1. Introduction

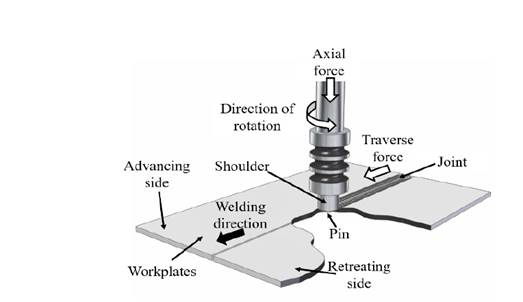

Friction Stir Welding was first developed by The Welding Institute (TWI, Cambridge, UK) in 1991 [1]. This process employs a nonconsumable rotary tool, consisting of a shoulder and a usually threaded pin that plunges into the materials that are going to be welded together and moves along the joint line. A general outline of the process is shown in Fig 1. This process results in weld formation and microstructural modification [2]; as the friction between the tool and materials to be welded increases the temperature of the welding zone, material flow starts around the moving tool leaving a welded joint behind. This heating is the result of intense plastic deformation and the contact conditions between the material and the tool surfaces as stipulated in the work by Fonda et al. [3]. At the end of the path, the tool is removed leaving a small hole. This process presents the advantage of generating healthy joints on low weldability materials such as 2xxx and 7xxx aluminum alloys. It also allows to weld dissimilar materials such as different types of aluminum alloys, polymers to Al, Al to steel, and Al to Mg [4,5].

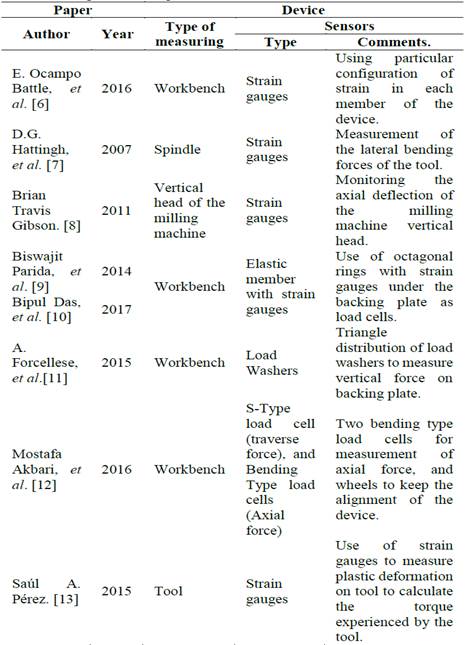

There have been reports of two types of force and torque measurement equipment in literature [6-13], depending on the sensors position. The first type of measuring locates the sensors on a device on top of the workbench. The second type locates the sensors on the spindle, the tool, or even the head of the milling machine. Both types of measuring present advantages and flexibility depending on the types of sensors used. On Table 1 a description of 8 measuring devices found in literature is presented.

This paper aims to present the design and development of a novel axial force measurement device for FSW and its performance according to results of similar measurements found in literature and instrument repeatability.

