1. Introduction

When talking about baked goods, it is essential to refer to their expansion capacity as an indicator of quality, due to the important influence this property generates on the sensory perception of consumers. Then, it is necessary to look for ways to optimize this process, adapting it to the particular needs and properties of the wide range of products offered by the industry. In this way, the term leavening agent or leaven products is used. Most of the baked products are leavened by dough expansion, resulting in products with a larger volume, and an open and porous texture [1].

The leavening action can be achieved by various methods, including yeast fermentation, mechanical incorporation of air by mixing and shaking, formation of steam in the oven, and production of carbon dioxide and/or ammonia by chemical agents. However, the creation of the initial air bubbles during the mixing phase is critical before any of the other leavening agents can take effect [2].

Chemical leavening agents are a group of predominantly inorganic salts that, when added to the dough or batter, either individually or in combination, react to produce the gases that form the nuclei for texture development within products such as biscuits during baking [3]. This gas is made from the reaction that takes place when mixing a source of carbon dioxide and an acid and they come into contact with water. During the first cooking phase, as a result of the temperature increase, gas bubbles grow due to the air expansion, the water evaporation, the decrease in the solubility of gas in the aqueous phase, and the formation of carbon dioxide (CO2) by the leavening agent or agents [4]. Most chemical leavening systems consist of a source of carbon dioxide (leavening base) and one or more food acids.

Acid is the most diverse component in chemical leavening systems and can have a variety of compositions that determine when CO2 gas is released [5]. Leavening acids are selected primarily based on reactivity: at what rate they react and at what temperatures [6]. Baking soda is one of the most used bases in food industry. Chemical leavening agents involve the action of an acid on the bicarbonate to release carbon dioxide for dough aeration during mixing and baking [7]. The production of CO2 influences the expansion of dough (a hydrated matrix of flour and sugar) during mixing and cooking, and determines the final properties (i.e. volume, texture, color) of the baked product [5].

Baking powder provides a complete leavening system in a single product. It is composed of sodium bicarbonate, one or more leavening acids, and a diluent, typically starch or calcium carbonate [7]. Salt and acid react with each other in the liquid phase of dough once they come into contact. They are kept separated by the inert component (e.g. dry starch) to avoid a spontaneous reaction [4]. Baking powders are classified by type of release (single acting or double acting). Single acting baking powders contain only one acid, which can be fast acting and react in the mixer or can be slow acting and react in the oven. Double-acting baking powders contain fast-acting and slow-acting acids. An ideal double-acting baking powder will release a small amount (20%) of carbon dioxide in the mixer and the rest in the oven [1].

Launching a new product into the market, in this case a baking powder, requires an evaluation of its effects on a base product as one of its fundamental steps. Therefore, a muffin was chosen as a test product to verify the influence on the quality and sensory characteristics of different baking powders. The objective of this study was to evaluate the effect of different types of baking powder on the quality properties of muffins.

2. Materials and methods

2.1. Materials

The PHF, PH14, PH16 baking powders were provided by Química Básica SAS (Medellín, Colombia), the commercial samples of baking powder were: Fleischmann (Fleischmann Food SA, Palmira, Colombia) and Carolesen (Colorisa S.A., Sabaneta, Colombia). The other ingredients were obtained from local distributors.

2.2. Farinographic analysis of baking powder and wheat flour mixtures

For the farinographic analysis, flour and baking powder mixtures were selected based on the formulations used to prepare the muffins, using 98.5% wheat flour and 1.5% of each baking powder. The measurement was performed on a Farinograph (Farinograph®-AT, Brabender® GmbH & Co. KG, Duisburg, Germany) according to the AACC method 54-21.01, with a run time of 30 min [8]. The parameters evaluated were water absorption, dough development time (DDT), dough stability, and mixing tolerance index (MTI).

2.3. Muffin preparation

For the preparation of muffins, a formulation based on 100 g of flour, 43.5 g of milk, 75 g of powdered sugar, 28 g of butter, 28 g of margarine, 60 g of eggs, 0.3 g of salt, and 1.5 g of baking powder was used. Five treatments, two commercial samples of double-acting baking powder, Fleischmann (FL) and Carolesen (Ca), and three samples - PHF, PH14, PH16 - developed by Química Básica SAS, were analyzed. Initially, sugar, margarine, and butter were mixed in a mixer (Kitchenaid Artisan, mod. KSM150PSER, USA) at different speeds: 60 rpm (1 min), 95 rpm (1 min), 135 rpm (2 min), 180 rpm (3 min). Next, the eggs were added at intermediate speeds of 95 rpm (30 s) and 135 rpm (15 s), then, solids were added until a homogeneous mixture (95 rpm) was obtained, and finally milk was added at 95 rpm (30 s) and 135 rpm (15 s). The batter was poured into molds in 40g portions and baked in an electric oven (Tecnoeka KL 884-HT Padova, Italy) at 155 °C for 20 min. Upon leaving the oven, muffins were unmolded, allowed to cool for 30 min and packed for further analysis.

