1. Introduction

Service companies currently count on three tasks: competitive differentiation, quality of service and productivity [1,2]. The first refers to the tasks assumed by companies to be considered better than their competitors, attract more customers and obtain more sales. This differentiation is sought in different ways: quality, prices, innovation distribution channels or a mixture of them [3]. The quality of service lies in delivering, in a better way than competitors, a better product and service [4]. This new business situation, in which the service is the center of the activity needs to adapt new concepts and points of reference for orienting the characteristics of the service to the client's perception [5].

The current trend of management makes the companies to be inclined to customer satisfaction, as one of the most important goals of the organization [6]. Health institutions should not escape from this purpose, since in its simplest conception is patient's well-being their raison for being. According to Toledo Curbelo [7] health services systems in the world have very similar characteristics regardless of the area in which they are developed. It is said that there exist four different groups or patterns of organization of health systems:

1) Public assistance: services of poor quality and coverage with human resources featuring low preparedness (Asia, Africa and America).

2) Health insurance (Europe, Japan, North America, Chile).

3) Free enterprise system: a combination of these services, but private attention prevails (United States).

4) National Health Service: service for different economic bases (Cuba, England, Sweden).

Health services look for models allowing them to offer a quality product with efficiency and effectiveness. For this reason, the hospital improvement process is conceived to achieve service excellence: high quality, acceptable costs, and oriented to satisfying the clients’ needs [8]. In this context, the Cuban health sector features good results: 10.4 of gross birth rate, 9.5 of gross mortality rate and 4.0 of infant mortality rate (evaluated every 1,000 inhabitants). In addition to these indicators, Cuba also shows a life expectancy of 79.74 years and a high medical potential. The National Health System has: 110 intensive care rooms, 120 intensive municipal areas, 449 polyclinics, 111 dental clinics, 131 maternal homes, 12 research institutes, 690 medical libraries, 155 nursing homes, 293 grandparent homes, 52 geriatric services and 30 psycho-pedagogical medical centers [9].

Despite the encouraging results of the Cuban health system, it is necessary to focus on the improvement of health services, considering the international advances achieved in this sector [10,11]. In an exploratory study carried out in hospital services, some improvement opportunities in the medical service level were identified. The service is affected by a shortage of material resources and information, large-scale increase of inventory (financial capital immobilization), depreciation of the logistics infrastructure and inadequate preparation of the managerial support staff [12]. Disposable materials are not produced in large scale and high-tech equipment, which is quite expensive, is purchased abroad. Another important element is the insufficient collaboration among the elements of the supply chain in terms of resource planning in order to guarantee health care activities [13,14].

The previously described situation reveals the need to improve the management and logistical process in the Cuban hospital supply chain. From the concept point of view, it is necessary to focus on flows planning and control, and on the efficiency of goods replenishment. Also, it is important for the services quality, the timely related information, backwards and forwards, in order to satisfy the patients requirements [15]. Therefore, supply chain management plays a fundamental role since it represents the set of companies integrated efficiently through collaborative relationships in their key processes. The objective of this relationship is to place the inputs resources in each chain process, at the right time and at lowest cost; for seeking the greatest impact in the value chain members and satisfying the requirements of final consumers [16,17].

In correspondence with the above mentioned, the general objective of this research is analyzing the health supply chain in a Cuban territory. The present research has great significance because it allows discovering the problems affecting the full satisfaction of the client (patient), considering the availability of resources on time and at the lowest possible cost. It also permits a detailed analysis of logistic flows in order to improve the relationships between the supply chain actors, thus achieving better planning and execution of logistics activities.

This research was carried out for the first time on 2011 [13] and then the data was updated in correspondence with the 2018 situation. At international level, the analysis of the health sector has been an active research subject; in the management areas some of them focus in:

The allocation of medical staffs or patients scheduling to improve the service performance [18,19].

Optimal structure of hospital supplies, beds, surgeries or general care capacities, through the mathematical modeling in different scenarios [20-23]

Analyzes of the hospital logistics from the assistance centers characteristics, but mainly internal hospital supply chain [2,22].

The hospital supply chain sustainability is a basic approach from the economic, social and environmental points of view [24].

Others focus on particular elements, such as medicine management [25] or hospitals information systems [26].

