1. Introduction

Sweet corn (Zea mays L. var. Saccharata) is characterized by its high sugar content, which makes it attractive for the production of processed foods, as it is mainly consumed as a fresh vegetable or as an industrialized product in the form of a canned whole grain [1]. The few alternatives of transformation of this maize variety, generates the need for its application in the development of new products with commercial interest, such as beverages. A beverage formulated with sweet corn pulp contains a large amount of sedimentable particles that can generate an unstable behavior in the food suspension.

Hydrocolloids are hydrophilic polymers widely used in food systems because of their ability to modify rheological properties, providing a viscosity modification, forming gel structures or stabilizing suspended particles, among other properties, thus prevent phase separation is generally associated with poor quality [2,3]. The addition of gums, such as CMC, xanthan gum, Arabian gum, gellan gum and guar gum, has been studied recently in the formulation of beverages [4-8].

The potential use of Aloe vera gel as ingredient in the formulation of food products, including ready-to-drink beverages, has increased, because of its therapeutic and functional properties and hence its beneficial effects on human health [9]. The gel is composed mainly of galacturonic acids and glucoronic acids attached to sugars like glucose, galactose and rabinose; Other nutrients such as vitamins, enzymes, amino acids, minerals and trace elements. Bioactive compounds include organic acids, phenolic compounds and phytosterols [10]. Like the suspensions of some hydrocolloids or food gums that form gels, aloe vera gel develops viscoelastic behavior, so its addition in food products could affect the rheological properties.

Rheological properties are important for food quality control, structure analysis and process engineering applications [11]. The flow behavior can be determined by a rotational test, and the literature reports numerous mathematical models to describe this property, including the Power Law, Herschel-Bulkley, Bingham and Casson models [3,12-14]. The viscoelastic properties of food structures have been evaluated to determinate stability in food dispersions, such as beverages, and these are influenced by chemical composition, processing conditions and the addition of some ingredients such as stabilizers [5,15-20].

Given the limited information regarding the use of sweet corn as a basis for formulating a natural drink, the present study evaluated the effect of adding xanthan gum (XG), carboxymethyl cellulose (CMC) and aloe vera gel (AV) on the rheological properties of a drink prepared from sweet corn in order to study the stability of suspended particles.

2. Materials and methods

2.1. Formulation and preparation of beverages

The drinks were formulated using sweet corn (Zea mays var. Saccharata). This raw material was obtained from local markets, and the following ingredients were used during beverage preparation: condensed milk added as a sweetener; aloe vera gel (AV) to enrich its nutraceutical value by adding physiologically active components; two types of hydrocolloids as stabilizers, namely, xanthan gum (XG) and sodium carboxymethyl cellulose (CMC); and preservatives such as sodium benzoate and potassium sorbate.

The preparation of the drinks began with the removal of the pulp obtained from the milling and filtering of grains. The percentage of pulp added was 20% w/w, using water as a dispersion medium and condensed milk (12.4 %w/w) for a total soluble solids concentration of 10°Brix. The mixture was heated at 72°C for 30 min and cooled to room temperature. Then, homogenization was performed with an Ultraturrax T25 homogenizer (IKA, USA) at 12,000 rpm for 5 min, and the AV and mixture of hydrocolloids was added in the amounts defined for each treatment in the experimental design. Finally, the preservatives (0.125 %w/w) were, added and the beverage was bottled.

2.2. Rotational test

Flow curves of sweet corn beverage were obtained using a viscometer DV-III Ultra (Brookfield, USA), with a geometry of coaxial cylinders, at temperatures of 10, 20, 30, 40 and 50°C, which was controlled by a thermostated bath. Three scans of shear rate (γ) in the range from 0 to 100 s-1 were performed - first ascending, then descending and finally ascending again - in order to eliminate possible thixotropy in the sample. The data of the last curve obtained were taken and held for every procedure in triplicate [7,21,22]. The experimental values of the different flow curves obtained were fitted to Power Law (eq. 1), Herschel-Bulkley (eq. 2) and Casson (eq. 3) models.

Where n is the flow behavior index, K is the consistency coefficient (Pa.sn), and σ0 is the “yield stress” defined as the minimum shear stress needed to start the flow.

