1. Introduction

From the Greek prefix bio, a series of scientific-technical terms have been developed to define different types of materials, for example, polymeric materials synthesized by microorganisms are often called biosynthetic plastics or natural polymers, but if these materials are subject to microbiological degradation, they are called biodegradable plastics. From the above point of view, a biopolymer then are large molecules, which are chemically structured by the union of hundreds of thousands of molecules called monomers that form linear chains, branched or in the form of three-dimensional networks. However, as is well known, the polymers used for the manufacture of finished parts are usually not pure; in this case, they are specific formulations according to specific demands of these products [1].

In recent years, various researches have been carried out to make polymer processing an issue of economic and energy saving, as it is well known that the polymer industry is an industry necessary for daily consumption in different sectors [2]. Today, public concern for the environment and the availability of limited fossil fuel resources has forced governments, businesses and scientists to propose alternatives to oil through the development of sustainable materials based on renewable resources. Within the framework of sustainable development, new materials are conceived with the aim of increasing their biodegradability properties, and therefore, in an economic situation such as the present one, the use of green composite materials is advantageous not only for the environment [3], but also from an economic point of view, as they moderate the use of energy and other resources and increasingly prevent pollution and waste through cleaner production and recycling. Regarding the composition of waste, about 56 % of plastic waste is made up of packaging, and of these, 42% come from domestic use.

There are natural polymers (Fig. 1) of commercial interest coming from Cassava [4], Arracacia [5], Cotton, Silk, Wool among other sources. An example of this is cellulose, used in the manufacture of fabrics and paper from wood. The natural polymer obtained from silk is a polyamide similar to nylon. Wool containing lalolein is another example of biopolymers [6]. The polylactic acid is an example of it; its obtaining has been widely studied and developed. The process consists in the extraction of starch from a specific biomass source. The most widely used substrates in industry are sucrose from cane sugar and sugar beet (refined sucrose and glucose), lactose from whey, and dextrose from hydrolysed starch. Other natural polymers of great interest are those obtained from rubber (Hevea trees) and Guayule shrubs.

According to the publication of Palanisamy et al., (2019), polymers for the manufacture of packaging (39.4% in 2018) are mainly polyethylene (PE) and polypropylene (PP), followed by polystyrene (PS), polyvinyl chloride (PVC) and obviously polyethylene terephthalate (PET) due to their use in the bottled beverage industry. Also, with a lower consumption, but not less important, polyamides (PA) and polyurethanes (PUR) being the latter more useful in other types of uses such as the construction industry (as thermal insulators, coatings and resins), the automotive industry (for the use of boards, fenders, seats), the electrical industry (cable insulation) and also for the footwear industry (soles). According to the aforementioned data, a general review of biogenerated polymers and additives or fillers, which are used in their formulations, is presented below. And considering the exponential increase of the market of all these types of polymers, the additives or fillers most used for several types of biogenerated polymers are exposed, which can similar mechanical properties the formulations of totally synthetic polymers that are elaborated nowadays.

2. Biopolymers

2.1. Chitosan

An example of research on biogenerated materials is chitosan [7], Chitin [8] is a polysaccharide similar to cellulose except that the OH group in C-2 is replaced by an acetamide group (CH3CONH), being the main component of the hard outer covering (exoskeleton) of crustaceans such as lobsters, crabs and shrimp. It has a higher degradation temperature than chitosan, due to higher crystallinity and a lower degree of polymerization [9]; however, chitosan has higher activation energy due to the crosslinking propitiated by the free amino group. Chitosan has a relatively low content of crystalline regions, this is what makes it attractive for pharmaceutical and biotechnology applications [10].

In several recent investigations, this polysaccharide has been used for the production of several biogenerated materials. For example, Allouche, Guibal, & Mameri (2014), published that from chitosan, a biogenerated material is obtained for use in the adsorption of mercury. They call it a bio-sorbent. This material demonstrates selectivity for mercury, as indicated by its study, so adsorption is easy to carry out. Depending on the absorption characteristics and cylindrical shape of this material, there is no other similar material on the market that can adsorb the amount of mercury as this one did.

