1. Introduction

The civil construction is thought to be one of the most productive industries for the economic and social development of a region. However, environmental impacts resulting from the consumption of natural resources or the generation of waste are a contemporary problem, and there must be a balance among them, as a way of not compromising environmental sustainability [1].

The introduction of new materials in civil construction led to relevant technological advances, especially with the increased use of plastic materials. Civil construction supply chain accounts for 20% of plastic material consumed in the world, being the second most important industry, after packaging [2]. Taking into account that part of such consumption is transformed into waste in urban areas, the relevance of civil construction is considerable. Thus, studies to reuse these materials or other waste in components of building products or systems are needed.

A viable alternative to incorporate polymeric waste is to use it for lightweight concrete, which, besides not overloading structures, has mechanical impact properties in flooring systems and consequent impact sound reduction in the lower pavement [3,4].

The use of polymeric waste in cementitious composites is the object of researches whose focus restricts to properties regarding the use as a fiber; however, the incorporated quantity is reduced, if compared to the use of polymer in the form of grains or aggregates. [5] complement that the disadvantage of adding polymers to cementitious matrixes is that it represents a reduction of mechanical properties and an increase of the elasticity module, leading to more deformations. Nonetheless, it presents an improvement in thermal insulation and in acoustic performance [4]. Recent results also point out the need of new studies to assess granular polymeric waste incorporated to cementitious-base matrixes.

It is known that the use of ethylene vinyl acetate (EVA) in concrete, as a substitute to the use of conventional aggregates, brings air incorporation through the component own porosity. [6] states this solution turns into an efficient method to provide concrete with acoustic insulation.

EVA is one of the main inputs in the leather-footwear industry, used to produce soles for shoes. This material is supplied in reduced thickness boards and variable widths. For footwear production these boards are cut off, which generates leftovers, leading to disposal costs for the company that generated the waste and also to environmental impacts.

The Brazilian civil construction industry is adapting to ABNT NBR 15575: 2013 [7]- Performance Standard. Such normative specifies, through qualitative requirements and quantitative criteria, the acoustic, thermal & structural performance, durability and fire resistance requirements, among others. The sector investigates alternatives to comply with acoustic performance requirements for buildings, with competitive solutions that allow for the proper disposal of waste coming from other industries.

In this scenario, added to the need of using polymeric waste, the goal of this study is to analyze different EVA solid ratios and grain sizes in the development of lightweight concrete subfloor slabs, in order to mitigate the impact sound in flooring systems, with two types of replacements, one with the coarse aggregate replacement and the other with total replacement, both of coarse and fine aggregate.

2. Insulation impact sound in floors

Polymers may be defined as substances composed of macromolecules formed out of the same structural unit, called monomer, repeated several times, and connected among them covalently [8]. The EVA polymer is composed of a high technology mix of ethyl, vinyl and acetate, with the mechanical behavior of an elastomer, and reversible elongation in a long strip of deformation at room temperature [1].

The insulation of impact sound in overlapping rooms receives an efficient treatment through floating floors, composed of a resilient base among two rigid plates, floor slab and coating. These flooring systems use resonance and damping concepts to reduce vibration in the rigid base and increase the acoustic insulation [9], and this principle is broadly used in independent layers systems. However, this same principle can also be met with the incorporation of resilient materials in cementitious mixes. According to [10], materials used for this purposes are based on polymers, which allow broad reuse and recycling possibilities.

These materials promote a mass reduction in flooring systems and are susceptible to deformations, which may lead to changes in the damping capacity over time. This approach was investigated by [11], who found differences in the mechanical impact damping capacity, with high damping losses in fibrous materials in open-cell materials, comparatively to closed-cell materials. Besides, [12] points out that different types of resilient materials used in vibration damping show different behaviors due to sound frequency, such as cork, cork-based composites, felt, polymeric foams and elastomers, which may be used in the form of liners or plates, in high frequencies, for which the static deflections are reduced.

All of these materials have part of their elasticity determined by the way the air behaves when the material is compressed. Low density, open-cell materials may have deformations due to permanent compression, besides presenting wear and tear problems in the coating joints. On the other hand, closed-cell materials show a pneumatic effect caused by air contained in its interior [11,13].

According to [15], the use of resilient bases in buildings has certain specificities, when compared to the use in isolated equipment. Impact sound insulation must provide bases that are rigid enough to assure stability during the use of flooring system; however, they will have their insulation capacity reduced when compared to softer materials. Thus, acoustic and mechanical properties for these materials must be equally considered [13].

In this sense, studies proposing compounds with cement, natural aggregate and/or light aggregates have been designed to characterize and analyze the technical viability of different types of mixes. Differences caused by a higher water absorption in lightweight aggregates are indicated as the main concern in the proposal of new cementitious materials and more specific tests to characterize these aggregates are still in a discussion [15] Especially for the use in flooring systems with concrete slab, studies about the influence of lightweight aggregates porosity [15, 16], the type of light aggregate used [17,18], and of polymeric waste grain size [4]; indicate that the adequate characterization of these aggregates may determine the control on the flooring system acoustic performance regarding impact sound.

