1. Introduction

According to the Statistical Bulletin of the National Confederation of Transport [1], the Brazilian road network has about 1.7 million kilometers, of which about 211,418 km are paved roads. These routes are responsible for 52.2% passenger traffic and 61.1% cargo transportation in Brazil, with the remainder being distributed among other modes of transport, namely, airways, waterways and railway transportation [1]. Of the total paved, approximately 95% have surface course divided into the groups of hot mix asphalts and cold mix asphalts [2].

The surface course is composed of a mixture of mineral aggregates with asphalt binder at adequate percentages, and is therefore called asphalt mixture, forming an impermeable, flexible layer resistant to traffic demands and climatic influences [3,4]. A well-designed surface course, besides providing comfort and safety to users, guarantees a longer useful life to the pavement, mainly by protecting its underlying structural layers, absorbing part of the demands imposed by vehicular traffic [5]. According to Santos [6], if a surface course is poorly designed and structurally flawed, it is probable that there will be premature defects on the pavement surface and, therefore, the underlying layers will be unprotected and deteriorate rapidly with traffic and climate, considerably affecting the highway’s service.

According to Balbo [7], asphalt mixtures require a strictcontrol during design, plant mixing and field execution, meeting requirements for strength, flexibility and durability to support traffic and climate action. In order to meet these requirements, it is important to analyze the materials used in asphalt mixtures, their technological characteristics and the mechanical behavior of compacted asphalt mixtures.This author points out that the relevance of the mix design process, in particular, lies in the technical need to select and provide its component materials (aggregates and asphalt binder) according to predefined criteria, aiming at obtaining an engineered product that is workable in the spreading and compacting stages, stable under the action of static or moving loads and little susceptible to the pathologies resulting from the traffic and weather action.

This relevance therefore supports the interest in developing research to assess the influence of the intervening factors in the mix design process on the technically desirable properties of asphalt mixtures for asphalt pavement design purposes. Examples of research involving this theme include Renken [8],Ahmad et al. [9],Vega-Zamanillo et al. [10], Zumrawi and Edrees [11], Al-Humeidawi [12], Han et al. [13] andAl-Khateeb et al. [14].

In agreement with Bernucci et al. [2], the Marshall mix design method, which is regulated in Brazil by ME 043 [15] and NBR 15785 [16], is widely used in Brazil because of its simplicity and low-cost methodology. However, a more recent technique has been an advance in design methodologies, which is the Superpave mix designmethod, since it is believed to better simulate the field conditions, considering climatic and traffic variables as parameters in the choice of materials to be used in the mixture. It should be noted, however, that the Superpave mix design method is still restricted to a few research centers in Brazilian universities.

Regardless of the design method used, special care should be taken in defining the theoretical specific gravity (Gt), which is the maximum specific gravity value to be employed incalculations of the percent air voids (Vv), percent void in mixed aggregate (VMA) and percent voids filled with bitumen (VFB) [17].

This paper addresses a comparative study using two different methodologies for calculating the maximum specific gravity, based on the theoretical specific gravity and the measured maximum specific gravity, respectively. The design of hot asphalt mixtures was carried out according to the Superpave mix design method.

2. Material and methods

2.1. Material

For the laboratory tests, the following aggregates were used: gravel 0, gravel 1 and stone powder. These aggregates came from the Ervália Quarry, located in the municipality of Ervália, Northern Zona da Mata, State of Minas Gerais. The particle size range adopted in this study was the gradation B of ES 031 service specification [18], intended for the surface course of flexible pavements. The asphalt binder used in the research was the CAP 50/70, from StraturaAsfaltos S/A, located in the city of Betim, State of Minas Gerais, Brazil.

2.2. Methods

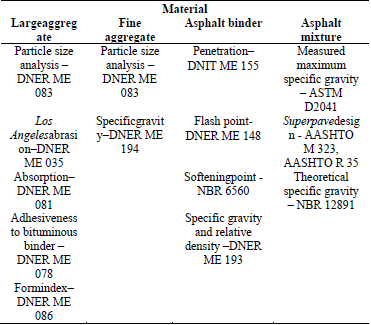

Table 1 lists the tests and determinations made on the material and asphalt mixtures provided in this experimental research, with a corresponding indication of the adopted standard (DNER and NBR are Brazilian technical standards).

