1. Introduction

The cocoa or cacao (Theobroma Cacao L) is a tropical tree native to humid climate of Central and South America [1], 1999) and one of the main ingredients of chocolate [2]. Studies have shown that the consumption of cocoa products has a positive effect on health, mainly attributed to the high antioxidant activity present in cocoa [3]. The cultivation of cacao in Brazil started initially near the Amazon in 16th century [4], later extended to the southern region of Bahia, in 18th century [5]. This region became the world’s largest cocoa producing area, after Côte d’Ivoire [6]. Even before the crisis that damaged the cacao cultivation in Brazil during the 1980s [7] and its development in Malaysia (in the 1980s), Indonesia (1990s) and in African countries, America South remains a considerable volume of world production of cocoa [8,9]. The cocoa beans production estimates for the period 2013-2014 indicate a production of 210.000 tons of cocoa beans, corresponding to 4.8% of world production [10].

Cocoa cultivars production coming from the Brazilian territory began in the 1940s with the arising of the first industries [6]. In the 80s, based on government’s incentives and the increase in cocoa prices on the worldwide market, this sector received large investments and Brazil has become one of the leading cocoa processors in the world [8]. Multinational companies such as Cargill, ADM and Barry Callebaut dominate the cocoa processing in Brazil and in the world, reaching about 75% of world production process [12].

The cocoa liquor solidification process is influenced by several factors which can further have interactions. The final effect of the process is observed in the physical state of the cocoa liquor, represented by its final temperature. Due to the complexity of the effects caused by these factors and their interactions in the cocoa liquor solidification process there is a need to analyze the processing system to establish a standardized production with reduced waste and improved quality in the production process as well as various studies recorded in others area [12,13]. Therefore, this study aims to optimize the factors that influence the processing of cocoa cultivars during solidification of liquor. Studies on improving the processing of agricultural products are important for improving the economic viability and competitiveness of the activities related to farming [14]. Therefore, a design of experiments (DOE) was proposed in random blocks with split plot system (split-plot), factorial 23 and three repeated measurements. A DOE consists in a series of tests which measure the factors of a process to observe and identify possible changes in process response variable [15,16]. Experimental methods are widely used in the research area, such as: optimization the screw conveyor dryer [17]; influence of cocoa butter in the refining by carbon dioxide [18]; optimize the process variables for blended nectar based upon papaya (Carica papaya) [19]; the quality of the chocolate milk [20], among others.

2. Cocoa processing

The processing of cocoa almonds starts in farms, after the harvest, the seeds are removed from the fruit, stacked and covered with banana leaves to suffer a natural fermentation and subsequently subjected to a drying process. This step will ensure the preservation of the physical and chemical characteristics, organoleptic and qualitative [21], and is an important stage in the development of chocolate flavor precursors [22]. After the initial processing of the cocoa at the farms it begins its processing in the industry.

Historically, the cocoa processing industry was divided into two filaments: the ‘traditional’ grinding line and the chocolate manufacture. The traditional grinding line, focus of this work, is specialized in roasting and grinding of the cocoa seeds into a liquid paste, and successive pressing of this cocoa liquor into cocoa cake and cocoa butter. Meanwhile, the chocolate manufacture is directed in chocolate production based on ‘dedicated’ cocoa liquors mixed with additional cocoa butter, sugar and other ingredients [11].

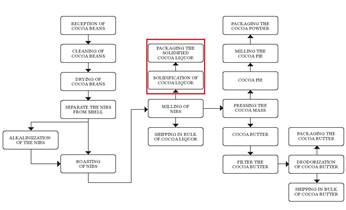

The process steps of cocoa almond beneficiation performed in the traditional grinding line industry is illustrated in Fig. 1. Off the cocoa seeds received in the industry, about 84% is converted into “nibs”, the remainder (16%) are impurities, moisture and shelled. Before the fermentation and roasting of cocoa seeds are obtained the “nibs”, which correspond to clean kernels obtained after the removal of the shell [23]. Then there is the grinding of "nibs" to production of sub products, such as cocoa butter, cocoa powder and cocoa liquor [24].

