1. Introduction

The behavior of the asphalt binders has been affected due to the increase of traffic loads, accompanied by an increment in the travel speed, among others. Likewise, In Colombia as well as elsewhere, the number of vehicles on the streets has increased so significantly as the annual traffic report of the Colombian Transport Minister points out [1]. These situations create the need of more resistant and resilient pavement structures and has led to use novel technologies and additives mixtures in asphalt concretes.

Several materials and techniques have been used for the purpose of optimizing the performance of Hot Mix Asphalt (HMA). It is possible to improve certain characteristics of the asphalt in the refinery process. Nevertheless, these modifications are not enough with issues such as: the increase in the total temperature interval [2]. Polymers as Styrene-Butadiene-Styrene (SBS), listed as one of the best additives for asphalt modifications [3] or elastomers like the Crumb Rubber (CR), largely used since the 60’s -extracted from vehicles tires that have reached the end of their service life- have been used and studied yielding good performance results, contributing to reduce HMA cost by substituting part of the aggregates of asphalt binders. The latter polymer is also presented as a solution to resolve the problem that discarded tires represents for the environment and the citizens health. At the same time, natural asphalts like asphaltite have been widely used, upgrading the bitumen performance at high temperatures and increasing the structure hardness [4].

Previous investigations carried out to date, although they have been notable, they have not yet evaluated the qualities of C.R and natural asphalt in the same mixture and in the proportions considered to be optimum for each additive by prior studies. The chief purpose of this research is to analyze the stiffness, under axial compression loads, of the modified asphalt mixtures with rubber derived from used tires and asphaltite. Incorporated by wet process which is generally used because of the good results [5,6] and varying the additives ratios, the load application frequencies and the temperature in which the test will be carried out. The dynamic mechanical analysis was performed by using the METRAVIB DMA+1000 and the results which were plotted, mainly, in Black Space and Cole-Cole plot, showed substantial improvements in the bitumen behavior.

2. Background

The liquid petroleum asphalt, also known as bitumen, is a viscoelastic material that has been used extensively in the industry for; road paving, waterproofing roofs, and more [3]. Today, the research focuses on the need to improve the qualities of this compound by means of additives than can enhance the performance in adverse conditions: whether natural (e.g., high temperatures, rain) or human-induced.

The use of additives in the asphalt as CR represents not only a solution to environmental problems but also is an effective way to upgrade the asphalt resistance. It has been determined that the service life of CR modified mixtures can be doubled, and simultaneously, exhibits a decrease in temperature susceptibility and penetration. Even though, according to [7], depending on the size and quantity of CR this can enhance or jeopardize the Performance Grade at low temperatures of the asphalt binder. Furthermore, this polymer manages to improve the elastic response, the rutting resistance, increase the softening point [8,9] and facilitates integration of reclaimed pavement with HMA [10]. What is more, the CR provides an economic advantage over polymers like SBS [11] among other things. Notwithstanding, this elastomer increase the mixture viscosity reducing their workability.

On the other hand, it has also been proven that asphaltite creates a reduction in penetration of the asphalt and thus, the stiffness and resistance to permanent deformation of the binder is enhanced [12]. It has been widely used to improve the performance of asphalt binders at high temperatures. In spite of, after the incorporation of the mineral the cracking tendency increase showing brittle behavior at low temperatures because of its elasticity loss [5,13]. Moreover, it has been found that this natural bitumen is successful in diminishing the cost of production of the asphalt binder [14].

This way, the simultaneous use of these additives in the asphalt mixture -assessed in this investigation- could improve; the flexibility, the resistance to heavy loads and to thermal stresses that deteriorate the HMA, could reduce the viscosity increase by adding CR and, eventually, it is possible to obtain a decrease in the production cost.

