1. Introduction

The increasing complexity of production systems has led to difficulties in abnormal situation detection. Most common alarm generation platforms available in SCADA systems depend on a direct variable measurement and a comparison with static thresholds. Multiple research efforts have been directed in developing fault detection and isolation schemes that do not require direct variable monitoring [1-2].

Desirable features of a Fault Detection and Identification (FDI) algorithm are: The ability to detect and isolate previously known and unknown faults, robustness, adaptability to the evolution and degradation of the system, the ability to explain fault nature and simultaneous fault detection. Two major approaches have mainly been used for FDI: The direct use of signal processing using statistical methods or clustering algorithms, among other possibilities, or fault detection based on residual generation and processing. These methods have been usefully applied in different fields [3-6]. However most of these algorithms are designed for detection of very well-known faults, presenting difficulties when facing new faults or when their magnitude change.

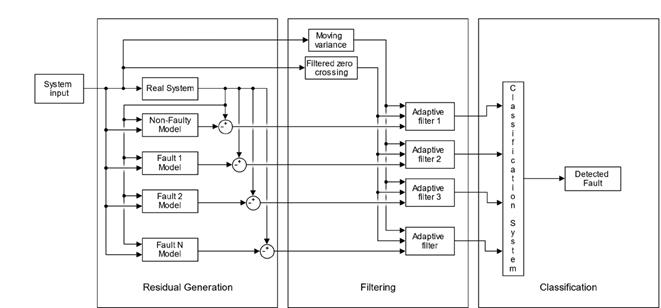

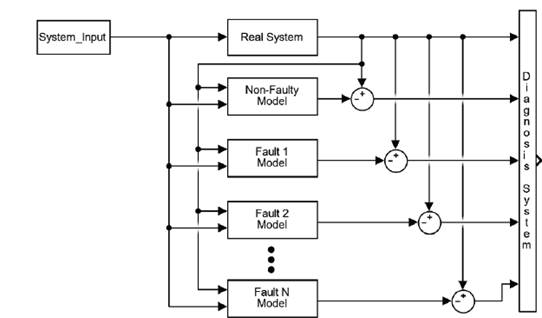

Analytical redundancy is the process of residual generation by means of the comparison between real processes and models of normal and faulty conditions. This approach has been widely applied and allows the detection of known faults. Its main disadvantage is the need of a different model for each faulty scenario, which difficulties the fault isolation in not very well-known systems. Fig. 1 shows the general framework of this approach. Usually, the non-faulty model is used to determine small deviations from the operating points.

Source:The Authors.

Figure 1. Analytical redundancy general architecture for residual generation and evaluation.

On the other side, data oriented strategies have been used for new fault detection. In [7] deviations from operating conditions are detected and classified to define new clusters for classification purposes, allowing the isolation of new faults. Commonly, data clustering around normal and abnormal operating points is carried out using classification or feature extraction algorithms [8,9].

For the formulation of preventive maintenance programs, not only fault occurrence detection is important but a more comprehensive understanding of the fault and its intensity. This fact has led to the formulation of some fault detection algorithms for specific applications where a detailed knowledge of the system is required. In [10], a strategy to detect gear cracks in wind turbines is proposed through a multi-channel sensor system and a statistical method for processing. A more general approach is proposed in [11] showing the isolation of multiple faults with varying magnitude in the hydraulic actuators of wind turbines.

In this paper, a strategy for residual generation by using multiple fault models and its evaluation using an adaptive filter by means of statistical information from the input to reduce modeling error and increase robustness. The filter is trained by means of a genetic algorithm used to find the optimal coefficients to balance the speed of detection and robustness. Simultaneous fault data is included in the modelling phase, allowing multiple fault detection. Finally, the residuals are classified using a standard neural network for classification. First, it is presented the NARX model construction for residual calculations. Then, adaptive filter design from input statistics is depicted. Finally, the training of the isolation system is described.

The proposed strategy is applied to a mechatronic test bench driven by a DC motor with controllable stiction, backlash and rotational inertia changes, to simulate either ball bearings degradation or poor lubrication, coupling looseness and belt failure.

