1. Introduction

Currently, research related to food science and engineering is oriented towards the search for new processed foods that, in addition to their characteristic nutritional contributions, can contribute to the health status of consumers; as it is the case of foods that have characteristics of antioxidants, hypoglycemic, anticancer, prebiotic, hypocholesterolemic, among others. These properties are fundamentally based on the chemical composition of these foods that are characterized by having anthocyanins, flavonoids, sterols, bioactive peptides, terpenoids, vitamins and some minerals. [1].

In the case of foods produced from fruits, it is sought that the processing techniques help the conservation of most of these components, since many of them are thermolabile or react very easily with the help of light, oxygen, pH changes among others [2].

The mango (Mangifera indica L.), is a tropical fruit with high acceptability for Colombian consumers due to its excellent organoleptic properties and its benefits in terms of the consumption of its bioactive compounds such as carotenoids, vitamins and some minerals such as K, Ca, Na, P and others at the trace level. In Colombia, around 250000 tons are produced per year, making it the 20th place in the world in terms of producing countries and possessing 0.6% of the world market. Of the total production, 20% corresponds to Tommy Atkins variety [3].

The mango pulp is characterized by its high fiber and water content, accompanied by a high content of organic acids, especially citric acid, which make it attractive to the consumer when it is organically unripe. These concentrations decrease as the fruit matures and the content of soluble solids (sugars) increases its concentration, this biochemical process is due to the presence of the hormone ethylene, which is responsible for helping the biosynthesis of endogenous hydrolytic enzymes of the fruit such as amylases and chlorophyllase, which in turn are liable for the progressive unfolding of starch and chlorophyll. With the determination of the sugar / acid ratio, authors propose the calculation of the ripeness index for fruits and thus approach their chemical composition [2]. In addition to these chemical characteristics, the pulp of the mango fruit has significant amounts of niacin, riboflavin, thiamin, retinol and ascorbic acid, which allows it to be classified as a functional food if consumed fresh and if the preservation of these components is ensured during the transformation and conservation chain [4].

The mango peel is a waste that is characterized by its high water content, phenolic compounds, hemicellulose and cellulose, which due to its high levels of production and transformation generates a high pollution causing some environmental problems if no innovation treatment is done on this residue [5, 6]. The fiber has gained attention from a scientific perspective due to its high content of phenolic compounds and fiber, since it has been determined that they have antioxidant properties and as a prebiotic agent respectively [7,8].

The bars of fruit, known in Colombia as snaks, are characterized by having a high content of fresh or dehydrated fruit pulp accompanied by several chemical compounds that help improve their texture, flavor, color and aroma, among these are: sugars (sucrose, glucos, fructose), anticompactants (soy lecithin), acidity regulators (sodium citrate or sodium ascorbate) and stabilizers (xantan gum, arabic, carboxymethylcellulose, starch). To produce these snaks, a dehydration operation is necessary, which is responsible for eliminating the water and generating the texture of the bar itself. Within these techniques is the convective drying, extrusion, lyophilization, ultrasound, microwave, among others [1,4].

The drying process can cause changes in the optical properties (color and appearance), sensory properties (smell, taste), structural properties (density, porosity, and specific volume), mechanical properties (texture), rehydration properties (rate of rehydration and the capacity of rehydration), and the nutritional characteristics (vitamins and proteins), improving in some cases some of those indexes of quality (flavor, digestibility, etc.) [4,9].

The most widely used drying techniques for these purposes is the convective drying coupled with microwave pulses as it is very low cost, easy to use and its treatments at temperatures between 40 to 60 ° C help the conservation of functional chemical compounds of the fruit, besides protecting the flavor and the characteristic aroma of the fruit [1].

The objective of this work was the formulation and characterization of a bar of fruit base pulp and mango peel (Mangifera indica) variety Tommy Atkins.

