1. Introduction

Mango has a great importance for several tropical countries around the world. In Colombia, cultivation of mango represents about 2% of the total sown area (27.473 ha), and it is the 6th of the seven permanent cultivations existent in the national territory, with a mean annual production of 224.934 t [1].

It should be noted that mango production is ranked as 7th among the ten main production chains in Colombia. It is consumed by 15% of population being the 2nd fruit more consumed in the country [2].

Despite the promising prospect on mango cultivation in Colombia, currently there are problems in the postharvest stages like: high price dispersion due to variability on fruit quality, excessive fruit handling in the distribution chain and economic instability due to price variability in the market. The more important consequences are the economic instability of producers and the high losses and wastes of the fresh product [3].

In Colombia, about 9.76 Mt of food are lost or wasted every year, of which 62% correspond to fruits and vegetables [4]. The National Department of Planning (DNP) affirm that about 34% of the 28 Mt of food produced annually is lost or wasted. The volume of losses and waste is alarming: for every three tons of food produced, one is lost or wasted. In the case of fruits and vegetables the amount is even more alarming, the losses and waste are estimated in 58% of the total production [4].

Given the commercial importance of mango and the context of food waste in Colombia, a strategy in the processing and postharvest handling is required. The present research considers the drying with osmotic dehydration (OD) pretreatment for this purpose.

The OD is a conservation alternative, which significantly reduces the water activity in food. Therefore, it limits deterioration processes, especially in the outermost cells that are dehydrated in greater rate, and can act as a barrier for the rest of the tissue [5].

The OD as pretreatment of hot air drying is one of the most used methods, because it improves the final product properties and keeps its quality attributes, especially the nutritional value. These advantages have contributed to the continuous study of its applications in a wide range of agricultural products [6].

A wide variety of research on OD a pretreatment in fruits and vegetables has been developed, evaluating different ranges of temperature and sucrose concentrations both in the process and in the quality of the final product. However, the behavior of whole cane sugar in this process has not yet been studied, considering that it has great nutritional properties and its use is of great interest to producers; which would give an added value to the sugar cane chain

Therefore, the aim of this research is to evaluate the effect of temperature and whole cane sugar concentration as a pre-treatment of convection drying on the physical-chemical properties of mango (Tommy Atkins). Unlike most of the researches carried out, this one considers a Central composite rotatable design, to obtain statistically significant and predictable response surfaces and thus obtain more information about the dependent variables studied. The optimal point of the osmotic solution temperature and concentration gives the optimal response about the process and the final product quality.

2. Materials and methods

2.1. Material Source

The research was carried out in the Postharvest laboratory of the Department of Civil and Agricultural Engineering at the Universidad Nacional de Colombia - Bogotá D.C. It has a mean room temperature of 22 °C and 37% of relative humidity.

Tommy Atkins variety mangoes used were purchased in a local supermarket in the Bogotá city and were selected for each run with similar size, color and firmness, considering that they were free of physical damages due to blows or diseases. Mangoes were washed with cold water and were cut in pieces of about 2x2x1 cm. the dimensions were measured with a Vernier caliper. Moisture content of fresh and dried samples was determined using a vacuum oven (SL Shel Lab, USA) according to the methodology of AOAC 934.06.

2.2. Osmotic Pretreatment

Mango pieces were immersed in osmotic solution of whole cane sugar between 30 and 65 °Brix and temperatures between 50 and 80 °C for 1 hour. To prepare the solution, an analytical balance (XT220A, Precisa, Switzerland whit precision of 1.0x10-3g) was used. The concentration was verified using a refractometer (HSR-500, ATAGO, Japan).

To keep the temperature during the pretreatment, a thermostated bath (D-20K, DiEs, Korea) with agitation at 30% (equipment agitation scale) and temperature control was used.

After the pretreatment, the samples were removed from the solution, and the dimensions of three pieces in each run were measured to determinate the shrinking after the convective drying.

