1. Introduction

One of the great problems of humanity today is its dependence on fossil fuels which, in addition to being limited, have a negative environmental impact and economic disturbances [1].

Most of the energy currently used in the world comes from fossil fuels. They are used in transportation, to generate electricity, to heat environments, for cooking, etc. Oil is a non-renewable resource, that generates air pollution. This has generated a concern that, leads to the search and the study of new sources for the production of biofuel. The challenge is to ensure that those energy sources are gradually replacing the fossil fuels. Biomass could be an alternative source to produce biofuels.

Among the most competitive biofuels are: bioethanol, waste of oils used in cooking, fuel cells, biogas, microalgae, natural gas, natural gas compressed, Jatropha curcas, manure, wood chips, agricultural wastes, fats, animals, cotton peel and hydrogen.

Ricinus communis L. is a plant of easy growth, both wild and in greenhouses, with great adaptability, good reception and distribution throughout the territory of Ecuador. The main component of its seed is ricinoleic acid. It is an inedible crop, which grows in arid and poor terrains so potentially, it does not compete with lands where it is possible to produce food. A vegetable oil is obtained from its seeds, called castor oil [2]. It is presented as a renewable energy alternative, from which petroleum substitute raw materials can be developed, this is the reason why the castor oil plant is known as the "green oil".

Although the cultivation of the castor oil plant is not very well-known at world-wide level and its oil does not have a wide market, it is estimated that it is much more economic than the petroleum. Previous studies [2-5] show that it is suitable for the production of biofuel. The castor oil plant oil, whether for extraction of pure vegetable oil or as raw material for the production of biodiesel, offers perspectives of an environmentally friendly production.

The above assumes the hypothesis: Would the use of castor oil as biofuels produce some change in the energy matrix of Ecuador and its consequent reduction of the environmental impact?

This research is in full agreement with the National Plan for Good Living (PNBV), of Ecuador [6], as well as with the local, regional and national development needs.

It is part of the axis: Patrimonial sustainability and the objective 7 of the PNBV: "Guarantee the rights of nature and promote territorial and global environmental sustainability", consolidating import substitution. This research satisfies the indications of Ecuador's scientific policy on the search for alternative sources of energy, which is a strategic interest.

The main objective of this work is to evaluate the feasibility of the project that use the biomass of castor oil plant, as a renewable source of energy that contribute to the reduction of the environmental pollution and oil exploitation and incorporation of land, currently marginal, to the production process.

2. Materials and methods

In order to carry out the research, the information was taken from a study case. The process of harvesting and planting of the castor oil plant will be located in the province of Manabí, population of Calceta; the plant and offices will be located in the province of Pichincha, Quito.

For the location of the plant was considered the most appropriate place depending on the benefits of the climate and soil.

For the development of this research the following model (6 stages) of making a business plan [7-10] was applied:

Market process

Production or servicing process

Management process and business organization

Business law process

Financial process

Environmental process

The qualitative assessment of the environmental impact of the production and use of oil of the castor oil plant in Ecuador for biofuels, is based on data obtained through the literature [2-5] and consultations with 17 experts (engineers and/or mechanical licensees, Chemical, Biologists and agronomists) with the application of consensus techniques (Delphi Technique, Kendall W) and group work techniques.

