1. Introduction

World trade in primary commodities such as cocoa beans is of great importance for developing countries, especially for Colombia, where this crop has become an interesting potential post-conflict option for cultivation. The international cocoa market is highly competitive. While most larger world producers are characterized by bulk cocoa production, Colombia is renown for producing “fine flavor” cocoa. The quality of the cocoa beans and their cocoa-products, such as chocolate, not only depend on the raw material, but also the prevailing agro-climatic and edaphoclimatic conditions, the cultural practices and the post-harvest processing techniques used. The genotypes influence both the quality and the intensity of flavor, as determine the type and quantity of the aroma precursors [1]. Besides, the smell, taste, smoothness, texture are traits that define the quality of cocoa-products also depend on how it was processed.

Cocoa fermentation is one of the most important post harvest stages that determine the final quality of the product. In this stage, biochemical changes occur inside the grain that give rise to aroma and flavor precursors that transfer an additional value to cocoa production [2]. Previous studies [3] describe that fermentation is based on two different but correlated phenomena: i) the microbial fermentation that leads to the elimination of mucilage and the onset of the biochemical reactions inside of the grain, ii) the biochemical reactions which begins with the death of the embryos caused by the acids and temperature generated by the fermentation process. This originates a chain reaction that includes the generation of alcohols and acids, and changes in pH and moisture, among others. It also gives rise to the aromatic substance indicative of good cocoa. These phenomena must have a good homogeneity and practices otherwise undesirable flavors, low quality grain and low sensory profile would be developed. Thus it is connected to the low technification and development of standards for the benefit of cocoa and the deficient standardization of quality control [4]. These factors affect economic growth, because quality represents good price and benefit to the farmer [5]. At the commercial level, the cocoa-chocolate chain is controlled by cocoa processing companies, which punish poor grain quality, devaluing its price when purchasing [6].

In recent years, researches have focused on new materials with high yield and tolerance to common deseases [7,8]. Due to the complexity of the fermentation process, which has not been completely understood yet, it is not possible to ensure the quality and homogeneity of the cocoa beans and their derivative products.

In Colombia the fermentation is carried out with a mix of different clones, and this could affect the performance and quality of the final product, because this mix brings a wider aromatic and flavor profile given for the effect of the genotype, also could be a negative effect because each clon requires different fermenting conditions. In agreement with the above mentioned, the aim of this work is to study the microfermentation process of the five most cultivated cacao clones from the department of Huila, for identify clones than present similar characteristics and then could be fermented together and lead to high quality cocoa products. Results allow to recommend possible mix of cacao varieties that lead to homogeneous and high quality cocoa product.

2. Materials and methods

2.1. Plant material

Cacao clones ICS95, ICS39, ICS01, CNN51, TSH 565 were collected from Huila department in Colombia mainly from two municipalities, Algeciras (2°31'19" N and 75°18'52" W, at an altitude of 1,528 meters above the sea level) and Rivera (2°46'38" N and 75°15'19" W, at an altitude of 700 meters above the sea level). These two municipalities are part of the Fedecacao-AGROSAVIA network program.

Mature cacao pods without mechanical or biological damage were harvested, washed with water and then with alcohol at 70% before opening. This was carried out 24 hours after harvesting.

2.2. Physical and chemical characterization

Physicochemical evaluation was made based on qualitative and quantitative descriptors in order to generate a profile for each clone evaluated. For this, the protocols published by CATIE were used [9].

2.3. Monitoring of fermentation, drying and cutting test

Change of pH (AOAC 981.12-ISO184) and total acidity (NTC 4623 and NTC 5114) in the seed under fermentation were recorded. After fermentation, the cocoa mass was spread out on mats or trays with moveable roofs for drying until reaching ca. 7% of water content. Drying reduces the bitterness and astringency of the beans, but also encourage the development of the chocolate brown color that is typical of well-fermented beans. Then, the cut test was carried out on beans according to the qualitative classification of the NTC 1252 [10].

2.4. Fermentation

The cocoa mass of each clone was fermented independently in triplicate using plastic jars with a capacity of 800 g. These samples were kept at a controlled temperature of 35 °C during the first three days, and then the temperature was increased to 45°C remaing so until the end of fermentation.

