1. Introduction

The NPDP are an interesting subject and focus for researchers of different academic areas. The large number of unplanned events that usually appear in these types of projects can complicate its scheduling. In this article, the resource-constrained project scheduling problem (RCPSP) has been considered as a suitable reference to address the scheduling process in NPDP.

Traditionally, the RCPSP has been solved taking into account deterministic input parameters. However, this approach is only applicable when parameters such as the availability and quantity of resources required, the involved costs or the activities duration are assumed as static values.

The static or deterministic RCPSP does not apply to NPDP since its activities are executed under unforeseen circumstances. Therefore, this type of project must be analyzed as a non-deterministic problem and its input parameters must be analyzed under a probabilistic or uncertain context, for example, using probability functions, fuzzy numbers or other types of representation.

In this article, the RCPSP is analyzed under a probabilistic context, since the activities duration and the impact of the risks are represented by probability distributions. Also, the appearance probability of new activities, different to those originally planned, are incorporated as an additional parameter. Therefore, the problem analyzed is called RCPSP with random duration of activities and stochastic tasks insertion.

The purpose of this research is to develop an optimization model to solve the RCPSP in NPDP and obtain a robust baseline for the project. The proposed model to solve this problem covers three stages: in the first, the risks and their impacts are identified; in the second, the activities duration is estimated from a redundancy based method; and in the third, an integer linear program to generate the project baseline is solved. Stage two of the model is flexible because any redundancy based method can be used to estimate the duration.

Two versions of the model were designed and compared in order to select the best one. The first version uses a method to estimate the activities’ duration based on the expected value of the impact of the risks and the second version uses a method based on the judgmental risk analysis process.

A case study that describes the process to develop a material for the leadframe of a semiconductor package was used as a reference project to apply the two versions of the optimization model. The baselines obtained from each version of the model were compared using a robustness indicator. It is important to remember that a robust baseline will require few adjustments when the disruptions affect the activities duration. Therefore, 10000 scenarios were generated through a Monte Carlo simulation process.

The article has been organized as follows: section 2 describes the main characteristics of the RCPSP with random duration of activities. In section 3, a brief literature review is presented, which refers to the most relevant articles on the project scheduling problem applied to NPDP. Section 4 describes the proposed model to solve the RCPSP with random duration of activities and stochastic tasks insertion. Then, section 5 presents a case study, which is resolved in section 6 using the first version of the proposed model. Subsequently, in section 7 the second version of the model is applied, this version uses an alternative method to estimate the duration of the activities. The baselines obtained by the two versions of the model are compared in section 8. Finally, section 9 presents the conclusions of the investigation.

2. Resource constrained project scheduling problem with random duration of activities

The RCPSP seeks minimize the project duration taking into account the availability of resources, the activities duration and their precedence. In the formulation of the optimization model n activities are defined and identified by a subscript (i or j) with values between 1 and n. For practical programming reasons, the first and last activity are represented as fictitious activities of zero duration.

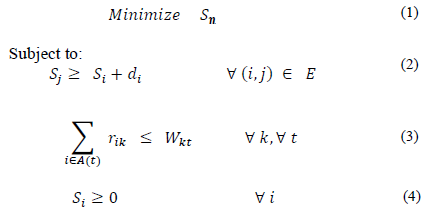

The time horizon is divided into partial periods represented by a subscript (t) with values between 1 and T. In each period, activity i consumes r ik units of the renewable resource k. The maximum amount of renewable resource k available for each period t is defined as W kt . Some mathematical models also include non-renewable resources and partially renewable resources [1]. A mathematical model to solve the RCPSP can be expressed as linear program [2]:

Where S i represents the start times of each activity i, and d i its duration. Eq. (2) establishes the start times for each activity j taking into account the start times and the duration of the preceding activities. E represents the set of activities and their precedences. Eq. (3) refers to the restriction of renewable resources, since the active activities in period t cannot exceed the available amount of type k resources. Finally, eq. (4) indicates that the start times are continuous positive variables.