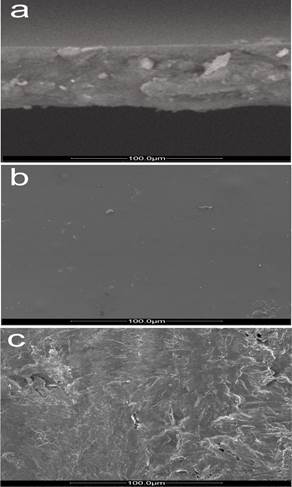

Lei et al., (2014) carried out the processing of PET/PP films mixed with chitosan and various preservatives for food packaging. This material was produced from plasma treatment, which showed that surface hydrophilicity and roughness of PET/PP films increased after treatment. They also noticed a good addition of some of the preservatives on the surface of the material. Inhibition ratio studies were made against microorganisms, which gave very promising results regarding microorganisms such as E. coli and S. aurus. The result of the release profiles of the additives in the material showed that the higher the temperature and acidity, the higher the release speed of the antimicrobial additives, but it decreases with the increase of the ionic force regulated by the sodium chloride due to the intermolecular and intramolecular repulsive force of the chitosan, which destroys a section of the chitosan chain and reduces the release speed. Sucrose decreases the ionic mobility of the entire system by reducing the dissolubility and release speed of the preservatives.

In the work of Kurek, Galus, & Debeaufort (2014), they present a report of a biobased polymer made from chitosan and whey protein, which is used in the form of one- and two-layer films. It was observed that when having two layers, it presents good mechanical properties, but when increasing the percentage of chitosan, the elongation increased. By having two layers of the material (chitosan-milk whey) the vapor permeability was reduced in comparison to only one of the layers. In addition, a good adhesion between chitosan and whey protein. The authors recommend this material for edible film applications in foods, where the film can be dissolved during the cooking and consumption process.

Niu et al., (2014) considered the affinity between chitosan and polylactic acid and obtained a material made from two biopolymers. This copolymer is synthesized from a microemulsion. The H-RMN analysis indicated that the polylactic acid was grafted onto the main chitosan chain through the reaction between the carboxyl groups of the polylactic acid and the amino groups of the chitosan. This allows the final product to have the biological properties of chitosan and the mechanical properties of lactic acid.

In addition, Seo et al., (2014) used three types of materials to form a membrane that could be used for bone regeneration (GBR) and dental implants. It is made of silica and functionalized carbon nanotubes with chitosan which offer promising results. By adding the nanotubes to this formulation (approximately 3% by weight), the modulus of elasticity and tensile strength increased with respect to the membrane without nano tubes. They also observed that there was good bio-activity and good tissue response. With the incorporation of carbon nanotubes, the rate of hydrolytic degradation was reduced in saline phosphate buffer tests (PBS as opposed to polybutylene succyanate also abbreviated PBS), because the chemical interactions of carbon nanotubes, chitosan and silica improve resistance to hydrolytic ruptures, concluding that the higher the concentration of carbon nanotubes, the degradation is reduced.

2.2. Polybutylene succinate

The biodegradable synthetic polymers produced by microbiological and chemical synthesis are mainly aliphatic polyesters, from natural polymers and their mixtures. These include polybutylene succinate (PBS), aliphatic thermoplastic polyester with biodegradability, processability (fusion), thermal and chemical resistance properties, suitable for obtaining biodegradable materials [16]. This polymer is obtained from the condensation polymerisation of succinic acid (CH2)2(CO2H)2 and 1,4 butanediol (HOCH2CH2CH2CH2OH). Its mechanical properties are excellent and can be processed by conventional techniques using polyolefin equipment in the temperature range of 160 - 200 °C [17]. Succinic acid (HOOCCH2CH2COOH) and its anhydride have unique properties attributed to the succinyl group [18]. Due to its versatility, it is used as an intermediary in the formulation of pharmaceuticals and in the synthesis of different biodegradable materials. Succinic acid can be obtained from two possible sources, one is from petrochemistry and the other is fermentation by some bacteria.