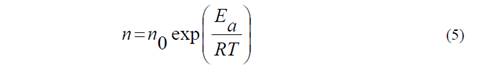

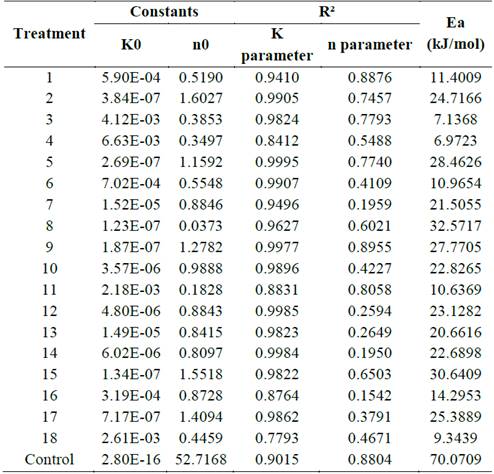

The effect of temperature on viscosity was studied by analyzing the consistency coefficient (K) and flow index (n), using the Arrhenius equation (eq. 4 and 5) as a first approximation.

In this equations K0 is the frequency factor (Pa.sn), n0 is the fit parameter associated with the flow index, Ea is the activation energy (J/mol), R is the gas constant (8.314 J/mol K) and T is the absolute temperature (K). The constants K0 , n0 and Ea were obtained from an exponential fit [20, 23].

2.3. Oscillatory test

To analyze the viscoelastic behavior of sweet corn beverages, oscillatory dynamic tests were performed in an Anton Paar MCR 302 rheometer (Anton Paar GmbH, Austria), with a system of parallel plates (25 mm diameter) and Peltier temperature control. The tests were conducted with a 1-mm gap based on the methodology defined by Mezger [24] and Augusto, Ibarz and Cristianini [16]. Initially, a sweep of amplitude between 0.01 and 100 % was carried out to establish the linear viscoelastic range (LVR), within which a constant amplitude to continue the frequency sweep of 0.01 to 100 Hz was chosen. Each procedure was conducted in triplicate at temperatures of 10, 20, 30 40 and 50°C.

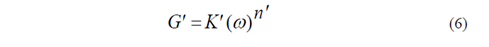

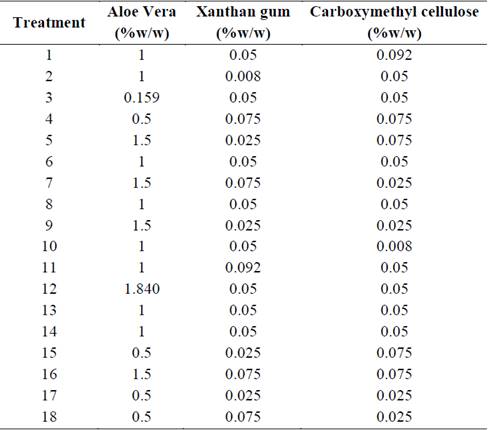

For each value of oscillating frequency (ω), values for the elastic or storage modulus (G'), viscous or loss modulus (G") and the loss tangent tan (δ) were obtained. The loss tangent was evaluated at an oscillatory frequency of 0.1 Hz to study the effect of the addition of hydrocolloids and aloe vera gel on the viscoelastic behavior and stability of beverages [25]. The modules were studied as a function of frequency, fitting the experimental data to models (eq. 6 and 7) commonly used in foods and dispersions [20].

where K’, K”, n’ and n” are the coefficients of the regressions that relate elastic and viscous moduli. The effect of temperature on G’ and G” was studied by analyzing K’, K”, n’ and n” using the Arrhenius equation (eq. 4).

2.4. Statistical analysis

The rheological behavior of the different formulations was studied through regression analysis, and quality adjustment was established based on the coefficient of determination (R2) and the mean square error (MSE). Furthermore, the significance of the model and parameters were calculated at a significance level of α=0.05.

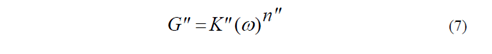

For statistical analysis of the data, a central composite rotational experimental design was used, applying response surface methodology to evaluate the rheological properties of the beverage that provide stability, according to three factors studied: XG, CMC and AV concentration (tab. 1). Eighteen treatments were performed with 4 central points, and the control sample corresponds to the beverage formulated without adding hydrocolloids and AV.

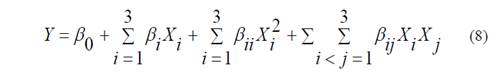

The experimental design was evaluated using a multifactorial ANOVA with a level of significance of α=0.05. The response surfaces were calculated using the following second-order model (eq. 8).

where Y is the response calculated through the model; β0 , βi , βii and βij are the regression coefficients for the linear and quadratic intercept and interaction terms, respectively; and X is the independent variable. The relevance of the models was determined through regression analysis, a test of lack of adjustment and the coefficient of determination (R2).