Under a non-deterministic focus, the input parameters of the integer linear program (d i , r ik , or W kt ) must be modeled as probability functions, fuzzy numbers or other type of representation. An extensive review of scientific literature about the RCPSP under a non-deterministic focus can be consulted in [3]. In this article, the RCPSP is analyzed under a probabilistic context, since the activities duration and the impact of the possible risks are represented through probability distributions. The duration can be modeled from historical information, data from similar projects or through the experience of expert personnel.

Procedures to solve the RCPSP with random duration of activities are designed taking into account predictive, reactive or proactive strategies. According to [4], a predictive strategy takes the average durations of the activities as input data in order to create a project baseline. A reactive strategy re-schedules the original baseline when an unexpected event occurs. A proactive strategy takes into account the variation of the activities duration to generate a robust baseline for the project. A baseline can be considered robust when few adjustments are required for facing the project’s disruptions.

According to the scientific literature review carried out in this research for the period 1996-2019, the solution techniques most frequently used to solve the RCPSP with random duration of activities were the Genetic Algorithms [5-16] and the Critical Chain Method [17-28]. The RCPSP with random duration of activities and stochastic tasks insertion was presented by [29]. In that work, the appropriate size of the project buffers was computed in order to support the disruptions that may appear during its’ execution.

3. A relevant literature review for the scheduling problem in NPDP

According to the documents identified in the Scopus database for the period 1996-2019, the project scheduling problem applied to the NPDP was addressed in 19 research works. These contributions correspond to 6.64% of the total scientific articles related to the project scheduling problem.

Although some of these works used fuzzy numbers to represent the activities duration, the most frequent representation was from probability distributions.

In 1996, Schmidt et al. [30] modeled the duration of activities through discrete probability distributions and proposed a mixed-integer linear program to maximize the net present value in a new product development project. The mathematical model did not take into account the restriction of resources; however, it incorporated two very important elements of analysis: the probability of carrying out successfully each project activity and the occurrence probability of the futures scenarios.

In 2001, Subramanian et al. [31] addressed the scheduling problem of multiple projects with constrained resources (RCMPSP) and presented a procedure that combines mathematical programming with discrete events simulation to assess uncertainty, to control the risk in the selection of NPDP and to schedule the tasks. The combined simulation-optimization model maximized the net present value taking into account the probability of carrying out successfully each project activity, their random duration, and the uncertainty of the amount of required resources.

The RCMPSP applied to the NPDP was also analyzed by Choi et al. [32], who used a discrete time Markov chain to analyze the costs variation, the probability of success or failure of each activity and their random duration. Three heuristic procedures were used to create an adequate state space to solve the mathematical model by Dynamic Programming. In 2005, Gao et al. [33] proposed a heuristic algorithm that took into account the randomness in the activities duration, the possibility of reworking, and the inclusion of concurrent activities that shared scarce resources. At the end, the algorithm obtained a probability distribution for the project duration and for the start times of each activity.

Then in 2006, Mizuyama [34] proposed a heuristic solution algorithm to solve the project scheduling problem (PSP) without constrained resources, based on a probabilistic decision-making process in multiple stages. The proposed algorithm evaluated the possibility of shortening the project activities in order to meet the due date, and at the same time reduce the negative impact generated by the quality of each sub-deliverables of the project.

Later, Zafra-Cabeza et al. [35-36] proposed a novel approach that not only took into account the random duration of each activity but also the impact of the possible risks of a project. The formulated mathematical model uses a Model Predictive Control (MPC) technique to evaluate the risks impact of a project and the possibility of carrying out mitigation actions. The proposed procedure allowed solving the project scheduling problem (PSP) without constrained resources, supported by a Petri network type p-timed. According to the authors, this type of network provided a dynamic model to represent the time and cost of a NPDP.