2. Methodology

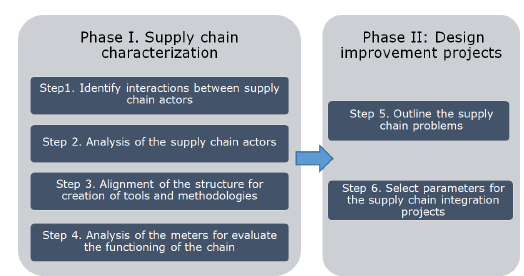

The methodology to be used is an approximation to that developed by Medina Azevedo [27]. It covers two phases: a supply chain characterization and an improvement project design. The Fig. 1 shows the six steps of the methodology.

Phase I. Supply chain characterization

The phase objective is identifying the market segment where to act and the characteristics of all supply chain actors. It is necessary to know the procedures and indicators that are measured, in order to determine the focus of the improvement actions. This phase is broken down into four steps.

Step 1 - Identify the interactions among actors

It is carried out with the purpose of focusing the services on the customer's needs by determining the market. It is based on the development of specific service packages for each client’s group, for guaranteeing the necessary resources to carry out the activities at the right moment. The techniques to be used to collect the information are interview and review of documents.

Step 2 - Analysis of the supply chain actors

In this stage a characterization of the supply chain actors is made, to know their particularities and distinctive features according to services levels, resources, technology and products, among others. It takes into account some of the following elements: mission or social object, service packages referring to each group of clients (in case they are different), raw material consumed, facilities and equipment used, third-party policies, available technology, product line (components) and services offered by the companies, logistical training of the human resources and production projects (integrated or modular).

Step 3 - Alignment of the structure for the creation of tools and methodologies.

First, it is necessary to define the scope of the analysis that will be carried out and the tools and methods that will be used. For this, a consultation is made to the actors of the supply chain to determine the available information and select the appropriate tool.

For the collection of information, depending on the type of questions, several scales can be used [3]. For the closed questions were used the dichotomous scale (the question presents two possible answers), the Likert scale (a statement to which the interviewee shows their degree of agreement or disagreement) [28] and multiple choice (the question presents three or more possible answers).

Once the checklist to be used has been defined, the diagnosis of the actors' logistic activities is made to detect the strengths and weaknesses in the supply chain. As second activity, the connections between material, information and financial flows are identified; and the main deficiencies are defined in order to analyze how they affect the implementation of activities.

Step 4 - Analysis of metrics

It aims to evaluate the functioning of the supply chain using indicators, which are defined and calculated in the logistic actors and in the hospital. These indicators measure and control the actors’ activities with the aim of improving them by reducing the margin of errors.

Phase II. Design of an improvement project

This phase intentions is to suggest possible solutions for the problems detected during the course of the previous phase.

Step 5 - Outline the supply chain problems

Subsequently, the existing problems in the supply chain are summarized taking into account the previous steps, mainly the step three and four.

Step 6 - Select parameters for the supply chain integration projects

In this stage it is necessary to consider all the results obtained in phase one, since these constitute the basis for developing new indicators for the interrelation improvement among the supply chain actors. The tools used are information research, document analysis and brainstorming.

3. Results

The results obtained in the general study of the hospital supply chain of the country, and the exemplification thereof in a territory, are presented below.

3.1. Phase I: hospital supply chain characterization

Currently in Cuba there are 210 hospitals, 506 polyclinics, 14 007 consulting rooms for family doctors, 156 elderly homes and 2 167 pharmacies, among other institutions [9]. Due to the diversity of health institutions, the characterization of the hospital supply chain in the territory of Matanzas focuses on a maternity hospital.

3.1.1. Step 1: Identify the interactions among actors

The market segments attended are women in fertile age, pregnant women, puerperal women and newborns. The services provided specifically depend on the pathology of the patient, considering the characteristics of the hospital, the service of delivery assisting was taken as a reference. This service has some specific resources needed as they are shown below: diagnosis means (X-rays, Clinical Laboratory, Bacteriological), medicines (anesthesia, serums, oxytocin), disinfectant substances (Lysol, Benzalkonium, Hydrogen peroxide), medical supplies (gloves, sutures, cotton, gauze, alcohol, speculum, neck clip, hemostatic forceps, needle holder, scissors, handle and scalpel blade, hand pump, forceps) and non-medical supplies (sterile clothes, electric power, stretcher, etc.).