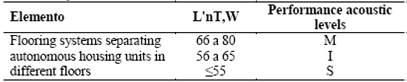

Concerning flooring systems requirements, ABNT NBR 15575 (2013) [7] sets performance acoustic levels, as minimum (M), intermediary (I) and superior (S), according to Table 1. These requirements must be met in all housing buildings.

3. Experimental program

The experimental program included the aggregates characterization, concrete dosage, subfloor slabs molding and the impact sound test, with two types of replacement of natural aggregates for EVA. In the first stage, natural coarse aggregates (crushed stone) were replaced for EVA in the mix, in the equivalent grain size. In the second stage, the coarse aggregates replacement was maintained, besides partially (50%) replacing fine aggregates (sand) for EVA. The experimental program does not include mechanical tests, because the material developed is used only as a non-structural coating.

3.1. Materials characterization

3.1.1. Cement

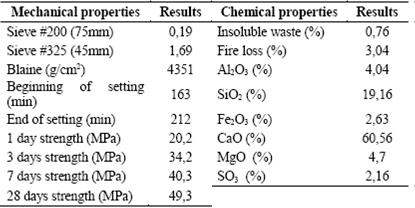

It was chosen to use high initial resistance cement, whose values of strength, beginning and end of setting and waste retained in the #75μm sieve are in compliance with thresholds set forth by Standard [19] and are presented on Table 2

3.1.2. Fine aggregates

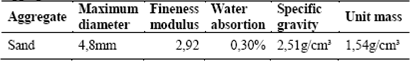

The sand used as fine aggregate shows characteristics featured on Table 3.

3.1.3. EVA aggregates

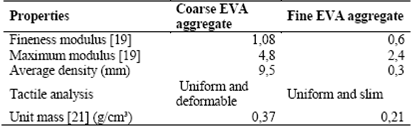

It was carried out coarse and fine EVA aggregates characterization for dimensional, tactile, particle size distribution and unit mass analyzes. Results obtained in the materials characterization are presented on Table 4.

3.2. Slabs dosage and thickness

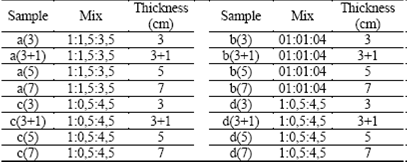

For the comparative analyzes of lightweight concrete and thickness, three mixes in volume were carried out (cement: fine aggregate: EVA coarse aggregate): ‘a’, ‘b’ and ‘c’. In mix ‘d’, it was counted on a higher use of EVA aggregates, considering there was also a partial replacement (50%) of fine aggregate for EVA of similar grain size. For each unit mix three levels of subfloor slab thickness were defined, being that for the 3cm-thickness slab, a 1cm conventional mortar coating was tested, simulating finishing. Dosage is shown on Table 5.

It must be observed that the proportion between aggregates and cement is always the same, 1:5. EVA fine and coarse aggregate ratio varies from one mix to another. . Mixes ‘c’ and ‘d’ are those with the highest coarse aggregate ratio, which tends to create hollow spaces among the elements, once the quantity of sand used is not enough to fill the space among bigger aggregates. The difference between unit mixes ‘c’ and ‘d’ is that, in the former the fine aggregate is river sand, while in the latter there was a partial replacement (50%) of it for EVA crushed small aggregate.

3.3. Slabs molding and impact sound test

A variable height mold was used to manufacture the slabs, for the application of pressure in the four extremities of the set, through the use of threaded bars, nut and washer. For the execution of slabs with 1cm of coating, initially mortared coating was laid and later the filling with lightweight concrete was performed. After concreting, the slabs were taken out of the mold, then 24h of curing and sent to an air-conditioned room with a 23 +/- 2°C temperature and 100% of relative humidity, until the date set for the acoustic test (28 days).

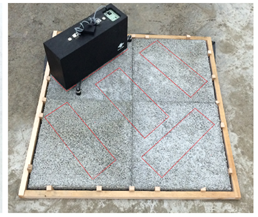

A performance standard (ABNT NBR 15575:2013) points out the impact sound test procedure referenced by ISO 140-7 [20] and ISO 717-2 [21]. Tests were performed in overlapping rooms, separated by reinforced concrete slabs with 10 cm thickness, with masonry walls and solid bricks coated with mortar. The emitting and the receiving rooms have a 16.24 m² floor area and 44.82 m³ volume. The tested sample was of 1m², which was constituted of four 50 cm x 50 cm slabs. The samples reduced dimensions met cost reduction, time and waste production requirements designed by this research [11], Fig. 1.

For noise generation, Bruel & Kjaer model 3207 (Fig. 2) standardized brand impact sound generating source was used. The measurement equipment was the sound level analyzer from Quest Technologies model 2900, class 1, with an octave band filter, in three different positions, as shown in Fig. 1.

4. Results and Discussion

4.1 Slabs specific mass

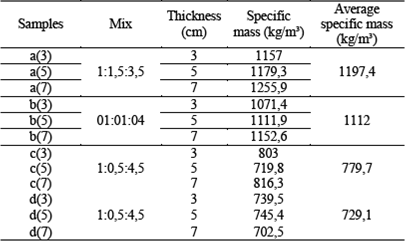

The samples of subfloors specific mass tests (ABNT NBR 9778:2009) [22] were performed after 28 days of setting, and results are shown on Table 6.