3. Materials and methods

3.1. Materials

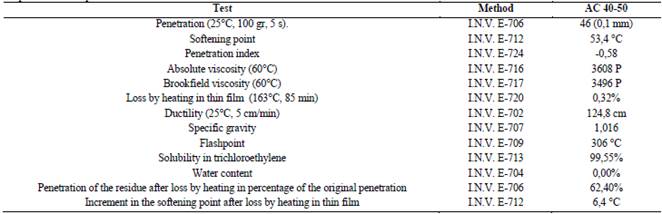

It was used Asphalt Cement (AC) 40-50 acquired from the asphalt plant MPI Ltda. located in the city of Barrancabermeja (Colombia). This material, derived from petroleum, combined with aggregates of various sizes creates the HMA: flexible structures willing to withstand the vehicular traffic. The used bitumen exhibits the characteristics shown in Table 1.

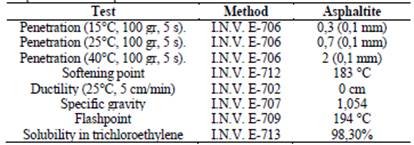

In a like manner it was used Asphaltite: the natural bitumen commonly used in modified HMA, which contains high purity hydrocarbons and presents large amount of asphaltenes providing rigidity to the asphalt binder. This material was obtained from a mine in Cesar (Colombia) and was crushed to have particles which pass through sieve N°80. The asphaltite characteristics are shown in Table 2.

It was also used crumb rubber from recycled tires, provided by Reciclair (Bogotá, Colombia), as AC modifier. The grinding process of discarded tires can be carried out by cryogenic grinding technologies or by ambient grinding process (in which tire is processing at or above room temperature). In this research the rubber was ground by ambient process to pass through sieve N°100. [16] Notes that CR surface area resulting of ambient grinding is twice bigger than the one obtained using the other method, deriving in a high complex modulus and a greater phase angle in modified bitumens, which means a better resistance to deformation and a better recovery. The amount incorporated for the CR modified bitumen was 8% of asphalt weight, identified as the most suitable according to previous studies [17].

Finally, it was used aggregated extracted from the Chicamocha canyon (Santander, Colombia) given by Prevesa Ltda. This material was finely crushed with the aim of obtaining particles passing through sieve N°100. By means of laboratory characterization was obtained the specific weight of the aggregate and, thereby, was found the volumetric equivalence between CR and aggregate in the mixture.

3.2. Modified asphalt mixtures

Using different modifiers percentages, four base mixtures with neat asphalt were made. Briquettes, with dimensions 2 cm in height and 1 cm in diameter, were subjected to axial compression test at different frequencies and temperatures, taking into account the reference AC. The test was performed twice for each briquette to obtain accurate results.

First, briquettes of neat asphalt were made as benchmark. Second, a combination of asphalt and asphaltite was made, adding 5 and 10% of mineral in relation to total AC mass by using the wet process at a temperature of 160°C for 20 minutes. Conditions suggested by literature with the intention of preserving the initial properties of the bitumen, since the exposure to higher temperatures for longer periods during blending will induce aging due to loss of chemical compounds by oxidation. Then, an AC mixture by adding 8% CR was made. Afterwards, 8% CR and asphaltite (A/AC = 5% and 10%) were incorporated and finally, briquettes of asphalt and asphaltite were made, this time replacing the volume of CR incorporated in the AC and rubber mixture by fine aggregate maintaining the blending conditions for every sample (i.e. 160°C for 20 minutes). The latter combination arises with the intention of analyzing the behavior of the asphalt with asphaltite and the fraction of fine aggregate that is normally suppressed of the conventional grading of pavements in which have been incorporated ground rubber. Hereby, it is possible to have an idea of the advantages or disadvantages that may cause the replacement of the mineral fractions by the recycled polymer in the proposed asphalt combination.

3.3. Dynamic viscoelastic properties

Through the dynamic machine METRAVIB DMA+1000 it was possible to determine the asphalt properties after testing the briquettes by traction-compression tests with a fixed dynamic displacement of 1E-5 (m), different loading frequencies (1,3, 5, 7, 10 and 25 Hz) at various temperatures (0, 5, 10, 15, 20 y 30°C).

After testing, the complex modulus (E*) of modified asphalts was assessed. This number can be expressed as the absolute value of the root of the sum of the squares of the viscoelastic response of the compound (eq. 1).