3.1.2. Step 2 Analysis of the supply chain actors

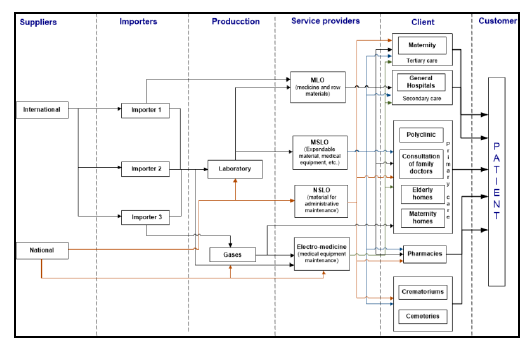

For warranting the service in this type of hospital a complete supply chain is deployed, some of the actors are common for other type of hospitals or health institutions. The main actors are shown in Fig. 2 and characterized below.

Source: The Authors.

Figure 2 Hospital supply chain in a Cuban territory, with a focus on tertiary care in maternity hospitals.

Pharmacies: the pharmaceutical service is responsible for supplying industrial and non-industrial drugs, reagents and other materials necessary for patients’ care. It promotes the adequate dispensation of its products preferably by Unit Dose, advising the medical staff on the adequate dosage of the medications, therapeutic alternatives, adverse reactions, and detection and reporting of possible drug interactions.

Import company: they are responsible for choosing and contacting the suppliers that provide the country with the raw materials and products necessary to meet the demand for medicines.

International supplier: they are several, but the main ones are China, India, Italy and Spain. These are the main import sources for raw materials such as packaging material, bulbs and chemical components and reagents. Likewise, some other stuff such as spare parts, technological equipment and some finished products come from abroad.

National supplier: national suppliers guarantee non-medical resources, such as textiles, medicinal plants, paper and others.

Laboratory: pharmaceutical laboratories ensure a large part of the table of basic medicines for health centers in the country. Laboratories produce pharmacological families and, in turn, work with serial production lines. The production of most of the groups is present in the laboratories of two regions of the country. However, some specific medications are produced in a single laboratory and must be distributed throughout the country.

In these laboratories, the stage of introduction to the market is also carried out, with the tasks related to the regulatory evaluation for the approval of a new medicine. In addition, they participate in the economic and scientific-technical analysis of the research of a new medicine jointly with research centers.

Industrial and Medical Gases of Cuba (Gases): This company belongs to the Industries Ministry and its mission is to meet the demands of customers in the quantity and quality required, since the products and services they provide are essential for production and human life. They supply to hospitals medicinal oxide, and also to other clients, carbon dioxide and nitrous oxide.

The required product is packaged in large bottles that are subjected to a hydrostatic pressure test to avoid any problem. The gases’ distribution is carried out daily in the company's own trucks.

Medicine Logistic Operator (MLO): these products are distributed by the logistic operator's subsidiary, present in all Cuban provinces. They prepare a plan, one year in advance, based on consumption studies to guarantee the necessary medicines for the population through health institutions. The MLO distributes more than 868 medicines, 283 of these one is imported and the rest are of national production [25]. The distribution is carried out in a fixed period of day for each health institution type and size (between 5 and 7 days) according to the request made to all health institutions in the province.

Medical Supplies Logistic Operator (MSLO): the second logistics operator belongs to the Public Health Ministry and its mission is to provide medical supplies to hospitals and others health units. Its corporate purpose is: “distribution, wholesale and retail sale of medical supplies”. It commercializes more than 3,000 products such as:

Expendable material (95% is imported): plastic syringes, gloves, cotton, tape, probes, injectors, gauze among others.

Instrumental: needles, glass syringes, 3-way keys, tweezers, cannula, speculum, etc.

Clinical Laboratory Glassware: test tubes, sheets, covers and holders.

Dental material (70% is imported).

Medical equipment is supplied by distribution plans depending on the activity level of each hospital.

Resources for optics; lenses, glasses, armor, crystals, etc.

Spare parts and accessories for electro-medicine workshops.

Both logistics operators provide distribution services to hospitals, polyclinics, stomatology clinics and pharmacies in the province. Then, each institution needs to receive, at least, two deliveries to complete the inventory.

Non-medical Supplies Logistic Operator (NSLO)

The third logistics operator is a wholesale and retail of non-medical resources that ensure the proper functioning of the health system in the territory. It guarantees the transportation of non-medical resources, the maintenance of the sanitary and administrative transportation means, as well as the constructive maintenance of the health facilities.