2. Description of treated faults

Positioning systems are usually composed by the actuator, the drive, the rotational load and the angular sensor. This kind of systems are commonly applied in load displacement mechanisms and machine tools [12]. Three common faults in the rotational mechatronic systems are addressed in this paper: backlash in the coupling, static friction due to bearing fault or poor lubrication and changes in the rotational inertia.

2.1. Backlash

In electromechanical assemblies, alternating loads may cause an undesirable backlash induced by the degradation of flexible couples and the wear of gears. This fault affects the normal operation of the mechanism causing noise, vibrations and positioning errors. Backlash can be described as an abrupt change of rotational inertia, followed by a collision between the coupling surfaces, affecting the performance in control tasks. This nonlinear phenomenon has been addressed in literature for modeling [13], detection [14] and compensation purposes [15,16]. Backlash is particularly hard to model using linear identification techniques due to impacts, vibrations and looseness, caused by the mechanical gap, specially under turn inversion conditions.

2.2. Bearing faults

Bearing degradation is the most commonly reported fault in rotary systems. It is caused by poor maintenance, polluting and corrosive agents, overloads or natural degradation of the bearing. This fault is characterized by two parts. The low speed component can be associated to a static friction condition [17]. This fault is particularly important because it is associated with an abrupt motion starts and an actuator breakdown due to blocking and overheating. On the other side, the dynamic component is related to high speed vibrations [18].

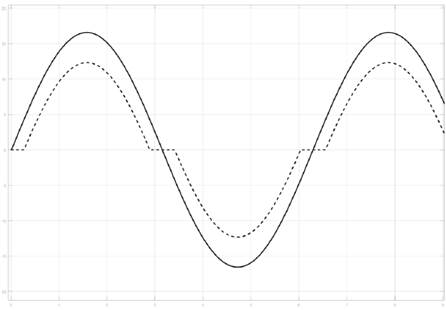

For the scope of this work, only the stiction condition is considered because of its importance in low speed positioning systems. Fig. 2 shows the effect of this fault under a sinusoidal input. Here, the fault is characterized by the dead band for small inputs.

2.3. Rotational inertia changes

This fault can be present when the mechanical load of the system is lost due to a broken key or a flexible belt. For modeling purposes, it can be represented by a sudden and permanent change of inertia.

2.4. Combined faults

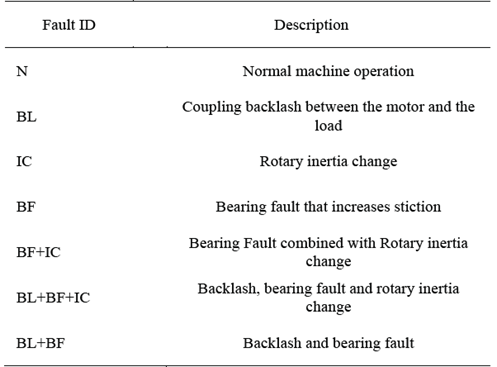

In analytical redundancy fault detection approaches, each fault is usually modeled independently. This method normally produces poor Fault Detection and Isolation, under combined faults. To deal with this, a combined fault scenario is considered where multiple faults may occur at the same time, and each combined condition is treated as a new fault. Table 1 summarizes the considered faults.

3. FDI scheme

The block diagram of the fault detection system is shown in Fig. 3. Initially, the residual generation block consists of multiple Nonlinear AutoRegressive networks with eXogenous inputs (NARX) trained for each fault condition. The residuals are obtained from the comparison between the measured and predicted values. The filtering block includes a set of first order filters that consider the moving variance and zero crossings of the speed. To balance sensibility and robustness, the filter coefficients are tuned through a genetic algorithm. Finally, fault isolation is carried out by using a neural network with filtered residuals as inputs, and the classification result as output.

3.1. Residual generation with NARX

Artificial Neural Networks as universal approximators have been used in a wide variety of static systems where experimental data is available. Their ability to generalize and identify complex relationships has led to a wide range of applications in noisy environments. NARX networks are a special architecture where past inputs and outputs are fed back to model the dynamical behavior of the system. This allows network training using traditional gradient-descent techniques for discrete time nonlinear systems.