Succinic acid is the intermediary in the tri-carboxylic acid cycle and is therefore a final product of the energy metabolism of many anaerobic, aerobic or facultative microorganisms [14]. Microorganisms include Actinomycetemcomitans, Anaerobiospirillum succiniciproducens and Mannheimia.

To give an example to this type of materials, [19] carried out the study of a copolymer based on poly (butylen azelato-co-butylen succyanate), of which they analyse its thermal properties, its crystalline structure and morphology, as a function of crystallization kinetics and in the same way, they analyse its degradability. In this work it is observed a random distribution and points of fusion within a wide range of temperatures of these copolymers, which go from 36 °C to 113 °C. The copolymers crystallized according to the monoclinic alpha structure (α) of PBS and the orthorhombic structure postulated for the polybutylene azelate, depending on the dicarboxylate unit that predominates in the copolymer. From this, it was obtained that the structure of the polybutylene azelate is favored (interestingly) when the samples cooled rapidly (even from the melt), which increased the degree of crystallinity. In terms of degradation, the preferential enzymatic attack by amorphous regions, the spherulitic morphology that distinguishes this type of materials stand out. Therefore, samples with controlled biodegradability can easily be generated by copolymerization. This study demonstrates the obtaining of materials with very promising properties and degradability studies, which had been carried out in blends of biogenerated materials.

Wang, Yu, & Ma, (2007) studied the crystallization of a copolymer made with polyhydroxybutyrate (PHS) and PBS, ranging from a dispersed phase to a continuous phase of 20 to 70% by weight of PBS, observing a co-continuous phase in 50% by weight of PBS. The growth rate of PHB spherulites is reduced by increasing the amount of PBS. The overall crystallization rate of PHB improved with the incorporation of PBS. The increase in the crystallization temperature range is attributed to the modification of the mechanism of multiple nucleations (as they are homogeneous, heterogeneous and self-improved). Using Differential Scanning Calorimetry (DSC), it was determined that the overall crystallization rate of the PHB improved with the addition of PBS and greatly improved the processing capacity of the material.

On another side, as published by Kim et al., (2005), they obtained a copolymer made from adipic acid/PBS. In this case, they observed that by increasing the content of long poly(adipic acid) chain sections in the main PBS chain, the crystallinity decreases and reflects the increased flexibility of the final material (because PBS is known to be a highly crystalline material), without compromising its degradability. The authors conclude that copolymerization has better mechanical properties than physical mixtures.

Chen, Chueh, Tseng, Huang, & Lee, (2003) presented a material elaborated with PBS and silica nanoparticles obtained by pyrolysis. Compounds containing silica nanoparticles with a larger surface area, according to some studies, seem to have a higher density of network structures, which increases their modulus of elasticity in this type of compounds. These interactions are verified by the tensile test observing behaviour similar to rubber, which describes a strong interaction between silica and PBS. In the dynamic mechanical analysis, it was observed that the glass transition temperature increases and it is displaced at higher temperatures in the improved composite material, due to the interactions between PBS/silica. Due to hydrophobic functionalization, motion in the molten state is reduced, which could have drastic consequences for the processing of the material.

According to Ali & Mohan, (2010), they made mixtures with carbon nanotubes (CNT) and PBS. In their study they showed that the rheological fusion properties of PBS improve with the addition of CNT. They also observed that the processability of these mixtures showed a thinning by shearing. Their contribution is significant because as properties improved these composite materials give a potential alternative for the substitution of polyethylene (PE) and polypropylene.

