1. Introduction

Since the introduction of SS in 1988, the methodology has evolved to become part of quality management, this as a management approach in project management. The range of applications for SS continues growing due to defects that are located within organizations, seeking its reduction, as well as the improvement of processes and products, to become a business strategy focused on satisfying the needs of customers [1].

According to Tlapa, Limon, García-Alcaraz, Baez and Sánchez the adoption of SS has increased significantly in those organizations that seek to apply better practices to enhance or maintain competitiveness [2].

Since its implementation, this methodology has evolved to be part of quality and project management and become the business strategy focused on the needs of customers, whose main objective is the reduction of costs in manufacturing, services and variation in the processes to achieve a non-defective production ratio of 99.999998% or the generation of 3.4 defects per million opportunities. Due to the foregoing and to the benefits obtained, this methodology has become a popular strategy in the development of continuous improvement in the manufacturing, public service and administrative areas.

That is why, it seeks to identify the main applications reported in the recent literature, as well as the main CSF that must be considered to achieve the success of its implementation.

2. What is Six Sigma SS?

To understand SS it is first necessary to provide a conceptual definition and identify an underlying theory, although the tools and techniques in SS are surprisingly similar to previous approaches to quality management, SS provides an organizational structure and benefits that had not been seen before over previous approaches to quality management. It also creates new challenges for professional researchers and administrators [3]. In general terms, [4] Arturo Garza-Reyes, Flint, Kumar, Antony, and Soriano-Meier consider SS as one of the most important developments for quality management and process improvement of the last two decades, for their part Arturo Garza-Reyes and Sagnak and Kazancoglu [5,6] Acharya and Mathur, [7] Linderman, Schroeder, Zaheer, and Choo and Al-Agha and Al-Agha [8] Al-Agha and Al-Agha state that SS has three meanings, first, that it is a statistical measure of variation that when is achieved, a process would produce 3.4 defects per million opportunities, second, which is a philosophy and management strategy that allows organizations to obtain lower costs, guaranteeing competitive operations and third, that it is a problem solving and improvement methodology that can be applied to any type of process to eliminate the root cause of the defects. SS is also defined as a business strategy that focuses on improving the understanding of customer requirements, commercial systems, productivity and financial performance [9].

Due to the diverse definitions reported in the literature, it can be said that SS is a project-based management approach to improve the products, services and administrative processes of the organization, also, represents an opportunity for organizations to achieve competitiveness in the market in which they are developed. SS is used as a set of improvement techniques in any part of a business, not only with a focus on product quality [10], but also considered as a strategic corporate initiative to increase profitability, increase market share and improve customer satisfaction through statistical tools and techniques that can lead to great advances in quality, providing to the business leaders and executives the strategy, methods, tools and techniques to change the organizations culture [11]. In this regard, SS is a technique that provides valuable benefits for an organization. As it has been shown in the literature, SS not only focuses on the improvement of production and manufacturing processes, since over the time its applications have diversified giving entry to the administrative part of any organization, interested in continuous improvement in a holistic way and not with a particular focus for a specific process, in addition the administrative part represents an important process for the adequate organizational performance.

According to the above and regardless of the kind organization who develop SS as a competitive strategy, they will benefit from knowing specifically on which factors they should focus their attention and the interrelationships that exist between them for the correct development of the projects, expanding the view of the resources that must be managed and how they should be done so that the project provides the desired results. It is important to consider that the administrative part of any company must know clearly the processes that are developed for the fabrication of their products, to be able to focus efforts on the necessary resources, such as the human and economic resources. If this is achieved, the organization will have a competitive advantage over others.

On the other hand the literature has reported that organizations have different approaches, for example, the quality of their products, customer satisfaction, maximize their profits and develop their administrative processes appropriately, but above all to achieve competitiveness in the environment that are developed. In order to achieve this they are immersed in strategic decision-making with long-term repercussions, where there is a likelihood of not being able to foresee all short-term commercial possibilities. It is in these activities where organizations seek to support themselves with various quality and continuous improvement tools that allow them to achieve competitiveness. Here the field for the deployment of SS is open as an organizational and administrative strategy since it brings benefits in relation to resource efficiency, customer satisfaction and profit maximization, thus advancing on the path of competitiveness.

And so, it is considered relevant to review the literature to show the recent applications and implementation areas where SS is currently being developed and finally to present an analysis of the CSF reported by various authors, providing the most suggestive for the development of SS projects.