2. Materials and methods

2.1. Concept design

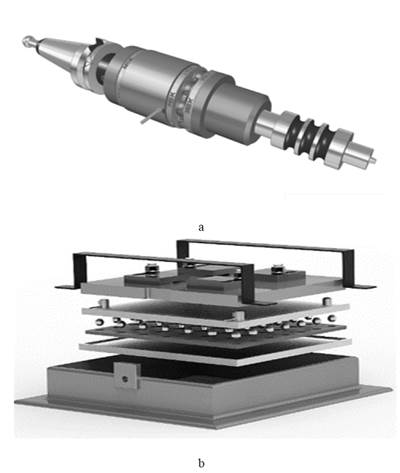

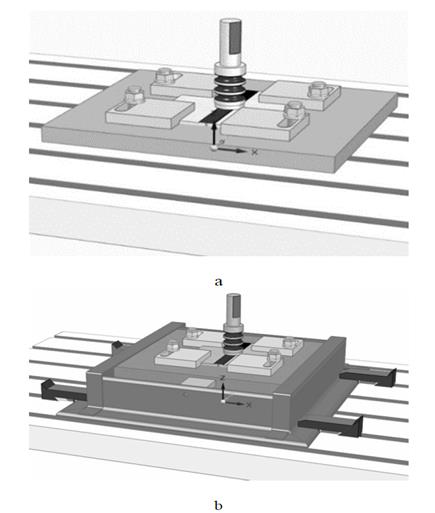

The device for axial force measuring was designed considering the Ulrich methodology [14]. The requirements were repeatability in the measurement of force, a load capacity up to 21 kN, for machine and operator, and ease to assemble and couple to the CNC system. It should also allow the exchange of tools, ergo different shoulder diameters. Two possible concepts were explored, the first was as presented in Fig 2 a , a system set directly on the spindle; however, this concept presented stability problems due to the magnitude of the loads at high rotational speeds, which did not satisfy the safety requirement. The second concept sets the entire system on the machine workbench; this concept was the most appropriate for the requirements and was finally built (Fig 2 b).

The selected device employs, besides the essential items for FSW, two load cells and a couple of additional supports for balance, a tailor made flat ball bearing that, in conjunction with the frame, allows two degrees of freedom, so that further ahead an additional load cell can be included to measure traverse force.

2.2. Static forces analysis

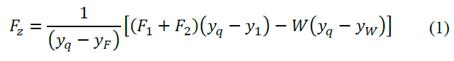

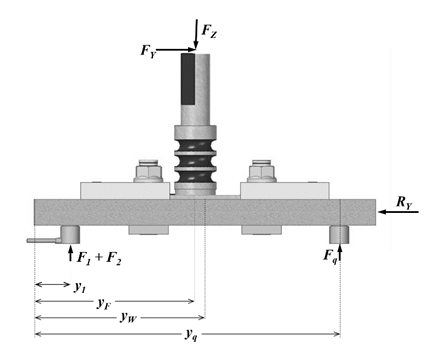

According to the free-body diagram (Fig 3), forces measured by the vertical load cells are F1 and F2. FZ is the axial force. As references y1 is the coordinate of the application point of F1 and F2; yw represents the location of the center of mass of the system; yq stands for the coordinate of the additional supports, and yF coordinate of the position of the tool as it advances on the plates to be joined.

Source: The Authors.

Figure 3. Schematic for the calculation of the forces applied during the process. Free body diagram.

A static analysis was performed to obtain the axial force FZ(Eq. 1). The static equation was then included in the software code. The system then reports data on a text file which includes four main columns: time, load cells measurements (F1 and F2), position of the tool (y), and calculated axial force (FZ).

2.3. Joint fabrication

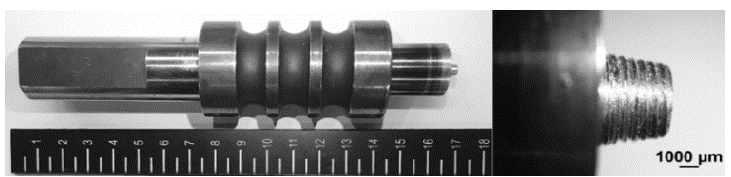

Friction stir weldments of AA 7075-T6 aluminum alloy were carried out using a convex shoulder and conical shaped pin made of H13 tool steel, as presented in Fig 4. Parameter combinations used ranges from 600 to 1600 RPM and 40 to 140 mm/min for rotation and travel speed respectively. Welds were carried out randomly, dwell time was set at 20 s, plunging speed at 30 mm/min, and tilt angle was also set at 0°.

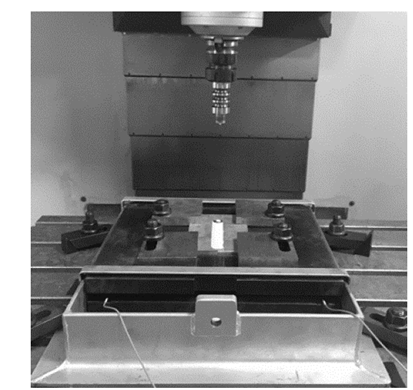

Axial force measuring during welding was performed using the previously described device (Fig 5) attached to an adapted CNC machine in position control mode. Both load cells were previously calibrated, and the basic static force equation was experimentally verified.