2.4. Physicochemical properties

Initially, the specific gravity was evaluated as the ratio of weight of a known volume of batter, to the weight of an equal volume of distilled water at 28 °C using a standard container [9,10]. The pH of the batter was measured with a potentiometer (pH 211, HANNA Instruments, Italy). The weight loss was calculated by weighing samples before and after baking [11]. The moisture content was determined according to the AACC method 44-19.01. Water activity (aw) was measured with a dew point hygrometer (Aqualab series 3TE, Decagon, Devices, Pullman, WA, USA). The millet seed displacement method was used to measure the specific volume of the product, [8] and its height was measured with a digital caliper (500-172-30 Absolute digimatic, Mitutoyo, Aurora, IL) from the base to its highest point [12]. The pH of the final product was determined based on the AACC method 02-52.01 [8] and its titratable acidity, expressed as a percentage of lactic acid, was quantified according to the standard AACC method 02-31.01 [8].

The color analysis was analyzed in CIELab space with a colorimeter (Konica Minolta, Chroma meter CR-400) considering the illuminant D65 and the 10 ° observer. The inner part of the product (crumb) and the upper part of the muffin (crust) [13] were evaluated. For the texture profile analysis (TPA) and crumb firmness, muffins were cut at a height of 25 mm from the base and a texture analyzer (TA-XT2i, Stable Micro Systems, Godalming, U. K.) was used. The TPA test was performed with a 75 mm cylindrical probe (SMSP/75) for the TPA test with pre-test, test and post-test speed of 1 mm/s, 1 mm/s, and 10 mm/s, respectively. Hardness, springiness, resilience, cohesiveness and chewiness of the product were determined. For crumb firmness, a 12.5 mm cylindrical probe (SMSP/12.5) was used, the parameters were pre-test speed of 1 mm/s, test speed of 1.7 mm/s, and post-test speed of 10 mm/s [14].

2.5. Image analysis

In the image analysis, muffins were cut at a height of 2.5 cm from the base and a 1 mm thick slice was taken, which was scanned (HP Photosmart D110a, Hewlett Packard, Beijing, China) and analyzed using the image program (ImageJ), which uses the contrast between two phases (pores and solid parts) in the image. This method allows to examine the number and the size of pores by means of ComputeStats and BinariseSEM tools [15].

2.6. Storage and sensory analysis

According to the results obtained from the physicochemical properties evaluated and the statistical analysis, one of the treatments with the best quality and texture characteristics was chosen and compared with the commercial sample presenting the best quality properties for muffins. Samples were stored in polyethylene bags at room temperature for 7 days and their moisture content and crumb firmness were evaluated with the methodologies previously described on days 0, 2, 4, and 7. In addition, a sensory analysis was performed using a consumer acceptance test and quantitative descriptive analysis (QDA). Samples were evaluated by scoring the intensity of each attribute on an unstructured scale of 10 cm (0 = low intensity, 10 = very strong intensity) [16]. The acceptability test was performed with a panel of 100 people - 60 men and 40 women between 16 and 36 years old - for day zero (0) of storage, overall texture, flavor, and acceptability were rated. The QDA was carried out with 15 semi-trained panelists for days zero (0) and seven (7). Training sessions of 30 min were conducted over a period of 1 month to develop the terminology and describe the key sensory attributes of muffin samples [17]. Chewiness (The amount of work required to masticate the muffin into a state ready for swallowing), stickiness (The degree of adhesion of muffin on the wall of the mouth), hardness (Force required to compress and/or break the muffin between the teeth) and volume of samples were evaluated [18].

2.7. Statistical analysis

Statistical treatment was carried out using a one-way ANOVA with the type of formulation as a factor. The comparison of means was performed using a Tukey test with a level of significance of 5 % using the Minitab 18.1.0 statistical program (Minitab, State college, PA, US). Data were given as the mean ± standard deviation. All the measurements were carried out in triplicate.