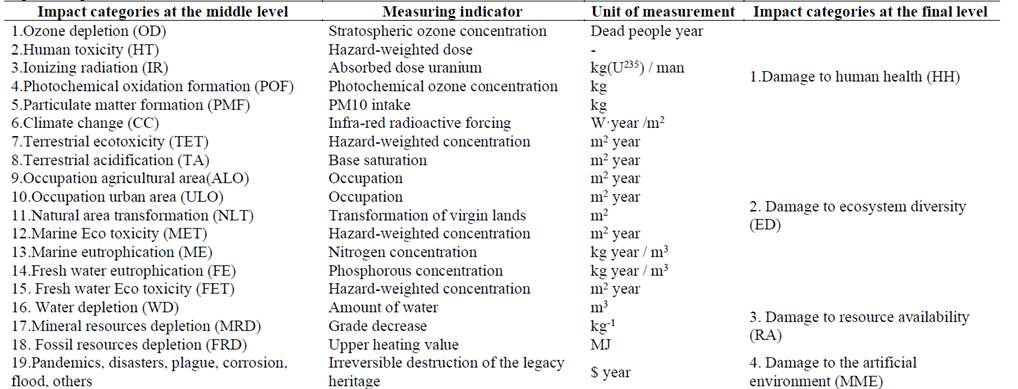

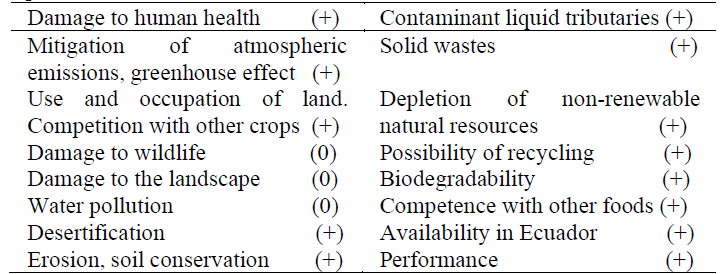

Likewise, the weighted average valuation of the potential environmental impact of the biomass is evaluated. In order to carry out the evaluation, the environmental impact assessment matrix [11-12] was conceived by the authors, which allows us to determine in a weighted way (%) the impact of the castor oil plant oil of the 19 activities that form its life cycle [12], in the 19 middle-level impact categories and the 4 impact categories at the final level [13]. Impact categories are shown in Table 1.

Table 1 Impact categories at the middle and final level of the environment.

Source: The Authors, adapting from [14].

The 19 activities of the life cycle of the production of castor oil plant oil considered are:

Preliminary step:

Determine the land (location, characteristics, rainfall)

Buy and purchase implements and machines - agricultural work

Buy and acquire seeds, tools and equipment, oil extraction labor

Agricultural step:

4 Preparation and attention of the soil, agronomic techniques and phytosanitary

5 Planting: sowing, watering, germinating

6 Fertilizing (nutrients - substrate)

7 Applying chemical pesticides and pesticides

8 Cultural work: pruning and weeding

9 Picking the fruit

10 Transporting the fruit

Industrial process step:

11 Peeling the fruit

12 Obtaining the co-products, cake, glycerol, etc.

13 Pressing the seeds - extracting the oil

14 Refining the oil

15 Storing and packaging the oil and co-products

16 Distribution and use of oil and co-products

17 Uninstalling the ecosystem

Recycling step:

18 Waste treatment generated by the uninstallation

19 Reuse, recycle or recover debris from the uninstallation

3. Results and discussion

3.1. Market process

In this process the following actions were developed [13]:

- Identification of the potential market based on a study of supply and demand.

- The behavior and growth of demand and potential customers was compiled and projected.

- The existing supply in the study area was analyzed.

- The unsatisfied demand that justified the feasibility of the project was obtained.

- The market and sales plan was developed.

- Mission, vision and social values were conceived.

- A SWOT matrix (S: strengths, W: weaknesses, O: opportunities and T: threats) was developed for strategic analysis.

- The eight marketing strategies (Product, Price, Placement, Promotion, Personnel, Process, Physical Test, and Productivity) were defined and developed.

3.2. Production process

- In this process the following actions are carried out [13]:

- The project functionality, size, maximum capacity (SME 2.87 m3/d), the inputs and technology required, and territorial requirements were defined.

- The macro localization, the micro localization, the location of the castor oil plant plantation and the location of the industry were decided.

- Machinery, equipment, office equipment, furniture and appliances, computer equipment, vehicles, etc. were defined.

- Quality and properties, price, availability and marketing capacity for raw materials and other inputs material were considered.

- The industrial process was defined, consisting in 5 steps: seed milling, oil extraction, oil distillation, biodiesel production and the oil cleaning process.

- The process flow diagram and the map process were prepared.

3.3. Management process and business organization

- In this process the following actions are carried out [13]:

- The structural organization chart was determined.

- Procedural manuals were prepared.

- The composition of human capital and the manual of functions were established.

- The specificities for each department (General management, Administrative area, Financial department, Technical and production department, Marketing department, Maintenance and safety area) were prepared.

- The talent plan (objectives, role to be fulfilled by the management of human capital) was defined.

The functions of the management process (importance, principles, decision making, integration, motivation, communication and supervision) were declared.

3.4. Business law process

The proposed company ranks among SMEs. It will be constituted as a Limited Liability Company; it will also have a hierarchical and legal administrative structure. The partners respond for social obligations up to the amount of their individual contributions and make the trade under a corporate name or objective name, in this case, under the regulatory framework of biofuels to be developed in Ecuador.

This is provided for in the Constitution of the State of Ecuador, the Law on Biofuels (December 2010) and the Law on Environmental Protection under the policies of the Consultative Council on Biofuels, the Ministry of Production, Employment and Competitiveness Coordination, The Ministry of Electricity and Renewable Energy, the Ministry of Agriculture, Livestock, Aquaculture and Fisheries, the Ministry of Industry and Competitiveness, Petro Ecuador, Ecuadorian Institute for Standardization and the National Hydrocarbons Directorate. The company will operate under the rules of the Superintendence of Companies, the Internal Revenue Service and other regulatory institutions.