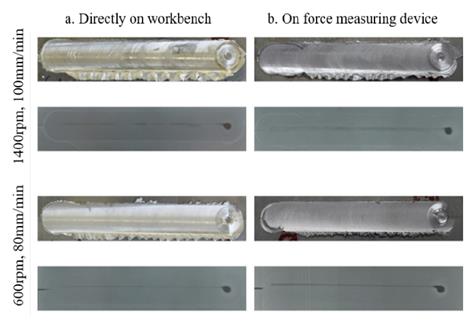

In order to determine if the device configuration had any effects on weld soundness, tests with identical parameter combinations were carried out on both, the basic FSW set-up directly on top of the CNC workbench (Fig 6 a) and the instrumented force measuring device as illustrated in Fig 6 b . X-ray inspection was then performed; tunnel or wormhole type discontinuities, with very similar shapes and dimensions, were found for each combination, suggesting that both configurations offered similar stability, thus non-affecting weld soundness.

Source: The Authors.

Figure 6. Configurations: a) basic backing plate on workbench, and b) force measuring device set-up.

All data acquired was processed and analyzed, in terms of both time and distance. Seeking to establish the instrument repeatability, multiple replicates of particular parameter combinations were carried out and maximum and average axial forces were compared.

3. Results and discussion

3.1. Axial force graph

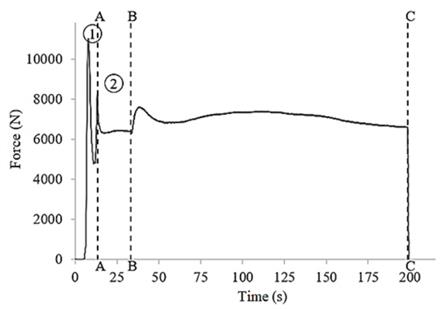

Upon completing the static calibration of the device, it was necessary to perform a weld to evaluate force signal during the actual process. Parameters used were 800 RPM rotational speed, 40mm/min travel speed, and 20s of dwell time. Measured axial forces are presented in Fig 7. The main stages of an FSW axial force graph are: time between 0 seconds and the line AA show tool plunging, between lines AA and BB is the tool dwelling, and after line BB is the actual welding. Fig 7 also shows one peak on the left side when the pin makes contact with the plates, and the second and shorter peak indicates when the shoulder touches the plates.

Source: The Authors.

Figure 7. Axial force graph generated by the device while making a AA7075-T6 weld using 800RPM and 40mm/min.

In the literature [9,11,12,15-20], most of the reported graphs present two peaks during the plunging stage, a stable part during the dwelling stage, and a stable state during the welding.

3.2. Radiographic inspection tunnel defects

Inspection of welds obtained using the configurations presented in Fig 6 indicate that discontinuities are similar for both arrangements, therefore, the force measuring device does not affect the process parameters. In Fig 8 photographs of the visual and radiographic inspection of a couple of parameter combinations, the presence of tunnel or wormhole type discontinuities as well as similar shaped flash are presented.

