1. Introduction

Mine planning can be defined as the strategy of choosing the best set of blocks to be extracted in a period, which will provide the highest financial return to a mining company. Different stages of mine planning (long-, medium- and short-term) aim at different objectives, e.g., to maximize net present value (NPV), reduce costs and reach grade and tonnage targets. According to [1], at each time horizon (daily plans to life-of-mine), a planner selects blocks or regions of material (from a block model) to be extracted in each period (or across multiple periods) of the horizon. The block model is usually generated from the geological data containing such information as density, tonnage, grade, lithology and geotechnical parameters. The input of conventional mine planning is usually a single estimated orebody model [2].

Optimization addresses the forecasting, maximization and management of cash flows of a mining operation and is the key to the financial aspects of mining ventures [3]. To reach the objectives of an optimization problem, different strategies are envisaged through the use of computational tools, aiming to maximize - or minimize - the objective function. The approaches to mine planning optimization (such as Lerchs & Grossmann [4], Pseudoflow [5] and Direct Block Schedule [6]) are implemented as several software algorithms that consider as many parameters as possible to obtain results that are more realistic. An optimization model must involve the costs, especially mining and processing costs, and the generated income. The basic input data to the optimization problem is a set of economic block values representing the net value of each block. These block values are determined using the cut-off grade, costs, prices, recovery, dilution, density and operational parameters (e.g., slope angle, capacities, and production) [7].

Over the years and with the technological advances, more variables have been added to the optimization process, making it more realistic and adherent to the operational data. Among these improvements, simulated block models can be cited, i.e., multiple equally probable models considering grade and geological uncertainty. A method for capturing the uncertainty is to create stochastic simulations of the resource model, where the stochastic behaviour expresses the uncertainty or variability of the model’s properties [8]. A common technique for creating multiple realizations is through geostatistical simulation procedures, e.g., turning bands, LU decomposition and sequential Gaussian simulation. Simulation also provides a means for incorporating a quantified risk analysis within the planning and design procedures [9].

Considering uncertainties in mine planning is a necessary task for achieving the expected targets, regardless of the planning stage considered. Spleit [10] stated in his thesis that one of the key risks in a mining project was geological uncertainty because the understanding of the geology, spatial distribution and variability of the ore qualities could only be inferred from limited data that was not necessarily representative of the entire deposit. The larger the amount of available information is, the greater the chance of obtaining better results. The use of geological uncertainties is an already well-understood task and is a part of the planner's routine when some variables have not been fully included to date and require more attention. Dilution is an example of a variable with few developments regarding its impact on mine planning, especially in regard to dilution in open-pit mining.

Dilution can be defined as waste or low-grade materials (below the cut-off grade) that are not separated from the ore during the operation; it reduces the quality of the mined ore [11]. Matthews [12] defined ore loss as a reduction of ore volumes in the mining process due to misclassification of ore as waste in the ore control process, exclusion of discontinuous mineralization from mining due to geometry or continuity, and mechanical losses in the mining process. Xingwana [13] affirmed that the inability to minimize ore loss can thus impact negatively on mine output through the loss of revenue. He also cited that ore dilution can impact negatively on the mine profit margin as a result of the extra costs involved in mining and processing of the waste that is treated as ore.

Instead of quantifying dilution in mining studies, it was common to assume a general dilution such as 5% for massive deposits, and 10% for tabular-shaped deposits [14]. The dilution is not always an analysed and systematically calculated factor, often it is just a factor applied to the whole deposit or some zones of the deposit to satisfy the needs of audits [15]. Dilution as well as ore loss are factors that should be always considered for tonnage and grade estimates during mine planning.

According to Câmara et al. [16], in open-pit mining, dilution is generally accounted for only as a misclassification of blocks in the block model estimates. Rossi [17] showed the importance of incorporating an appropriate amount of dilution in the “undiluted” resource model such that a recoverable reserves model would eventually be obtained. The study of Bertinshaw and Lipton [18] reviewed various approaches to the estimation of dilution and ore loss, as implemented in computer block models, and considered these variables as an essential part of any ore reserve estimate or mine schedule. A probabilistic approach to calculate the dilution and the ore loss of a long-term model, considering the simulation results was presented in [19].

In addition to misclassification of blocks, another type of dilution − operational dilution − should be considered in mine planning, especially over a short-term horizon. An approach to determine operational dilution as the incorporation of waste material into the ore due to the operational inefficiency of separating materials during mining, considering the physical processes and operational and/or geometric configurations of mining with the available equipment was presented in [15].

This paper will show how the use of information of geological uncertainties can contribute to control the operational dilution in open-pit mining, besides enabling the development of mine plans seeking to minimize dilution. To this end, the proposed methodology will present an evolution of the routine presented in [16].