2.3. Convective drying treatment

The dehydration process was completed with drying in a forced convection oven (OMS100, HERATHERM, Germany), at 70 °C until the equilibrium moisture content was reached. Weight measurements were made on an analytical balance (PB3001, precision of 1.0x10-3g. Mettler Toledo, Switzerland).

2.4. Experimental design

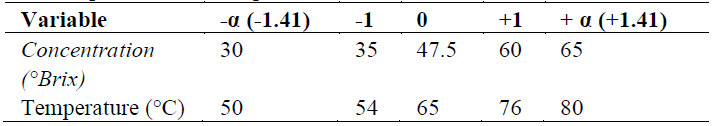

As mentioned previously, for the osmotic pretreatment the central composite rotatable design was used, with concentration and temperature of solution as independent variables. Table 1 shows the developed experimental design.

The design shown in Table 1 contemplates the denominated “axial points”, which are related to the encoded value ± α. In each test, the following values and physicochemical properties were determined.

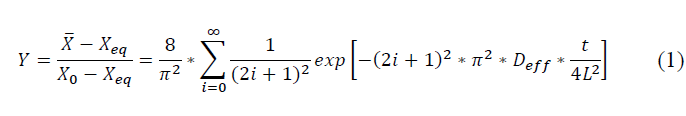

Effective diffusivity: Using Fick´s law, the diffusivity was determined for a flat plane from the eq. (1).

where;

Deff: Effective diffusivity, cm2 s-1.

Y: Moisture content, dimensionless.

: Mean moisture content, kgH2O * kgDS-1

: Mean moisture content, kgH2O * kgDS-1

Xeq: Equilibrium moisture content, kgH2O * kgDS-1

X0: Initial moisture content, kgH2O * kgDS-1

i: Terms of the series.

t: Time, s.

L: Half - thickness of the sample, cm.

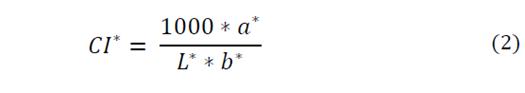

Color: It was determined using a colorimeter (CR-400, Konica Minolta, Japan), configured in the scale CIE-L*a*b*, where L* is luminosity or brightness, a*: green (-) to red (+) coordinate, and b*: blue (-) to yellow (+) coordinate. The measurement was made before the pretreatment and after the convective drying in three different pieces. Three readings were made for each piece in both sides and a mean for every value was determined. The obtained data was used to calculate the color index (CI*), according to the eq. (2).

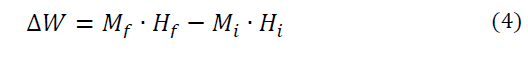

Water loss and osmotic solution gain in pretreatment: The net mass loss (∆M) in the pretreatment was determined by weighting the full solid sample before (Mi) and after (Mf) the pretreatment using an analytical balance (XT220A, Precisa, Switzerland). In addition, it was calculated with the eq. (3).

Water loss (∆W) in pretreatment was calculated from the humidity before (Hi) and after (Hf) the OD (eq. 4).

The osmotic solution gain (∆S) was calculated indirectly from the eq. (5).

Water Activity: It was measured using an equipment (Hygrolab 3, Rotronic, USA). The measurement was made in three pieces of fresh sample and three of dried sample for each run.

Tasting and acceptability test (AT): The test was made giving samples to 25 non-trained juries in the Universidad Nacional de Colombia- Bogotá D.C. Each jury received 3 samples from 3 different runs to qualify their perception of color, texture and flavor in a hedonistic scale between 1 and 9; where 9 is very pleasant, 5 is admissible, and 1 very unpleasant. Additionally, the juries determined the consumption probability in the following scale: none (0%), unlikely (25%), maybe (50%) and very likely (100%).