Dynamic programming was once again used as a solution technique by Creemers et al. in 2010 [37] and in 2015 [38]. The authors designed a model that incorporates technological development alternatives and seeked to maximize the expected net present value of a NPDP. The proposed model incorporated the probability of success or failure of each activity and its random duration.

In 2014, Mohammadi et al. [39] presented a solution procedure to the project scheduling problem (PSP) without constrained resources based on the Dependency Structure Matrix (DSM) and the Monte Carlo simulation techniques. In this research work, the DSM was uses to arrange the precedence relationships of activities and the information flows between them. The simulation process generated different scenarios from the probability distributions associated with the activities duration and a parameter related to the overlap between tasks. Finally, when the simulation process stabilizes, the average value for the project duration and its variance are computed.

In 2016, Nelson et al. [40] proposed a model that uses GERT type networks. According to the authors, GERT-type networks allowed adequate representation of parameters such as the random duration of activities, the possibility of executing an activity more than once, or the anticipated completion of the project. In this research work, the GERT type network was modeled by means of a simulation process based on Monte Carlo techniques. Additionally, the concept of concurrent engineering was associated with the principle of rework and the overlap of activities.

Also, in 2016, Nasr et al. [41] presented an analytical method to estimate the expected duration of a NPDP without constrained resources, this method uses a Markov Chain with reward as a starting point of the process. The information flow and the reworks were represented from a DSM.

Recently, the RCMPSP was addressed again in an article published by Song et al. [42]. In this research work, the authors proposed a simulation model based on agents and applied to a new product development program. The designed model is supported in heuristic techniques integrated with schedule generation schemes (SGS) and includes both proactive and reactive scheduling.

In this literature review, only four articles that tackle the RCPSP with random duration of activities were identified. In the other cases (9 articles), the mathematical models presented do not take into account the resources restriction; therefore, the problem addressed was the PSP with random duration of activities.

On the other hand, it is important to indicate that the articles described above assumed that the probability distribution of the activities duration included all the impacts caused by the project's risks. The exception to this approach was proposed by Zafra-Cabeza et al. [35-36] who presented a detailed analysis of each risk associated with the project’s activities.

4. An optimization model to solve the resource-constrained project scheduling problem with random duration of activities and stochastic tasks insertion

The proposed model to solve the problem consists of three stages: identification of risks, estimation of the activities duration and generation of the project baseline.

4.1. Stage 1: identification of risks

According to Elmaghraby [43] the project duration can be affected by two types of risk: the first, known as external risk, refers to events that interfere with the normal development of activities, such as equipment failure, loss of documents and accidents at work, among others. The second, called internal risk, refers to the margin of error caused by estimating the activity duration in the absence of external risks. The internal risk isn’t related to external events and doesn’t cause interruption of activities.

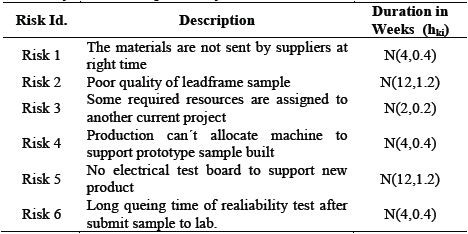

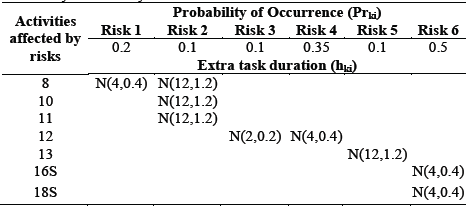

The external risks identified in this stage must be associated to each activity of the project, indicating their impact and probability of occurrence. The impact of an external risk implies carrying out an extra task whose duration can be represented through a probability distribution. Likewise, the probability of occurrence of each risk can be determined based on the experience and judgment of experts. In order to organize information about the risks and their impact on the activities, a risk activity matrix is build (see Table 3) using the following nomenclature: Pr ki indicates the probability of occurrence of external risk k that affects activity i and h ki refers to the random duration of the extra task executed when the external risk k appears and affects activity i. Table 3 only includes the activities that are affected by risks.