3. Results and discussion

3.1. Farinographic analysis of baking powder and wheat flour mixtures

Table 1 presented the farinograph properties for wheat flour and baking powder mixtures. Water absorption was lower for baking powder and wheat flour mixtures with respect to wheat flour and there were no significant differences between mixtures. The addition of baking powders affected the DTT of dough, or time required to reach the consistency of 500 UB, which was significantly higher for all mixtures with respect to wheat flour. There were significant differences between baking powders and wheat flour mixtures, being FL the one with the highest value and PHF the one with the lowest. Similar results were found for this parameter when using a fermented liquor as a leavening agent, concluding that this increase could be due to differences in the physicochemical properties between the leavening components [19]. The mixing tolerance index (MTI) for the mixtures was significantly lower than that of the wheat flour. This result indicates that the addition of baking powders prevents the wheat flour from weakening rapidly after reaching maximum development. In addition, with the exception of PHF, mixtures showed significantly higher stability than wheat flour.

Table 1 Farinograph properties of baking powder and flour mixtures.

| Treatment | Water absorption (%) | Development time (DDT) (min) | Stability (min) | Tolerance Index (MTI) |

|---|---|---|---|---|

| H | 63.8 ± 0.1a | 10.8 ± 0.05c | 14.5 ± 0.07c | 38.5 ± 0.7a |

| PH16 | 63.1 ± 0.0b | 19.4 ± 0.04ab | 17.0 ± 0.24b | 6.5 ± 0.7b |

| PH14 | 63.0 ± 0.1b | 18.1 ± 1.27ab | 17.1 ± 0.33b | 6.5 ± 0.7b |

| PHF | 63.1 ± 0.0b | 17.9 ± 0.62b | 14.5 ± 0.19c | 6.5 ± 0.7b |

| Ca | 63.0 ± 0.0b | 18.3 ± 0.66ab | 16.5 ± 0.62b | 7.5 ± 0.7b |

| FL | 62.8 ± 0.1b | 20.6 ± 0.05a | 18.5 ± 0.41a | 7.0 ± 0.0b |

* Values in the same column with equal letters do not vary significantly (P <0.05).

Source: The Authors.

3.2. Batter properties

Table 2 showed the pH and specific gravity results. The PHF, PH14 and PH16 treatments did not show significant differences with respect to commercial treatments, being Ca the treatment with the lowest pH (6.79) and FL the highest (7.14). The retention capacity of air and gases produced by leavening agents in the batter is clearly reflected in their specific gravity values [13]. According to the results presented in Table 2, this retention capacity did not vary significantly between treatments.

Table 2 Physicochemical properties of the formulations.

| Batter | Muffins | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sample | pH | Specific Gravity | Height (mm) | Specific volume (mL/g) | Weight loss (%) | Humidity (%) | Aw | pH | Acidity mg/mL (lactic acid) |

| PH16 | 6.98 ± 0.04ab | 1.00 ± 0.01a | 47.66 ± 0.35a | 80.93 ± 0.79a | 18.12 ± 0.16a | 24.31 ± 0.18b | 0.89 ± 0.00 a | 7.90 ± 0.03a | 0.10 ± 0.00b |

| PH14 | 6.97 ± 0.09ab | 1.00 ± 0.04a | 45.80 ± 0.04b | 82.13 ± 0.88a | 17.80 ± 0.26a | 25.67 ± 0.18a | 0.90 ± 0.00 a | 7.87 ± 0.02ª | 0.09 ± 0.00c |

| PHF | 6.99 ± 0.03ab | 1.02 ± 0.02a | 45.14 ± 0.51b | 72.85 ± 1.12b | 17.58 ± 0.46a | 25.25 ± 0.20a | 0.90 ± 0.01a | 7.68 ± 0.02b | 0.10 ± 0.00b |

| Ca | 7.14 ± 0.15a | 1.00 ± 0.00a | 45.42 ± 0.18b | 83.10 ± 1.12a | 18.08 ± 0.28a | 25.60 ± 0.33a | 0.89 ± 0.00 a | 7.83 ± 0.02ª | 0.08 ± 0.00d |

| FL | 6.79 ± 0.04b | 1.01 ± 0.02a | 45.86 ± 0.78b | 81.14 ± 0.86a | 17.78 ± 0.10a | 25.72 ± 0.23a | 0.89 ± 0.01a | 7.37 ± 0.08c | 0.14 ± 0.00a |

* Values in the same column with equal letters do not vary significantly (P <0.05).