3. Materials and methods

Following the procedure suggested in [12] and [13] the materials used for this research were articles selected from the following databases: EBSCO, ELSEVIER, EMERALD, SPRINGER and TAYLOR & FRANCIS, the databases consulted for the search of articles, a total of 83 articles were found mentioning the SS strategy and critical success factors, in Elsevier a total of 33 articles were located, in Emerald 25 articles, in Ebsco 5 articles, in Springer 3 articles, Taylor & Francis 2, the remaining 15 were selected from various databases.

In this respect, the publications mostly considered for this research are those that were reported preferably in a period from 2013 to 2017, however, publications were taken into account, although in a lower percentage of previous years. In addition to the considerations already mentioned for the selection of articles, another important factor for this process was the search for articles that preferably included the keywords: Six Sigma; Administrative strategy; Applications; Implementation areas; Critical success factors, in order to present an updated review that provided a beneficial contribution for those who wish to carry out the implementation of SS in their companies. SS is currently considered an important management tool for national and international companies.

The efforts for the selection of articles were made with the objective of integrating this document with an adequate number of updated bibliographical references, with which a more complete and renewed literature review about the SS methodology will be obtained.

4. Methodologies used for SS

The methods used in investigations reported in the literature mainly come from the application of techniques belonging to SS, for example, DMAIC (Define, Measure, Analyze, Improve, Control), DFSS (Define, Measure, Analyze, Design, Verify), Brainstorming, Root cause analysis, Histograms, Control charts and Analysis of the capacity of the process, which will be taken up in the following sections.

Nevertheless, the objective of this literature review is not to provide a methodology for the application of SS, seeks to provide researchers and administrators of organizations with an overview of the main factors on which they should focus for the correct and successful implementation of SS, and present to researchers the main areas of implementation shown in recent literature.

Due to the above, the following sections describes the results found in the literature review, showing the areas of implementation and the critical factors reported by the researchers, as a way to provide a guide for interested in developing SS in their organizations.

5. Results

This section presents the results of the investigation. In order to show the results in a clear and orderly manner, they will be presented through the following subsections.

5.1. Main applications and areas of implementation of SS strategy

In the beginning of SS application, the areas that most commonly developed the methodology were those dedicated to the manufacture of products, since the main objective was the continuous improvement of the processes and products they manufactured, mainly through the minimization of times and defects, where the main objective was customer satisfaction interest that continues to prevail for organizations, as mentioned by Antony, Gijo, Kumar, and Ghadge, the main focus manufacturing organizations have always had is to improve the quality of their products and processes. They also mention that currently the popularity of SS in other sectors is growing exponentially, especially in banks, hospitals, financial services, aerospace industry, public services and administrative, etc [14].

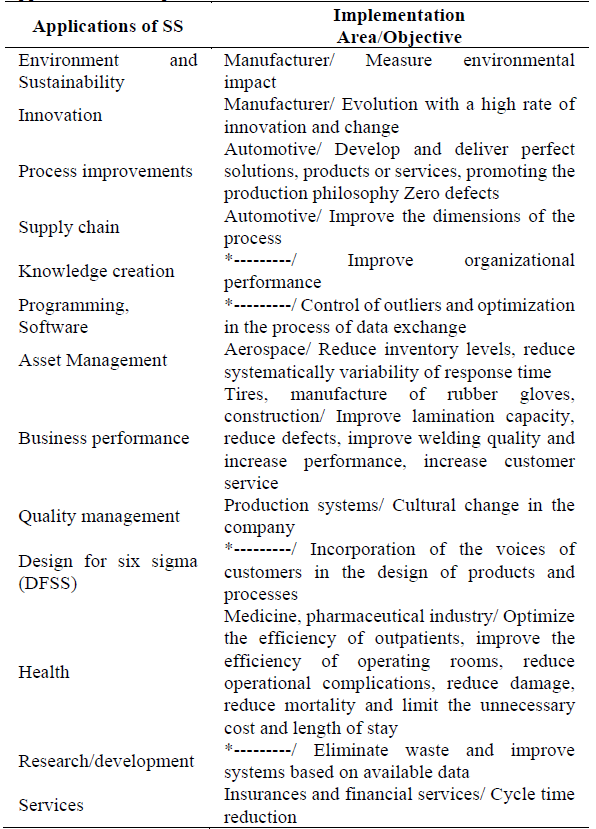

The real global market has experienced a significant increase in the use and development of the SS methodology, where a wide variety of organizations are looking for best practices to increase or at least maintain competitiveness, resulting in a large number of companies obtaining economic benefits while improving relations with customers through SS. As it is observed, the applications that have been given to the SS methodology are very diverse; all of them coincide in the benefits that can be achieved with a good implementation. This has led many organizations to implement SS as a business strategy to increase their profitability, improve the quality of its products and processes, reaching to improve their productivity and competitiveness. The applications and implementation areas located in this review are summarized in Table 1.