2.5. Fermentation index

The fermentation index (FI) corresponds to the absorbance ratio measured at 460 nm (yellow oxidized polyphenols) over the one measured at 530 nm (anthocyanins). Then 0.2 g of cocoa seeds taken radomly and placed in falcon tubes, mixed with 20 ml of methanol: HCl (97: 3) homogenized and placed under cold conditions (8°C) for 19 hours. Then, these were centrifuged for 20 minutes at 10,000 rpm and at 4°C (Thermo Scientific). Finally, the supernatant was taken and read in a spectrophotometer (Helios zeta, Thermo Scientific spectrophotometer) at absorbances of 460 and 530 nm [11].

2.6. Total polyphenols

Total polyphenols (TP) was quantified using the Folin-Ciocalteu method on cocoa bean extracts and results were expressed in gallic acid equivalents (mg GAE/g of extract) with reading at 760 nm (Helios zeta, Thermo Scientific spectrophotometer) [11].

2.7. Sensory evaluation

Every cocoa bean fermented was subjected to a sensory evaluation (AGROSAVIA-Nataima panel). In each session, the panel evaluates cocoa liquor samples (temperature of 35 °C) as follows. i) basic flavors such as acidity, bitterness, and astringency, ii) specific flavors such as floral, fruity, and walnut iii) tastes acquired as raw or green, among others. All these parameters were based on the NTC 3929 [12], with an adjustment in the rating scale from zero (0) to 10.

3. Results and discussion

3.1. Physical and chemical characterization

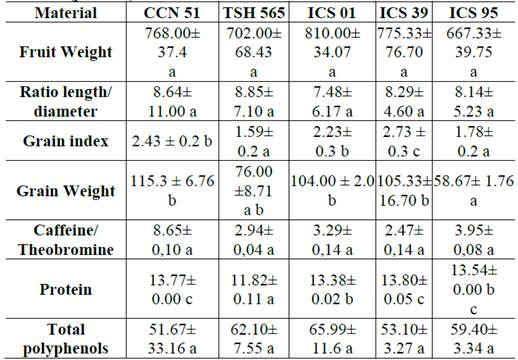

Table 1 presents the averages of the physical and chemical characteristics of 15 fruits of five cocoa clones at their optimum maturity stage. According to a study [13], trinitarian-type cocoa contains a theobromine/caffeine relation of 5 to 10. According to the current study data, only clone CCN 51 is within the reference range. The remaining clones showed a lower value, which could be due to cross-pollination in the growing area. Clone ICS01 showed the highest percentage of caffeine content, meanwhile theobromine content did not present significant differences. These compounds are important in cocoa since they constitute 99% of the alkaloid content, and these allow classifying the genetics of the clone [14]. In non-fermented and dried grains, theobromine values ranged between 0.91-1.38%, and for all the cocoa beans from every clone studied after three days of fermentation and further drying, values decreased ranging from 0.26-0.48%. Similar contens with no variations were found between the fermentation time, and theobromine and caffeine concentrations [15,16]. Regarding crude protein, the results achieved (Table 1) are in accordance with other studies that showed protein contents from 12.0-13.4% [17-19].

Table 1. Physical and chemical results of five cacao clones (Theobroma cacao L.) n = 15 ± Standard error; Clones with a common letter are not statistically different (p > 0.05).

Source: The Authors.

Nevertheless, there were significant differences in the crude protein content (P < 0.05), where clone TSH 565 reported the lowest percentage, conversely to clone ICS 39, which showed the highest value. Protein in cocoa beans are composed of 43% globulin, which comprise vicilin and albumin [17]. The degradation of albumin is limited during fermentation, contrariwise to vicilin-type globulin (7S), which is degraded into derivatives such as hydrophobic oligopeptides. These are furthermore, converted into hydrophilic oligopeptides and free hydrophobic amino acids that play a decisive role in cocoa quality [20]. Additionally, proteins also interact with tannins through hydrogen bonds, which gives rise to brown pigments, characteristic of the chocolate color. Therefore, proteins play and decisive rol in cocoa quality.

Cacao materials showed significant differences in fermentation index and weight. Clones ICS39, ICS01 and CCN51 achieved the highest values. These parameters are directly related to yield and commercial value, and therefore, are important as quality parameters.

3.2. Fermentation monitoring

Fig. 1 depicts the behavior of pH throughout microfermentation, which begins with yeast multiplication as they use the sugar contained in the pulp to release ethanol. This is followed by growth and multiplication of lactic acid bacteria and acetobacter that releases lactic and acetic acid, respectively, decreasing pH. These acids migrate toward the inside of the seed penetrating the grain, and initiating the stimulation of enzymatic reactions [21]. The pH values achieved by the ICS 01, ICS95 and CCN51 clones ranged between 4.9-5.09, which are adequate according to recommend stated to obtain good quality cocoa [22-24].