2.5. Data treatment

The experimental data obtained in each run were treated with the software STATISTICA version 10, to obtain by regression the effective diffusivity for each one, the ANOVA analysis and the second order model. This model describes the behavior of the measured variables with the variation of the independent variables, encoded according to the description in Table 1. In the model determination, a 95% confidence level for effective diffusivity, color index, water loss, sugar gain and water activity was used. In the case of the tasting and acceptability test (color, texture, flavor and consumption probability), a confidence level of 90% was used. The analysis was completed obtaining the response surfaces when the results of statistically F-test analyses were performed.

3. Results and discussion

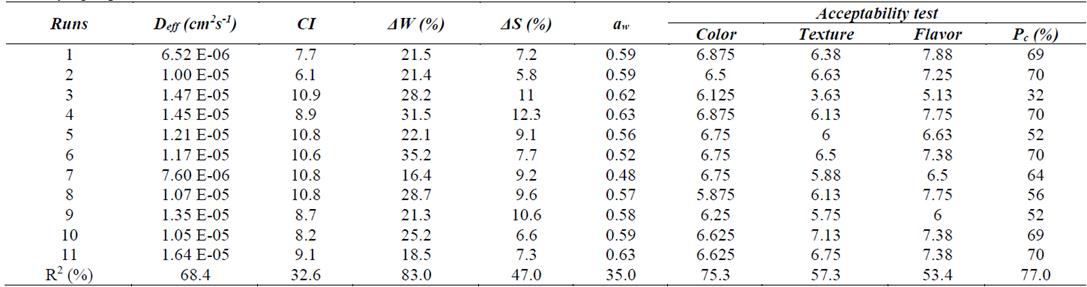

Accordingly with the experimental design for effective diffusivity, color index, water loss, osmotic solution gain, water activity and acceptability test, the means obtained are shows in Table 2.

Table 2. Effective diffusivity (Deff), color index (CI), water loss (∆W), osmotic solution gain (∆S), water activity (aw) and acceptability test (AT) of mango pieces after drying experimental runs.

Source: The Authors.

3.1. Effect on diffusivity

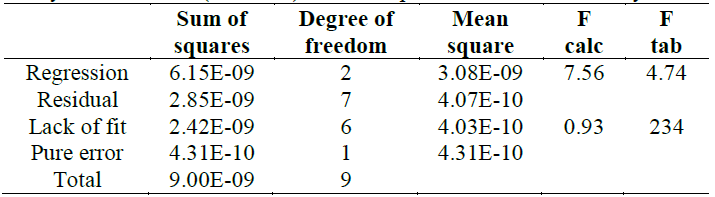

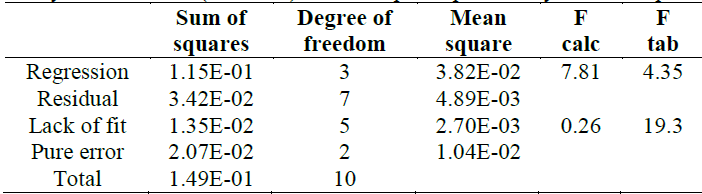

The diffusivity in mango pieces, using Fick's law for plane sheet, was statistically influenced only by the temperature in OD and not by the concentration. The nonsignificant parameters were not considered on the further regression and ANOVA and the F test. Thereafter, a predictive model was generated by pure error analysis. Table 3 show these results.

The proposed model to represent the effective diffusivity is shown as a re-parameterized model to the uncoded variables in eq. (6):