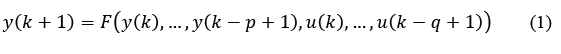

In NARX systems, the predicted value is given by

Where F is a nonlinear function for p delayed outputs y and q delayed inputs u. Different number of delays can be taken for each input and output. Besides, controlling the number of delays in the outputs is useful for step ahead prediction and forecasting models.

3.2. Residual filtering

Modeling real systems always attaches difficulties when dealing with uncertainty, and disturbances. Despite of the fact that NARX models learn from real data and generalize main features of the system response, there are small differences between measured and predicted data called residuals. These signals contain unmodeled dynamics together with some measurement errors. Residual filtering is necessary to prevent the false detection of faults and to increase robustness. Multiple previous works [19-21] propose filtering strategies that suppress undesired components of these signals, usually through threshold calculation or statistical processing.

However, this adaptation generally does not consider the correlation between faults and input nature, which is appropriate under linear conditions.

Backlash is a nonlinear fault present under drastic changes of the system speed. On the other hand, stiction is not present when the machine is in movement. These nonlinear faults are highly dependent on the operational condition of the machine derived from the input signal.

3.2.1. Moving variance

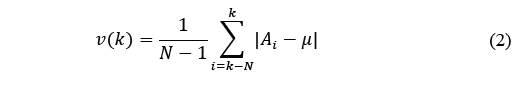

Moving variance is a statistic measure of a signal variability over a fixed length window. It is commonly used to detect signal change points. It is defined as

Where ( is the mean of A. The window size N is chosen in terms of sensibility for adequate speed of detection. The key of using this statistical measure is that when the desired working speed is low, the system is more affected by static friction, such as the residual.

3.2.2. Decelerations count for backlash detection

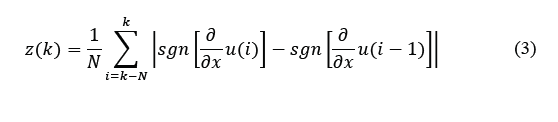

To increase the sensibility and robustness of the system, abrupt speed reductions are measured by counting the number of zero crossings of the acceleration in a moving window.

This measure is given by

Where N is the window size for the zero crossing count. The purpose of this adaptation is to make the filter more sensitive when inputs might cause backlash, and more robust in other cases.

3.2.3. Adaptive filter design

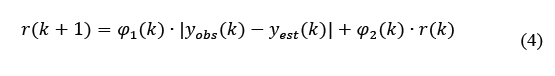

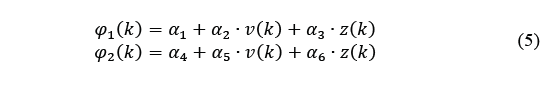

A first order filter design for residuals is depicted in equation 4

where coefficients

and

and

are obtained as follows

are obtained as follows

Both filter coefficients consider an offset and a weighted sum of moving variance and filtered zero crossing count of input signal derivative.

3.2.4. Filter training

Filter coefficients are found through a genetic algorithm optimization. For the fitness function, first, a classification vector is obtained when comparing the filtered residual with a threshold over the training signal of length L. Then, missed classifications are computed and a distance measure is obtained using the 2-norm criteria. The individual is encoded by using real valued chromosomes. One set of coefficients represents the filter design. An extra chromosome for threshold selection is added. The training goal is to increase separability of faults reducing false classification while keeping detection time as low as possible.

3.3. Residual evaluation with Neural Networks

Residual filtering is followed by a classification process for fault isolation. Different faults cause distinctive residual characteristics. Multiple classification techniques can be used for this task. Feedforward Neural Networks are suitable for residual classification and has been extensible used.

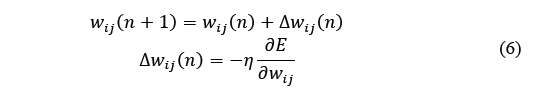

Neural networks training is usually carried out by back-propagation of error and weight correction according to the following rules

where E is a differentiable error function, w ij is the connection weight between neurons i and j, and ɳ is the learning parameter.

