1. Introduction

Colombia is country rich in natural resources due to its geographical and climatic conditions, which is why the fruit sector presents a great development opportunity due to the special conditions for fruit harvesting. Colombian fruits have a better quality compared to those grown in other countries, given its organoleptic characteristics mainly in matters concerning color, flavor, aroma and higher content of soluble solids. Most of the production comes from trees dispersed in small plots of land or homemade orchards worked by hand. In these orchards, a mixture of several species can be found, with the fruit tree of the region generally predominating [1].

According to Agricultural Evaluations (EVAs) from the Ministry of Agriculture and Rural Development, among the production lines with the highest yield in fruit production are banana (39%), citrus (12%), pineapple (9%), avocado (5%), tomato (4%), mango (3%) and passion flower plants such as badea, cholupa, curuba, granadilla, gulupa and passion fruit (2%). The departments with the largest planting area are Antioquia (11%), Santander (10%), Meta (8%), Arauca (7%) and Cundinamarca (6%) [2].

The development of the activities of the food fruit industry results in the generation of waste that is produced in different quantities and different compositions. This may or may not be hazardous waste, but it necessarily requires proper management. At this time, industrial development generates a large amount of waste, which demands new techniques or methods of use. In the different food production processes, in addition to the finished product and by-products, the resulting waste calls for plans with high reuse costs and for this reason, it ends up in landfills. Due to this problem, Law 99 of 1993 and 142 of 1994 were created for the Integral Management of Solid Waste in Colombia [3-5].

According to data from the National Planning Department (DNP), in the country, 9.76 million tons of food are lost and wasted annually, equivalent to 34% of total production. The greatest losses are registered in the fruit and vegetable chains (62%). The main stage of losses comes about in the production stage with 40.5% (3.95 million tons), followed by 19.8% (1.93 million tons) lost in the process of postharvest and storage, and 3.5% (342 thousand tons) in the industrial processing phase [6].

Therefore, it is necessary that actions aimed at achieving sustainability do not focus solely on production and distribution, but that these efforts also focus on analyzing consumption patterns to minimize fruit loss and waste [7]. According to studies carried out by the United Nations Organization for Agriculture (FAO), five frontiers of the system are distinguished in the supply chain, of which the following aspects are considered as generators of losses and waste:

• Primary production

Due to variation and risks in agriculture, it is often difficult to accurately predict supply and demand. Similarly, a certain degree of mechanical damage and/or spillage takes place during harvesting as a result of deterioration caused by diseases, pests, environmental or climatic conditions. Therefore, fruit growers are compelled to planting in a greater proportion to the amount demanded by the market to protect themselves from those adversities and their consequences; fruit losses have a direct impact on the income of small fruit producers since they live on the fringes of food insecurity; 12% of Colombian households are farm workers with 65% of them living in poverty conditions and 33% in extreme poverty. In addition, it is common to find levels of informality in the legal tenure of their properties and they also have limited access to credit and technologies. At the same time, the indigenous and Afro-Colombian peoples that make a living from agriculture are among the most marginalized in the country due to the armed conflict, forced displacement, and land dispossession. As a result, all these situations bring about an important reduction in the availability of planting fields, basic services, infrastructure, quality education and health, among others. In a different scenario, these fruit losses are also caused by the volatility of market prices because if they are very low at harvest time, farmers may not offset the production costs and are forced to leaving the fruits in the field to rot. In addition, fruits oftentimes do not meet the minimum quality standards in terms of size, shape, color, and ripening stage [8,9].

• Postharvest handling and storage

Not all the problems are due to the lack of adequate storage facilities or deficiencies in the various links that make up the cold chain and transport. Losses in this phase are mainly caused by spills and / or deterioration during handling in commercial quality controls demanding, certain standards such as color, weight, defect-free condition and their nutritional content [10].

• Processing

Different fruit transformation processes also generate certain losses due to spills and/or deterioration during the different stages of washing, peeling, chopping (separation of the edible and inedible parts of the fruit), and cooking both at an industrial and domestic level. On the other hand, losses occur when fruits deteriorate, either because the packaging is not adapted to the needs of consumers or because of accidental packaging damage during the process.

• Distribution

In this link of the chain, losses are produced by poor handling in the transport of food because the cold chain is broken. In addition, waste and losses are caused by consumption deadlines and mishandling on the part of the consumer in the retail and wholesale markets or by changes in consumer preferences [11].

• Consumption

Current consumption habits and the negative attitude in some regions of Colombia have resulted in a considerable increase in fruit waste. In households, poor consumption habits and poor management of fruit-based foods, together with their ways of preserving, cooking and handling lead to significant amounts of food waste, which could have been avoided. Likewise, another cause of this waste in households is the lack of understanding of the information on the label in relation to the preservation and expiration of food. In the catering sector, there is also a very marked waste, both in the preparation, handling, and cooking of food in kitchens, as well as the waste made by customers [12].