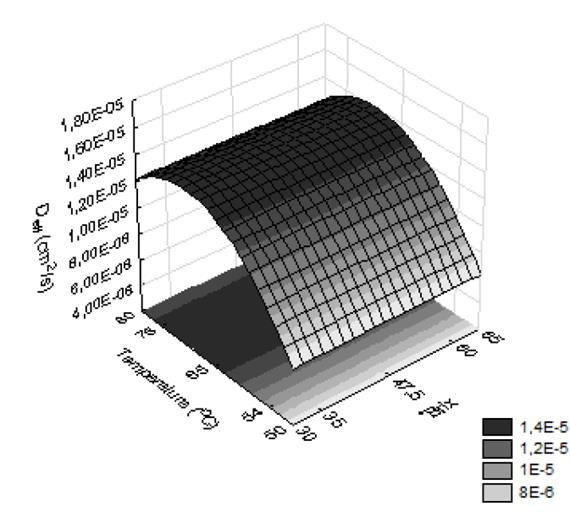

The most representative effect of the temperature of the pretreatment on the effective diffusivity is presented between 60 and 77 °C, where values are recorded between 1.2x10-4 and 1.4x10-4 cm2s-1. As is shown in Fig. 1, at temperatures close to 70 °C, the effective diffusivity is the highest. However, in values above this temperature and up to 80 °C, the diffusivity is slightly reduced. [7] determined a similar effective diffusivity of 1.79x10-4 cm2s-1 in mango pretreated with sucrose solution at 65 °Brix and 70 °C, thus, it can be inferred that sucrose has a similar effect to that of whole cane sugar on the effective diffusivity of mango.

In the opposite case, in temperatures lower than 60 °C, the diffusivity presents a reduction slightly more pronounced than in higher temperatures, presenting values up to 6.0x10-5 cm2s-1 at 50 °C.

3.2. Effect on water loss in osmotic pretreatment

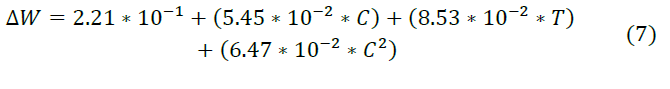

Water loss (∆W) in mango pieces was statistically influenced by both the temperature (T) and the concentration (C) of the pretreatment, as described in the re-parameterized model to the uncoded variables (eq. 7).

The obtained model turned out to be statistically significant and predictive, according to the ANOVA analysis and the F test presented in Table 4.

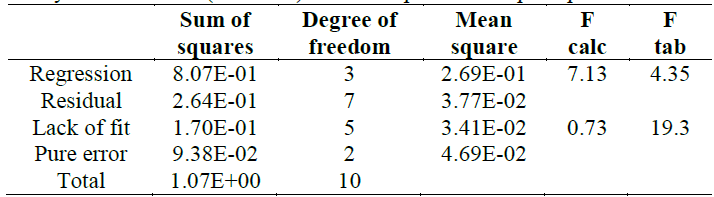

As shown in Fig. 2, the highest water loss is 40%, and is obtained with the osmotic solution of higher concentration and temperature, 65 °Brix and 80 °C, respectively. [8] obtained a water loss close to 20% in mango with osmotic pretreatment in a solution at 65 °Brix and 30 °C. Comparing with the results presented, it is observed that temperature has a great influence on the water loss during the pretreatment, with 50 °C the water loss is increased in 20% in one hour.

Additionally, in Fig. 2, the area of the response surface that is comprised in concentrations between 30 and 60 °Brix and solution temperatures between 50 and 65 °C, presents the lowest water loss, which ranges between 16 and 24%.