Wherein E 1 is a real number which represents the elastic response and E 2 is an imaginary number which corresponds to the viscous response of bitumen. Complex modulus depends on the temperature and frequency of application of loads. Likewise, in this study was evaluated the phase angle, through which the difference between stress and strain is seen, typical characteristic of viscoelastic materials [18].

3.3.1. Black diagram

The Black diagram represents the complex modulus versus the Phase Angle in the same instant at the same temperature. A smooth curve is indicator of time-temperature equivalency, while a disjointed curve exhibits a bitumen with high amount of asphaltenes or a modified bitumen with large amount of polymers [19].

3.3.2. Cole-Cole plot

The Cole-Cole plot shows the rheological behavior of asphalt in the complex plane, in which an imaginary part (Loss Modulus) and a real part (Storage Modulus) interact, corresponding respectively to viscous and elastic portion of the complex modulus of bitumen [18].

All the plot data is isochronous and isothermal, notwithstanding, it is possible to represent the Storage and Loss Modulus data at different temperature and frequencies on the same plot, creating an overall curve. Nevertheless, Cole-Cole plot can’t be used to determinate the viscoelastic properties of bitumen for a given temperature and loading frequency, which is usually needed in the analysis of pavement structure response. For this purpose it is appropriate to construct Master Curves [20].

4. Results and discussion

4.1. Rheological properties of HMA modified binders

4.1.1. Rheological curve

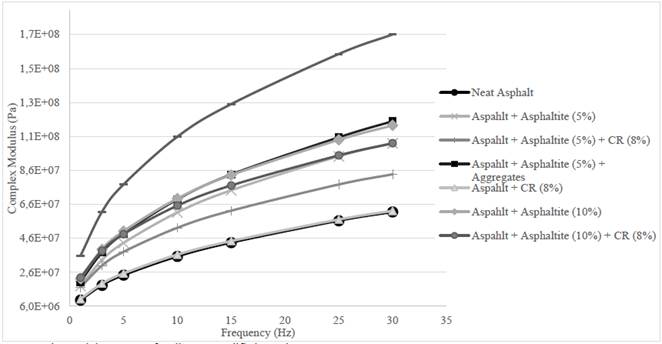

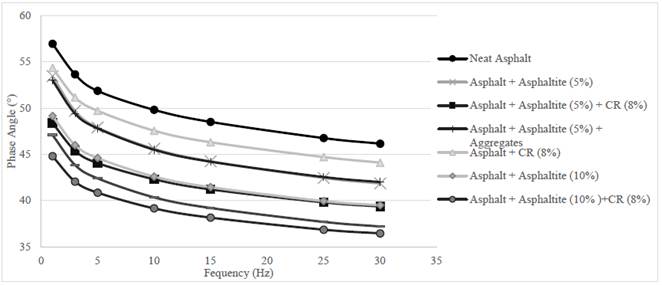

The relation of the frequency, with the complex modulus and the phase angle, appears in the Fig. 1, 2 at a reference temperature of 22°C. The complex Modulus in the Fig. 1 displays a considerable increase in the sample of Asphalt + Asphaltite (10 %) + Aggregates (equivalent volume), superior to all the other mixtures, especially at high frequencies. The samples of Neat Asphalt and Asphalt + CR (8 %) are those that present a minor │E*│which indicates that they have a minor resistance to the deformation. The asphalts in which natural asphalt and CR was added present a better complex modulus than the neat asphalt, indicating a major inflexibility that becomes more evident as the frequency increases. The phase angle in Fig. 2 presents a decrease for all the modified asphalt combinations, especially for the modified sample of Asphalt + Asphaltite (10 %) + CR (8 %). This allows to predict that a combination between these two materials can be a good alternative at the moment of forming an asphalt binder. Nevertheless, it is necessary to analyze the performance of the mixtures in depth because the increase of the stiffness can lead to a fragile behavior of the material.