5.1.1. Environment and sustainability

From the literature review, the impact of SS observed on the care of the environment, Chugani linked the positives for such on the issues of energy management, global warming, pollution and use of resources [5]. In this, Chiarini had as a main objective in his research to determine if lean production tools can help reduce environmental impacts in manufacturing companies [15]. The originality of his research lies in the observation and measurement of the effects on the environmental impacts with the implementation of lean tools, suggesting deepening the research for the ecologization of the processes.

On the other hand, in terms of sustainability De Freityas and Costa had as purpose in their research to verify how the application of SS can influence organizational sustainability through their projects, given that there are a few scientific studies that seek to evaluate the existing relationship between SS and sustainability [16]. In addition Sagnak and Kazaconglu mention that environmental considerations have led organizations to assume an important role in the design of ecological and recyclable products to complement the improvements in environmental standards of the service [17].

For this matter, the practice of SS can result in the reduction of contamination, that is to say that SS can have an effect on innovation and sustainability. So Parast had the goal of developing a theory to determine the effect of SS on innovation and the performance of the company, finally finding that the implementation of the SS projects in a highly dynamic and evolving environment with a high rate of innovation and change, was very risky due to the inability of SS projects to address radical change. Due to these changes, the competition between the industries became abrupt in seeking to be the best in its branch [18].

5.1.2. Process improvements

In relation to the processes that are carried out in the organizations, the continuous improvement of them is persistently sought, for this matter and particularly in the automotive area, Surange mentions that SS is applied as a powerful methodology that contributes to the reduction of costs, improves products and processes which leads to an increase in profitability and market share, being its main application the positive impact on the cost due to poor quality [19]. In the same sector Swarnakar and Vinodh, had as main objective the reduction of defects and the improvement of results, achieving with the implementation the reduction of defects, the downtime of a machine, reduction of the rejection rate of components of large inventory [20]. On the other hand Azadeh, Nasirian, Salehi, and Kouzehchi used the SS methodology with the main objective of evaluating and optimizing the consequences of SS in working conditions, the main ones to be evaluated were: general working conditions, development of personal, cooperation and companionship, work stress and safety. This study indicated that the general working condition factor has the greatest impact on the level of satisfaction, compared to the other indices [21]. Pugna, Negrea, and Miclea present a creative solution to improve an assembly process in an automotive company through the use of SS, Pugna et al, mentions the desire to achieve business excellence in the automotive industry and assumes the commitment to develop and deliver perfect solutions, products or services, promoting the production philosophy Zero defects and considers that SS is the best way to achieve quality and reduce waste by helping organizations to produce better products and services, faster and cheaper [22].

5.1.3. Supply chain

Erbiyik and Saru mention that SS has an important place for the development and reduction of the actions that do not have internal process in the supply chain of the companies, reason why in its investigation it explains the general structure of SS in regarding how to define the complex problems that are found in the supply chain in the context of an automotive industry [23]. In the study of Mishra and Kumar Sharma the objective was to improve the dimensions of the management process also in the supply chain, its objectives were achieved with the use of SS tools [24].

5.1.4. Asset management

In the work of Thomas the SS methodology was developed to perform the application of the asset management practices and an effective approach to create a solid strategy for an aerospace company. The company had high levels of inventory and needed an appropriate and more cost-effective service, so the SS approach was used giving special attention to the avionic repair facility, since the nature of component failures was more unpredictable and the inventory costs were higher than in other facilities within the company [25]. Thomas, Francis, Fisher and Byard mention the successful application of SS in a case study in an aerospace manufacturing company. In this work, significant improvements were achieved in the business performance, the main ones being: reduction of the construction time by 20.5%, improvement of the total delivery time to the client by 26.5%, reduction of the value-added time by 5% and reduction of the non-value added time by 44.5%, obtaining in addition a substantial economic savings [26].