3.5. Financial process

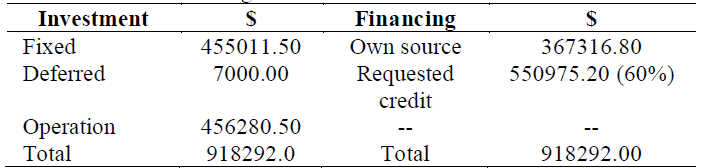

Studies of different types of oils indicate that they can compete commercially with traditional fuels. The competitiveness of biofuels is mainly due to local availability, which depends on the conditions of agriculture (where biomass comes from) and on the economic feasibility of the production. Table 2 presents the investment needs as well as the sources of financing for this case study for a 5-year period [13].

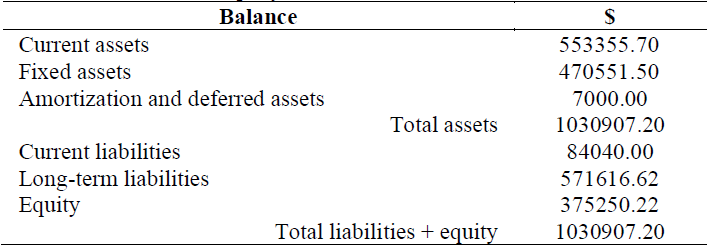

The requested loan will have a term of five years at an annual interest rate of 12%, with equal half-yearly payments and a semi-annual fixed fee of $84,040.35. Table 3 presents a general balance sheet of the company [13].

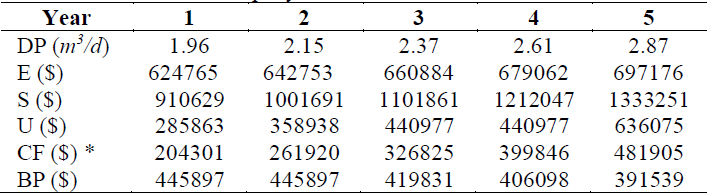

The projection of expenses (E) and sales (S), utilities (U), cash flow (CF), net present value (NPV) and annual break-even point (BP), In function of the daily production (DP), for a planning horizon of only the first 5 years, (for: sale price 5.32 $/ gal and industry operating days = 330 days), apresented in Table 4.

Table 4. Annual results of the company

Source: The Authors, adapting from [13].

* Active rate (interest) used to calculate the Cash Flow (according the statistical data from Banco Central): 12,84%.

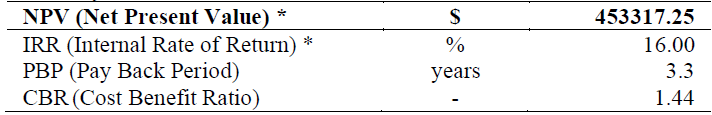

Table 5 shows the efficiency indicators obtained. A result of almost half a million $, after 5 years, can be considered a good result for a SME of the type that occupies us. The break-even point is achieved at 48.90% of the sales projection, in the worst case (year 1). Profits every year are positive, the average profitability is of the order of 47.10% / year. The results in Tables 4 and 5 show a good economic performance of the production of castor oil plant oil.

Table 5. Efficiency indicators.

Source: The Authors, adapting from [13]. * Calculated with financial Excel.

3.6. Environmental process

The main contributions and impacts generated by the castor oil plant agro-system can be framed as: the use of its biomass can lead to an increase in forested areas and halt deforestation in the most fragile ecosystems. In the semi-arid and unexploited dry regions, the regeneration of these soils will be important; the increase of biodiversity, the reduction of emissions of polluting gases, could be positive for the environment [3,5-6].

A qualitative assessment of the potential environmental impact of biofuel biomass for biofuel purposes is shown in Table 6.

As can be seen in Table 6, there are no qualitative negative impacts on the environment.