2. Materials and methods

2.1. Preparation of the sample

The mango variety Tommy Atkins was purchased at a local supermarket, from the department of Tolima, was selected by degree of maturity and size, washed with water and disinfected with 500 ppm sodium hypochlorite solution. The pulp and peel were chopped for the analysis and drying process.

mango

The raw material was characterized by determining the water activity (aw) using an Aqualab dew point hygrometer A.O.A.C 978.18 [10], the moisture content (Xw) by gravimetric method according to A.O.A.C 20.013 [10]; the soluble solids were determined by the refractometric method, with the help of a THERMO brand refractometer following the method A.O.A.C 932.12 [10]; the percentage of total fiber following the AOAC method 920.86 [10]; Total acidity (% AT) according to NTC 4623 expressed as a percentage of citric acid [11]; the color was determined in a MINOLTA CR-10 colorimeter with a D65 illuminant and with a standard observer of 10°, establishing the coordinates CIE-L* a* b*[2]; the content of total phenols was determined by the Folin-Ciocalteu method, the absorbance was measured 30 minutes after the start of the reaction in a visible UV spectrophotometer Hewlett Packard Chemstation 8453 G1115AA and gallic acid (GA) as standard for the calibration curve, it was read at 765nm. The results were expressed as mg AG / 100 g sample [12]. The vitamin C content was determined by the 2-nitroaniline colorimeter method, the absorbance was measured in a UV-VIS spectrophotometer at 540 nm. The results were expressed as mg ascorbic acid / 100 g sample [14].

2.3. Application of drying techniques

Convective drying (SAC) in hot air recirculation oven: The samples of peel and mango pieces were dried in an oven with hot air recirculation (SAC) at 40 and 50 ° C, registering weights every 30 minutes until weight constant.

Microwave-assisted convective drying (SAC-MO): SAC-MO combined drying was carried out in a conventional microwave oven adapted on one of its side faces to an air circulation system, with temperature regulation using the following parameters: temperatures of 40 and 50 ° C with microwave pulses of 4 seconds every 40 seconds, up to constant weight.

Freeze drying (Liof.): The pulp and mango peel samples were ultra-frozen at -80 ° C and then lyophilized at -47 ° C and 90 mtorr vacuum for 24 hours, 30 hours and 36 hours.

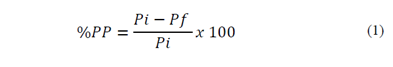

For the three drying techniques, water activity, color, total percentage of raw fiber and weight loss by initial (Pi) and final weight difference (Pf), expressed as a percentage of weight loss (% PP), were taken as response variables, according to the eq. (1).

The results were compared and evaluated statistically from unilateral ANOVA analysis at a 95% confidence level (P≤0.05).

2.4. Formulation of the mango-based fruit bar

The pulp and peel dried were subjected to a milling process in an IKA brand mill and six formulations were made varying the content of pectin, water, inulin, glycerol and ascorbic acid; the content of pulp and peel was constant in the different formulations.

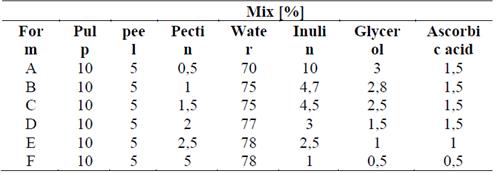

The percentages of pectin added to evaluate their behavior in the gelation of the mixture were the following: 0.5%, 1%, 1.5%, 2%, 2.5% and 5% of the total of the mixture. From these percentages were made the formulations for the elaboration of the fruit bar, which are shown in Table 1.

Obtaining the bar: the additives were mixed according to the formulations shown in Table 1, the mixture was placed in mold in order to obtain homogeneous bars, the bars were cooled to -4 ° for a period of one (1) hour for their compaction Finally, the bars are subjected to drying by hot air recirculation (SAC) at 40 ° C for three (3) hours.

characterization of the fruit bar

Physicochemical characterization: the parameters aw, Xw, ° Brix, total fiber, % AT, color, content of total phenols and vitamin C in two final formulations B and D were evaluated, in addition the texture was determined by quantifying the maximum puncture and penetration load with its respective deformation of the fruit bar with a STABLE MIC texturometer model TAXTPLUS using the Texture Exponent 32 Version 2.0.6.0 software.