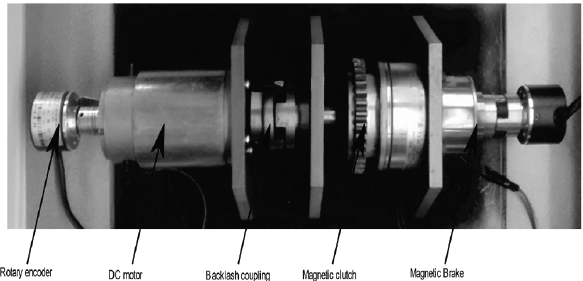

4. Experimental setup

Test benc shown in Fig. 4 was developed to replicate and identify the previously described mechanical faults. It was designed to accomplish with different fault degrees in rotary positioning control arrangements, a widely applied mechatronic system. A motor provides torque and speed through a coupling to the rotating assembly mounted on bearings, representing load. The permanent magnet brushed DC motor has an incremental encoder on its shaft to measure the position. The coupling has a flexible component for misalignment compensation. Wear of this part is usually responsible for backlash.

For comparative purposes, a second rotary sensor is placed at the output of the mechanism. In this test bench, the coupling gap can be adjusted to simulate fault. For stiction addition, a magnetic brake was installed, and its activation was related to the rotation speed. Magnitude of stiction can be set over a wide range. This mechanism can be used to simulate periodic disturbances with different profiles. Finally, for rotary inertia changes, a magnetic clutch attached to a fixed rotary load is used. Transmission sliding can also be simulated through this assembly.

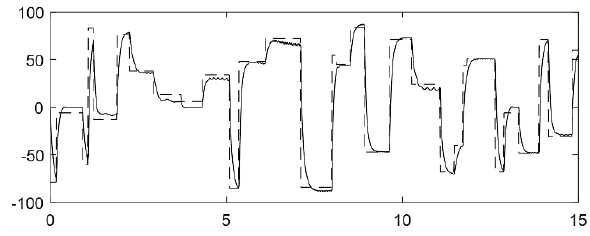

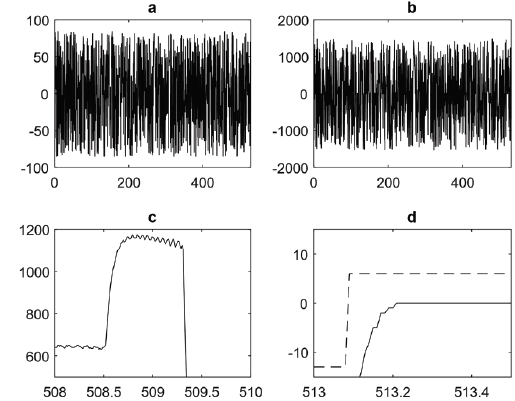

For the system modeling, a uniformly distributed signal in terms of duty cycle and length was designed. A sampling time for measures of 0.01 seconds was used. Fig. 5 shows 15 seconds of input and scaled measured signals without any faults applied.

The filter design for each fault in Table 1 was carried out through a real coded genetic algorithm. The training goal was to increase signal separability for normal and faulty conditions, as well as a reduction of missed classification reduction. Filter sensibility gets adapted to the input nature by using its moving variance and the zero crossing rate of deceleration.

5. Discussion

In this section, the analysis results are presented. A data set for each fault in Table 1 from 500 secs of operation were obtained and acquired for an off line learning process.

