1. Introduction

Chayote, Sechium edule (Jacq.) Sw., belonging to the Cucurbitaceae family, is important in nutrition since pre-Colombian times due to its easy cultivation and adaptation. It is a good source of dietary fiber [1] and rich in minerals, vitamins [2], and amino acids, making it an alternative to elaborate flour-based products.

The fruit has been used in the elaboration of juices, sauces, pastes, and infant foods. In Mexico, efforts have been made to increase the useful life of the fruit through dehydration. Results have been good and have permitted elaborating marmalades and other sweets [3].

The most common methods to dehydrate vegetables are hot air drying (HAD) and combined hot air - microwave (HAD-MW) drying, with the latter taking the least amount of time for dehydration. Convective drying (HAD) transfers heat to the solid, through a current of hot air, becoming a transporting agent of the water vapor being eliminated, which makes heating more uniform [4]; microwave (MW) drying alters in homogenous manner the fruit structure upon causing continuous movement of the water molecules, which diminishes drying time, increasing the quality and useful life of the products. The combination of these two techniques (HAD and MW), at 60 °C, potentiates reduction of time and avoids the loss of bioactive components of fruits and vegetables [5].

Hence, combining these methods permits increasing the useful life and improving the sensory characteristics of the products treated [6]. Hot air eliminates free water on or near the surface, while microwave drying eliminates internal water. Additionally, it is possible to maximize efficacy and reduce drying costs [4].

The best known and most widely used flour is wheat flour; however, in South America and in Andean and Amazonian numerous legumes, roots, tubers, fruits, and vegetables grow and which are very rudimentarily cultivated and which have high potential of being used and transformed into flours and/or starches. Transformation of these products into flours and/or starches constitutes the most efficient way of preserving raw material that overcomes post-harvest losses, or that is not fully exploited and which would help to diversify and innovate in the development of foods for conventional consumption or for special regimes, resolving local problems and even global issues of food demand [7].

The aim of this research was to determine the effect of the drying technique on some technical-functional properties of the chayote flour.

2. Materials and methods

2.1. Sample preparation

Chayote, Sechium edule (Jacq.) Sw., was acquired at a local market in the city of Armenia, with similar characteristics of color, size, texture, and without apparent mechanical damage. The vegetables selected were washed and disinfected with sodium hypochlorite solution at 500 ppm, according to the minimum requirements by the Codex Alimentarius for fresh fruits and vegetables [8], peeled and cut into sheets to be subjected to the drying process.

2.2. Application of the HAD and HAD-MW drying techniques

The chayote sheets were dried in a furnace with hot-air recirculation (HAD) at 40, 50 and 60 °C, taking mass registries every 30 min and, then, every hour until constant weight.

Combined HAD-MW drying was carried out in a conventional microwave oven adapted with an air circulation system in one of its lateral faces, with temperature regulation using the following parameters: temperatures of 40, 50, and 60 ºC with 4-s microwave pulses every 40 s; until constant weight.

2.3. Obtaining the chayote flour

The chayote flour was obtained with an IKA blade mill and sieved in Gilson equipment model SS-15 with sieve set of 50, 60, and 100, corresponding to 500, 300, and 250 µm, respectively.

2.4. Physicochemical characterization of the chayote flour

Humidity parameters were evaluated through the AOAC 934.06 method [9]; color was evaluated in a spectrophotometer (Minolta, CR 10), with D65 illuminant and 10° standard observer. From the samples’ reflection spectra, the study determined the CIE-L*a*b* coordinates, the pitch (hab*) polar coordinates, and saturation (Cab*) [10], ashes through the AOAC 923.03 method [9], and particle size (granularity) through the AOAC 965.22 method [9].

2.5. Determination of the technical-functional properties of the chayote flour

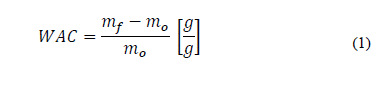

2.5.1. Water absorption capacity (WAC)

A 0.5-g amount of flour was weighed and 5 mL of distilled water was added, maintaining in agitation during 1 h. Thereafter, the samples were centrifuged at 4750 rpm during 30 min. Supernatant volume was measured in a graduated cylinder (10 mL) and its weight was determined [11]. The result was expressed with Eq. (1).

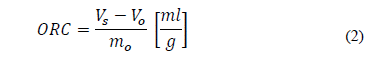

2.5.2. Oil retention capacity (ORC)

An amount of 0.5 g of flour received 5 mL of commercial oil and was subjected to agitation during 30 min. Then, it was centrifuged at 4750 rpm during 30 min. After centrifuging, supernatant volume was measured [12]. The result was expressed with Eq. (2).