2. Methodology

The methodology developed by [16,20] consisted of an automated routine for calculating operational dilution through the analysis of short-term mine plans (subsets of blocks to be extracted), analysing blocks’ grades, contacts and neighbourhoods to verify if there were differences between the planned grades and the measured data. This work proposes improving the mentioned methodology by incorporating the information of grade uncertainty to calculate the operational dilution. Another improvement was to rewrite the previous routine in the Python language to make the routine faster and more flexible, regardless of the mine planning software used. The routine is very straightforward and can be used for different deposits with different numbers of simulation scenarios. To use the proposed routine, it is necessary to input the data on block classification (ore or waste). Typically, this classification is based on rock type and grades prior to model definition. Another necessary input data are the columns that correspond to the grades.

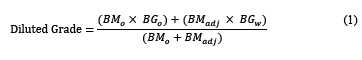

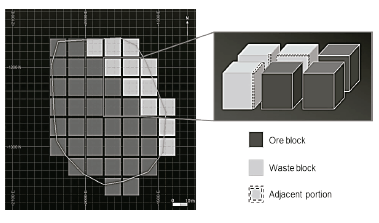

The process of calculating the operational dilution begins by characterizing each block planned to be extracted, and its neighbourhood. Depending on the block position (inside the mine plans or touching the borders of mine plan polygons), dilution will be calculated differently. For blocks located inside the polygon, dilution will be calculated based on the premise that equipment imprecision will keep the blocks from being extracted perfectly. If the contact between blocks is ore-waste, each portion of the waste blocks in contact with the analysed block will be incorporated with it (Fig. 1). As a result, the diluted grade will be weighed considering the new mass (eq. 1) incorporated in the ore block. The ore loss is not considered at this stage because the methodology assumes that it is better to recover more ore tonnage, even with the consequence of generating higher dilution, than having ore losses [16]. Crawford [21] also showed that reducing dilution through more selective mining often resulted in higher ore losses.

Source: Adapted from Câmara et al., 2018.

Figure 1 Blocks inside the mine plan and the influence of ore-waste contact. The dashed lines represent the portion of the waste blocks that will be added to the ore block during mining.

Where,

MB 0 is the ore block mass;

BG 0 is the ore block grade;

BM adj is the adjacent mass portion;

BG w is the waste block grade;

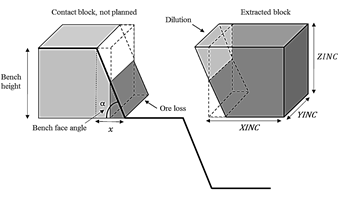

For blocks located at the borders of mine plans, the influence of the bench face angle will be considered. When extracting a block, operational conditions and rock stability must be respected by using a stable bench face angle. Fig. 2 shows how the bench face angle can influence on the planned mass and grade of a block.

Source: Câmara et al., 2018.

Figure 2 Dilution for blocks located at the borders of mine plans due to the influence of the bench face angle.

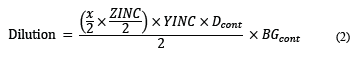

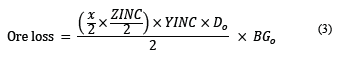

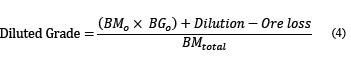

To calculate the diluted grade due to the influence of bench face angle (eq. 4), the mass of the triangular prism designated as dilution (eq. 2) will be added to the total block mass and the mass of the triangular prism designated ore loss (eq. 3) will be subtracted from it [16].

Where,

x is the base of the triangular prism formed due to the bench face angle;

YINC and ZINC are the block dimensions in Y and Z, respectively;

D cont is the density of the contact block;

BG cont is the contact block grade;

Where,

D 0 is the density of the ore block;

Where,

BM total is the total block mass;

As mentioned above, based on [16] an adjustment was made to incorporate the geological uncertainties. This adjustment refers to the variable corresponding to the cut-off grade. While in the previous methodology this value was fixed and read from a single column, in the presented approach the value is searched for among n columns that the model can have according to the number of simulations being considered.

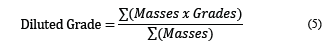

The diluted grade is calculated by combining the two types of dilution and ore loss, calculated block-by-block but computed for the whole period, as shown in eq. (5).

Hence, to calculate the diluted grade using eq. (1)-(5), n possibilities of grades will be considered. Depending on the number of simulations, this process could be very slow; however, using the Python application, the solution is obtained in a few minutes.

The result, instead of being a deterministic diluted grade for the whole period, will be a range of possible values of diluted grades according to the information from each simulation. All simulated scenarios have the same probability of occurrence; therefore, the probability distribution can be used to estimate the dilution range for each plan.