Source: The Authors.

Figure 1. Evolution of pH in cacao beans during the fermentation of five cacao clones microfermented independently.

In the case of pH, the degree and time of bean acidification during the fermentation process plays an important role in the formation of aroma precursors. The mucilaginous pulp undergoes ethanolic, acetic and lactic type fermentations, which releases organic acids that with further fermentation, increases acidity. These acids penetrate the bean that along with an increase in temperature due to exothermic reactions generates the death of the embryo. Then, these two conditions initiate a series of biochemical reactions. One of these changes is the breaking of the cell membranes, allowing the release of enzymes and mixture of substrates with the respective consequences on the formation of taste and aroma precursors [21,25].

According to different authors [21,26], the ideal pH of the cocoa fermentation at the end of the process is between 4.75 and 5.19. When the pH is less than 4.5, flavor precursors will be reduced and a slow diffusion of organic acids will be generated through the cotyledon. If the pH is higher than 5.5, the grains will not be well fermented, showing astringency and bitterness problems at the end of the process.

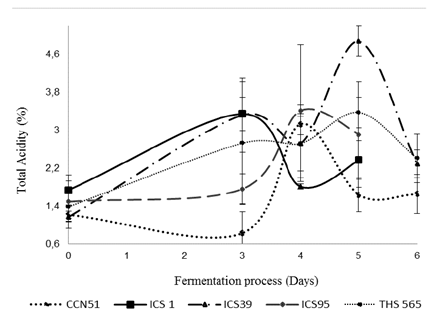

Fig. 2 shows that clone CCN 51, when compared to other clones, had the lowest total acidity percentage with 0.84%. Although the initial acidity is similar for all clones, during the process, each clone shows a different performance depending on the initial total soluble solids, and microbiota profile, among other factors. From Fig. 2 it can be stated that acidity raised until the third day, but after this day, it trends to remain stable. What has shown that during the first days there was the growth of key bacteria for the formation of chocolate flavor precursors, acetic acid formers, oxidation of ethanol and carbon dioxide generating the increase in acidity. Then, all clones ended with acidity between 2.4% and 2.8%, except CCN51, which remained with the lowest acidity (1.6%).

3.3. Fermentation index

Regarding the fermentation index (FI), significant differences were found on the fifth day. Clone ICS 95 showed the lowest fermentation index with a value of 0.66, and clone CCN 51 showed a FI of 1.20. This same behavior has been previously reported [27] where authors stated that the optimal FI is correlated to biochemical variables related to the origin of the material. In this project, clone ICS 95 has a suitable FI at day 4, and CCN 51 at day 5. As shown in Fig. 3, this upward behavior occurs due the relationship between the condensation of flavonoids and anthocyanins. The latter are hydrolyzed by the action of glycosidases, causing bleaching modifications in the grain. When higher condensation of compounds are found, a higher fermentation degree occurs [13,28].

Source: The Authors.

Figure 3. Evolution of the fermentation index of five cacao clones at the cotyledon level during fermentation.

The cocoa beans fermented showed a FI values from 0.65 to 1.27. According to different authors [14,21], FI values within 1 and 1.2 indicates that cocoa beans are sufficiently fermented; higher values are considered over fermented. Therefore, it can be stated that clones ICS 39, TSH 565 and CNN 51 are well-fermentated on the sixth day. This corroborates the results of the daily cut test. Clones ICS 95 and ICS 01, whose fermentation was stopped at day 5, reported FI values lower than 1, which could mean that these clones needed an extra fermentation day.

3.4. Total polyphenols

Fig. 4 depicts the behavior of TP throughtout fementation. From this figure, clone ICS 39 reported the highest concentration, i.e. 39.4 mg of GAE/g of dry cocoa without degreasing (w.s) meanwhile clone TSH 565 showed the lowest content, i.e. 23.4 mg GAE/g of dry cocoa without degreasing after 5 or 6 fermentation days.

Source: The Authors.

Figure 4. Evolution of total polyphenols of five cacao clones at the cotyledon level during fermentation.