In this article, the probability distributions of b i and h ki were taken as input data. On the other hand, external risks were assumed as independent and the probability of occurrence of external risks through the project planning horizon was considered constant.

4.2. Stage 2: estimation of activities duration

In this stage, any redundancy based method can be used to calculate the activities duration (d i ). The strategy requires to add extra time to the original duration in order to face the eventualities that may appear during the project’s execution. The new duration must be computed even for activities that could be integrated in the project´s network (stochastic activities). The redundancy based methods are considered proactive methods to solve the RCPSP under uncertainty [4].

In this article, two methods were evaluated: the first based on the expected value of the risk’s impact and the second on the judgmental risk analysis process. The application of each method created a different version of the proposed model.

4.3. Stage 3: generation of the project baseline

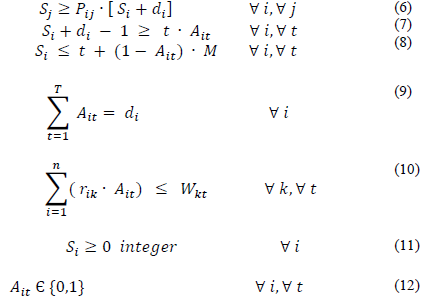

Once the activities duration (d i ) was computed, including the activities duration for the stochastic activities, the project baseline was obtained by solving the following integer linear program.

Input parameters:

d i : Estimated duration of the activity i (including the stochastic activities)

P ij : Binary parameter that indicates the precedence relation between activities. P ij is equal to 1 if activity i precedes activity j, and equal to zero otherwise.

The time horizon is splited in partial periods represented by the subscript t, which takes values between 1 and T. T is the maximum value for the project duration.

Decision variables:

S i : Planned start time of the activity i

A it : Binary variable that indicates if the activity i should be scheduled in period t. A it is equal to 1 if activity i is active in period t, and equal to zero otherwise.

The mathematical model proposed to solve the RCPSP with random duration of activities and stochastic tasks insertion is expressed as an integer linear program:

Subject to:

The objective function of the RCPSP seeks to minimize the makespan or project duration (S n indicates the start time of the fictitious activity n). Eq. (6) guarantees that the activities start only when their precedences have ended. Eq. (7)-(9) assure that A it is equal to 1 when activity i is active at time t, otherwise, A it is equal to zero. The contribution of each equation is presented below: eq. (7) allows A it to be 1 only if activity i has not ended at time t, eq. (8) allows A it to be 1 only if activity i started after of the moment t (big M represents a large number), and eq. (9) ensures that A it is 1 for the interval {S i , S i +d i }.

On the other hand, eq. (10) allows that several activities can be scheduled simultaneously as long as the available resources are not exceeded. Finally, eq. (11)-(12) indicate the conditions of non-negativity and the type of variable required.

The following considerations are also importants for the proposed model:

The duration of each activity must be estimated from any redundancy based method.

The durations calculated above must be adjusted taking into account the probability of ocurrence of each activity. This consideration only is applied to the stochastic activities, since their probabilities of appearance are different to 1 (one).

The durations obtained should be rounded to the nearest integer value, because the proposed mathematical model was formulated in discrete time [44].

The precedence relationships P ij associated with stochastic activities must be incorporated as input parameters. Therefore, the location of these activities in the network layout must be known in advance.

The proposed model only takes into account the renewable resources of the project.

This integer linear programming model was programmed in GAMS using MIP solver of CPLEX. Finally, the start times for each project activity (S i ) were obtained, and the project baseline was built.