3. Results and discussion

3.1. Rotational test

The fit of the experimental data showed that the Power Law and Herschel-Bulkley model were the most suitable to explain the rheological behavior of corn beverages, as higher values of the coefficient of determination (R2> 0.99) were achieved relative to the Casson model (R2 between 0.94 and 0.99), and in all cases, the models were statistically significant (p value <0.05). However, when analyzing the values of the mean square error (MSE), the Power Law model has less deviation than the Herschel-Bulkley model.

Regarding the significance of the obtained adjustment rheological parameters, it was found that the "yield stress" (σ0), which is present in the Herschel-Bulkley and Casson models, was not significant in any treatment (p value> 0.05). These results led us to select the Power Law model as the most suitable to explain the behavior of the flow in beverages formulated.

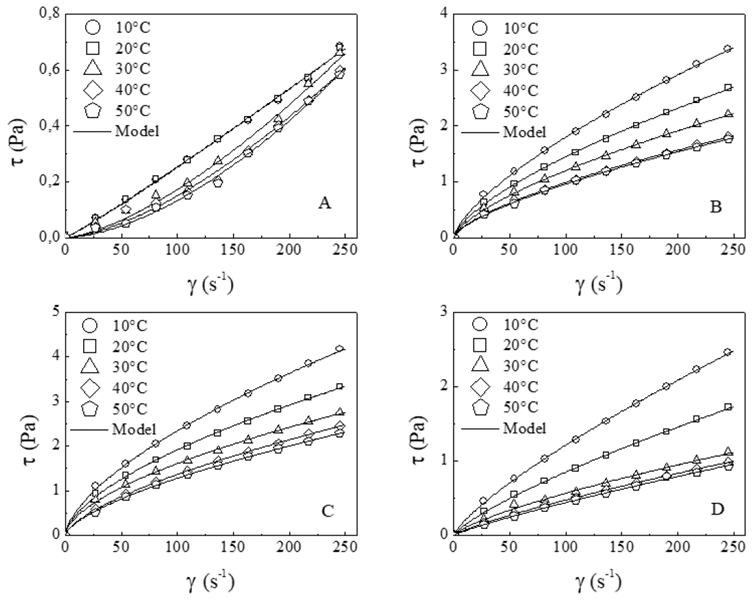

Fig. 1 shows the fit of the experimental data of some treatments and the control sample. Clearly, the flow behavior of corn beverages deviates from Newtonian character. The control sample showed values of flow index (n) between 1.07 and 1.65, typical of shear-thickening behavior, which can be attributed to the presence of corn starch in the suspension [14,20]. In contrast, beverages formulated with CMC, XG and AV showed values of flow index (n) varying from 0.5-0.9, indicating shear-thinning behavior. This shows that the addition of hydrocolloids significantly affects the rheological behavior of beverages, as demonstrated in previous studies [4,7,26-28]. Additionally, it has been found that the XG, CMC, and AV confer shear-thinning flow, and XG confers high viscosities at low rates of deformation, features that contribute to the stability of suspended particles [3,29-32].

Source: Elaborated by the authors

Figure 1 Flow curve of sweet corn beverages fitted to the Power Law model. A: Control, B: Central point, C: Upper axial point and D: Lower axial point.

The consistency coefficient (K) in corn beverages formulated with hydrocolloids presented values between 0.0036 and 0.2070 Pa.sn, which are within the ranges reported in the literature [20]. The dependence of the K value on temperature was satisfactorily described by the Arrhenius equation and setting parameters shown in tab. 2. It was observed that K decreases with temperature, which indicates a behavior similar to the viscosity. These results are consistent with those found by other authors [13,22,33-36]. This could have occurred because the temperature is an indirect measure of the internal energy, that increases and the intermolecular forces are reduced, causing its detachment and facilitating movement and vibration, which leads to less consistency or resistance [37].