Microbiological analysis: The microbiological analysis was performed evaluating the total coliform count, mold and yeast count according to ISO 7954 [13] and the total coliform count according to the methodology proposed in previous studies [14].

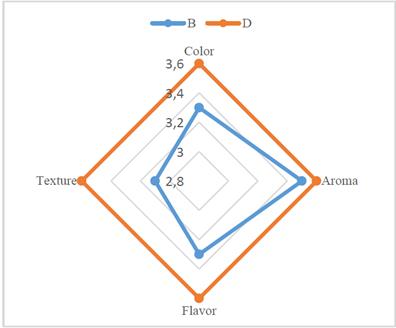

Sensory evaluation: It was carried out by a descriptive test quantifying the sensory differences by 10 semi-trained judges, who determined the sensory properties of the samples in the parameters of color, aroma, taste and texture. The evaluation was made using a scale of 1 to 5, being 1 the most unpleasant and 5 the most agreeable. The fruit bar formulations (A and B) were evaluated.

Statistical analysis: The study of the significance of the different effects and their possible interactions was performed using simple variance analysis (ANOVA) using the Tukey HSD test (Honestly significant differences) as a method of multiple comparisons, with a level of significance (α ) of 0.05, in the statistical package Statgraphics Centurion XVI.II.

3. Results and discussion

3.1. Characterization of the raw material

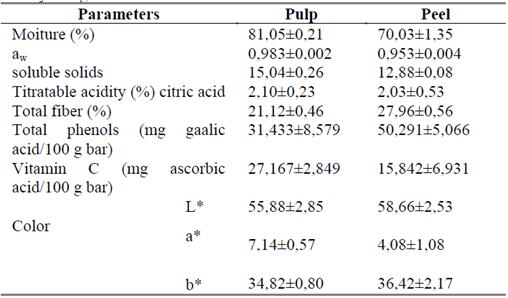

In Table 2, the physicochemical characterization of mango pulp and peel mango in a fresh state is presented.

Table 2. Physicochemical characterization the pulp and peel of Tommy Atkins variety mango

Source: The Authors.

The results obtained from the characterization of fresh fruit are an important starting point for the development of the project. As seen in Table 2, the pulp and peel mango contain a high moisture content of 81.05% and 70.03% respectively. The total fiber content of 21.12 and 27.96 for pulp and peel respectively, is higher than previously reported [6] in total fiber for mango variety Tommy Atkins of 19.96%.

The evaluated parameters of color, show values of luminosity (L *) average, the positive values of the coordinate a * locate the pulp in the scale of reds and the lower value that presents the shell is due to the green pigments characteristic of this variety of mango, the positive values of b * represent the characteristic yellow color of the mango fruit.

As seen in Table 2, the mango pulp has a higher content of vitamin C and a lower content of total phenols and total fiber with respect to the peel.

This is mainly due to the presence of the flavonoids contained in the skin responsible for generating the red colors in it and for the case of vitamin c, it is in the pulp where it is synthesized because it is there the free glucose molecules are found, which are the precursors for the biosynthesis of L dehydro ascorbic acid, which, as previously reported, can only be biosynthesized in plants.

3.2. Drying techniques

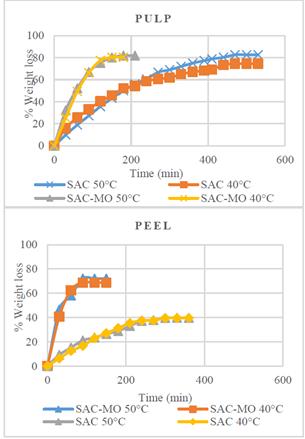

The Fig. 1 shows the drying process of the pulp and peel mango by SAC and SAC-MO techniques at different temperatures.

Source: The Authors.

