energía eléctrica usando métodos basados en el modelo y métodos basados en el conocimiento [PhD Thesis]. España: Universitat de Girona. Departament d'Electrònica, Informàtica i Automàtica, 2006. [ Links ]

[5] Feng, J. Q., WU, Q. H. and Fitch, J., An ontology for knowledge representation in power systems," control 2004, University of Bath, UK, 2004. [ Links ]

[6] Angeli, C., Diagnostic Expert Systems: From Expert's Knowledge to Real-Time Systems, Advanced knowledge based systems: model, applications & research, Eds. Sajja & Akerkar, vol. 1, pp. 50-73, 2010. [ Links ]

[7] Reason, J., Human error: models and management, BMJ, vol. 320, (7237), pp. 768 -770, Mar. 2000. [ Links ]

[8] Tavana, M., Knowledge-Based Expert System Development and Validation with Petri Nets, Journal Of Information And Knowledge Management, vol. 7(1), P. 37, 2008. [ Links ]

[9] Chaudhury, A., Marinescu, D. C. and Whinston, A., Net-based computational models of knowledge-processing systems, IEEE Expert DOI - 10.1109/64.207432, vol. 8(2), pp. 79-86, 1993. [ Links ]

[10] Silva, M., Las Redes De Petri En La Automática Y La Informática. AC, 1985. [ Links ]

[11] Tecuci, G., Steps Toward Automating Knowledge Acquisition for Expert Systems, in Proceedings of the AAAI-91 workshop, 1991. [ Links ]

[12] Queck, C., NG, P. W. and Pasquier, M., Integrated Process Supervision: A Structured Approach to Expert Control, in Proceedings of the 7th Portuguese Conference on Artificial Intelligence: Progress in Artificial Intelligence, 1995, pp. 323-334. [ Links ]

[13] Zapata, G., Automatización del Conocimiento para Diagnóstico Automático de Fallas en Centrales de Generación Hidráulica mediante Redes de Petri., presented at the XI Latin American Robotics Competition & Colombian Conference on Automatic Control & II Industry Applications Society Colombian Workshop - IEEE LARS - LARC & CCAC 2011, Bogotá, 2011. [ Links ]

[14] Arboleda, A., Zapata, G., Velásquez, J. and Marín, L., Software for Fault Diagnosis Using Knowledge Models in Petri Nets, Dyna, vol. 79(173), pp. 96-103, 2012. [ Links ]