For the determination of the maximum specific gravity, the following methods were used.

2.2.1. Theoretical Specific Gravity (Gt)

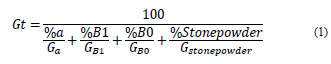

Theoretical specific gravity Gt is given by eq. (1) [19]:

where %a, %B1, %B0 and %stone powder are the masses percentages and Ga, GB1, GB0 and Gstonepowder are the apparent specific gravity of the asphalt mixture constituents.

2.2.2. Measured Maximum Specific Gravity (MMSG)

The determination of the measured maximum specific gravity (MMSG) followed the ASTM test protocol D 2041 [20], which apply the vacuum system for the expulsion of air between the clumps of the aggregates-asphalt binder.

In the Superpave design, the Level 1 analysis addressed the volumetric criterion, and the number of turns (N) to be applied by the rotary compactor was in the range from 3x106 to 107 solicitations of the standard axle of 8.2 tf (medium to high traffic volume). According to the estimated traffic, the following values of N were selected: Ninitial= 8, Ndesign = 100 and Nmaximum= 160. The application of the Superpave design method, for Level 1, basically comprised the following steps:

3. Results and analysis

3.1. Material characterization

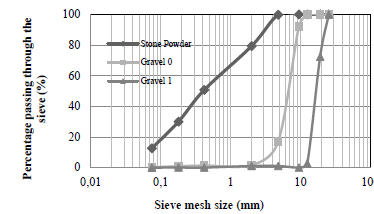

The respective particle size of the aggregates used in the composition of asphalt mixtures considered in the Superpave design are presented in Fig. 1.

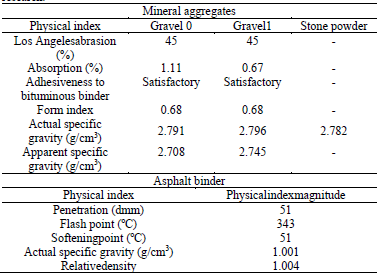

The physical characteristics of the mineral aggregates and asphalt binder used in the study are summarized in Table 2. It should be noted that the satisfactory result for adhesiveness to bituminous binder was obtained after using an improver additive (0.1% asphalt binder mass).

3.2. Characterization of mineral aggregate composition of the trial mixtures

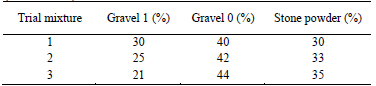

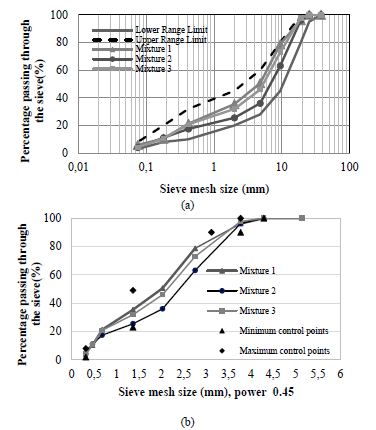

In accordance with the requirements of the Superpave mix design method, the three particle size compositions of mineral aggregates used in the design are presented in Fig. 2, together with the limits of the gradation B of ES 031 specification [18] and with the restrictions established by the control points. Table 3 lists the percent compositions in mass of the experimental mixtures of aggregates (trial mixtures). The control points correspond to the maximum nominal size (MNS) of the mineral aggregates referring to the mixtures (MNS = 19mm).

Source: The Authors.

Figure 2 Particle size curves of the trial mixtures of mineral aggregates used in the Superpave design method and respective classifications in the limits of the gradation B of DNIT (a) and in the control point requirements (b).