5. Case study

In this section a NPDP is presented. Many case studies provide basic information related to a project (list of activities, precedents, and duration) but the information related to the project’s risk analysis is scarce or non-existent. A case study presented by Lertapiruk [45] was selected as a reference because it provides detailed information on the project’s risk analysis. However, this case does not include data such as the random duration of activities, the probability of occurrence of risks, or the insertion of tasks in the project network. For this reason, a new case study was designed based on the information provided by Lertapiruk [45].

The case study presented in this article incorporates all the adjustments required to apply the proposed model. The project consists in developing a leadframe material for a semiconductor package. A new material can be obtained by applying a special technology called RT Technology. This new technology allows to increase the adhesion between the materials of the integrated circuit and the leadframe material.

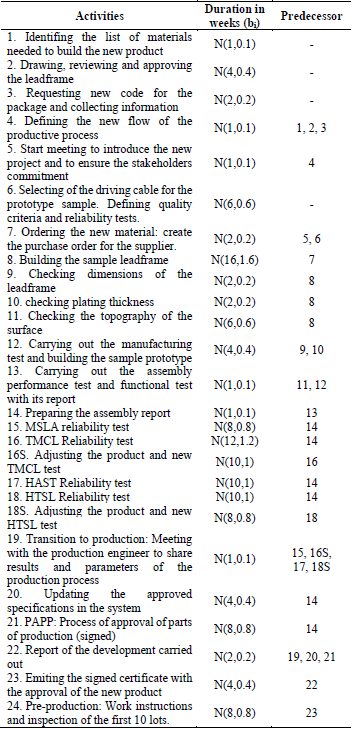

The activities required to develop the project, its durations (b i ) represented as normal probability distributions and the precedence relationships, are detailed in Table 1. It is important to remember that some data of the original case study [45] has been intentionally altered in order to transform this case in an RCPSP with random duration of activities and stochastic task insertion. As is presented in Table 1, activities 16S and 18S are stochastic activities, since they are only executed if the results of the TMCL and HTSL reliability tests are not accepted. For this project, the probability of failure of the TMCL (activity 16) and HTSL (activity 18) tests are 20% and 18% respectively; therefore, these values indicate the probability that 16S and 18S activities will be inserted into the project network.

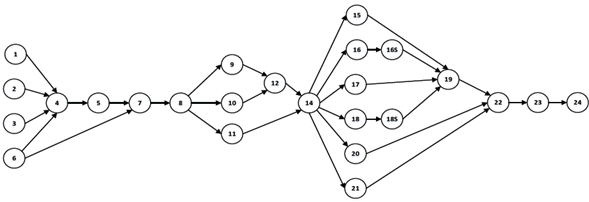

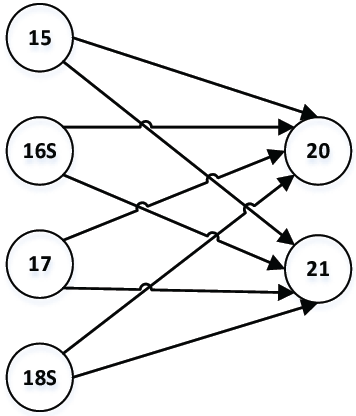

The network diagram of the NPDP was designed especially for this article and can be seen in Fig. 1.

However, a new product development project contains some decision activities, which could affect the continuity of a project. An unfavorable result in a decision activity can lead to the withdraw of the project and as consequence, the loss of the investment made up to that moment. For this reason, the decision activities and their predecessors should be scheduled as soon as possible, while the remaining activities should be scheduled once the decision activities are completed. This strategy seeks to reduce the loss of money if the project is canceled.

In this case study, the decision activities are placed in the reliability testing phase, and correspond to activities 15, 16S, 17, and 18S.

As stated earlier, these decision activities and their predecessors should be scheduled as soon as possible; while activities 20 and 21 should be scheduled immediately after the decision activities. One way to achieve this purpose is to add fictitious precedence (P ij ), as in Fig. 2.