Electro-medicine: it is subordinated to the Provincial Health Directorate and its mission is to guarantee, in a sustained manner, the technical services to medical equipment, spare parts and medical instruments. This allows the vitality of existing health units in the territory with optimal control and use of the available resources. It is in charge of the following:

Provide technical electro medical services free of charge to the units of the National Health System and charge other clients.

Discriminate on the technical status and quality of the electro medical equipment purchased by the units of the National Health System.

Provide repair service of medical equipment and supplies to third parties.

3.1.3. Step 3 Alignment of the selection structure for creation of tools and methodologies

To evaluate the supply chain of Matanzas Maternity Hospital, a simple checklist was developed as the information related to the logistics activities in this sector is not abundant. This checklist is made up of several references of good logistical practices [29-34] and consists of seven elements and 50 questions. From the application of the checklist to eight actors in the supply chain, a logistics diagnosis of the supply chain of the maternity hospital in a territory has been obtained.

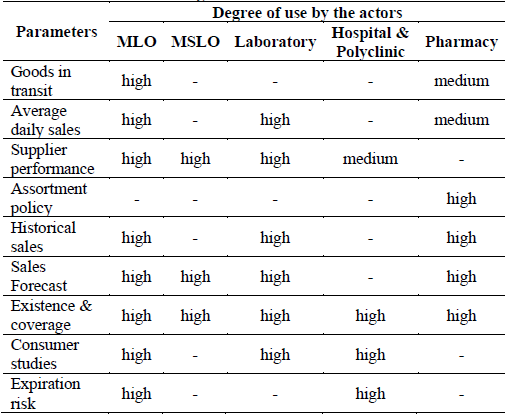

Demand: All the analyzed actors affirmed that the demand is generated according to the needs. The three logistics operators (MLO, MSLO and NSLO) are suppliers upstream and distributors downstream in the supply chain, so one of their functions is to manage the demand of national and international resources. For this they have a group of workers in charge of the forecasts and carry out studies on the variation of consumption and demand. In the case of Operator MLO, it was definitive that these needs are determined through reconciled plans that use a large amount of data and information for their preparation. The rest of the entities only carry out this study in relation to national products, although not all of them have the appropriate personnel, as in the case of pharmacy, hospital and electro medicine. Table 1 shows the different parameters that some actors use for the estimation process.

The study reveals that 60% of the entities take high-value sales statistics to manage the demand, with the exception of MSLO that does not consider it necessary at all, and the Hospital that does not use any historical data.

The performance of the supplier's delivery period is used by 70% of the actors, but in a wide variability prevails in terms of use; MLO, MSLP and Industry consider that this parameter has a high use value, the Hospital and the Polyclinic give an average value and the Pharmacy grants a low value. The terms existence and coverage on the unit, are highly used by all actors.

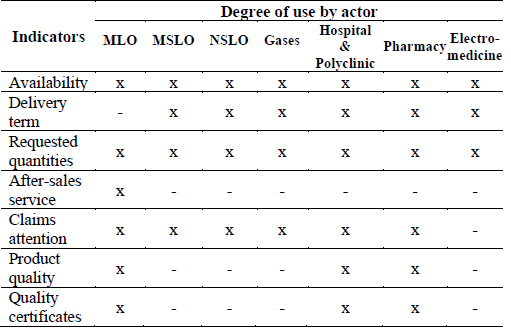

Suppliers: Regarding the selection and evaluation of suppliers, the actors have a well-defined portfolio that streamlines this process. The values vary from 3 to 5, which means that it is good to excellent; although, not all actors have the same level of requirements or are not used with the same systematism. The most commonly used indicators to evaluate the suppliers are product availability and quantity requested/dispatched (100%) and attention to the claims (86 %); as shown and highlighted in gray in Table 2.

The Medicine Logistic Operator (MLO), the Hospital and Polyclinic and the Pharmacy, evaluate 86% of the defined indicators. The logistics operators of medical and non-medical supplies and Gases take into account 57% of the indicators and the Electro-medicine only 43%.

Purchases: Sixty three percent of companies consider urgent requests and requests for unexpected needs, even though they do not assign them the same importance. The actors having more problems are Gases and the Polyclinic, since they consider that these unexpected or urgent needs have a great influence on purchase. Considering the frequency of urgent requests and unexpected orders and considering that all the entities declared that their purchases are governed by a previously established plan, it can be perceived that planning is not being carried out correctly. This situation directly affects the patient, since the actors who constantly issue urgent orders, due to the lack of products, are the hospital and the polyclinic.