2.3. Starch

Around 73 million tonnes of starch is produced worldwide (12% humidity) [23]. Over time, the demand for starch from non-food industries is expected to grow faster than the demand from food industries. This natural polymer, used in formulations to produce biogenerated materials, is a plant polysaccharide that is stored in the roots, tubers and seeds of plants and is also found in the endosperm of all grains, is made up of glucose units and contains two types of molecules known as amylose and amylopectin. Amylose is a linear polymer which is a long chain of glycosidic bonds α-1,4 [24]; while amylopectin is a branched polymer with bonds α-1,6 [25], which are located every 15 - 25 units. These ramifications make amylopectin less insoluble in water than amylose. The starch chains are associated by hydrogen bonds, forming a double helix, which is destroyed by heating with water. Depending on the source from which the starch is obtained, it may have different shapes (ranging from irregular shapes, polygonal in the plane, orthorhombic in space with rough appearance, may also be elliptical or spherical) [26], size (ranging from 10 μm to 15 μm), composition (amylopectin or amylose in greater or lesser quantity).

This material itself is a polymer, however it is not usually used for the manufacture of finished parts as a single component due to its limited mechanical and rheological properties. Therefore, it is often employed as a material binder of filler or reinforcement for other biogenerated polymers.

Starch and its derivatives are commercially produced from a wide range of raw materials such as corn, wheat, peas, potatoes and cassava [27], and is the main reserve material in photosynthetic plants, stored in many organs such as seeds, stems and roots in the form of granular components, insoluble in water [28]. Essentially composed of two main polysaccharides, amylose and amylopectin, these granules also contain some minor components, such as lipids and proteins [29]. Their size varies from 1 to 100 mm, they have a size, shape, and composition that depends on their botanical source [28]. The processing and properties of these semi-crystalline materials are closely linked to the genetics of starch and various levels of granule structure to macromolecular structure and crystalline macrostructures.

However, the hydrophilic nature of starch plays an important role in initiating biodegradation processes, but also limits its technical applications. Therefore, attempts have been made to overcome this limitation by modifying the starch structure, formulation, and processing techniques [30], taking into account that biodegradation or starch incineration does not result in any net CO2 gain, the manufacture of starch-based plastics as alternatives to common petrochemical spin-off polymers becomes attractive and is a factor that can significantly influence the overall performance and biodegradability of starch-based polymers or in mixtures with renewable sources such as lactic acid (Table 1), polycaprolactone, among others [31].

Table 1 Different polymer obtaining process using biogenerade compounds.

| Compounds | Polymer | Process | Author |

|---|---|---|---|

| Corn starch and thermoplastic chitosan | Blend | Melt extrusion | [32] |

| Corn starch and PLA 3152D | Compression molding | [33] | |

| Corn starch and PBS | Blend - Film | Compression molding | [34] |

| Starch and PVA 1179 | Compression molding | [35] | |

| Potato starch and PBAT | Film | Extrusion | [36] |

| Corn starch and PVA | Melting | [37] | |

| Cassava starch and PLA | Extrusion | [38] | |

| Chitosan, PVA and fish gelatin | Casting | [39] | |

| Chitosan and Carboxileter | Casting | [40] | |

| Chitosan and Zinc | Injection molding | [41] | |

| Chitosan and PLA 3052D | Extrusion | [42] | |

| Corn starch and PVOH | Casting | [43] | |

| Cassava starch, natural rubber and chitosan | Composite | Compression molding | [44] |

Source: The Authors.

This material has been used for the production of different biogenerated materials such as those presented below.

Vieira, Da Silva, Dos Santos, & Beppu, (2011) elaborated a material from poly (N-isopropylacrylamide) (PNIPA) and oligosaccharides of chitosan and soluble starch as dispersed phase, obtaining a material in the form of xerogel. From the tests carried out on these materials, it was found that these gels are pseudoplastics and that their viscosity depends on the molecular weight of soluble starch. The transition temperature is observed between 35 - 37 °C, which may allow the possibility of being used in the field of surgical medicine and as a support for tissue bio-engineering. It was determined that the porosity of xerogel and molecular weight is due to the structural hydrophobicity/hydrophilicity between the Y phases. They concluded that the material made of PNIPA + 5 % starch gel presents a well-defined structure in the form of interpenetrated networks.