3.3. Determination of the design mixture from the trial mixtures

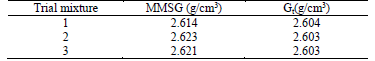

Based on the experience gathered in the Laboratory of Asphaltic Materials and Mixtures of the Federal University of Viçosa (UFV) and on previous knowledge of the behavior of mineral aggregates used in the mixtures, an initial binder content of Plof 4% was adopted for the three trial mixtures also including asphalt-aggregate adhesion improver additive in the content of 0.1% of asphalt binder. Table 4 lists the results of the calculations of the measured maximum specific gravity (MMSG) and the theoretical specific gravity (Gt) for each of the trial mixtures.

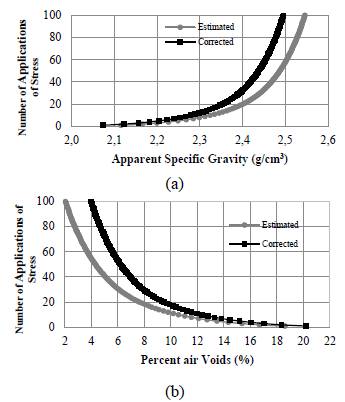

In the Superpave mix design method, the apparent specific gravity of the compacted mixture (Gmb) and, consequently, the percent air voids (Vv) should be corrected according to the final apparent specific gravity (Gmbfinal) of the mixture compacted by the Superpave Gyratory Compactor (SGC), obtained for the number of turns corresponding to the maximum number.

For comparison and exemplification, Fig. 3 illustrates the curves of Gmb and Vv, respectively, for a test specimen, according to the number of turns in the CGS, before (estimated value) and after (corrected value) applying the correction factor.

Source: The Authors.

Figure 3 Example of correction of the apparent specific gravity (a) and percent air voids (b) curves of the Superpave design method.

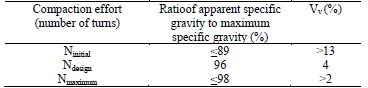

Regarding the traffic level considered in this research, Table 5 presents the volumetric criteria defined in the Superpave methodology for choosing the asphalt binder content.

Table 5 Superpavevolumetric criteria to select the asphalt binder content (MNS=19mm).

Source: The Authors.

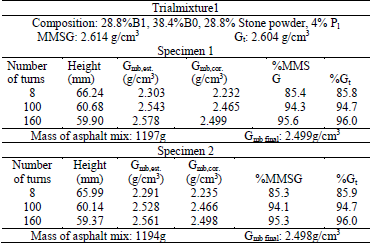

Tables 6, 7, 8 present the results of the compaction test of the three trial mixtures.

Table 6 Corrected apparent specific gravity and percentage of the corresponding maximum specific gravity referring to the compaction of the trial mixture 1.

Source: The Authors.

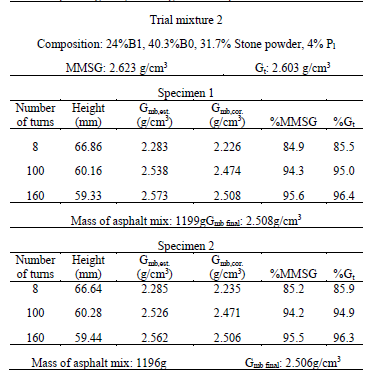

Table 7 Corrected apparent specific gravity and percentage of the corresponding maximum specific gravity referring to the compaction of the trial mixture 2.

Source: The Authors.

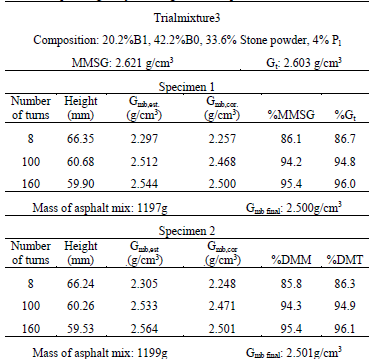

Table 8 Corrected apparent specific gravity and percentage of the corresponding maximum specific gravity referring to the compaction of the trialmixture 3.

Source: The Authors.

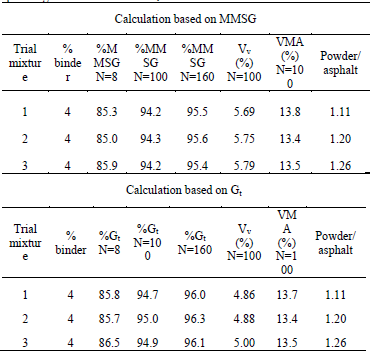

Table 9 presents the summary of the results with the volumetric properties of percent void in mixed aggregate (VMA), percent air voids (Vv) and the powder/asphalt ratio using in their calculation, respectively, the specific gravities MMSG and Gt.