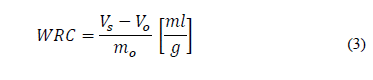

2.5.3. Water retention capacity (WRC)

An amount of 0.5 g of flour received 5 mL of distilled water, and it was maintained in agitation during 24 h. After this time, it was centrifuged at 4750 rpm during 30 min. Supernatant volume was measured after centrifuging [12]. The result was expressed with Eq. (3).

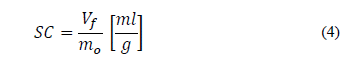

2.5.4. Swelling capacity (SC)

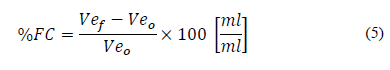

A total of 100 mg of flour was weighed in a 10-mL graduated cylinder. The test tube was filled to 10 mL with distilled water, the sample was dispersed by softly agitating and was left to rest during 16 h to achieve its hydration. After this time, the final volume occupied by the flour in the bottom of the test tube was measured [13]. The result was expressed with Eq. (4).

2.6. Statistical analysis

The significance study of the different effects and their possible interactions was conducted through the multifactor and simple analysis of variance (ANOVA) using the Tukey method (HSD) as multiple-comparison method, with a significance level (α) of 0.05, with the STATGRAPHICS CENTURION XV (version 15.2.05) statistical package.

3. Results and discussion

3.1. Obtaining the flour

Based on the CODEX STAN 152 norm [15] for wheat flour, the flour from the 100 sieves was selected with 250-µm particle size, given that this particle size is adequate to elaborate bakery products with wheat flour. Particle size in flours is related with its hydration and capacity to form a mass with good rheological qualities; smaller particles can incorporate more water, but generate very compact masses and difficult to cut. The HAD-MW drying method was selected because of its higher percentage of yield of the flour obtained through this technique.

Table 1 presents the total time in hours it took the chayote sheets to dry, according to the drying methods and the different temperatures used.

Table 1 Final drying times (hours) of the chayote sheets.

| Temperature (°C) | HAD Technique (h) | HAD-MW Technique (h) |

|---|---|---|

| 40 | 20.66 ± 1.52 | 6.83 ± 0.76 |

| 50 | 19.27 ± 1.78 | 5.12 ± 0.45 |

| 60 | 17.57 ± 0.95 | 4.20 ± 1.14 |

n: 5; ±: Standard deviation.

Source: The Authors

As noted, Table 1 presents a statistically significant difference among both drying techniques and the three temperatures evaluated. Drying through HAD - MW showed stability in weight prior to the 7 h of treatment, while in that dried via HAD the stability was reached around 20 h at 40 °C; with the drying time being greater with respect to the other two temperatures.

The chayote with an initial humidity at 94.66% ± 0.08 took longer to eliminate the water content in the HAD method than in the HAD-MW method, given that the conventional air circulation drying method is not very efficient because it is based only on the mass transference that takes place during the drying process, while que el combined method uses electromagnetic waves that help to heat the water molecules present in the food, thus, causing faster and more efficient dehydration. This agrees with that reported by Suarez [16] upon obtaining worm flour evaluating different drying alternatives that included HAD and HAD-MW drying.

The HAD-MW drying technique at 40 °C was selected because it permits conserving the bioactive components and avoiding damage in the structure, besides diminishing drying time.

3.2. Physicochemical characterization of the chayote flour

Table 2 shows the characterization of the chayote flour obtained via HAD-MW drying technique, in the parameters of humidity percentage, ash content, and color.

Table 2 Characterization of chayote flour dried via the HAD and HAD-MW techniques.

| HAD | HAD-MW | ||||||

|---|---|---|---|---|---|---|---|

| Parameters | 40 °C | 50 °C | 60 °C | 40 °C | 50 °C | 60 °C | |

| Humidity (%) | 7.43 ±0.00 | 6.95 ±0.01 | 7.05 ±0.00 | 7.75 ±0.00 | 8.83 ±0.01 | 7.83 ±0.01 | |

| Ash (%) | 0.06 ±0.1 | 0.05 ±0.0 | 0.06 ±0.0 | 0.06 ±0.1 | 0.06 ±0.1 | 0.07 ±0.0 | |

| L | 62.8 ±0.1 | 61.8 ±0.1 | 60.6 ±0.1 | 60.9 ±0.1 | 60.2 ±0.1 | 57.0 ±0.1 | |

| a* | 3.9 ±0.2 | 5.4 ±0.2 | 2.5 ±0.2 | 5.3 ±0.2 | 6.1 ±0.2 | 6.0 ±0.2 | |

| Color | b* | 27.3 ±0.0 | 26.2 ±0.0 | 26.6 ±0.0 | 25.8 ±0.0 | 28.0 ±0.0 | 27.0 ±0.0 |

| C | 26.4 ±0.1 | 26.7 ±0.1 | 26.7 ±0.1 | 27.8 ±0.1 | 25.3 ±0.1 | 26.6 ±0.1 | |

| h* | 81.4 ±0.2 | 78.2 ±0.1 | 84.6 ±0.2 | 78.8 ±0.2 | 77.6 ±0.1 | 76.7 ±0.1 | |

n : 5; ±: Standard deviation.