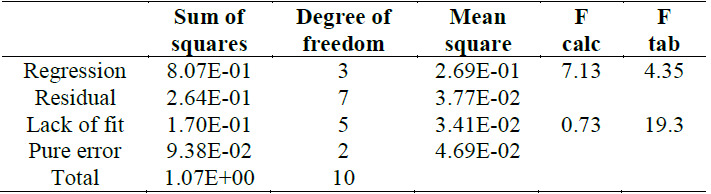

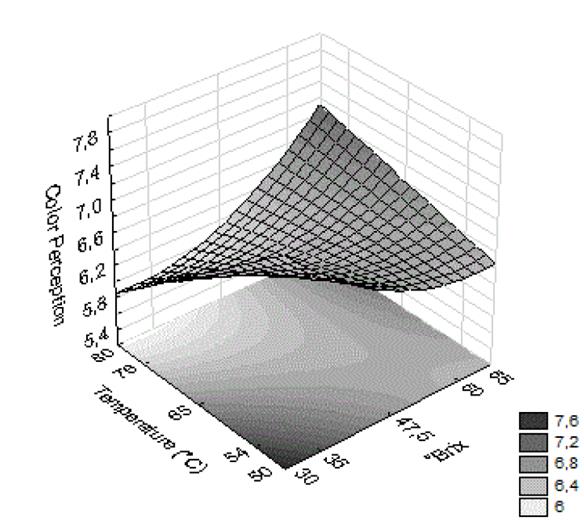

3.3. Effect on color perception

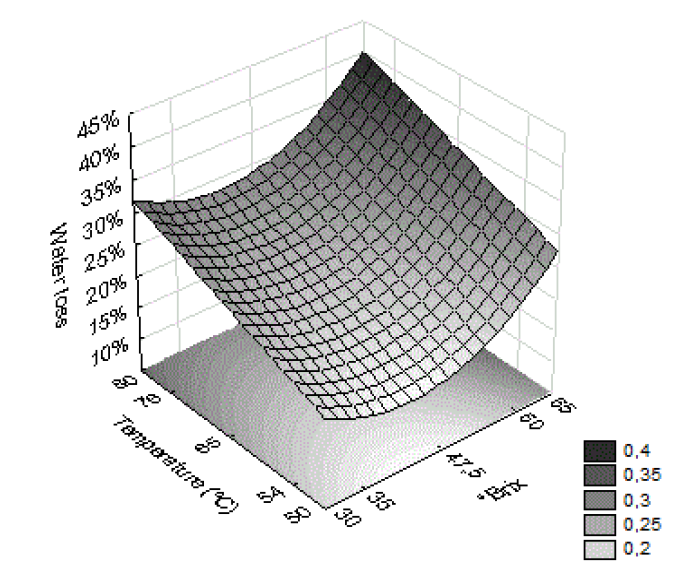

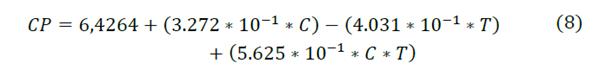

The color perception (CP) of the dehydrated mango samples was statistically related to the temperature (T) and concentration (C) of the pretreatment, as described in the re-parameterized model to the uncoded variables (eq. 8).

The obtained model turned out to be statistically significant and predictive, according to the ANOVA analysis and the F test presented in Table 5.

As shown in Fig. 3, the best color perception attributed to a highly pleasing rating (between 7.1 and 7.6 points) is obtained in the samples pretreated with the maximum and the minimum concentration and temperature (65 °Brix and 80 °C; 30 °Brix and 50 °C, respectively) with a greater tendency towards the minimum. [7] determined a greater sensory preference of samples of mango with osmotic pretreatment and convective drying, in comparison to those with dehydration by microwaves, solar and without osmotic pretreatment. In the same research, they found an average color preference of 7 points with a solution at 65 °Brix and 70 °C. These results shows a good acceptance for dried mango samples obtained by this dehydration method.

The largest distribution of the jury's color perception was in the other areas of the response surface. In Fig. 3, it is observed that the perception of color ranges between 5.9 and 6.7; which are ratings above the acceptable base (5) and up to the medium high level (7). According to the criteria of the jury, the color preference was in the samples that most resembled the fresh product, with a uniform distribution of color on all the surface of the sample.