Table 9 Summary of compaction parameters obtained in Superpave design, based on specific gravities MMSG and Gt.

Source: The Authors.

Conclusion based on the volumetric criteria in Table 5 and the results in Table 9 support that the trial mixtures 2 and 3 presented an acceptable percent void in mixed aggregate (VMA). However, the resulting powder/asphalt ratios are at the limit and above acceptable value (range of acceptable powder/asphalt ratio of 0.6 to 1, 2), being able to surpass this limit even with the increase in the percentage of binder. The trial mixture 1 had lower percent air voids (Vv) than the other trials for both MMSG and Gtmix design criteria and closer to Vv of 4% for Ndesign of 100, as well as met the minimum VMA requirement showing a more favorable powder/asphalt ratio.

From thesedata, the mixture of aggregates 1 (trial mixture 1) was selected as the particle size composition to be worked on herein, for both design procedures. Despite the selection of the same trial mixture, it should be emphasized that the percent air voids at N of 100 (Ndesign) differs according to the adopted procedure for the determination of the maximum specific gravity (Vv = 5.69 % for mix design according to Gt; Vv = 4.86% for mix design according to MMSG).

For the adopted trial mixture, two specimens were compacted with the SGC at 100 turns in the binder percentages of 4.3%, 4.6%, and 4.8%. The increase in the binder content over the initial binder content (Pl = 4%) is obviously justified by the probable reduction in the percent air voids and by the expectation of reaching Vv of 4% at Ndesign for an asphalt binder content in the adopted increase range. The specimens were prepared and analyzed in the same manner as in the selection of the design particle size composition.

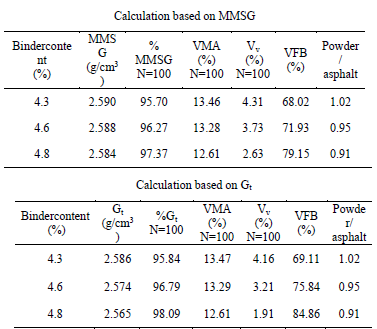

Table 10 presents the results of the parameters obtained for the three percentages of binder, for both mix design criteria.

Table 10 Compaction parameters obtained in Superpave design method, based on specific gravities MMSG and Gt.

Source: The Authors.

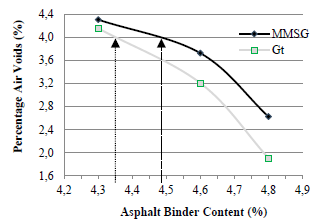

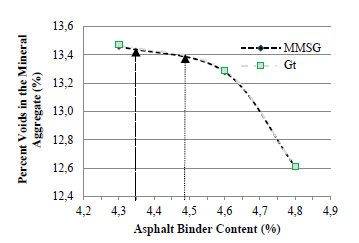

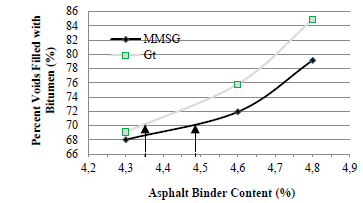

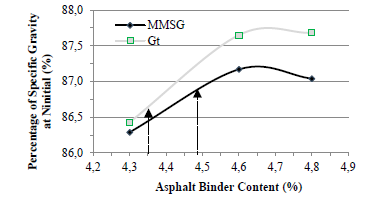

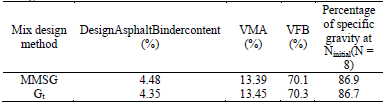

From the results, it was possible to construct the curve of percent air voids versus asphalt binder content for the determination of the design asphalt binder content of each dosage. According to Fig. 4, the Vvof 4% corresponds to 4.35% of asphalt binder content for the Gt-based mix design and 4.48% for the MMSG-based mix design. Applying these asphalt binder contents to the respective curves obtained by the MMSG and Gtmix design criteria,as shown in Figs.5, 6,7, resulted in thevalues listed in Table 11, depicting also the parameter percent voids filled with bitumen (VFB). The powder/asphalt ratio was 0.98 for the two design asphalt mixtures.