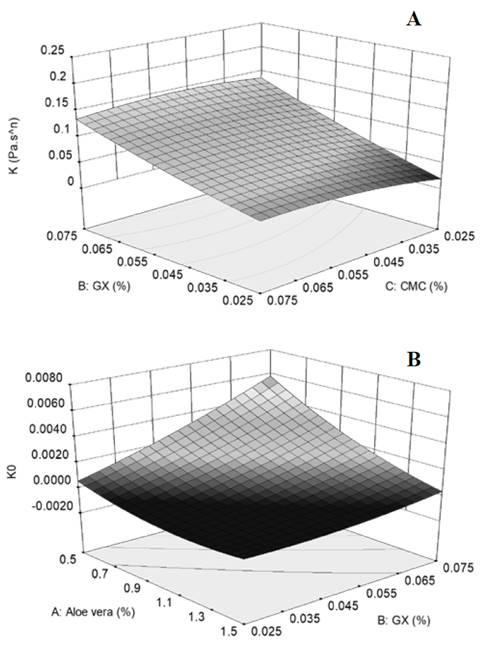

Due to the importance of studying the behavior of drinks during refrigerated storage, the behavior of the consistency coefficient to a temperature of 10°C was analyzed. In these conditions a significant effect of XG on the K value (p value <0.05) was found, whereas other factors did not influence the K value, indicating that a greater concentration of gum increases the consistency coefficient (fig. 2a). This is because the gum has a rigid isotropic structure of elongated rods with a random orientation relative, and its structure changes when the concentration is increased in the dispersion, resulting in formation of molecular interactions with high-molecular-weight aggregates and causing an increase in apparent viscosity [31,38-40]. Moreover, treatments 8, 11, 16, and 18, showed a higher coefficient of consistency at 10°C, which promotes suspension stability.

Source: Elaborated by the authors

Figure 2 Response Surfaces. A: Consistency coefficient (K) and B: frequency factor (K0) of sweet corn beverages.

A significant effect of XG and AV on K0 value (p value <0.05) was found, whereas CMC did not affect the K0 value. Higher values of K0 were obtained following a higher concentration of XG and a lower concentration of AV (Fig. 2b). Thus, AV concentration has an impact on the effect of gum, indicating a possible interaction between components. It has been shown that the functionality of a hydrocolloid is determined by the way it is mixed with other non-gelling ingredients [3]. XG is an anionic polysaccharide, and the presence of some components in the AV gel, such as salts and acids, affect ionic strength and load balancing in the system and thus its functionality [41].

The parameters of the consistency coefficient and frequency factor fitted to the quadratic model are shown in tab. 3. High coefficients of determination (R2>0.90), and no significant lack of fit was obtained, indicating that the model is adequate to explain the behavior of these variables.

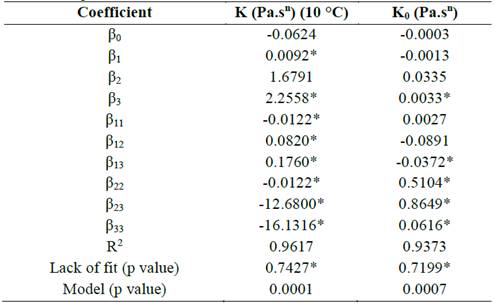

Table 3 Coefficients of fit to the quadratic model for rheological parameters of sweet corn beverages

Source: Elaborated by the authors. *Not significant (p>0.05)

The flow behavior index (n) of the drinks was not properly adjusted to the Arrhenius model in most of the treatments (tab. 2). Similar results have been reported in other studies [20,30]. The behavior of the flow index of corn beverages at 10 °C was not significantly affected by the factors studied (p value >0.05). Therefore, at the storage temperature, it can be assumed that the flow index (n) is constant across all concentrations of gum and AV.

In the control sample, the Ea value was higher than that in the beverages formulated with XG, CMC and AV, indicating a significant effect of temperature on viscosity [14,33,42,43]. Of the three components, only the XG concentration had a significant effect on Ea (p value<0.05), which may be caused by conformational changes that occur during heating gum affecting the viscosity of solutions [3,44].