Cocoa liquor is sold in two ways: in bulk, shipped in tankers or packed in paper bags. The cocoa liquor packaged in paper bags must be cooled until it reaches a solid state. The cocoa processing industries have difficulty in this cooling step, this process is considered a constraint to increased productivity. Furthermore, there is a serious loss of production volume at this stage due to off-specification product, more specifically the liquor unsolidified. These losses result in reduced productivity and increased production costs due to the need to rework the material.

3. Materials and methods

This DOE study was conducted in a cocoa processing industry, located in the city of Ilhéus, Bahia, located in the geographic coordinates 14º47’20’’ south latitude and 39º02’5’’ west longitude, the average altitude of 52m. According to the climatic classification of Köppen-Geiger, the climate is humid with hot summer in the Cfa group, with a mean annual temperature of 24 °C and average relative humidity of the air greater than 80%.

The cocoa liquor solidification process occurs through its cooling in heat exchangers and a solidification tunnel. A pump is responsible for moving the cocoa liquor from tanks to solidification tunnel. In this process, the liquor suffers his first cooling through two heat exchangers, called votators. These devices use a cooling system with cold water (4 °C), which exchange heat with the cocoa mass that is in an initial temperature between 42 °C and 45 °C. Then the liquor is sent to a treadmill directed to the cooling tunnel with indoor temperature between 5 °C and 8 °C. At the end of the cooling tunnel, the cocoa liquor should be in a solid state in order to allow packaging in the packaging paper. However, in cases which liquor is not cooled enough to reach a solid state to be packed and need to be reprocessed, results are losses in cocoa processing.

In the solidification process two different specifications of cocoa liquor are processed, according to its granulometry from different cocoa cultivars. The cocoa liquor specifications are called: natural refined (refined) and natural dense (dense).

3.1. Experimental methods

Information on the factors that influence product processing system was collected by the staff of operators involved in the production system. The main concern of operators is related to the physical condition of the quality of the final product aspect, in which the product must be completely solidified. It was observed the difficulty for operators in determining the settings of the process factors. In this setting, each operator, according to his experience, has different measures for adjusting the factors for the solidification of the cocoa liquor.

Operators identified seven different factors that could influence the process performance: (i) type of cocoa liquor; (ii) cocoa liquor temperature in the beginning of the process; (iii) pump flow rate; (iv) water temperature in votators; (v) opening the feeding nozzles; (vi) speed of the conveyor and (vii) temperature inside the tunnel. These factors, four of them, were considered to be noise factors: (i) temperature of the cocoa liquor in votators; (ii) the water temperature at votators; (iii) opening of the nozzle and (iv) internal temperature in the tunnel, because of the impossibility of changing the values of the levels of these factors during processing. This factor had their standard level during the experiment treatments. Three factors were measured for the experiment:

Cocoa Type: Natural refined cocoa liquor and natural dense cocoa liquor. Currently there is no difference between treatments for the different types of cocoa. It is expected by the professionals that this factor may affect the solidification process, as well as interact with others.

Pump Flow Rate: 45% and 60% of the power applied to the pump motor. If the pump flow rate is high there may be an increase in fluid pressure line, clogging of nozzles, and overcome the cooling capacity of the process.

Conveyor Speed Rate: 80% and 100% of the power applied to the mat engine. If the tunnel conveyor speed is high, the time of passage of the cocoa liquor by cooling tunnel will not be sufficient to solidify the liquor.

The response variable to be measured during the experiment is the solid state of cocoa liquor, measured from the product temperature at the exit of solidification tunnel. The recommended tool for the measurement of temperature is the thermometer, which uses a measurement system in accordance with EN 13485 (European Standards). The cocoa liquor cooled at 25 °C will achieve its solid state. The cocoa liquor cooled to a temperature below 25 °C results in slower processing and thereby reducing production capacity. The cocoa liquor cooled to a temperature greater than 25 °C results in the need for reprocessing the material, as it remains in its liquid state and preventing realize their packaging.