5.1. Normal operation

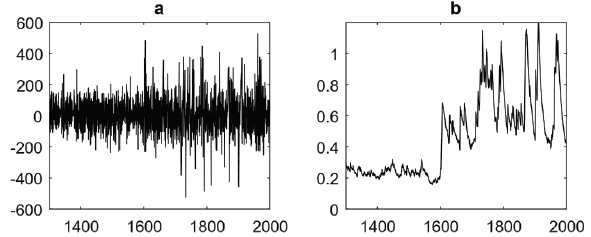

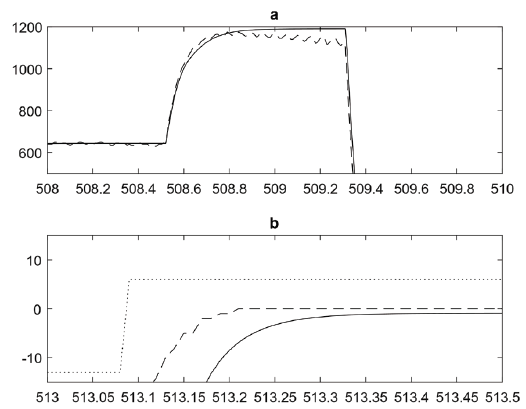

In Fig. 6, the input-output signal of the healthy system is shown. A closer look reveals a first order response with small oscillations close to the steady state and a deadband around zero, which is common in DC motors operation. After the NARX network training, a model was obtained for normal operation. Fig. 7 presents a comparison between measured and predicted signals for the first order components and the deadband. The residuals were obtained from the difference between these signals attributed to measurement errors and unmodeled dynamics. An adaptive filter design was carried out through the depicted genetic algorithm to find coefficients in equation 5. Under these settings, the training goal was to isolate the normal condition from all other operational states, including the full set of faults. Fig. 8 shows filtered and unfiltered residuals. It can be seen the transition out of normal operation close to 1600 sec.

Source: The Authors.

Figure 6 (a) Input signal (b) Output signal (c) First order and oscillatory components (d) Deadband around zero with small input(dashed) and output(solid).

Source: The Authors.

Figure 7 presents a comparison between measured and predicted signals for the first order components and the Figure 7. Predicted (solid) vs measured (dashed) signals for first order response (a) and for deadband zone (b).

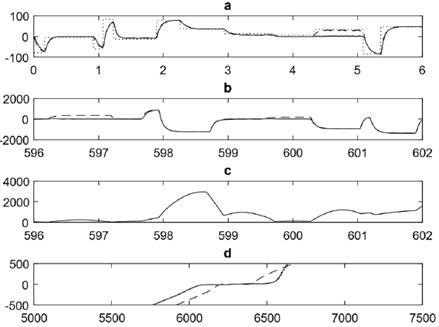

5.2. Bearing fault

For this fault, the stiction from the magnetic brake was introduced into the system. Fig. 9(a) shows in detail the measured differences from this state to the normal operation. The increase of the deadband can be seen close to zero. Fig. 9(b) also illustrates the comparison between output data from normal operation and faulty state modeled systems using NARX networks. It can be seen output differences around zero, as expected for this fault. Fig. 9(c) shows the input variance at the same time. It can be seen an inverse relation between this signal and fault occurrence. This fact is exploited to vary the filter sensitivity to improve detection. Finally, Fig. 9(d) shows model outputs for a sinusoidal input to highlight the deadband increase around zero.

Source: The Authors.

Figure 9 (a) input(dottet) vs measured output for normal operation (dashed) and for bearing fault (solid) (b) comparison between predicted values from normal model (dashed) and bearing fault model(solid) (c) Moving window variance for input (d) deadband around zero from normal and faulty models

5.3. Rotational Inertia changes fault

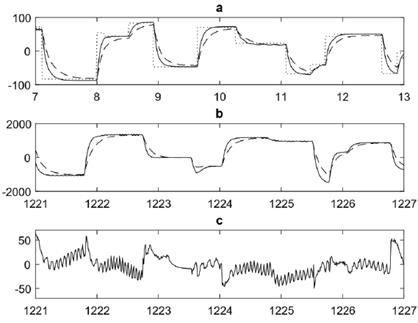

Fig. 10(a) shows the effect of this fault in the time constant of the first order response of the system. Fig. 10(b) compares normal and faulty model outputs. Filter adaptation was not necessary for detecting this fault, due to its linearity and magnitude. Finally, Fig. 10(c) shows the residual signal. Its increment close to the fault occurrence, can be evidenced.