5.1.5. Knowledge creation

In this diversity of applications we can mention Boon Sin, Zailani, Iranmanesh and Ramayah, whom investigated the existence of a relationship with the processes of creation of organizational knowledge, socialization, externalization, combination and internalization, obtaining as a result that the knowledge creation process of an organization positively affect knowledge and at the same time, knowledge positively affects the success of the SS project and the success of the SS project leads to a better organizational performance [27].

5.1.6. Programming and software development

Another of the applications for SS is the one found in the research of Čampulová, Veselík and Michálek, in which control diagrams and SS-based algorithms were developed for the identification of outliers in experimental data, this is especially useful to control the quality of the data that is measured continuously with high temporal resolution and for reduction of outliers since the manual control of the quality of the data requires a lot of time [28]. On the other hand, Chen, Fan, Xiong, and Zhang, propose the management of SS based on the JMP / SAP software design (used for the planning of production and for the development of statistics), in this study they looked for the optimization in the process of data exchange, based on the traditional management of SS, since it improves the acquisition and analysis of data, which to a certain extent guarantees the efficiency of the data [29].

5.1.7. Business performance

In the work developed by Zhang, Wang, Goh and He a project was carried out to improve the capacity of cold rolling and meet the thickness requirements. Through the implementation a significant financial impact on the profitability of the company was achieved. The conclusions of their work mention that it has been reported that many of the most important companies in the world have implemented the SS administration to improve the quality of their products and services [30]. In the work of Gupta, Acharya and Patwardhan, it is intended to show how SS can be used to address specific issues such as the reduction of defects, as results confirmed that SS can serve as an important tool to reduce defects in the tire manufacturing process in India [31]. With the same objective Jirasukprasert, Garza-Reyes, Kumar and Lim presented an industrial case to demonstrate the empirical application of SS to reduce the defects of the product within a manufacturing organization of rubber gloves, obtaining as a result the optimization of two variables in the process [32]. In the application developed by Hassan, SS was used for a welding wire manufacturing plant with the aim of improving the welding quality and increasing the performance of the manufacturing process [33].

5.1.8. Quality management and Design for Six Sigma (DFSS)

Another important application for SS is the one proposed in the research carried out by Cervera, who mentions that the application of SS in the models of quality management supposes a change in the culture of the company. However, the call to lead with this process of change is directed to top management, through the implementation of a system of permanent and participatory continuous improvement and management, it is also mentioned that SS is a great tool in regards to the improvement of the productive systems [34]. Wang, Yeh, and Chu used the DFSS as a proactive system that involves the incorporation of the voices of the clients in the design of products and processes and it is also used to establish a quality design through the application of preventive thinking and tools in the product development process. They mentioned that in order to obtain the effectiveness of a DFSS project, the company's high levels must commit to invest resources, promote, update and support the program [35].

5.1.9. Health, research and development

Up to this point the literature suggests that, the main applications of SS are developed in the manufacturing industry with the main objective of reducing defects and improving processes. However it also states the use of SS applications in the field of medicine; in the study of Mason it is mentioned that SS has been applied in health centers since the 90's. In these applications the wide range of results can be grouped into six common objectives: optimize the efficiency of outpatients, improve the efficiency of surgery rooms, reduce operational complications, reduce damage, reduce mortality and limit unnecessary cost and length of stay. Most studies (88%) show improvement; however, high levels of systematic bias and imprecision were evident [36]. Ahmed, Manaf and Islam mention that defects and errors are not allowed in health care organizations, since a simple mistake can cost a human life, so in their research they discuss the effects of SS in various hospitals around the world through literature review, and the impacts that the methodology it has on health services [37]. In this branch, Lighter mentions that physicians and health administrators face an environment of increasingly competitive practice that challenges financial survival and only through increased quality and administrative efficiency, professionals will be able to navigate the changes in health care that are currently occurring. He concludes by mentioning that pediatric providers have significant challenges in this new environment, but that SS approaches and tools can contribute to the solution [38]. In this way Chiarini wanted to understand if some SS tools are useful to reduce the safety and health risks for nurses and doctors who handle cancer drugs with the additional objective of analyzing the economic improvements achieved by SS. This study resulted in an improvement in health and safety situation [39]. Laureani, Brady, & Antony developed their study in a hospital and show that novice users of LSS can provide value to the organization in a relatively short period of time. They also suggest that LSS education and training is useful because it allows users to choose the right technique for the context and use it appropriately [40]. Coleman conducted a study, where it is mentioned that the applications in this branch include the admission and discharge of patients, medication administration, surgery room, cardiology and intensive care [41]. On the other hand, Joel developed a bibliographic review on the basic concepts related to the critical success factors for quality management. They propose a model to identify the critical factors in the health sector, through the construction and validation of an instrument that will yield the results to be analyzed to determine the significant critical factors [42]. Panat, Dimitrova, Selvy Selvamuniandy, Ishiko and Sun research have as an objective to develop LSS in research and development organizations, aiming to eliminate waste and improve the systems based in the available data and at the same time would improve the innovative environment [43].