Results of the analysis of variance showed significant differences on day 4 and 5 of the fermentation process (P <0.05). All clones reduced their TP during the first three days of fermentation. After this time, the TP began to increase. Clone CCN51 achieved the highest concentrations on the fourth day and clone TSH 565 reached its highest value on the fifth day; afterwards, both concentrations began to descend. All other clones showed smaller changes. These behaviors can be explained in the initial composition of each material [28,5], but also by the fermentation performance, i.e. initial TP content, pH, total acidity (TA) percentage and temperature profile throughout the fermentation process. These factors influence enzyme activities that are associated with the polyphenol degradation or polymerization [29]. Increase in polyphenols may be due to the formation of polymeric proanthocyanidins (tannins), meanwhile their decrease can be caused by catechin and epicatechin oxidation to quinones.Cocoa polyphenols are important antioxidants [30], and however, their presence is associated to astringency and bitterness in cocoa products.

3.5. Final cut test

From the results of the cutting test and according to the NTC 1252 standard, it can be established that clone ICS 01 corresponds to a regular type of cocoa since it contains 65% of fermented grains and 35% of insufficiently fermented grains. Unlike clones TSH 565, CCN 51, ICS 39 and ICS 95, which exceed 65% of well-fermented grains up to 10% more, and a lower percentage of 25% ofin insufficiently, fermented grains, classifying them in premium cocoa. The presence of slate grains was only evidenced in clone ICS 01 however this percentage may be due to cocoa beans that did not have an adequate maturity degree [31].

According to studies carried out by Fedecacao [National Federation of Cacao Producers of Colombia], for a process of fermentation to be considered successful, well-fermented grains should show a proportion between 70% and 87% for these clones. Only clone ICS 01 showed values outside this range, which indicates inadequate fermentation [21].

3.6. Sensory evaluation

According to the sensory profiles issued by the panelists, it was observed that all clones are located in a medium-low cocoa flavor base (Fig. 5). This rating may be due to the cacao variety used, climate, soil, and postharvest treatment [32]. The lowest cocoa value was obtained by clone ICS 95 with an average rating of 2.67. This may be due to the use of immature grains, and these were further, not well fermented at the end of the process, giving little flavor accentuation [33]. In contrast, the CCN51 clone achieved the highest cocoa flavor values with a rating of 4.8.

Source: The Authors.

Figure 5. Sensory evaluation of five cocoa liquors (The aroma scores were 0, 1, 2, 3, 4, and 5, which represent intensities of: none, very weak, weak, middle, strong, and very strong, respectively)

In the case of flavors such as acidity, astringency and bitterness, the most remarkable is the low accentuation of these flavors in the grain [28]. Regarding acidity, a low-medium level was reported. Furthermore, clone CCN 51 was pointed out as the one with the lowest acidity (2.0), meanwhile clone ICS 95 exhibited the highest acidity (4.83).

In the case of bitter and astringent flavors, clone ICS 39 had a high score for both, i.e. astringency 6.25, and bitterness 5.0. This can be explained by the fact that this clone reported the highest polyphenols concentration at the end of fermentation as could be observed in Fig. 4. Probably polyphenols oxidation was not sufficient and the high presence of polyphenols brings astringency and bitterness into the final cocoa flavor [21].

In other flavors, clone ICS 01 showed a low score in floral notes (0.0). Perhaps, these absent notes were given by the low content of alcohols. For this same clone, a low score in fruity notes (0.0) were obtained, revealing that the concentration of aldehydes, ketones such as 2-methylbutanal and esters were too low, maybe because the drying and roasting processes were not appropriate, or this clone did not develop the necessary concentration of precursors during the fermentation process [19,34-36]. One of the most desired flavors is walnut, which according to the literature [36], is given by pyrazines that are the main components responsible for this attribute. This flavor was however, recorded in the materials TSH 565 (2.25) and ICS 01 (1.67) in a low scale. Likewise, the reduction of sweet flavors was attributed to the low content of aromatic acids and sugar degradation products.

Regarding flavors acquired that are classified as defective, e.g. green flavor, ony the clon ICS 39 obtained a (3.25) score in undesirable flavors, all of other showed low presence of undesirable flavors, which means that cocoa processing was acrried out successfully in all other clones.

4. Conclusions

Of the five clones evaluated at the individual microfermentation level according to NTC 1252, clones TSH 565, CCN 51, ICS 39 and ICS 95 exceed 65% of well-fermented grains, classifying them into the cocoa premium category. Only clone ICS 01 was classified as a standard type of cocoa. It requires at least one more day of fermentation; this behavior would affect the overall quality in a mix of cacao clones.

The sensory evaluation allowed finding desirable attributes such as cocoa, floral, fruity and nut flavors. Moreover, clone TSH 565 exhibited the best sensory profile since it shows a harmony between flavors. None of the clones registered mold flavors or smell of smoked ham that are problems due to over fermentation.