Source: The Authors.

Figure 4 Variation in percent air voids (Vv) with the asphalt binder content for the design particle size and corresponding design contents ofVv = 4%, according to mix design by MMSG and Gt.

Source: The Authors.

Figure 5 Variation inthe percent void in mixed aggregate (VMA) with the asphalt binder content for the design particle size and corresponding VMA values for the design asphalt binder content, according to mix design by MMSG and Gt.

Source: The Authors.

Figure 6 Variation in the percent voids filled with bitumen (VFB) with the asphalt binder content for the design particle size and corresponding VFB values for the design asphalt binder content, according to mix design by MMSG and Gt.

Source: The Authors.

Figure 7 Variation in the percentage of maximum specific gravity at Ninitial with the asphalt binder content for the design particle size and corresponding percentages of maximum specific gravity for the design asphalt binder content, according to mix design by MMSG and Gt.

Therefore, based on the experimental results of the Superpave design adopting the MMSG and Gt the resulting asphalt mixtures meet the volumetric criteria established by the specifications of the Superpave methodology, namely: VMA> 13.0%; 65%≤VFB≤75% for the adopted solicitations of the standard axle of 8.2 tf; percentage of the maximum specific gravityatNinitial smaller than 89%. From Table 11, it is possible to identify the influence exerted by the choice of the methodology for determining the maximum specific gravity on the results obtained in the Superpave mix design method, observing that the results of the obtained parameters indicated very close values, including the design asphaltic binder content.

Table 11 Results of the parameters of Superpave design method in the respective design contents.

Source: The Authors.

In a research aimed at evaluating the possible influence of the method for determining the maximum specific gravity on the volumetric parameters and, consequently, on the design content of asphalt mixtures dosed according to the Marshall design method, Vasconcelos [21] detected differences in the magnitude of this parameter for the three determination methods studied, with subsequent maximum difference between the design asphaltic binder contents of 0.4%, thus exceeding the maximum tolerance of 0.3% prescribed by the standard ES 313 [22] for hot asphalt mixtures, replaced with the current ES 031 [18]. Antunes and Nienov [23] conducted similar research, also involving the Marshall design method and two methods for determining the maximum specific gravity of asphalt mixtures, and obtained design asphalt binder contents differing in the order of 0.8%. El Sayed [24] reported similar experimental findings when studying the effect of different methods for determining the maximum specific gravity on the Marshall design of eight distinct mixtures (four gradations and two types of mineral aggregate), leading the author to recommend the adoption of the laboratory method, and not the theoretical, for the determination of the design asphalt binder content.

Interestingly, all the studies above mentioned refer to the Marshall design method, and there is a lack of research related to the same object of study addressing the Superpave design method, as presented here, emphasizing the relevance of this work. This importance can be further stressed when considering the contrast between the results obtained by these researchers and those obtained herein, which show, for the particularities of the materials and methods involved, the limited sensitivity of the Superpave design protocol to the possible variation in the maximum specific gravity according to theoretical and laboratory methods. The difference of 0.13% between the asphalt binder contents obtained in this research according to the two methods for determining the maximum specific gravity was lower than the tolerance prescribed by ES 031 [18]. It may be indicative of a possible comparative advantage of the Superpave design method over the Marshall method with respect to their respective sensitivities to the maximum specific gravity.

4. Conclusions

Considering the results of the present study, the comparative analysis on the influence of using two different methodologies for determining the maximum specific gravity in the Superpave asphalt mixture design showed no significant differences in the results of the obtained parametersfrom therespective design asphaltic binder contents.From a practical point of view, it may correspond to an advantage of the method, since similar research based on the Marshall design method evidenced the sensitivity of the design protocol to the type of maximum specific gravity adopted.In this way, further studies are encouraged to expand the database for this object of study, thus giving higher statistical reliability to the conclusions reached here.