Figure 1. Weight loss kinetics of pulp and peel mango by SAC and SAC-MO techniques at different temperatures.

As shown in Fig. 1, the pulp presents the highest percentage of water loss at 200 minutes for the SAC-MO drying method at temperatures of 40 and 50 ° C, while drying by SAC reaches the same percentage of loss of water at 400 minutes at temperatures of 40 and 50 ° C. In Fig. 1, the peel presented greater water loss with respect to the pulp, reaching equilibration at 100 minutes for SAC-MO drying at 40 and 50 ° C and for the SAC drying technique at 200 minutes.

For both the pulp and the peel, the most time-efficient method is microwave-assisted convective drying (SAC-MO).

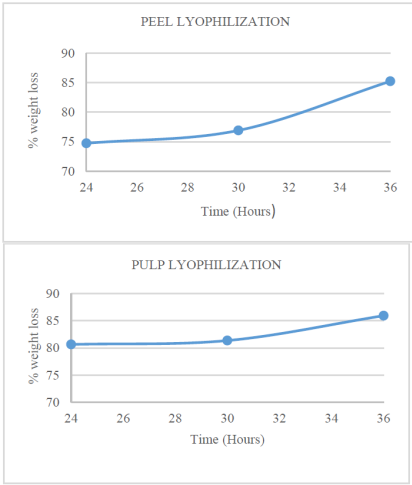

In Fig. 2, the weight loss process of the pulp and peel mango is shown by the lyophilization drying technique.

Source: The Authors.

Figure 2. Kinetics of weight loss of pulp and peel subjected to lyophilization.

As stated in different studies, lyophilization is an appropriate method for obtaining food powders, since it produces a porous structure that absorbs water easily, improving its rehydration properties and preserving most of the initial properties, including the concentration of bioactive compounds [15]. However, as seen in Fig. 2, the lyophilization process does not represent an effective technology in terms of time and moisture loss. In the 24- and 30-hour trials the weight loss is not significant.

The freeze drying, although it is a method of dehydration that does not significantly affect the characteristics of the fruit, is less efficient in terms of time and the equipment used in this research was not constant in the variables of pressure and temperature, so it is discarded in this phase of the project.

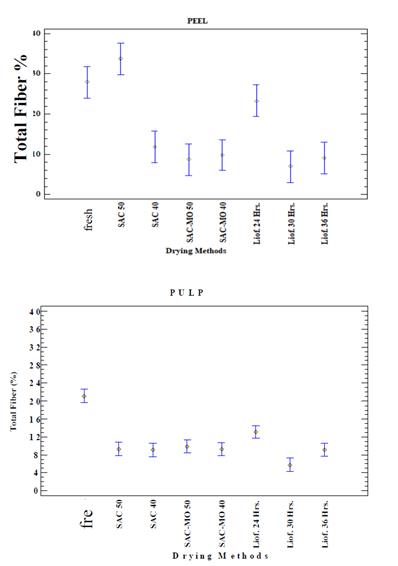

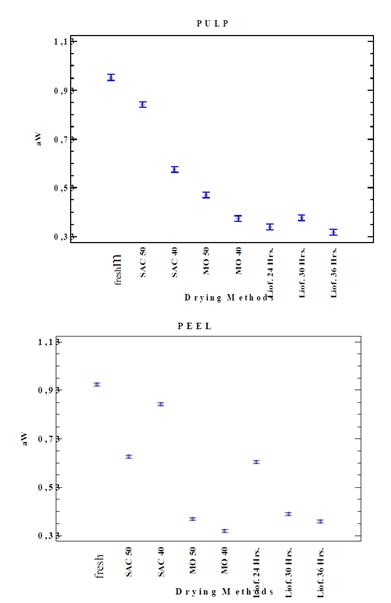

In the Figs. 3-5 the statistical comparisons by means of an analysis of variance of the water activity, percentage of total fiber and color change as response variables, with respect to

Source: The Authors.