Source: The Authors

As shown in Table 2, no statistically significant difference existed in the humidity percentage of the chayote flour dried via both methods (HAD and HAD-MW) and at the three temperatures; higher values were reported by [17] in obtaining flour dried via HAD. The low humidity of the chayote flour permits stability against microbial contamination and contributes to physicochemical conservation, given that it delays the rancidity of the lipids and reduces enzymatic activity. This parameter complies with that established in norms [9] and [15], where the value required must be lower or equal to 15.5%. Regarding the color parameters, it is observed that according to the L*, a*, b* coordinates a tendency to light yellow was noted; the parameter with the highest variability during the drying process at the three temperatures is the a* coordinate (red to green), presenting a darker tonality with a tendency toward red, which occurs due to oxidation processes taking place in the sugars present in chayote when subjected to drying. Diminished luminosity occurred.

3.3. Techno-functional properties

Table 3 displays the results of some techno-functional properties of the chayote flour obtained via HAD and HAD-MW drying techniques at 40 °C and with 250-µm particle size (100 sieve).

Table 3 Techno-functional properties of chayote flour obtained via HAD and HAD-MW dried at 40 °C.

| Techno-functional properties | Treatment HAD | Treatment HAD-MW |

|---|---|---|

| Water absorption capacity (WAC) (g water/g flour) | 6.80±0.28 | 6.80±0.28 |

| Oil retention capacity (ORC) (g oil/g flour) | 0.15±0.07 | 0.10±0.00 |

| Water retention capacity (WRC) (g water/g flour) | 1.85±0.21 | 2.50±0.71 |

| Swelling capacity (SC) (mL water/g flour) | NP | NP |

| Foaming capacity (CE) (%) | 66.6±0.0 | 33.3±0.0 |

Source: The Authors

Table 3 shows the results of some techno-functional properties, which provide information on the interaction of the flour components with water, helping to predict the behavior during processing and elaboration of products, and showing statistically significant difference in foaming capacity.

Flour has good levels of water absorption capacity due possibly to non-protein components, like carbohydrates, which can absorb and retain water. This is of interest when elaborating masses, given that it confers improved humidity content and softness of the texture [18]. This index represents the water-absorption capacity without dissolving proteins due to the presence of hydrophilic carbohydrates in the flour [19], which is of interest in bakery masses.

Water absorption capacity depends, mainly, on protein and some of its parameters, like size, shape, steric factors, and hydrophilic-hydrophobic balance of the amino acids in the molecules, as well as the lipids and carbohydrates. Flours with high WAC have more hydrophilic compounds and it is considered a functional property of proteins, fundamental in viscous foods, like soups, sauces, masses and baked foods, products requiring good protein-water interaction [20].

The chayote flour had no swelling capacity, which agrees with its low content of starch (approximately 1%), given that this property is closely related with the amount of starch present in the flour; swelling of starch granules and the resistance of the swollen granules when dissolved by heat or fragmented is what attributes this property [21].

Oil absorption capacity is desirable for preservation of aromas, to achieve improved palatability and increase the mean life of bakery products [22]; however, the chayote flour does not have good oil absorption capacity, which is a desired parameter considering current trends of low-fat foods. The values were lower than those reported by [23] for plantain flour dried at 100 °C with a value of 0.71 g and for oat flour at 0.78 g.

The flour’s foaming capacity is within the values introduced by [24], which found that for legume flours the foaming capacity was between 24% and 48%. The foam forming capacity depends on the amount of proteins present, on their structure, and on the relative ability of those proteins to denature, precipitate and diminish surface tension in the foam’s air-liquid interface; this indicates that a good amount of protein is needed to achieve foaming capacity. The reason flours are capable of producing foam is that proteins in flours have an active surface. Soluble proteins can reduce surface tension in the interphase between the air bubbles and the liquid surrounding them, thus, coalescence is obstructed. Additionally, the protein molecules can deploy and interact with each other to form a protein film or multilayer, with increased flexibility of the air-liquid interphase. As a result, it is more difficult for the bubbles to break and the foam is more stable [25].

The CE diminished when drying the flour through combined drying (HAD-MW), possibly due to greater denaturing of proteins, which is concordant with [25]. It is also observed that flour obtained via HAD has higher foaming capacity than that determined in legume flours [24], which makes it suitable for bakery use.

4. Conclusions

The drying method with the highest performance and efficiency was the el combined recirculating hot air drying-microwave (HAD-MW) and the temperature with the lowest loss of flour characteristics was 40 °C.

Chayote flour has physical properties of interest for the food industry, given its water and oil absorption index along with its foaming capacity.