On the other hand, Olivato, Müller, Carvalho, Yamashita, & Grossmann (2014), carried out the synthesis of a biogenerated material from starch/Poly(butylene adipate co-tereftalate) (PBTA) and tartaric acid was added as a compatibilizing agent. The results demonstrated the effectiveness of the compatibilizing agent since the mechanical properties were increased. In the FT-IR analysis, it was observed that tartaric acid reacts with the hydroxyl groups of starch. One application of this material could be to replace non-biodegradable bags.

Also, Le et al., (2014) conducted research to determine the mechanical behavior of a composite material based on starch and hemp fiber. The advantage of this type of material is that natural fibers have a high displacement value due to the fact that these fibers are highly deformable. In the case of this material starch/hemp fiber, the resistance to compression depends in little measure on the density of the material, since the material of 170.8 kg/m3 (to comparison of the material of concrete-lime that is of 330 kg/m3) presents values that go from 0.4 MPa and 0.5 MPa in average (to comparison of the concrete-lime that goes from 0.1 MPa up to 0.8 MPa in average). However, tensile strength depends entirely on the density of the material.

Similarly, Travinskaya, Savelyev, & Mishchuk (2014), produced a biogenerated material from aqueous dispersions of anionic polyurethane (APU) and starch, obtaining solid films with high aggregate stability and the ability to form solid films. The APU/starch films presented higher tensile strength, greater hydrophilicity and a greater capacity to undergo acid/alkaline hydrolysis compared to the APU; with only 1.5 % starch, 5.2 MPa was achieved (compared to starch alone (1.8MPa) and a little less than the solution without starch (8.7 MPa)). Starch imparts the characteristics of rapid degradation compared to polyurethane. The degradation was evaluated with microorganisms (Bacilus subtilis), which by means of study of contact angle in the films, it was verified that the more starch was added to the mixtures, the more hydrophilic was the film surface. The addition of starch to polyurethane resulted in the formation of amorphous micro-domains, thus predetermining the degradation of APU/starch systems.

Crépy, Petit, Wirquin, Martin, & Joly (2014), worked with the same material and created a high-range water-reducing admixture (also called HRWRAs) for concrete. Using starch as the main chain for this material (grafted with short chains of maleate, succinate, sulfopopylate and sulfobutylate) imitating the structure of petroleum-based HRWRAs. The starch can work with different substitutes and obtaining good results to carry out the function of the HRWRAs; in this case the group’s sulfato and O- ionic (as side chains) allow a better adsorption of the grafted starch, reason why a better retention of the fluidity of the concrete is observed. In the test of the resistance to compression of the mixtures of additives with starch (in appropriate concentrations) are comparable to the results obtained with Poly naphthalene sulfonate (PNS); it was observed that when the concentration of starch increases, the resistance to compression decreases. This starch-maleate and starch-sulfobutylene material proved to be a good substitute for casein in self-levelling concrete.

The composition, morphology and thermal and rheological properties of starch granules differ according to their natural origin, contributing to significant differences in properties and desired functionality [50,51]. Starch granules generally consist of approximately 25% amylose and 75% amylopectin [52-54]. The amylose/amylopectin ratio, transition temperatures, and gelatinization rate in starch granules vary depending on the source [55,56]. The high level of crystallinity results in higher transition temperatures, so granules more resistant to gelatinization [57], influence the rate of biodegradation.

Native starch granules (unprocessed or grafted) are semi-crystalline and hydrophilic and readily biodegradable [58], because they possess poor mechanical properties, which limits their use in the development of starch-only biodegradable polymers. In native starch granules, amylopectin is branched and forms the crystalline part, while amylose is the linear polymer associated with the amorphous phase. Some studies report that mixtures containing starches with linear structures are expected to biodegrade more rapidly compared to branched starches [59,60].