Source: The Authors.

3.3. Physicochemical properties of muffins

Table 2 showed the results for the physicochemical properties of muffins. The greatest height was for PH16 treatment, while the others showed no significant differences between them. On the other hand, PHF sample had a lower height and a lower specific volume, being the only one to differ significantly from the others in this last parameter. The height and specific volume of the product are indicators of the ability of the batter to retain gas produced through the reaction of leavening agents. These air bubbles are retained in dough or batter and they expand during the baking process. The relationship between dough aeration and height and volume parameters can also be expressed through specific gravity, a lower specific gravity is associated with a higher volume and height in the baked product [20]. Regarding weight loss and water activity (aw) no significant differences were observed between samples, whereas in PH16 moisture content, it was the only one with a significant difference and the one with the lowest value with respect to the others.

The pH and titratable acidity values of muffins showed an alkaline tendency, as expected with significant differences for the FL treatment with respect to the others, having lower pH and higher titratable acidity. The sodium carbonate formed by the decomposition of sodium bicarbonate is very alkaline and will tend to give a high pH values to the baked product. This is desirable in some applications, because high pH improves certain flavors in baked goods [21].

Table 3 exhibited the results for textural parameters of samples. The PH14 and PH16 samples showed greater smoothness with the lower hardness values at the crust and firmness for the crumb. Cohesiveness determines the internal resistance in the structure of a food and the ability of a material to stick to itself, and resilience or the ratio of recoverable energy as the first compression is released [22]. A product with high cohesiveness is more tolerant to handling through manufacturing, packaging, and marketing, so it will be presented to consumers in the expected state [12]. The PH14, PH16, and PHF treatments showed a lower cohesiveness and resilience. The Ca sample and the PH14 and PH16 treatments had a lower chewiness. Whereas there were no differences in the springiness results among treatments. This is a very important quality attribute of the muffin, which reveals the ability of the sample to recover its height during the time that elapses before the end of the first compression and the beginning of the second. Springiness is associated with a fresh, airy product; therefore, a high quality muffin will be associated with high springiness values [23].

Table 3 Textural properties of muffins.

| Treatment | Hardness (N) | Cohesiveness | Elasticity | Resilience | Chewiness (N) | Firmness ** (N) |

|---|---|---|---|---|---|---|

| PH16 | 12.34 ± 0.34b | 2.42 ± 0.02b | 1.30 ± 0.01a | 5.37 ± 0.14b | 38.84 ± 0.78b | 1.84 ± 0.01b |

| PH14 | 13.17 ± 0.16b | 2.42 ± 0.05b | 1.29 ± 0.03a | 5.48 ± 0.09b | 40.90 ± 0.58b | 1.80 ± 0.02b |

| PHF | 15.58 ± 0.3a | 2.41 ± 0.03b | 1.30 ± 0.01a | 5.43 ± 0.18b | 49.16 ± 1.14a | 2.07 ± 0.09a |

| Ca | 12.88 ± 0.16b | 2.44 ± 0.04a | 1.31 ± 0.03a | 5.72 ± 0.15a | 41.33 ± 0.85b | 2.04 ± 0.04a |

| FL | 15.07 ± 1.19a | 2.54 ± 0.02a | 1.31 ± 0.00a | 5.87 ± 0.08ab | 50.25 ± 4.03a | 2.01 ± 0.03a |

* Values in the same column with equal letters do not vary significantly (P <0.05).

** Firmness was determined for the crumb at the center of the product

Source: The Authors.

The pH of the final product can affect the color of a baked product, and can be controlled by the leavening complex. This is achieved by adjusting the balance between the leavening acid and the sodium bicarbonate (more acid, less soda) or by selecting the leavening acid [21]. Tables 4 and 5 showed the color parameters for the crust and crumb, respectively, for each of the formulations. Both the crust and the crumb had high luminosity values (L*) for all formulations, while in the crust, there was a higher color saturation than in the crumb. The parameters a* and b* in the crust muffin were positive, thus, they tend towards red and yellow; while the crumb had negative values for the parameter a* or with a tendency towards green and yellow tones. The difference between the color of the crumb and the crust was due to the fact that the crumb temperature is not as high as the crust temperature and, therefore, a non-enzymatic browning reaction does not occur (caramelization or Maillard reaction) in the crumb [24]. The total color difference ΔE was evaluated with respect to the two commercial samples (Ca and FL). It has been observed that the perception of color difference Δ𝐸 varies according to the color and sensitivity of the human eye [24]. The treatment with lower Δ𝐸 with respect to commercial samples for the crust was PHF, while for crumb was PH16.