The risks that can affect the project are showed in Table 2 and the risk activity matrix is presented in Table 3.

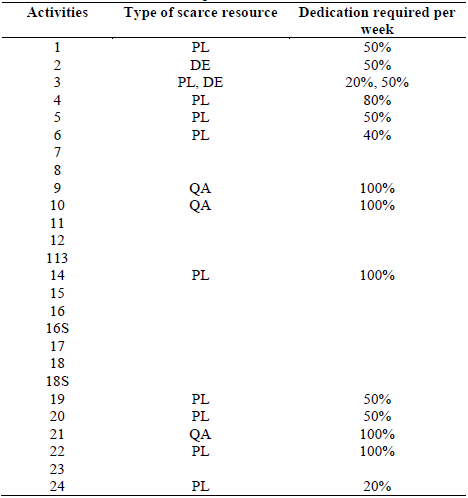

Additionally, it is important to remember that critical project resources can limit the simultaneous scheduling of some activities.

In this case study, the critical renewable resources correspond to the time dedicated by the specialized personnel: project leader (PL), quality assessment operator (QA), and design engineer (DE).

Table 4 shows the dedication time required by specialized personnel to execute each activity. The dedication was associated to the percentage of time required to contribute to the project activities.

The availability of time assigned for the project is 100% for the project leader, 100% for the quality assessment operator, and 50% for the design engineer.

6. Solution of the case study from fist version of the proposed model

Zafra-Cabeza et al. [36] analyzed the impact of risks mitigation strategies on project scheduling and compute the duration of each activity based on the negative impact of external risks and the positive impact from the mitigation strategies.

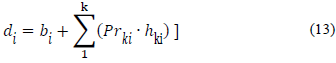

According to this referent, the activity duration i (d i ) can be estimated as the total expected duration, computed from the sum of the expected value of the basic activity duration (b i ) and the expected value of the extra tasks (h ki ):

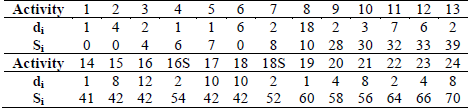

The durations for each project activities were calculated based on the data of Tables 1 and 3 and applying eq. (13). Subsequently, the start times were obtained by solving of the integer linear program presented in section 4.3. The results can be seen in Table 5.

Table 5 Estimated durations and start times obtained by the first version of the proposed model

Source: The Authors.

Additionally, the project duration (S24) was 78 weeks. To take into account the durations of the stochastic activities (16S and 18S) were adjusted according their probabilities of occurrence.

7. Solution of the case study from second version of the proposed model

A method based on the guidelines of the judgmental risk analysis process [46] has been used as an alternative procedure to estimate the activities duration (stage two).

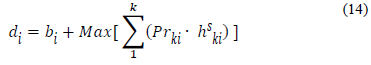

This method is based on a pessimistic risk analysis, since the estimated duration (d i ) corresponded to the maximum value obtained in a simulation process.

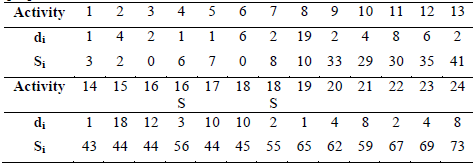

Eq. (14) is used to generate 1000 duration scenarios for each activity i. This equation takes into account: the expected value of the basic activity duration (b i ), the probability of occurrence of each risk (Pr ki ), and the simulated duration of each extra task (h s ki ). The probability distributions to obtain h s ki appear in Table 3.

8. Comparison of generated baselines

In this research, a reactive procedure was designed in order to simulate the real execution of the project and at the same time, compare the baselines generated by each version of the proposed model. The proposed reactive scheduling is supported in a parallel schedule generation scheme, which allows to re-schedule the activities and to make the adjustments if a disruption appear during the project’s execution.

Subsequently, the start times were obtained by solving the integer linear program presented in section 4.3 (see Table 6). Additionally, the project duration (S24) was 81 weeks.