4.1.2. Fatigue cracking analysis

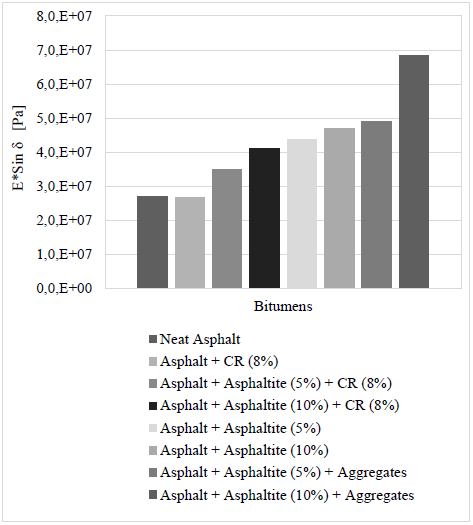

Doing an analogy with the Superpave design system created in the Strategic Highway Research Program (SHRP), in where the value of G*sin δ is used to analyze the performance of the asphalt considering factors as the climate, the value of E* sin δ was evaluated at a reference temperature of 22°C in order to observe the predisposition of the asphalt mixtures to the fatigue cracking. The product of the complex shear modulus G* and the sine of the phase angle is used in the method Superpave to design the asphalt binders in order to control the fatigue of the material. Low values resulting of the product of G*sen δ are considered to be optimal looking for a greater resistance to the cracking by fatigue [21]. In this light and before the notable increase of the complex modulus in the majority of the studied bitumens, it is decided to make the analysis of the samples presented in Fig. 3. It is shown that the increase of the complex modulus of the bitumens results in an increase of E*sen δ, which means that it has a negative impact in the resistance to the cracking of the material. The mixture of clean Asphalt + Asphaltite (5 and 10 %) + Aggregates showed the major values, whereas the combination of asphalt with CR did not generate significant changes with regard to the neat asphalt. Is it important to notice that, though there is an increase in E*sin δ in the mixtures of asphalt, asphaltite and rubber, the merger of these three components in the same bitumen improve the resistance to the cracking of the pavement in comparison with the mixtures in which was added, to the neat asphalt, asphaltite and aggregates. Thus, by replacing the aggregate for crumb rubber minimizes the possibilities of cracking of the material, which increase at the moment of adding asphaltite.

4.1.3. Isochronal plot

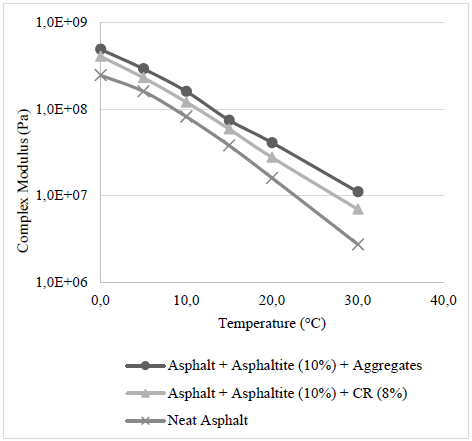

The isochronal plot represents the complex modulus against the temperature with a reference frequency and it is presented in the Fig. 4. Bearing in mind that the principal aim of this research is to study the variation of the stiffness in the bituminous combinations that have been proposed in relation to the base asphalt 40-50 and to determine if the proposed combinations can improve the performance of the pavements in comparison with the traditional mixtures, it is decided to select the briquettes of: Neat Asphalt, Asphalt + Asphaltite (10 %) + CR (8 %), Asphalt + Asphaltite (10 %) + Aggregates. Due to the good behavior exhibited depending on E*. The latter briquette refers to a mixture of asphalt, natural asphalts and a volume of aggregates, equivalent to the volume that occupies the ground rubber in the second mixture among the selected ones.

The increase of E* in the whole range of temperatures of both modified mixtures in relation with the neat asphalt is kept uniform and represents an improvement in the stiffness of the asphalt, which means a better resistance before the application of external loads. Although CR's addition diminishes the complex modulus in comparison with the sample in which aggregates were added, it remains greater than the modulus of the neat asphalt. This fact emphasizes the assumption that the incorporation of natural asphalts and recycled crumb rubber to the neat asphalt can be a way of improving the stiffness of the pavement binders.