3.2. Statistical methods

The studied system of cocoa cultivars processing has a high complexity of setup time (conducting change) of the equipment depending on the type of processed cocoa liquor in the production of large batches (batch). The production of a type of liquor can occur for weeks. Because of this, the randomization of different types of cocoa liquor analyzed in the experiment is impracticable due to the impossibility of raw material exchange, production volume and cost. Therefore, a robust DOE in random blocks named split-plot experiment in a factorial arrangement 2³ was chosen [15].

This type of experimental project includes performing tests with each of the combinations of the experimental setup 23, three factors (type of cacao liquor, pump flow rate and conveyor speed rate) on two levels each, resulting in a block of eight experimental trials. The randomized blocks were replicated three times, for improved accuracy of the results, generating a total of 24 experiments. It was estimated the percentage of importance and influence coefficients of the factors in the averages temperatures in the final liquor solidification process. Statistical analyzes were performed at the program Minitab 17® [25].

4. Results and discussion

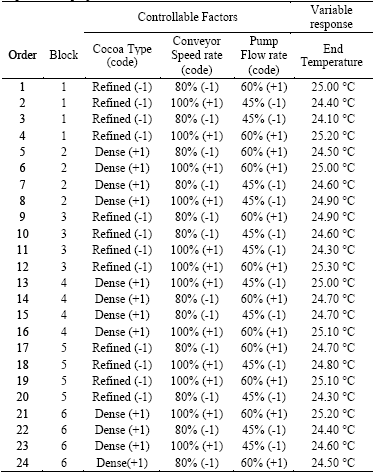

Data collection was performed on 09.23.2014 for the first block (natural refined liquor), and 09.30.2014 for the second block (natural dense liquor). For the implementation of the experiment, the entire processing system was controlled to experimental error and noise factors were considered controlled, and: (i) the temperature of the liquor in the votators in the range of 43°C to 45°C; (ii) the water temperature in votators is 4°C; (iii) the opening of the nozzles was standardized to a pressure of 5 atm (506,625 kPa); and (iv) the temperature inside the tunnel in the range of 4°C to 6°C. Table 1 shows the measurements of the experiment, with the randomized order of trials for blocks.

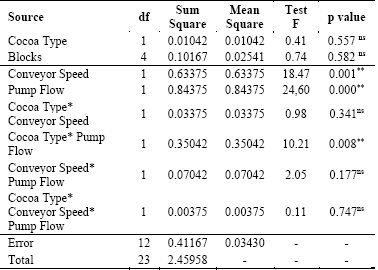

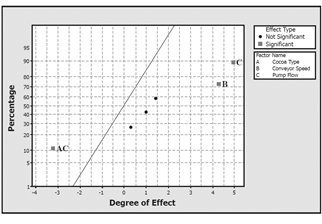

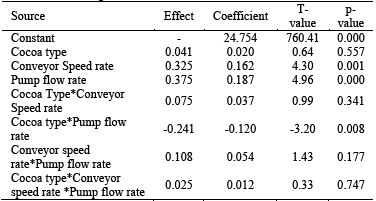

We can observe in the analysis of variance (ANOVA) that the factors conveyor speed rate, pump flow rate and the interaction cocoa type versus conveyor flow rate are statistically significant (p -value<0.01), showing an effect on the final temperature of the liquor. However, the effect of the type of cocoa liquor was not significant at the final temperature (p-value=0.557), as shown in Table 2.

The results indicate differences from the assumptions of process operators. These operators suggested that the density of the liquor of cocoa type (refined or dense) had effect on the solidification process. Overall, scientific research about the problem provides relevant grounds for breaking paradigms and opinions based on assumptions of the process operators.

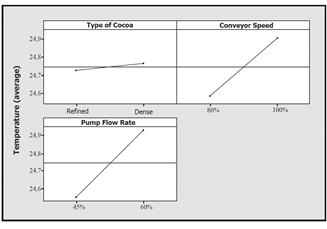

Fig. 3 shows average temperatures of the analyzed factors. This result indicates that there is a change in the final temperature when altered levels of the factors conveyor speed rate and pump flow rate, corroborating the results of analysis of variance (see Table 2). As the conveyor speed rate at a lower level, increases the liquor residence time in the cooling tunnel, the raw material (cocoa) is exposed to a lower temperature for a longer time, resulting in a lower final temperature, and higher solidification of cocoa.