5.1.10 Services

Another area that has recently become relevant in SS applications, is the one mentioned in the study by Sarkar, Mukhopadhyay and Ghosh, is the service sector. In this case, the reduction of cycle time is one of the key issues, so this work is aimed at reducing the cycle time in the process of liquidating claims in insurance or financial services, as well as demonstrate that combine lean concepts or techniques with SS can accelerate the approaches in solving problems [44].

Finally, and because customers demand more and more high quality and reliable products at low cost, the construction industry also faces greater competitiveness caused by globalization and deregulation in companies, this is mentioned by van den Bos, Kemper and de Waal in their study on how to improve the performance of LSS in a construction company, concluding that although the implementation of LSS tools have higher introduction costs, in the end to compete in the current construction industry, the continuous improvement of the process will be increasingly important in the daily organizations work [45].

In this same industry, Banawi and Bilec mention that construction consumes an important amount of resources that annually generates a significant waste and producing a large amount of emissions. In this study two issues were highlighted in the construction process: delays and potential errors of the estimate and purchase of material; besides it is described the environmental impact derived from the waste analyzes its causes to improve the performance of the process [46]. Noriega Morales, Valles Ch., Torres-Argüelles, Martínez G. and Hernández G, described in their work the application of several SS tools to explain the necessary changes of improvement in a company that manufactures concrete blocks. The main tool used was DMAIC, which is part of the SS methodologies. In their study, they demonstrate the application of SS as feasible and how it produces attractive financial and operational results in this segment of the construction industry. As main result, they obtained the increase in customer service through the rapid delivery of complete orders [47].

Through the literature reviewed for this research, it can be seen that the applications of SS have been diversified through time. SS initially developed with the firm objective of reducing manufacturing defects in a specific production process. Over time and the various benefits that have been achieved with SS, the organizations not only deploy the strategy with that particular vision, now the administrators of the organizations have decided to implement SS in various areas as they achieve more substantial benefits. In this regard, the administrative part of an organization benefits since it achieves better performance in its own processes, which leads to continuous improvement, saving of resources and the correct administration of them.

Due to the diversification of the use of the SS strategy, several authors have studied and reported numerous applications and areas of implementation, in which different CSF have been detected in projects. However, the literature has not reached a generic concentration that explains what factors should be considered regardless of the area in which you want to deploy the strategy and therefore the administrators and leaders of the organization do not have a way that directs them to where they need to focus the efforts and resources in an appropriate manner.

From the various applications mentioned above, the existence of CSF have been detected in the development of SS projects, which are suggested to be considered in the deployment of improvement projects within the organizations, for which the following section has been elaborated with the factors that are considered critical to achieve success in the projects.

5.2. Critical success factors of SS

In relation to the critical factors that are considered as the most relevant, Pamfilie, Draghici and Draghici mention that, one of the most important aspects when applying the methodology is too involved all the employees of the company [48]. For Antony, Karaminas one of the most important factors to consider are the skills and training of "Black Belts". They also mention the importance of knowing their roles and activities within the project [49]. Elias, on the other hand, focuses on the importance of the stakeholders in the development of the projects, since they are the ones that provide support to the organization [50].

For Albliwi et al., in recent years lean and SS have become the most popular business strategy for the development of continuous improvement in the sectors of manufacturing and services. Continuous improvement is the main objective for any global organization that wants to achieve quality, operational excellence and improved performance in their processes [51].

Hilton and Sohal mention these factors are related to leadership, communication, behavior, policies, culture and organizational support, education, training and competence of SS experts, improvement teams and project management [52].