To increase functional properties, native starch granules can be modified into thermoplastic starch (TPS) using physics (milling, ultrasound, and the addition of plasticizer and other additives), chemistry (esterification, etherification, grafting, crosslinking, and oxidation), or enzymatic treatments [61-63]. Micronization of starch granules results in reduced size, improved amylose content (amorphous region), compatibility with other polymers and additives, and increased susceptibility to microbial/enzymatic attack [64].

Other studies have shown that TPS improves its traction properties, biodegradability and bioactivity when bioglass is added in the development of bone tissue compounds. In addition, this study reports that the addition of bioglass to TPS improves the tensile strength, modulus, in vitro bioactivity of the compound, reduces the ductility and in vitro biodegradability of the composite material. However, the authors of this study mention that an interconnected porous structure in the composite morphology of TPS/bioglass is required for this material to be viable in bone tissue engineering [65].

2.4. Polylactic acid

Another of the biogenerated polymers is polylactic acid (PLA), which is an aliphatic bio-polyester produced from lactic acid monomers, which can be obtained from the fermentation of carbohydrates such as starch [30], cellulose (mainly corn and cassava) [2], so it is obtained 100% by renewable resources. It is biodegradable under certain conditions, so it is used in the biomedical and pharmaceutical industries. Previously, it was rarely used due to the high cost in the synthesis of this polymer, now it is more used due to obtaining it by fermentation. It is either amorphous or semi-crystalline according to the purity of its stereoisomeric composition (Table 2).

Table 2 Properties improved from blends of TPS and PLA.

| TPS/PLA | Impact strength (KJ/m2) | Tensile strength (MPa) | Elastic modulus (MPa) | Type of Starch | Reference |

|---|---|---|---|---|---|

| 100/0 | 0,7 | 19,5 | - | ||

| 90/10 | 0,3 | 14,1 | - | ||

| 75/25 | 0,2 | 12 | - | ||

| 60/40 | 0,4 | 11,2 | - | Wheat | [67] |

| 25/75 | 1,7 | 30,2 | - | ||

| 0/100 | 11,9 | 68,4 | - | ||

| 100/0 | - | 9.3 ± 0.4 | 61.9 | ||

| 80/20 | - | - | 224.1 | ||

| 60/40 | - | - | 789.7 | ||

| 60/40 | - | - | 117.9 | Corn | [ ;68] |

| 80/20 | - | - | 2780.4 | ||

| 0/100 | - | - | 3174.6 | ||

| 72/28 | - | 6.7 ±0.423 | 66.38 ±10.88 | Cassava | Authors |

Source: The Authors.

For example, by using 100% L-PLA, a material with a high melting point and high crystallinity is obtained. But if a mixture of D-PLA and L-PLA is made, an almost 100% amorphous polymer is obtained with a glass transition temperature of 60 °C [66]. In this case, the studies performed by Soares, Yamashita, Müller, & Pires (2014) obtained a polymer film made from thermoplastic starch (TPS)/PLA. Of all the physical-chemical characteristics that were evaluated (crystallinity, morphology, affinity for water and mechanics), they noted that the slower cooling of the films, the more crystalline, less permeable and less soluble in water compared to those cooled quickly, observing that the cooling speed affects the crystallinity and morphology of the films. Others were tested by coating them with chitosan, proving to be resistant to water (due to the hydrophobic properties of this material), they also pesent better interaction between the phases and better mechanical properties [70].

For their part, Jia, Gong, & Hogg (2014), developed a self-reinforcing polymeric composite (SRC) from PLA and PBS to obtain films. These materials showed a 70% increase in PLA modules -SRC have higher tensile strength and Young's higher modulus taking as reference the PLA-PBS mix data. The behaviour observed is attributed to the fact that there is greater interfacial adhesion between the PLA-SRC elements.