Figure 3. Activity water of pulp (a) and peel (b) and subjected to drying treatments.

As shown in Fig. 3, there is a statistically significant difference for the pulp and mango peel in the water activity between the SAC, SAC-MO and lyophilization drying techniques, with a p-value of 0.001 and a level of 95.0% confidence.

The microwave-assisted convective drying method (SAC-MO), in addition to having shown better weight loss performance with respect to time (Fig. 1), is also a technique that yields lower water activity results in less time, such as it is observed in Fig. 3, both for pulp and for the peel, this parameter is important in the quality of the pulp and peel dehydrated. The water activity values of SAC-MO at 40 and 50 ° C for the peel are like those reported previously [6] in the production of peel powder Tommy Atkins mango.

The water activity of the lyophilized samples for 24 hourss greater, this is directly related to the moisture content and may represent a parameter of low quality since it propitiates the optimum environment for microbial growth and does not obtain a product formulated with the texture characteristics expected.

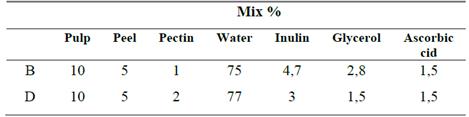

As seen in Fig. 4, there is a statistically significant difference in the percentage of total fiber between SAC and SAC-MO drying techniques with freeze-drying at 24 and 30 hours of drying for the pulp; while for the peel this difference occurs between SAC-50 ° C and freeze-drying 24h with the other treatments, with a p-value of 0.001 and a confidence level of 95.0%.

The percentage of total fiber is one of the most important characteristics in the pulp and peel mango, so it is important that the drying process does not alter this component. As shown in Fig. 4, the SAC drying method at 40 ° C and SAC-MO present positive results for this nutritional variable both in the pulp and in the mango peel. The fiber content in the peel is like that of the pulp, it can be due to the pulp that remains attached to the peel and increases the percentage of total fiber quantified.

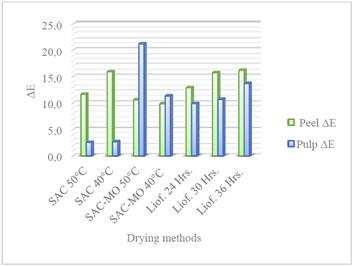

The determination of color as a quality parameter was evaluated with respect to the CIE L * a * b *coordinates of pulp and peel (Fig. 5), taking into account that the consumer is expected to relate to the first seen the bar formulated with the color of the fresh mango.

Considering that the Tommy Atkins mango peel presents red, green and yellow pigments, it is difficult for it, when dehydrated and ground, to present values of ΔE close to 2.5 that represent a similarity with the fresh peel. With the pulp variations are due to the state of maturity, since a higher content of sugars, during the dehydration process generates a series of chemical reactions between carbohydrates and amino acids, also called non-enzymatic browning, the result is a darkening of the samples [16], so that the differences with respect to the fresh pulp are statistically significant as shown by the value of ΔE in Fig. 5.

3.3. Formulations of mango-based fruit bar

The design for the formulations (Table 1) had as a starting point the percentage of citrus pectin, evaluating its power of gelling the sample in percentages that varied from 0.5 to 5% of the total of the mixture, being the formulations B (1%) and D (2%) those that had a better texture and physical appearance result to be sensory evaluated. The preselected formulations B and D are shown in Table 3.

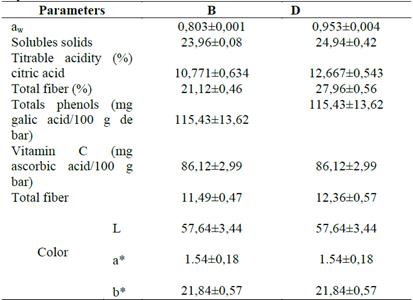

The addition of inulin increases the functional characteristics of the fruit bar, due to its prebiotic behavior, defined by its selective ability to stimulate the growth of a group of bacteria in the colon (bifidobacteria and lactobacilli), with the consequent decrease in other species which can be harmful (example: E. coli and bacteria of the species Clostridium spp.) [17]. Glycerol is used for the decrease of water activity in food systems [18] and improves the texture of pectin gels, giving plasticity to the product [19]. Ascorbic acid in small quantities prevents oxidation of the product, preventing color changes. The proportion of peel and pulp is defined mainly by the color it brings to the formulation and the total fiber content.

characteristics of the fruit bar

In Table 4, the physicochemical characterization of formulas B and D of the fruit bar is shown.