3.2. Oscillatory test

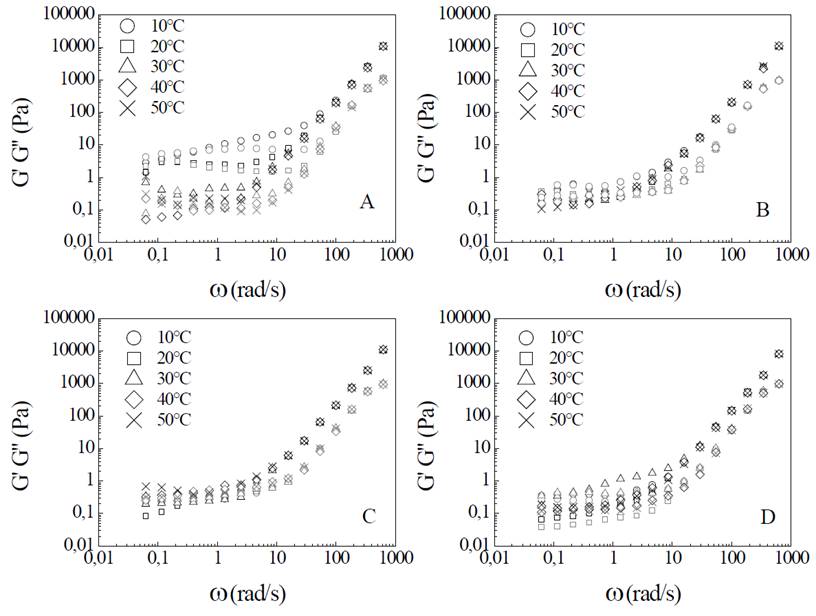

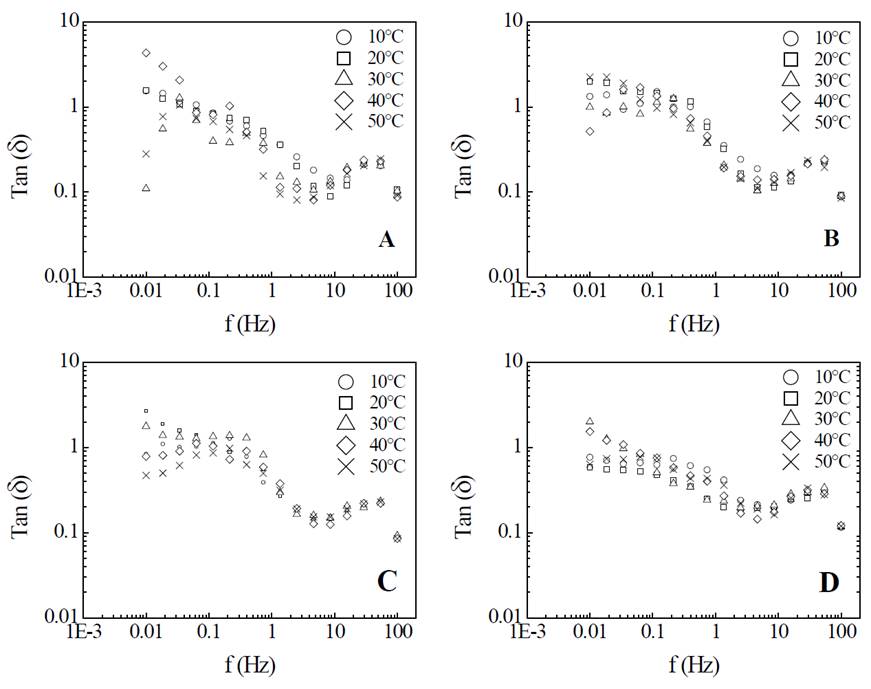

From the amplitude sweep a value of 0.3 % was selected for frequency sweeps. The behavior of the storage modulus (G') and loss modulus (G") as a function of oscillatory frequency (ω) of 0.0628 to 628 rad/s (0.01-100Hz) at different temperatures was plotted (Fig. 3). It is noted that G' and G" tend to increase with the oscillatory frequency. The storage modulus (G') was always higher than the loss modulus (G") over a wide frequency range, approximately from 2.5 to 628 rad/s (0.4 to 100 Hz). For high frequencies of oscillation the elastic properties are predominantly viscous, indicating weak character or viscoelastic gel in corn beverages [20,24]. This behavior is confirmed by the values of loss tangent (tan (δ)), which was lower than unity (tan (δ) <1) in a large high-frequency range (Fig. 4). At low frequencies, the behaviors of some drinks have cross-over points in which G" prevails over G'. This phenomenon is typical of concentrated solutions and has been observed in beverages stabilized with similar concentrations of gums [4,17,45].

Source: Elaborated by the authors

Figure 3 Storage (G') and loss (G") modules of sweet corn beverages. A: Control, B: Central point, C: Upper axial point and D: Lower axial point.

Source: Elaborated by the authors

Figure 4 Loss tangent of sweet corn beverages. A: Control, B: Central point, C: Upper axial point and D: Lower axial point.