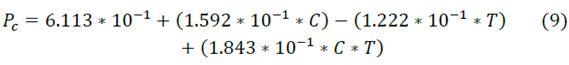

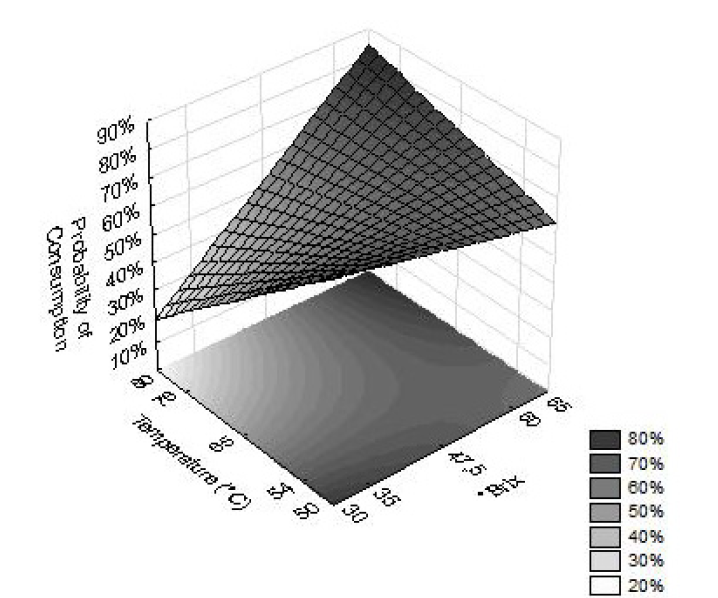

3.4. Effect on probability of consumption

The probability of consumption (Pc) of the dehydrated mango samples was statistically dependent on the temperature (T) and concentration (C) of the pretreatment, as described in the re-parameterized model to the uncoded variables (eq. 9).

The obtained model turned out to be statistically significant and predictive, according to the ANOVA and the F test presented in Table 6.

Table 6. Analysis of variance (ANOVA) for the response probability of consumption.

Source: The Authors.

According to Fig. 4, the probability of consumption, as well as the perception of color (Fig. 3), have their greatest value in pretreatments with high and low temperatures and concentrations (80 °C and 65 °Brix; 50 °C and 30 °Brix, respectively).

The maximum probability of consumption is greater than 80% in the pretreatment with the highest temperature and concentration. In Fig. 4, it is observed that the area of concentrations between 30 and 47.5 °Brix, and temperatures between 65 and 80 °C, has the lowest probability of consumption with a value between 30 and 50%.

3.5. Effect on color index, osmotic solution gain in pre-treatment, water activity, texture perception and flavor perception

The osmotic pretreatment does not have a significant effect on the color index, osmotic solution gain in pre-treatment, water activity, texture perception and flavor perception. Table 1 shows the means and the R2 obtained, accordingly with the experimental design for these variables.

In Table 2 it is observed that the color index shows a tendency, since the temperature varies in some cases. There is an increase with maximum values between 9 and 11 points, with the highest temperatures of the solution (76 and 80 °C). The lowest value of color index was presented in the solution of 54 °C and 60 °Brix.

On the other hand, there is no clear trend in the variation of the osmotic solution gain in relation to the temperature or the concentration of the solution. The maximum osmotic solution gain (12.3%) was recorded at high temperature (76 °C) with a high concentration (60 °Brix). However, in a lower temperature (54 °C) at the same concentration, the sugar gain drops to the minimum (5.8%). [8] found that in the OD in mango, after 60 min of process in a solution at 65 °Brix and 30 °C, the sugar gain was close to 5%. Regarding the data obtained, any relationship is not presented. The above can be attributed to the behavior of the whole cane sugar as an osmotic agent.

The distribution of the data, as shown in Table 2, does not show a clear trend between water activity after convective drying and pretreatment conditions. The maximum values of aw were obtained in low, medium and high concentrations: 35, 47.5 and 60 °Brix, respectively. However, the temperature evaluated in these three cases is medium-high, with values between 65 and 76 °C. [9] evaluated in their research the mango dehydration with osmotic pretreatment in 40%, commercial sucrose solution at 60 and 70 °C. They found that the samples had a water activity between 0.610 and 0.612, which are similar to the values obtained in this research. It should be noted that for all tests, water activity values were obtained where damage to the product is not expected due to bacteria or fungi proliferation.