5.4. Backlash fault

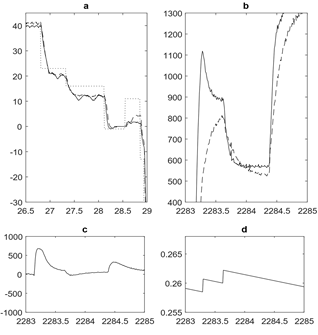

Backlash is characterized by an oscillatory response after abrupt input changes, as shown in Fig. 11(a). Although NARX network for this fault was successfully trained (Fig. 11(a)), residual signal increases (Fig. 11(c)) when backlash occurs, as shown in t = 2283sec. During this time, the filtered count of decelerations also increases (Fig. 11(d)). This measurement was used to rise the filter sensibility.

5.5. Multiple faults

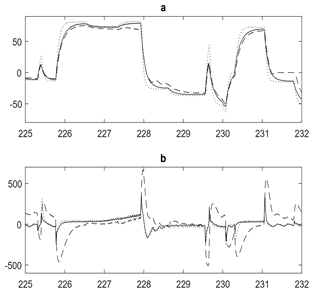

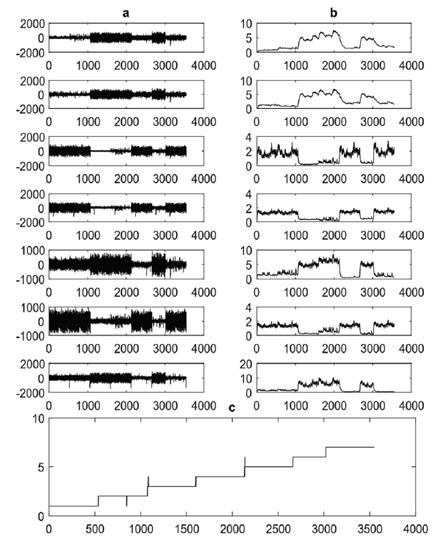

Fig. 12(a) shows the combined effect of backlash, the stiction fault and the abrupt rotational inertia changes. Residuals for each combined case are depicted in (b). This data was also used for modeling to ensure the multiple fault detection.

5.6. Residual evaluation

Finally, Fig. 13 presents the classification through a neural network classifier for successive fault applications where each class from table was successfully identified by keeping low missed fault identifications and with an adequate speed of detection.

Source: The Authors.

Figure 13 (a) Residuals for operative conditions in table 1, (b) Filtered residuals (c) Classification output according to fault index.

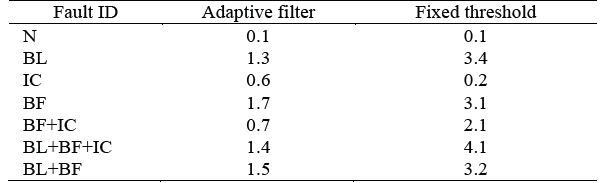

Finally, to evaluate the effect of the adaptive filtering, a fixed threshold first order residual classifier was implemented without considering any statistical input information [2]. The filter coefficients were found increasing the separability of each class, independently. Table 2 shows the classification errors in percentage for each fault.

Although both schemes show high performance considering the low error magnitudes, two facts can be extracted from this data. First, filter adaptation improves the fault detection particularly for nonlinear behaviors. This was expected considering the effect of the input nature in backlash and stiction. On the other side, normal operation and pure linear faults are slightly worse. This fact can be attributed to the faster filter response close to the fault occurrence in the absence of adaptation.

6. Conclusion

In this work, an analytical redundant scheme for fault detection and identification in mechatronic rotating systems is proposed. First, data from normal and faulty conditions is acquired. Coupling backlash, bearing stiction and abrupt inertia changes are considered as faults. Then, system models are obtained using NARX networks because of its capabilities for linear and nonlinear modeling. Multi-fault data is included for redundant detection and modeling. Residuals are obtained comparing measured and predicted values. The obtained signal is filtered using an adaptive method that considers input behavior in terms of moving variance and deceleration zero crossing rate. These input indicators allow increased sensibility and robustness for backlash and stiction faults. Filter constants are obtained through genetic algorithm optimization.

Finally, residuals are classified using a neural network. The proposed methodology proves to be useful detecting single and multiple fault detection on a test bench. In future studies, Fault intensity studies will be considered and implemented into a Fault Tolerant Control scheme.