3. Results

To validate the methodology, the routine was tested in a case study using monthly mine plans and calculating the dilution and ore losses based on the simulated block model containing 30 equally probable scenarios of grade values. Based on the grades’ uncertainty, dilution can have different values according to the analysed scenario.

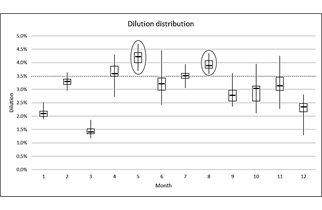

The results were arranged in a box plot (Fig. 3) to examine the dilution as a function of the grades’ uncertainty, for each planned month. Dilution was observed to vary from 1.35% to 4.7% during the 12 months evaluated; however, to understand the influence of the uncertainty, each month must be analysed individually. For instance, the 6th, 10th and 11th months resulted in greater internal variations; the 5th and 8th months had a small variation but presented dilution values higher than 3.5%. Both situations indicated a need for a detailed assessment to understand the reasons for such phenomena.

Source: The Authors.

Figure 3 Box plot showing the dilution distribution considering 30 grade simulations per month.

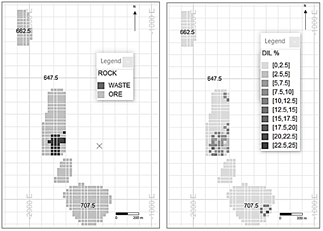

As each analysed scenario presents a possible distribution of dilution values, to visually analyse the results, a legend was created based on the 90th percentile (P90) of 30 simulations. The value of P90 was chosen because it means that 90% of results were lower than this value, i.e., this scenario would be considered conservative.

3.1. 5th and 8th months

The 5th and 8th months presented the highest dilution intervals (represented by the largest box plots) of 12 months analysed. Fig. 4 shows the blocks planned to be mined in the 8th month (right side - dilution legend (P90); left side - rock types). It is observed that all planning polygons have dilutions greater than 3%, exceeding 15% at certain points, indicating that dilution occurred not in a localized way but in the entire plane. When analysing the data on the rock type (ore or waste), it is observed that the high dilution values occur in the contact zones between ore and waste blocks. This observation indicates that such dilution cannot be avoided if the plans are designed with such selectivity. Hence, the choice will be between controlling dilution through smaller extraction polygons, which means more selectivity and consequently lower productivity or accepting dilution as reasonable and considering it in the planning.

3.2. 6th, 10th and 11th months

In the 6th, 10th and 11th months there was a large variation in the dilution results with values considerably lower than the maximum values. This fact indicates that these very distinct values may have occurred in isolated areas. Fig. 5 shows the blocks planned to be extracted in the 10th month (right side - dilution legend (P90); left side - rock types). In contrast to the previous analysis (of the 8th month), the areas with the highest dilution were in this case concentrated at specific points, which leads to the conclusion that it is possible to correct the mining plan at these specific locations.

4. Conclusions

Usually, the block grades are diluted by a given fixed value, considering both operational dilution and dilution related to misclassification of blocks. Quantifying operational dilution through techniques applied to block models and short-term mine plans can better control dilution than merely applying a best-guess factor to the block model.

Through the results of operational dilution calculated using the information of each simulated model, it was possible to understand the probability distribution of dilution, allowing the verification of the areas that were most prone to suffering dilution. With this information, the mine plan can be directed to control these areas through more selective dig lines or a different short-term schedule, aiming to reduce the dilution effect.

It is important to compare the use of information from deterministic block models and that of information from stochastic block models. It is known that deterministic block models, usually estimated by ordinary kriging, result in smoothing. This drawback can be overcome by using stochastic block models that guarantee global accuracy. In the case study presented, the use of stochastic models gives a higher-confidence evaluation of uncertainty, as the result is obtained through a probabilistic analysis and is not limited to a deterministic single value providing the average value and the interval that it can vary within.

In addition to the block grades, density is another parameter that could have a major impact on the dilution result. If there is great variability in the density values, this attribute must also be simulated, to ensure greater precision in the dilution results. However, for this case study, there was no need to simulate the density values, since the they were very similar in the blocks, which would result in a non-significant impact to dilution control.

The approach presented in this study demonstrates that it is possible to measure and control operational dilution values resulting from a given mine plan. However, how this information will be used will depend on each specific situation. If the choice is to reduce dilution as much as possible, the consequence will be lower productivity, which can be quite detrimental to the operation, depending on the orebody type. If it is not possible to increase the selectivity of the operation, the obtained results can be used as an adjustment factor to the plans, resulting in better adherence of the planned data to those actually executed.

The dilution calculated in this study is operational, meaning that the observed values are not particularly low; generally, the dilution used in mine plans will take into account factors other than operational. For this reason, it is important to try to minimize the operational dilution as much as possible (or feasible, given the operating conditions and geometry of the orebody), since among the dilution types, this is one that can be controlled.