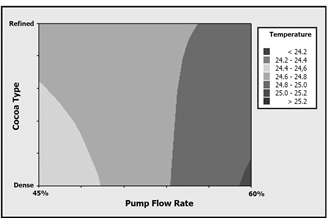

The results of variance analysis (Table 2) indicate that the interaction between the type of cocoa liquor and pump flow rate factors is significant at the 5% level (p-value=0.008) (Fig. 4). Although the factor of cocoa type (dense and refined) not directly affect the final temperature of liquor, its interaction with the pump flow rate is significant. With a lower level of the pump flow rate, the temperature of the refined type of cocoa liquor is less than dense type of cocoa liquor, but when the pump flow rate is changed to a higher level, the temperature of the refined of cocoa liquor becomes higher than the temperature of the dense of cocoa liquor.

It is observed that as the pump flow rate increases, a greater amount of product is inside of the cooling tunnel. Consequently, the temperature of the liquor is high due to a lower heat exchange. The interaction between other factors was not statistically significant: type of cocoa liquor versus conveyor speed rate (p-value = 0.341), conveyor speed rate versus pump flow rate (p-value =0.177) and type of cocoa versus conveyor speed rate versus pump flow rate (p-value=0.747). Fig. 5 illustrates the percentage of importance and the effect level of all factors analyzed in the experiment. The factors “pump flow rate” and “conveyor speed rate” has positive level of influence 4.95 and 4.25, respectively, and the interaction cocoa type versus pump flow rate has negative influence -3.20 for the solidification of cocoa cultivars.

The regression equation of the model for the analysis indicates an R square of 82.46%. This result indicates that this regression equation obtained in the analysis can account for 82.46% of the variability. The coefficients of the variables and their effect on the temperature are presented in Table 3.

By replacing all the coefficients in the regression model it is possible to estimate the temperature of the cocoa liquor to the end of the process. For refined Cocoa refined, all factors in high levels reach a final temperature of 25.66°C process temperature above 25°C recommended for the process. For the dense cocoa type, all factors in high level reach an average temperature of 25.46°C. This temperature is slightly lower due to the interaction between cocoa type and pump flow rate (p-value= 0.008). For both types of cocoa, all variables in high levels results in liquor not in solid state and in losses in cocoa processing. For the refined cocoa, the results recommend using one of the factors in low level. The conveyor speed rate in low level (80%) estimate a final temperature for the liquor of cacao refined of 24.99°C. For the pump flow rate in low level (45%) the results indicate a final temperature of 24.26°C for the liquor refined cacao. For the dense cacao liquor the results of the regression model also indicates to use at least one of the factors in low level. Using the low level of conveyor speed rate (80%), the estimated final temperature of the dense cocoa liquor at the end of the process is 24.39ºC and using low level of the pump flow rate (45%) the estimated final temperature is 24.98ºC.

5. Conclusions

This article aims to optimize the factors that influence the processing of cocoa cultivars during solidification of liquor. The utilization of an experimental design in random blocks with split plot system (split-plot) allows performing the experiment without harming the cocoa processing industry. This design of experiment can help the managers to improve the processing of agriculture commodities that are frequently produced in batches.

The results indicate that the type of cocoa liquor (refined or dense) present no significant difference in the final temperature of the solidification process. It was identified the interaction between the type of cocoa liquor and the pump flow rate (p-value=0.008), indicating higher levels of pump flow increased more the temperature of the refined type of cocoa liquor then the cocoa dense type. The factors “pump flow rate” and “conveyor speed” were identified as the most crucial for the final temperature of cocoa liquor in the end of cooling process. The regression model estimates that the use of factors "pump flow rate" and "conveyor speed" at high levels results in final temperatures above 25 °C for refined or dense cocoa liquor. For both type of cocoa liquor, the regression model estimates that the use of at least one of the factors in low level resulting at the temperature below 25 ºC. The type of split-plot experiment allowed identify appropriate levels for each of the investigated factors that affecting the solidification of cocoa liquor, as well as better understand of the factors that constitute the cocoa processing system.