Table 4 Color parameters of the crust in the muffins

| Sample | Crumb | ||||||

|---|---|---|---|---|---|---|---|

| L* | a* | b* | C* (Saturation) | h* (Tone) | Δ𝐸 (Ca) | Δ𝐸 (FL) | |

| PH16 | 58.05 ± 0.07ª | 13.32 ± 0.34ª | 36.26 ± 2.43c | 37.79 ± 3.66b | 69.62 ± 1.43ª | 3.88 | 3.87 |

| PH14 | 56.52 ± 0.21b | 15.09 ± 0.90ª | 36.37 ± 0.86bc | 39.38 ± 0.82ab | 67.47 ± 1.37ª | 3.77 | 3.43 |

| PHF | 58.05 ± 1.14ª | 12.98 ± 2.26ª | 40.11 ± 0.83ª | 42.20 ± 0.84ª | 72.08 ± 3.07ª | 2.00 | 2.50 |

| Ca | 56.12 ± 0.24b | 13.24 ± 0.7ª | 39.62 ± 0.71abc | 41.78 ± 0.51ab | 71.52 ± 1.17ª | 0.00 | 1.39 |

| FL | 56.19 ± 0.25b | 14.62 ± 0.3ª | 39.75 ± 0.67ab | 42.35 ± 0.79ª | 69.81 ± 0.81ª | 1.39 | 0.00 |

* Values in the same column with equal letters do not vary significantly (P <0.05).

Source: The Authors.

Table 5 Color parameters of the crumb in the muffins.

| Sample | Crumb | |||||

|---|---|---|---|---|---|---|

| L* | a* | b* | C * (Saturation) | Δ𝐸 (Ca) | Δ𝐸 (FL) | |

| PH16 | 77.69 ± 0.39ab | -0.47 ± 0.05c | 25.62 ± 0.49ª | 25.62 ± 0.50ª | 0.95 | 1.22 |

| PH14 | 77.22 ± 0.43ab | -0.51 ± 0.14c | 26.05 ± 1.43ª | 26.06 ± 1.43ª | 1.58 | 0.87 |

| PHF | 76.80 ± 0.49b | 0.14 ± 0.08ª | 25.89 ± 1.33ª | 25.89 ± 1.33ª | 1.79 | 1.22 |

| Ca | 78.31 ± 0.33ª | -0.14 ± 0.03b | 24.97 ± 0.36ª | 24.97 ± 0.36ª | 0.00 | 1.98 |

| FL | 77.55 ± 0.4ab | -0.19 ± 0.06b | 26.79 ± 0.89ª | 26.79 ± 0.89ª | 1.98 | 0.00 |

* Values in the same column with equal letters do not vary significantly (P <0.05).

Source: The Authors

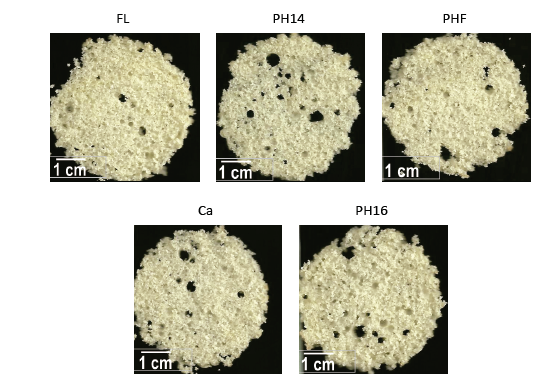

3.4. Porosity

Fig. 1 depicted the scanned images of the different treatments and Table 6 showed the quantitative information obtained through the image analysis performed. In the images, a porous structure was seen as a product of the expansion of gas bubbles during the baking process. In the quantitative analysis, no significant differences were found between treatments in the total number of pores. Regarding the distribution of pores size, FL presented a higher percentage of small pores, while PH14 showed a higher percentage of large pores, as evidenced in the images.