4.1.4. Cole-Cole plot

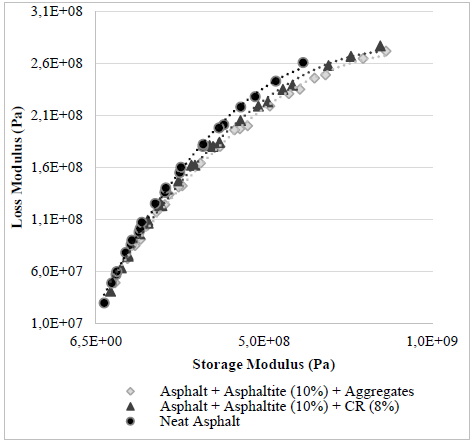

The performance of the complex modulus of the asphalt in a complex plane can be assessed in Fig. 5. At high temperatures, the three briquettes display a similar behavior with low elastic response and low Loss Modulus. Albeit a lower elasticity in neat asphalt is perceived.

As the temperature decrease, the difference between the neat asphalt and both modified mixtures are appreciated. The last two sustain a similar performance demonstrating a remarkable rise in elastic capacities by increasing in Storage Modulus which allows to the asphalt binder to have a better rutting resistance, among other qualities. It should be noted that the replacement of aggregates by CR offers an economic alternative and, at the same time, an environmental solution, reinforcing the qualities of the novel mixture.

4.1.5. Black space

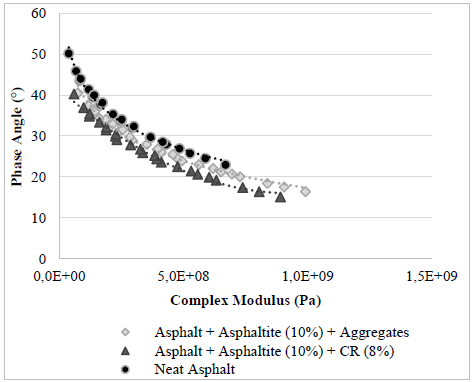

The Black Diagram graph presented in Fig. 6 points out a tendency towards a lower phase angle in the asphalt modified with asphaltite and rubber, followed closely -as expected- by the asphalt modified with asphaltite and the portion of fine aggregate. This indicates a better elastic response. At the same time, the resistance to permanent deformations is improved in comparison with neat asphalt. In the same way, can be observed a greater reduction in the phase angle in the crumb rubber modified mixture regarding the others samples and this remains constant along the experiment, demonstrating the trend of polymers to create a continuous elastic network when dissolved in the bitumen [22]. Predictably, the asphalt that was not modified with polymers presents a higher complex modulus; nevertheless, its phase angle is higher than in the others blends, which could generate a brittle pavement at low temperatures as can be inferred from Fig. 3.

The present study measured the stiffness of the asphalt modified with crumb rubber and asphaltite assessed at different temperatures and loading application frequencies for determinate if this simultaneous combination of additives may represent mechanical and economical improvements to the asphalt binders as well as a solution to the environmental problem discussed above.

5. Conclusions

Based on the findings of this experimental investigation it was determined that the simultaneous combination of these two materials, in proportions of 8 % of polymer and 10 % of asphaltite, gives substantial improvements to the asphalt. An increase in the rutting resistance is demonstrated in the Fig. 6 where is appreciated rise in the complex modulus; doing of this mixture a compound capable of supporting greater loads than the conventional asphalt, achieving a minor thermal susceptibility in the whole range of the evaluated temperatures and exhibiting a decrease in the phase angle of the proposed binder agent. Upgrades which combined with the increase in the Storage Modulus estimated in Fig. 5, allows the compound to have a greater elasticity and a better recovery after suffering deformations, avoiding possible problems in the pavement caused by the low flexibility in the asphalt binder. Nevertheless, the increase in the stiffness of this mixture generate a major value of E* sen δ, which means that it has minor resistance to the cracking fatigue in relation with the neat asphalt.

Future experiments can direct the research towards the study of the behavior of the proposed mixture under shear stresses in order analyzes the Shear Modulus G* and the phase angle (ẟ) and thereby find the fatigue cracking resistance of the material that undoubtedly represents a viable alternative at the moment of constructing more resistant pavement binders, with a minor cost and environmentally friendly by using discarded vehicles tires.