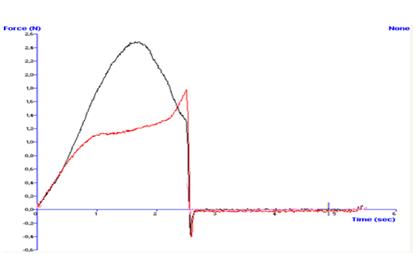

The water activity in formulation D is lower and is consistent with the addition of a higher percentage of pectin, similar values were reported by [9]. The mango-based bar has lower water activity, total fiber and higher % acidity, soluble solids, vitamin C and total polyphenols content with respect to the pulp and peel fresh, this increase is due to the mixture of the pulp and Mango peel and the addition of substances such as ascorbic acid and inulin increase these values in the formulated fruit bar. Formulation D contains a higher percentage of total fiber, % acidity, soluble solids and better texture results (Fig. 6) and is the formulation with greater sensory acceptance, as shown in Fig. 7.

The formulation D shows greater symmetry in the curve thrown by the texture analysis, which suggests homogeneity in the mixture and better texture, with a maximum value of 2.4900 N, expressed as hardness. Formulation B is less consistent with a value of 1.7762 N and in the time duration in which the cutting force is exerted it shows an irregular behavior (Fig. 6), this is attributed to a higher moisture content, and less gelling of the bar taking into account that this formulation contains lower pectin content (1%).

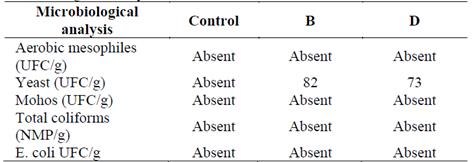

The results obtained in the microbiological analysis (Table 5) show mainly that the fruit bars formulated are suitable for human consumption. The absence of microorganisms evidences an important quality parameter. This is mainly due to the fact that the raw materials of vegetable origin go through a method of dehydration (drying), which significantly reduces the risk of microbiological contamination of the formulated product. The final stage of drying also decreases the moisture content and water available for microbial growth. These values are in accordance with NTC 6005 [20] which establishes the microbiological requirements for minimally processed foods (mesophiles <100,000 CFU / g and for E. coli <100 CFU / g).

In Fig 7, the radials of the sensory analysis of the formulations B and D are shown in the parameters of texture, color, aroma and taste and the preference between the two formulations.

The sensory analysis shows a notable difference between the two formulations, with D being the best qualified in all the parameters evaluated, with an average acceptance of 3.6 on a scale of 1 to 5 and was chosen by most panelists as the formulation preferred by its characteristics in general. A higher percentage of pectin and addition of glycerol improves the texture of the fruit bar. The aroma of the fruit bar was almost imperceptible, and the color was altered after the drying process of the mixture. In general, the fruit bar was well accepted by the sensory panel.

4. Conclusion

The mixture of pulp and mango peel in obtaining a fruit bar is a viable alternative for the use of agroindustrial waste such as peel, mitigating the environmental problems of the generation of these residues and using their bioactive compounds in the formulation of Functional Foods.

The formulations for the optimal mixture of a fruit bar, had good results in terms of total fiber content, and functional compounds such as polyphenols and ascorbic acid important in antioxidant activity.

The mango-based fruit bar with formulation D (2% pectin) obtained better results at the sensory level, althoughthe average rating of the parameters evaluated (3.6) suggests that they can be improved at the level of color and aroma.