Table 6 Number of pores and distribution of pore area for different formulations.

| Pore Area Range (cm2) | PH16 | PH14 | PHF | Ca | FL |

|---|---|---|---|---|---|

| 0 - 0.005 | 70 (70) | 62 (62) | 66 (66) | 63 (63) | 82 (82) |

| 0.006 - 0.040 | 29 (29) | 27 (27) | 27 (27) | 33 (33) | 29 (29) |

| 0.041 - 0.090 | 5 (5) | 5 (5) | 5 (5) | 5 (5) | 4 (4) |

| 0.091 - 0.202 | 0 (0) | 2 (2) | 1 (1) | 1 (1) | 0 (0) |

| 0.203 - 0.500 | 0 (0) | 0 (0) | 0 (0) | 0 (0) | 0 (0) |

| Total number of pores ** | 102.67 ± 8.49a | 95.17 ± 1.65a | 100.22 ± 9.9a | 101.33 ± 6.03a | 115.22 ± 1.92a |

* Values in the same column with equal letters do not vary significantly (P <0.05).

Source: The Authors.

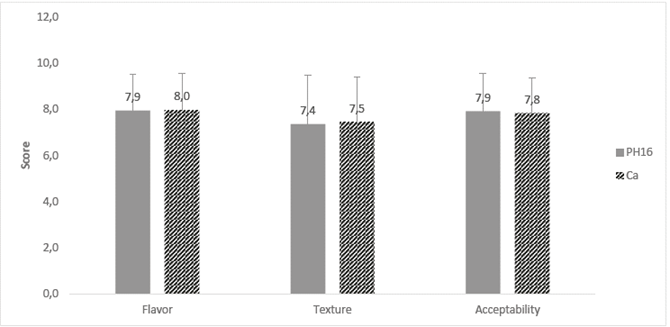

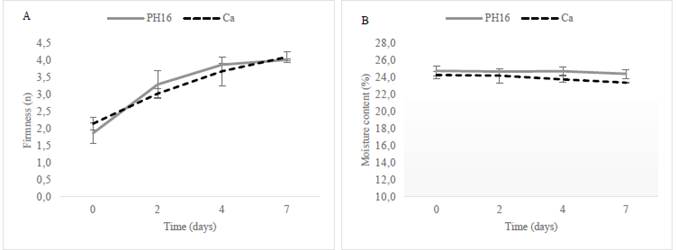

3.5. Storage and sensory analysis

Storage stability or shelf life of baked goods could be defined as maintaining the sensory and physical characteristics associated with freshness, such as crumb softness, compressibility, and moisture by preventing the alteration associated with aging during storage [25]. Based on the results for height, moisture content, texture, color, and porosity in the physicochemical analysis of samples, the PH16 and Ca treatments were selected to perform the storage and sensory analysis. Fig. 2 showed the storage behavior of samples for the firmness (A) and moisture content (B) parameters. Both treatments presented similar behaviors for the two variables evaluated. While moisture content remained approximately constant, firmness tended to increase over time. This result coincides with those reported by other authors [13,20].

Source: The Authors.

Figure 2 Behavior of firmness (A) and moisture content (B) of muffins in storage

Fig. 3 showed the acceptability results for the two samples evaluated on day zero of storage. In general, consumer acceptance was high for both products. There were no significant differences in any of the three parameters evaluated for both samples. However, some consumers found the PH16 sample drier than the commercial sample.

Fig. 4 depicted the results for the QDA by the semi-trained panel for days 0 (A) and 7 (B). There were no statistical differences between both treatments for the variables evaluated on each of the storage days. However, there was an increase in hardness during storage, which was in agreement with the results of the instrumental analysis. Similarly, chewiness, which is defined as the time required to chew the sample or the number of times it must be chewed before it can be swallowed, increased significantly over time. Stanyon and Costello [26] observed that drier samples required more time to absorb enough saliva and to be swallowed.

4. Conclusions

Baking powders evaluated in muffins showed similar behaviors. The farinograph properties of the wheat flour were favored when baking powders were added, by increasing their stability and MTI. According to the physicochemical properties, it was determined that the most suitable treatment was PH16, being the highest (47.66 ± 0.35 mm), with lower moisture content (24.31 ± 0.18), lower hardness (12.34 ± 0.34 N), and lower crumb firmness (1.84 ± 0.01). The quality and sensory behavior of this sample in storage did not differ significantly from the commercial sample. Thus, the pH16 reference baking powder showed the sensory and quality characteristics closest to commercial brands, being a product with high potential to enter into the local market