MLO and MSLO agree that the purchase request can be considered, in some very specific cases, to generate the purchase, which would mean that planning was not carried out correctly. The Hospital and the Polyclinic recognize it with an average value, and Electro-medicine considers it as one of the most influential aspects in the purchase. The most used routes to place orders with suppliers are personal visits, telephone calls and, in some cases, written communications.

Most entities consider the inventory behavior to purchase, except NSLO, which ratifies the poor planning of this actor. In general, of all the activities of the purchasing processes, the most important are the purchasing plan and the inventory behavior, which are used by 87.5% of the entities.

Storage: Of the logistics entities analyzed, only MLO counts on adequately qualified personnel to carry out the work assigned to the warehouse, as well as the administration and reception. Regarding storage specifications, such as the storage limit and the use of height, only MSLO, NSLO and Gases comply with both restrictions. Electro-medicine and MLO have deficiencies in the use of height, even though the second has the necessary equipment to maintain the climatic conditions to preserve the quality of the medicines (refrigerated chambers, refrigerators, and temperature and humidity meters).

The Hospital and the Polyclinic do not have handling equipment to facilitate the reception of the product. In addition, the physical conditions of the Hospital warehouse are completely unfavorable. Many of the products deteriorate due to the lack of air conditioning and the absence of shelves to place the materials separated from the floor and, therefore, to avoid damage due to humidity.

In MLO, 60% of the inventory is replenished daily and in Gases 10%, in MSLO and the Polyclinic is replenished 10% every 15 days and, in the rest, the replenishment is every 30 days as an average: NSLO in 60%, Hospital in 10%, Electro-medicine in 10% and Pharmacy in 60%. From this behavior, it seems that the best actors in terms of inventory rotation time are MLO and Gases.

Gases, the Hospital, the Polyclinic and the Pharmacy inspect the lot received considering four indicators: quality, quantity, timely arrival and expiration date. The three logistics operators do not account at least one parameter and Electro-medicine only verifies receiving the proper amount.

Distribution: One of the fundamental activities to analyze on distribution is the transportation process. The 75% of the actors that provide some type of logistics services do not have specific transportation means matching the characteristics of the goods to be moved. Most of the goods to be transported are packed in corrugated boxes, and the existing vehicles do not guarantee the adequate conditions of the stocks. Only MLO has adequate vehicles dedicated to the transport of medicines.

The gas distribution cycle and MLO is the shortest time to supply the product to health entities (five to seven days), while MDSLO and NSLO are distributed every 28 days. The health entities (Hospital and Polyclinic) are not considered as distributors, since once the product is received in the warehouse, the doctors take out the materials as they need them, they have not established a certain time. In the case of Electro-medicine, it depends on the breakages reported, if there is no rupture and the equipment have no scheduled maintenance, the materials remain in the warehouse.

Customer service: In general, all entities present problems in the performance of logistics functions due to the lack of specialized personnel, with the exception of MLO which has some qualified personnel in the matter (around 83%). The actors that offer opportunities for promotion and professional improvement in logistics activities for workers are MLO, MSLO and Gases; they have a logistics training program.

Every member of the supply chain considers that it satisfies the customer taking into account the treatment, quality and quantity of the product or service demanded, and the responses to the customer's complaints. The most critical parameters for MSLO are the product and service quality. For the Hospital, the Polyclinic and the Electro-medicine the most important thing is the quality and quantity of the product. In the case of the pharmacy, its greatest difficulty lies on dealing with customer complaints. As for the rest of the parameters, the entities consider that they can guarantee them with a performance ranging between good and very good.

Information ways most commonly used by members of the supply chain are personal visits and telephone calls. The actors affirm that the first route generates a waste of time and transportation costs but allows better negotiation with the supplier regarding the delivery terms. MLO is the best company in terms of media use, since it is the only company in the supply chain that has access to the Internet and connection in real time with all its branches. Entities with greater communication difficulties are Gases and the Polyclinic; the first one uses email and the second convey all the information in the documents.

Environment: With regard to the care and protection of the environment, it can be said that none of the entities in the supply chain establishes a clear policy in this regard. In organizations, workers are not encouraged to participate in cleaning activities and to improve the environment hosting their entities.

4. Discussion

4.1. Step 4: Analysis of metrics

It shows the main indicators that are measured in the hospital and the degree of correspondence they have with the logistic activity of the entity: Occupational index, Actual beds Average, Average stay, Rotation rate, Infant mortality rate, Maternal mortality rate, Net mortality, Low birth weight index, Number of surgical operations, Number of researchers, Cost per department and Idle products.