The fit to second-order models indicates that the viscoelastic behavior of drinks (G' and G") is dependent on oscillatory frequency, with R2>0.94 and R2>0.97, respectively. In general, the values of consistency coefficient K' were higher than the values of K", confirming that the elastic component overrides the viscous component (G'> G"). This phenomenon has been observed in fruit juices and other products derived from plants [5,16,37,46]. The values for n’ were higher than the values of n". This implies that G' is more dependent than G" on oscillating frequency [37]. At low frequencies (<2.5 rad/s), G' and G" modules were almost independent of oscillatory frequency and reached similar values. The effect of the concentration of XG, CMC and AV on the parameters of fit to second-order models, K’, K”, n’ y n”, was not statistically significant.

The adjustment of K’, K", n’ and n” (eq. 6 and 7) to the Arrhenius equation showed that the viscoelastic behavior is not satisfactorily described by this model (R2<0.5), then there is no linear dependence between the viscoelastic parameters studied and the temperature.

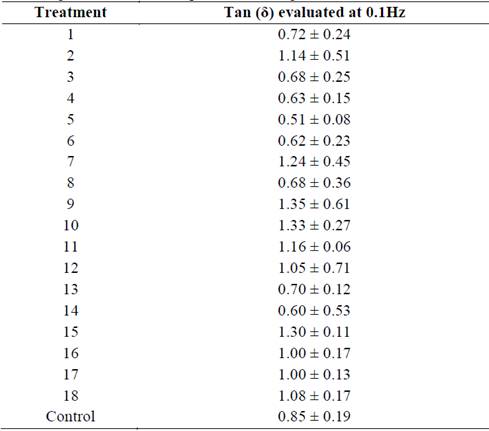

The loss tangent tan (δ) has been considered as a relevant measure of physical stability, with tan(δ)<1 behavior indicating some form of stable dispersion [24]. It has also been shown that when tan (δ) <0.5, dispersions stabilized with gums are less susceptible to phase separation [25]. Consequently, this parameter was evaluated at a frequency of 0.1 Hz to study the effect of the concentration of hydrocolloids and aloe vera gel, as well as the effect of the temperature, on the viscoelastic properties of corn beverages. The frequency value (0.1 Hz) was selected because that point produces low deformation conditions of the product or rest, such as during storage and sedimentation of suspended particles [37].

Tan (δ) at 0.1 Hz is not statistically significant affected by temperature (p value >0.05), as shows treatments studied (Fig. 4), even this behavior is more evident at higher frequencies. Additionally, the loss tangent is not affected by the concentration of gums and AV (p value >0.05) at storage conditions of 0.1 Hz and temperature of 10°C. It is possible to establish that the average value of tan (δ) in beverages formulated with hydrocolloids was 0.94, slightly higher than the control beverage with a value of 0.85; however, in both cases, some stability was observed (tab. 4).

Values of tan (δ) under the established frequency and temperature conditions were in the range of 0.5-0.7 and were achieved with treatments 3, 4, 6, 8, 13 and 14. Treatments 6, 8, 13 and 15 correspond to the central point of the experimental design, that is, XG and CMC concentrations of 0.05 %w/w and 1 %w/w AV. Treatments 3 and 4 correspond to equal concentrations of gum (0.05 %w/w and 0.075% w/w, respectively), and lower AV concentrations (<0.5 %w/w). Therefore, it is evident that the desirable viscoelastic properties (tan (δ) <1) are achieved at gum concentrations ≥ 0.05% w/w in the same proportion and a maximum concentration of 1% w/w AV.

4. Conclusions

The addition of hydrocolloids and aloe vera gel to formulated beverages with sweet corn induced significant changes in flow behavior, from a shear-thickening to shear-thinning character. In general, the behavior of drinks was satisfactorily described by the Power Law model. The parameters associated with the viscosity exhibited temperature dependence by an appropriate fit to the Arrhenius equation. The activation energy results indicate that the addition of aloe vera and hydrocolloids increased stability of the beverages when temperature variation is produced since its viscosity is less affected than the viscosity of the beverage without stabilizers. The viscoelastic profile of beverages formulated with gums and aloe vera gel was found to have weak gel predominance of the elastic component compared to the viscous component on a wide range of frequencies, which demonstrates good stability of the suspension. However, these properties were most suitable when high concentrations of hydrocolloid (≥ 0.05% w/w) and low concentrations of aloe vera (≤ 1% w/w) were added, and the stability was retained at conditions of low strain.