Regarding the theoretical aspect, several studies report that there are factors that influence the execution of SS projects in different degrees. Those which have been considered most relevant according to Júnior and Lima are the lack of alignment of the SS project with the objectives of the company, the quality of the projects did not meet the expectations of top management, little participation of the leaders and development of projects at inadequate times for the company. However, several authors consider numerous critical factors for the development of SS projects in organizations [53].

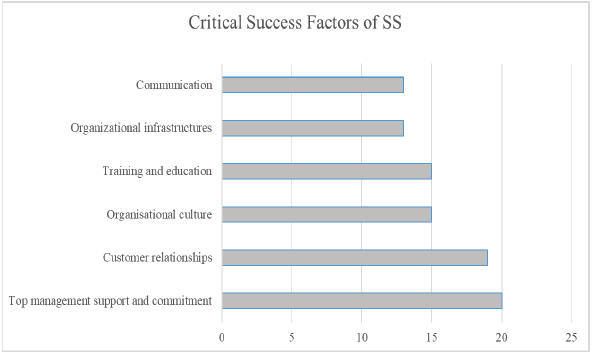

In order to present the results graphically, in Figure 1, the CSF are observed in order of importance, defined by the number of authors who have mentioned them in their research. It is important to indicate that through the review of literature, a total of 16 CSF were identified, however for this article, the 6 most outstanding were considered, which show at the graphic.

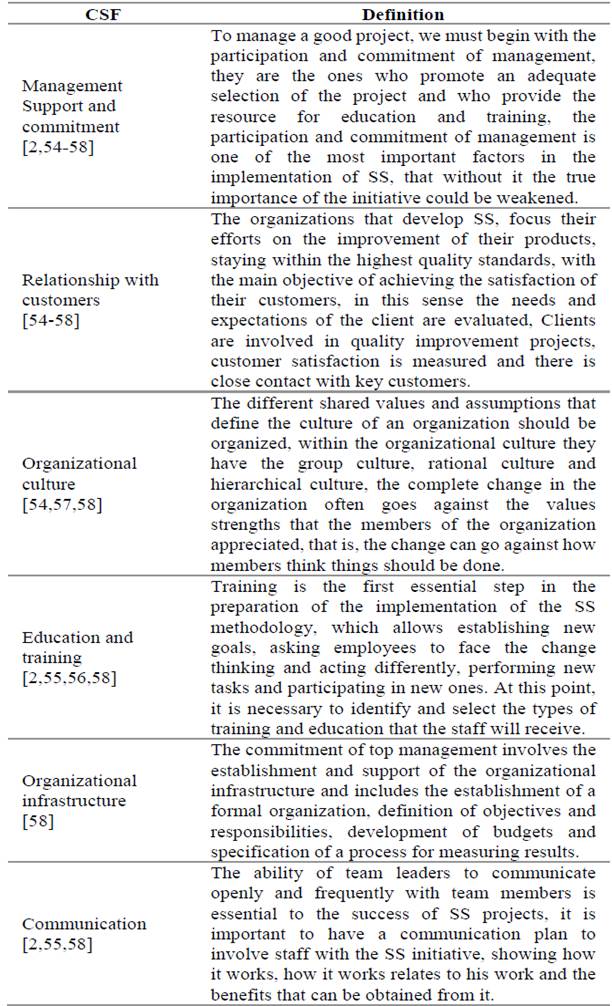

To achieve a better understanding of the CSF considered for this research: support and commitment of management, relationship with customers, organizational culture, education and training, organizational infrastructure and communication, table 2 presents the definition of the same.

6. Conclusions

Although the utility and advantages that can be obtained with the implementation and development of the SS strategy and the positive results that can be achieved in the different areas and sectors of application are widely recognized in the literature, it is concluded that there are sectors in which can be deepened. Several are the findings detected in this literature review, starting with the variety of applications and areas of implementation of SS followed by the critical factors for the achievement of the objectives. It is important to emphasize the scope that the strategy is currently having and how it has diversified the sectors from where its implementation was commonly seen, as was the manufacturing and industrial areas. However, through the benefits obtained, its applications have been developed in other sectors, such as service, environment and health.

Despite the fact that a large and diverse number of applications and areas have been located where SS has recently been developed in the literature, it is convenient to conclude that research on environmental impact is needed, since that concern for the environment has turned essential for organizations, so it seems appropriate to inquire more about this research gap.

In relation to the health/medical sector, literature reports that SS has been implemented in specific health care organizations. However, Sabry mentions that there is a lack of studies that investigate the broader SS status in these institutions, so it is suggested to conduct more research in this sector [59].