Among the logistic entities, MLO constitutes the example to follow because it defines a series of indicators based on the proposed objectives to constantly improve the efficiency of its processes. The rest of the logistic entities present serious problems since they do not establish any indicator allowing them to control the resources. They only control the indicators of traditional economic performance, which confirms the lack of homogeneity and integration among the actors integrating the chain.

Phase II. Design of an improvement project

4.2. Step 5: Outline the hospital supply chain problems

Based on the results of the checklist and the interviews conducted, the main problems and the strengths and weaknesses of the supply chain are identified.

Main problems

Poor resource planning based on the hospital and polyclinic care activity, since they do not have the adequate personnel to carry out the necessary studies of the demand.

Lack of equipment in health entities and the few that exist are in unfavorable conditions.

Inadequate physical conditions of the warehouses (little space, bad floor) and insufficient management means, such as forklifts and pallet trucks.

There is no uniformity or proper treatment to the packaging of the goods.

Delays in the replacement and distribution cycle due to problems with trucks and vans (Breakage, lack of spare parts, fuel shortage).

Deficit of indicators to measure the effectiveness of logistic processes.

The allocated budget does not correspond to the actual planning of what is consumed from the warehouse.

Strengths: Every actor performs periodic checks to verify the quantity and conditions of the stocks.

Weakness

The information is not managed in an integrated manner by the supply chain actors and its digitalization is very deficient.

The transport means do not meet the necessary requirements to move the product in optimal conditions.

There is no strategic mechanism that links actors in the supply chain, which fundamentally affects the planning process and the rest of the activities derived from it.

In general, logistics staff does not have the knowledge and skills necessary to perform their tasks.

4.3. Step 6: Select parameters for the supply chain integration projects

Constantly companies must examine their operation to improve those areas that may present some type of conflict. From the point of view of the supply chain, the logistical evaluation has been extended to all the companies that integrate it. In this sense, the improvement in a supply chain must guarantee the sustainable and continuous growth, not only of a company, but of the entire supply chain.

In the study of the supply chain the main parameter to work is the integration around logistics activities. To contribute to this purpose and solve some of the problems detected in this research, several projects are proposed:

Establish a joint (collaborative) planning mechanism among the actors of the hospital supply chain.

Develop and implement a training plan for the staff performing logistic functions, as well as a basic orientation for the rest of the participants in the chain.

Create a working group of the supply chain constituted by a representation of the medical assistance personnel and the logistics sector in order to meet the needs of clients.

Design a joint investment and maintenance plan for the supply chain.

Develop a research project with the School of Computing Sciences of Matanzas University for the development of an integrated information system using the existing software and the necessary development.

In this context, other research focused on the health sector has been developed. For example, the case of the analysis of the management level of the drug value network in the Cuban health system [25]. This is based on the analysis of a part of the health sector, engaged in studying drug supplies specifically. Other studies focused on the diagnosis and design of medication logistics operators in healthcare centers and community pharmacies for their traceability. On the other hand, procedures and models are developed for the planning of medicines, materials, and process management in the hospital sector [35]. Unlike these, this scientific research was based on a holistic analysis of a hospital supply chain in a Cuban territory. Where the study of logistics-related stakeholders, their strengths and weaknesses for hospital decision-making converge. The limitation of this is framed in the possibility of calculating the logistics costs of the operations in the object of study.

5. Conclusions

An adaptation of a methodology for the analysis of supply chains was carried out and a checklist was developed to evaluate logistics management based on some of the best national and international practices. This combination was made considering the simplicity of the evaluation because the logistics information available in the sector is very scarce. A basic diagnosis of the logistics in the hospital supply chain of a Cuban territory was made, which allowed corroborating the little attention to this type of activities in the Cuban health sector. The personnel in charge of the logistics activity, in the majority of the participating actors, lack the adequate training and education.

The weaknesses and strengths of the supply chain were identified. Among the main weaknesses are poor joint planning, the insufficiency of adequate means of transport and the limited use of technologies for the information registration and transmission. Five projects were defined to improve the interrelation, especially logistics, among the actors in the supply chain. The collaborative planning strategy, the integrated information system and a logistics training program are those that have the greatest impact. This study demonstrates how the application of the supply chain approaches to hospitals, can contribute to improve the service level to the patients.