Table 6 Estimated durations and start times obtained by the second version of the proposed model.

Source: The Authors

The parallel schedule generation schemes schedule the activities in some decision points along the planning horizon. Each decision point is progressive and corresponds to an iteration. The designed algorithm starts at time zero of the timeline, where activities that do not have precedence are scheduled, only if the resources are available.

The activities scheduled simultaneously are called active activities. When the active activity of shorter duration has ended, the next decision point is set and a new list of candidate activities to be scheduled is created. This list of activities must meet with the restrictions of precedence and availability of resources.

In case that the candidate activities to schedule overcomes the availability of resources, the activities are selected according to the order indicated by the baseline and their random duration is computed just at the moment when each activity is scheduled by the schedule generation scheme. The procedure is repeated until the list of activities is empty, at that moment, the real start times of the activities (SR i ) are obtained from the start times obtained in the reactive scheduling.

The deviations between the planned start times in each baseline (S LBi ) and the real start times (S Ri ) are the starting point to analyze the robustness of the proposed model. However, the robustness concept implies to compare a solution with several execution scenarios. Therefore, in this investigation the baselines of the two versions of the proposed model were compared with the results of the reactive scheduling for 10000 simulated scenarios from Monte Carlo technique.

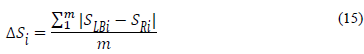

The comparison was made using the solution robustness indicator (SR) which measures the average deviation between the start times planned in the baseline (S LBi ) and the real start times (S Ri ) [47-48]. The first step to obtain the solution robustness indicator (SR) is to calculate the average deviation for each project activity (ΔS i ) using eq. (15):

S LBi : Planned start time in the project baseline for the activity i (i=1, 2, ... n).

S Ri : Real start time in each scenario R for the activity i (R=1, 2, ... m).

Subsequently, each value ΔS i was used to obtain the solution robustness indicator (SR) using the eq. (16):

A robust scheduling is a feasible solution with a minimum deviation from the optimal values of each scenario generated by the random parameters of the model.

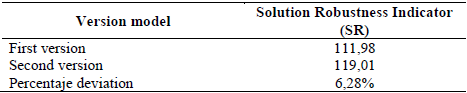

Therefore, the robustness analysis focused on computing the solution robustness indicator for the baselines generated by the two versions of the proposed model. For the case study, the following results were obtained:

According to Table 7, the version of the model that used the method based on the expected value of the impact of the risks, generated the most robust project baseline.

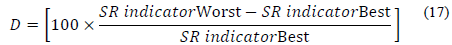

The percentage deviation between the robustness indicators of the two versions of the model was 6.28%. This percentage deviation (D) was calculated from the eq. (17):

Where:

SR indicator best : Robustness indicator for the version of the model that uses the expected value of the impact of the risks.

SR indicator worst : Robustness indicator for the version of the model that uses the judgmental risk analysis process.

9. Conclusions

In this article, an optimization model was developed to solve the RCPSP with random duration of activities and stochastic tasks insertion. From this model, a project manager can obtain the new product development project baseline.

A case study adjusted that incorporates the main features of a NPDP was designed in order to apply the optimization model.

The starting point of the proposed model was the identification and quantification process of project risks; Subsequently, the risk’s impact was associated to each project activity in order to estimate its durations. Finally, the project baseline was generated by solving an integer linear program.

Two versions of the model were proposed: in the first, a method based on the expected value of the impact of the risks was used to estimate the duration of the activities, and in the second, was used a method based on the judgmental risk analysis process.

The generated baselines were compared, in terms of robustness through a solution robustness indicator (SR) that measures the average deviation between the planned start times for each baseline (S LBi ) and the real start times (S Ri ) obtained from a simulation process. According to the results, the version of the model that uses the method based on the expected value of the impact of the risks has a better performance than the version that uses the judgmental risk analysis process.