Regarding the perception of texture, it is observed that in the concentration higher than 47.5 °Brix, the perception of texture is maintained between 6 and 7 points. However, there is no relation between the effect on texture perception and the temperature of the pretreatment. The texture preference according to the evaluating jury was presented in those samples that were not either hard, or soft, as in the case of the pretreatment of 47.5 °Brix and 65 °C, which obtained the highest rating for texture (7.1 points). It was evident that the hard textures did not generate a positive response, as is the case of the 35 °Brix and 76 °C sample that obtained an average texture score of 3.6 points (very low).

In the data it is also observed that there is a slight tendency to stabilize the perception of flavor between 7.5 and 8 points with the increase in the concentration of the solution, more specifically above 47.5 °Brix. Above this value of concentration, a slight relation is identified with the temperature increase or decrease. In the trials above 47.5 °Brix, it is observed that, although the concentration increases, the variation of the temperature defines to some extent the perception of the flavor because both decrease or increase in the same way.

As mentioned above, the taste preference was given to samples where a bittersweet and sweet flavor was assimilated, depending on the organoleptic sensitivity of the jury. The highest score for flavor was presented in the samples pretreated in osmotic solution of 35 °Brix and 54 °C, where the jury argued that the taste was much more pleasant.

3.6. Optimization of osmotic pretreatment

After obtaining the models that were statistically significant and predictive for the variables (effective diffusivity, water loss, color perception and probability of consumption), they were analyzed together to determine an optimum point of the concentration and temperature of the osmotic pretreatment.

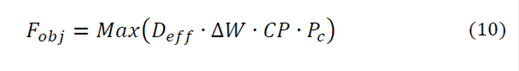

To determine this point, an optimization model was designed aiming to maximize the value of the set of response variables, which were statistically influenced by the pretreatment conditions. The objective function of the model is as follows (eq.10):

where;

Deff: Effective diffusivity, cm2s-1.

∆W: Water loss in pretreatment %.

CP: = Color perception, scale from 1 to 9.

Pc: Probability of consumption %.

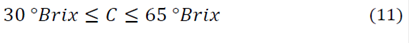

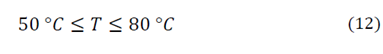

The solution to the optimization function was found using the Solver tool of the Microsoft Excel 2016 software. The solution obtained is valid only within the concentration and temperature intervals used. Thus, the objective function is subjected to the following restrictions (eq. 11,12).

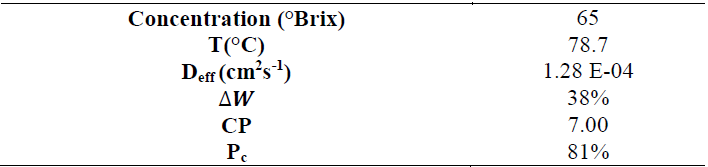

The result of the optimization model is presented in Table 7, where the maximum value of the objective function is reached at the maximum concentration and temperature of the pretreatment solution, which is consistent with the analysis of the results obtained individually for each variable. To validate the optimal point, it is recommended to carry out three experimental runs (65 ° brix and 79 ° C) and compare the results.

4. Conclusions

The pretreatment of mango pieces with osmotic solution of concentrated whole cane sugar affects significantly the effective diffusivity, water loss, color perception and the probability of consumption. On the one hand, the temperature of the solution influences all these variables. On the other hand, the only variable that concentration does not influence is the effective diffusivity.

Regarding the color index, sugar gain, water activity and perception of texture and flavor, there was no statistically significant effect of the variables evaluated in the pretreatment, nor a clear trend with the concentration and temperature of the solution.

According to the effects that were statistically significant on the mango pieces, the optimum pretreatment point is found in concentrations and temperatures close to 65 °Brix and 79 °C, respectively.

For future research, the authors recommend a proximal analysis of the raw material, and study the effects of drying on them.