It was found that the higher the amount of EVA coarse aggregate, in relation to the fine aggregate, the smaller is the specific mass, due to a higher number of hallow spaces among bigger particles. Even the 1:0.5:4.5 unit mix presented a specific mass 35% smaller than the 1:1.5:3.5 mix, with a 417.7 kg/m³ reduction. The 3cm lightweight concrete slabs with 1cm coating were not considered in the calculation, once they are added with conventional mortar. There was a slight variation in specific mass values among slabs with the same mixes, due to the slab production process.

4.2. Impact Sound Test

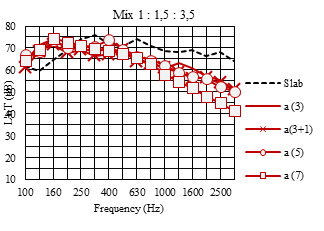

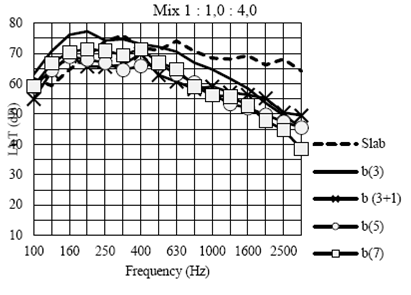

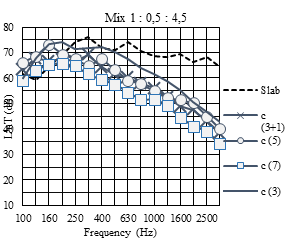

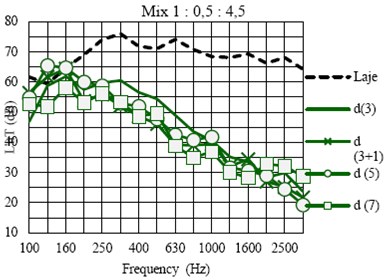

Results obtained in the impact sound test are shown on Figs. 3, 4, 5 and 6, grouped by mix used.

All samples met the acoustic performance required, through impact sounds that are lower than the reference concrete slab acoustic performance, showing the technical viability of EVA aggregate use to replace conventional ones for this purpose. Values measured point to a higher reduction of sound levels in frequencies from 630Hz for all compositions that were studied. With this behavior, the EVA aggregate maintains the pneumatic effect of mechanical damping reduction, even with the grain surfaces in contact with cement paste.

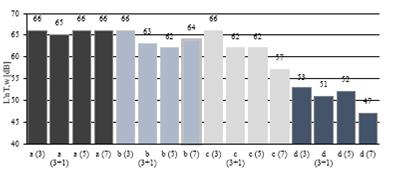

Among the variables that were analyzed, differences in ratios of conventional and EVA aggregates were determinants to the samples’ acoustic performance, except for the 3cm thickness, which showed certain constancy. Other thickness levels present higher impact sound values for smaller specific masses, that is, for a smaller quantity of EVA coarse aggregate. This behavior intensified for the 7cm thickness, as observed in Fig. 3. Fig. 7 shows mean impact sound pressure levels for samples that were tested.

The gradual evolution of sets due to an increase of EVA coarse aggregate ratio in the composition is perceptible. In addition, slabs with the best performance were those in which there was a total replacement of coarse aggregates and partial replacement of fine ones, reaching values of 47dB for 7cm-thickness slabs. It was observed a correlation between the specific mass values and impact sound, which can help in future studies, using a more economical and faster method to analyze acoustic performance in slab systems.

Finally, it is possible to rank the systems studied based on ABNT NBR 15575:2013. The reference slab is classified as minimum performance, while EVA coarse aggregates and natural fine aggregates systems (‘a’, ‘b’ and ‘c’ mixes) are classified as having an intermediary performance. Slabs containing EVA coarse aggregates only and those with partial fine aggregates (‘d’) are classified as higher performance slabs.

5. Conclusion

After assessing the samples, it is possible to conclude that:

The incorporation of EVA aggregates in concrete is an efficient way, with reduced cost, of incorporating air and reducing slabs specific mass, leading to a reduction of acoustic transmission of impact sound in flooring systems; thus, it was proposed the use of polymeric waste as a building element;

In the acoustic performance classification, the variation in samples height was the main variable of influence in the first mixes, prevailing in relation to waste use percentages. When using the fine aggregates replacement, EVA waste had a higher influence on slabs acoustic performance;

Both phases of this study have indicated that lightweight aggregates are determinants in the reduction of measured impact sound values, being that all sets reached at least an intermediary performance according to ABNT NBR 15575:2013 classification. When comparing values obtained in lightweight subfloor slabs to those of the analyzed conventional slab, all sets presented noise decrease, allowing for more comfort in rooms.

In the experimental phase, it was found that that thickness variation is not linear with the increase in impact sound acoustic insulation. Variation took place with a stronger influence of the smaller grain size of the EVA waste aggregate.