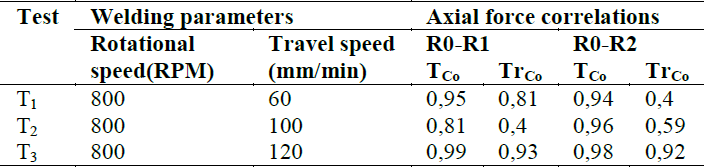

3.3. Repeatability

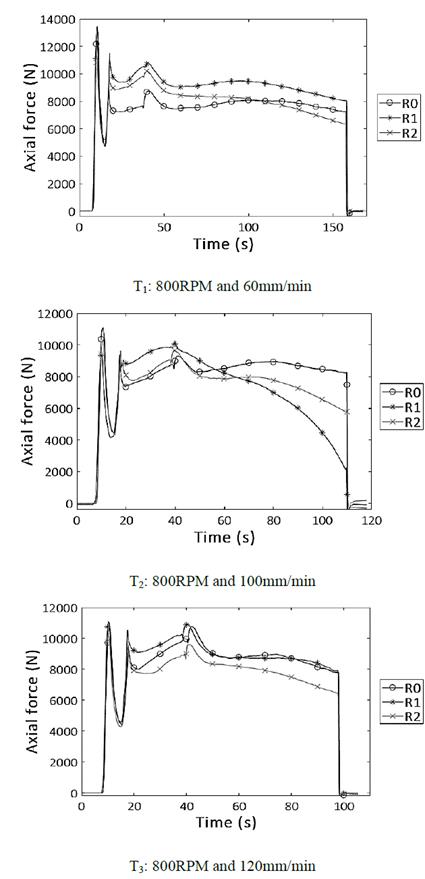

Tree combinations of operational parameters were used to verify the repeatability of the device. Table 2 presents data extracted from the recorded axial force; correlation coefficients were used to compare the behavior between the first measurement, R0, and two replicates. The total correlation columns, TCo, correspond to the correlation of all measurements beginning when the tool first touches the plates. In addition, the travel correlation, TrCo, relates to data obtained only while the tool advances along the joint. According to the results, there is a dependence between two measurements made with the same parameters.

Therefore, the device has repeatability while measuring during each test, with TCo between 0,81 and 0,99. Although, TrCo was a wider range: 0,40 - 0,92. T2 shows the most dissimilar behavior when comparing replicates and R0, according to the results of Table 2. The authors have several hypotheses for this behavior which can be related to the reproducibility of the actual test if considering uncontrolled process variables and their effects. Fig 9 shows the measured axial force graphs considered.

3.4. Level surface of axial force

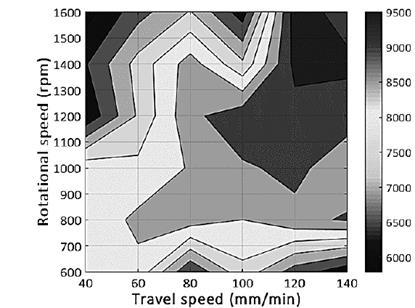

Fig 10 shows a contour plot of average axial force during welding for 36 different parameter combinations using values between 600 to 1600 RPM and 40 to 140 mm/min for rotational and travel speed respectively. In general, for aluminum alloys, axial force decreases when increasing the rotational speed of the tool; this can be related to the temperature of the workpiece increasing with rotational speed, so the material is softer. Additionally, an increase of travel speed signifies a growth in axial force. The combined increase of both rotational and travel speeds result in an increase on the average axial force [8,17,21-25]. Such behavior corresponds to literature reports for both experimental and simulated welds of AA7075.

Source. The Authors.

Figure 10. Level surface of axial force for different combinations of travel and rotational speed.

It also can be seen that opposite parameters, high rotational speed with low travel speed, and low rotational speed with high travel speed result in low average axial force. As a final comment, the set values of axial force used in force control than can be found in literature for AA7075-T6, for similar parameter combinations, agree with the range of values measured by the device [26,27].

4. Conclusions

Based on the presented results, the proposed device is capable of obtaining axial forces that, in shape, mean values and tendencies match the ones found in literature for similar conditions. The authors found that the repeatability of the device is acceptable in terms of total correlation (TrCo). Although, according to travel correlation (TCo), some inconsistencies needed to be accounted for. Differences in forces during welding can attributed to uncontrolled variables inherent to FSW, such as the increase in assembly temperature while performing consecutive welds, machine references set-up for each experiment, base material fixation on backing plate, and the accumulation of material on the tool surface. Radiographic inspection shows that discontinuities observed on the welds, using either the device or the workbench directly, do not have any significant differences. Therefore, there is no evidence that the device has negative effects on the stability of the welding process.