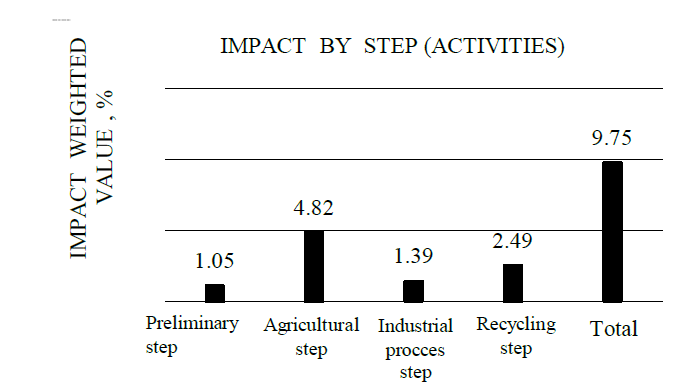

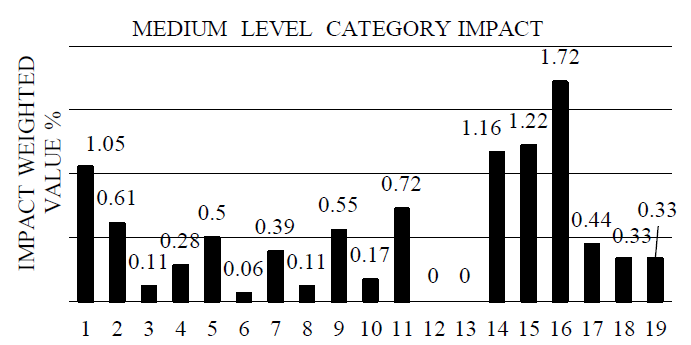

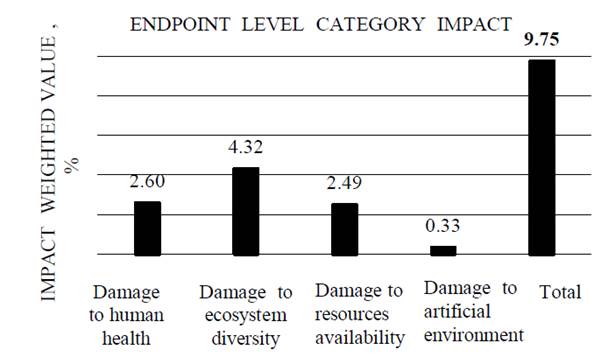

Appling the calculation matrix (Excel sheet), conceived by the authors [10-11,15] for the weighted evaluation of the environmental impact of the castor oil plant biomass, it came to the results showing in Figs.1-3 in a graphical comparison way.

Source: The Authors. Calculated with financial Excel

Figure 1. Weighted average assessment of the potential environmental impact (by 4 step - 19 activities) of castor oil plant biomass

Source: The Authors. Calculated with financial Excel

Figure 2 Weighted average assessment of the potential environmental impact (19 medium level) of castor oil plant biomass.

Source: The Authors. Calculated with financial Excel.

Figure 3. Weighted average assessment of the potential environmental impact (4 endpoint level) of castor oil plant biomass.

Table 6. Qualitative assessment of the potential environmental impact of the castor oil plant biomass.

Source: The Authors.

Caption: Positive impact (+), negative impact (-), no impact (0).

The sum of these four magnitudes constitutes the total potential impact, equivalent to 9.75%.

Damage to human health: 2.60%

Damage to ecosystem diversity: 4.32%

Damage to resource availability: 2.49%

Damage to the artificial environment: 0.33%

It is observed in the previous figure how the major impact is that which is related to the damage to the diversity of the ecosystem (which considers: depletion of the ozone layer, human toxicity, ionizing radiation, photochemical oxidation formation, the formation of particulate matter and climate change). This value is less than 5%, so it can be considered low.

The second value is also minor and it is related to the damage to human health (which considers: terrestrial ecotoxicity, terrestrial acidification, occupation of agricultural areas, occupation of urban areas, transformation of virgin lands, marine ecotoxicity, aquatic eutrophication, fresh water ecotoxicity).

Damage to the availability of resources (which considers water depletion, depletion of mineral resources, depleting fossil resources), is also low. Finally, damage to the artificial environment, understand the irreversible destruction of heritage legacy, it is almost nil.

The following changes are expected from this production:

Economic: A new renewable fuel will be available, which will have a positive influence on the improvement of the energy matrix, as it will enable a greater diversification of the fuels involved in the energy economy. By using biofuels (mixtures), it is possible to reduce the consumption of energy carriers of fossil origin by up to 15%.

Social: the project solves problems of rural energization, as a new fuel that influences a rise in the quality of life in remote places, as well as allows the creation of new sources of job.

Ecological: it is a totally ecological and biodegradable product; its cultivation reduces CO2 emissions to the atmosphere, which would contribute to the minimization of environmental damage caused by greenhouse gases, which is the policy of the Ecuadorian government.

4. Conclusions

The production of biofuels from Ricinus Communis L oil preferably in dislocated SMEs is economically feasible with a cost / benefit ratio of 1.44.

The process has a small weighted environmental impact (9,75%), which is favorable for the diversification of the sources involved in the energy matrix.

Economic, social and ecological changes could be expected with this production.