With this same polymer, Tábi, Égerházi, Tamás, Czigány, & Kovács (2014), obtained a composite from PLA and basalt fibers (short and long fibers), by extrusion and injection molding. This working group found that the longer the length of the basalt fibre, the better the mechanical properties. By increasing the weight of the reinforcement by 20 %, it was observed that the mechanical properties in general improve. The values were similar with long fiber composites at 20 % than with short fiber composites at 30. It was found also that long basalt fibers had the nucleation capacity, although it decreased when the length of the fibers increased.

Murugan, Han, Gan, Maurer, & Sudesh, (2016), also studied calcium carbonate nanocompounds (CaCO3) with PLA. Using stearic acid as a compatibilizing agent. With this modification, the dispersion of CaCO3 in PLA is improved. The differential mechanical analysis (DMA) generates an increase in the glass transition temperature (Tg) and in the storage module. As regards thermogravimetric analysis, the degradation temperature is lower when the concentration of CaCO3 in the polymer matrix is increased.

Loureiro, Esteves, Viana, & Ghosh (2014) developed from polyhydroxyalkanoates and polylactic acid (30:70), a composite material reinforced with cellulose fibres. From the data collected by the dart impact test, an irregular cellulose dispersion is confirmed by using 20 % of this fibre (given by the Halpin-Tsai equation (or also called mixture rule) which denotes a homogeneous dispersion with this percentage of fibres, also improves heat deflection (HDT) when it is homogeneously distributed in the polymer matrix, increases also traction and flexion. An interfacial adhesion between the continuous and discontinuous phase of the polymer was also found.

2.5. Nanometric scale: Nano-biopolymers

The problems caused by oil-based polymers motivate the use and development of biopolymers [75,76]. The growth rate of nanobiopolymer-based products is expected to be high, which may be around $2 billion by the end of 2020 [77]. Among these are cellulose, chitin, silk, starch, protein and bacterially derived polysaccharides. These biomolecules are widely available, sustainable, as well as biocompatible and biodegradable [3,42,75]. Consequently, nanotechnology is focused on the manufacture of structures at the nanoscale for commercial use to obtain new structural and functional materials. At this nanoscale, its properties and functions can be oriented towards optical transparency, colour and porosity [78,79].

The structures have many applications in industry in general, including polymer fillers to various high-tech fields, such as transparent display panels, ultrafiltration membranes, energy storage devices and catalytic supports [80, 81]. One of the sectors of major interest is the production of packaging, of a composite nature and with bioactive and intelligent properties (sensors). These materials are also used as surface coatings and to improve physical performance, durability and barrier properties, due to their size and high surface-to-volume ratio. Similarly, they are used to achieve a higher biodegradation factor than developed materials. Among these nanomaterials are nanolayers (coating), nanofibers (resistance) [82], nanoparticles (release or capture), nanotubes (rigidity) [15], nanocapsules (transport), among others. Most nanobiopolymer manufacturing techniques, such as mechanical insulation and chemical modification methods, require high energy consumption [78]. Several methods are available to obtain these nanocomposites [81, 83-85], which give them different properties for use, some of these methods include in-situ polymerisation, solvent interleaving or peeling, and interleaving or peeling by fusion. The latter being the most attractive process due to its versatility and compatibility. These nanobiopolymers are an alternative to minimize the environmental impact generated by non-biodegradable materials [38,77,86,87].

3. Conclusions

Different types of natural polymers which can be used to produce different biogenerated materials. The challenge for the plastics industry is to reduce the use of fossil materials and to be able to reduce production costs. Also, research is being conducted to develop new technologies and new materials which are biogenerated and biodegradable (or both) to alleviate a little consumption and use of these fossil materials, so now, it is our responsibility to achieve and investigate. At the moment these materials only play a secondary role in the plastics industry, although it will not be long before this is a thing of the past since some areas of industry are already used frequently and are incorporated in increasing proportion. It is undoubtedly a promising field of research that is presented in this review article due to the versatility of materials that can be made with a single type of natural polymer.