Therefore, it is concluded that the literature is unfinished, that it has gaps and controversies between the opinions of experts and much of the work carried out is empirical, lacking forcefulness to the theory, clarity and precision.

On the critical success factors, there are no satisfactory explanations that mention in which of them more attention should be paid, the resources that must be taken into consideration and how to achieve projects to provide desired results. In addition, there are few articles that emphasize quantitative research including mathematical models and clear guidance for those who wish to develop and implement SS.

Due to this, one of the objectives of this review was to present the most suggestive CSFs for consideration in the development of the SS strategy in organizations. In this way and reflecting on the various non-consensual opinions of experts in the area it is suggested that those who seek the continuous improvement of their administrative, production or manufacturing processes take into account the factors reported in this literature review. Particularly it is concluded that the recommended CSFs to examine when planning SS project execution are: Management Support and Commitment, Relationship with Clients, Organizational Culture, Education and Training, Organizational Infrastructure and Communication. While it is true, the success of strategy deployment cannot be guaranteed with the sole fact of considering CSFs, it is proven that better organizational results can be achieved in various areas that lead to continuous improvement.

Finally, based on the literature reviewed and the gaps identified, future research is recommended deepening mainly in the areas of sustainability and environment, health and medicine, as well as documenting the practices carried out in the services sector, in addition to enriching the literature with case studies where models can be created supporting the development of projects and where the factors that can affect the achievement of the objectives of an organization can be considered from the beginning.

7. Recommendations

Through the conclusions obtained in this literature review, recommendations for researchers are:

Due to the relevance of this topic and the interesting findings reported in literature, for example the sustainable benefits through the application of SS, is need in-depth research on the relation between SS and environmental impact and sustainability.

In-depth research in the practice of medicine and the benefits that can be obtained with the development of SS in institutions that are dedicated to health care.

Examine in depth the practices developed in the services sector, to enrich the literature on the application of SS in this sector.

Develop and implement mathematical models to identify the most significant factors in the deployment of SS, which clearly orient those interested in deploying SS in their companies.

Develop networking links with companies in the services sector and formalize practices that currently carried out with the support of SS.

Likewise, and with the literature review, some CSF were identified, as Management Support and Commitment, Relationship with Customers, Organizational Culture, Education and Training, Organizational Infrastructure and Communication, in this sense, recommendations for managers of the organizations interested in implementing SS as a competitive and improvement strategy are the following:

The management support and commitment turn out to be, the main CSF for the deployment of the SS projects, according to what is reported in the literature review, so it is suggested that the first step to start the implementation of SS is the commitment of the management and to be maintained throughout the entire execution.

The company's managers must maintain a close relationship with their customers, which allow them to know their specific needs and requirements, in such a way that they achieve an effective communication that allows improving their processes, products and services and directly impacting on the satisfaction needs.

The organizational culture is another factor that the leaders of the organizations should consider for the deployment of SS, because represent a set of perceptions, attitudes, habits, among others, that can present the members of the organization. If the organizational culture is considered during the SS deployment, the probability of achieving the objectives raised at the beginning of the implementation.

Literature also reports as CSF, education and training for all organization members, from management levels to operational levels, due to the importance of having knowledge of the tools and techniques necessary for the correct deployment of SS.

The organizational infrastructure turns out to be another CSF for the implementation of SS, as they are those elements with which the work team will count for the deployment, so it is suggested to the managers, to get involved in the projects since their planning, in such form that they have knowledge of the infrastructure that will be necessary for an adequate implementation of SS and to be able to support conveniently in the whole process of SS.

Finally, within the factors identified through this literature review, communication is a critical factor in the deployment of SS, consequently it is proposed to the managers of the organizations to have an exclusive area of communication, that at the same time, collaborates in SS projects, with the objective of informing and communicating about the progress made in the whole SS implementation process, from planning to closing and presentation of results obtained.

Only with the knowledge of the CSF cannot ensure the achievement of the objectives, also requires a hard work where should be considered since the planning and prior to the execution of the projects. In addition to a commitment of management throughout the implementation process, participation of all the members of the organization is needed.

Accordingly, the researchers report that if the FCE are considered and taken into account from the planning and execution of SS can achieve better results and objectives. Based upon the foregoing the organization and its leaders will take to continuous improvement and consequently to achieve the success in the implementation.