Packaging in the fruit industry plays a fundamental role in the safety, conservation, protection, quality, and useful life of fruits from the moment they are produced to their consumption. In addition, the label on the package is the main means to communicate relevant information on the nutritional value, ingredients, and storage conditions of the product to consumers. However, despite its tremendous importance, packaging generates a multitude of waste, causing a negative environmental impact depending on the composition of the package. The agro-food industry in recent years has invested its efforts in improving the management of packaging waste by reducing its impact as much as possible and guaranteeing the safety and quality of food. In 2017, The National Administrative Department of Statistics (DANE) registered that in Colombia, the production of plastic bags and packaging exceeded 60,000 tons compared to the previous year, concluding that supermarkets promote the unnecessary and excessive use of plastics. Therefore, the Office of the Attorney General of the Nation imposed a national tax (Law 1973 of 2019) that has obligations in the packaging, labeling, and generation of products, seeking the protection of public health. This concern is due to the fact that packaging involves the use of multiple chemicals in packaging materials such as additives, stabilizers, plasticizers or antioxidants and many of these substances can cause food contamination, which puts human health at risk by damaging the endocrine system, affecting brain development, as well as producing cancer and congenital malformations [13-15].

1.1 Theoretical framework

Next, a synthesis of the main bibliographical studies that allowed identifying the importance of the circular economy model and the process of making bioplastic from fruit residues or similar products is presented below for its study and implementation in the research that was carried out.

1.1.1 Circular Economy

It is a new model that encourages decoupling global development from the consumption of finite resources. This economy represents a drastic change in the different current systems of production and consumption and focuses on regenerative and restorative systems that maintain or generate value to products or natural resources by limiting the considerable use of inputs, raw materials and energy. On the other hand, this model avoids the creation of waste that causes negative impacts on the environment and health. The notion of the circular economy is not a new concept since in the 70´s great schools of thought related to this posture arose, which were not well known until the 90´s. For information purposes, Robert Frosch and Nicholas Gallopolous stand out for identifying the beginning of industrial ecology in "Strategies for Manufacturing" (1989), where they made comparisons of biological ecosystems with industrial ecosystems. In the same way, ideas of biological analogy in their various degrees and styles have been examined in different ways, among which are the "four laws of ecology" written by Commoner (1971); The closing and deceleration of loops by Stahel and Reday Mulvey (1981); Industrial and socioeconomic metabolism of Ayres (1994); Biomimicry by Janine Benyus in “Biomimicry: Innovation inspired by nature” (1997); Natural Capitalism by Paul Hawken Amory Lovins and Hunter Lovins in "Natural Capitalism: Creating the Next Industrial Revolution" (1999); "Cradle to Cradle (Cradle to Cradle)" by McDonough and Braungart (2002) and Blue Economy by Gunter Pauli (2010). In circular economy, consumption occurs in closed cycles of effective biological loops, it uses substitute product consumption, and is based on the three key principles: 1. Preserve nature and balance through regenerating, dematerializing, and sharing the flow of renewable resources; 2. Apply circularization, increase usage, and 3. Promote efficiency in order to eliminate negative effects. This economy brings remarkable benefits that positively impact society in general. According to the foregoing, the economic, social, and environmental opportunities generated by the aforementioned principles focus on generating greater economic growth, increasing employment opportunities, saving costs in raw materials, guaranteeing lower carbon dioxide emissions, preservation of soils, productivity, the better quality of life of the actors involved, reduced obsolescence, among others [16-27].

1.1.2 Bioplastics

According to European Bioplastics, a bioplastic is considered a bio-based plastic material (material or product derived from biomass), biodegradable (chemical process in which materials with the help of external agents degrade under defined conditions and time) or having both properties. These bioplastics provide benefits by reducing dependence on fossil resources, minimizing greenhouse gas and carbon dioxide emissions, diverting bio-waste from landfills, and achieving efficient waste management. In the Colombian Journal of agroindustrial research, Javier López, Julio Cuarán, Laura Arenas, and Luz Flórez propose the production of bioplastic based on the starch present in banana peels. Three tests were carried out eliminating the contaminants present in the residues by means of washing the peel with hot water, dehydrating, it for a week, and crushing it until turning it into powder. Next step, it was dissolved with 500ml of distilled water, until it reached the boiling point. Then it was liquefied until a mass was generated being dispersed and left to dry. On the other hand, there is the article “Bioplastic made from banana peel” from the Journal of Undergraduale Research, whose authors are Ruth Castillo, Eliasury Escobar, Dianeth Fernandez, Ramon Gutierrez, Jonathan Morcillo, Neryana Núñez and Sandra Peñaloza. They developed a research project to obtain a bioplastic based on starch extracted from banana peels, which are considered fruit residues, to be used as a raw material in the production of this bioplastic. The extraction took place through dehydration and by grinding the peel strips until obtaining a kind of powder, which is immersed in citrus juices, water, vinegar, and glycerin. The mixture is cooked until it becomes thick, then the homogeneous mixture is dispersed on a surface and left to dry [28-30].

2. Method

This research article was developed under the interpretive paradigm and the qualitative approach, with a descriptive literature review type methodology from secondary sources. For this purpose, three phases were constituted: an initial exploratory phase in which the structural characterization of the existing cases of circular agriculture was carried out applying the triangulation of multiple cases from the review and analysis of secondary sources; The second phase consisted of the analysis and validation of the causes associated with the low recovery of fruit residues outlined in an Ishikawa diagram (or cause-effect) type 6M, where the causes are extracted and prioritized through the application of the Vester Matrix. Then, a semi-structured interview is carried out aimed at the actors involved in the production and storage processes in the fruit sector, for which the sample is defined through probabilistic methods. The third phase consisted of a structural design for packaging manufacturing using the circular economy model, based on the solution of the different problems raised above, generating value for fruit residues under the Mares value chain [31-33].

3. Results

3.1 Phase 1. Characterization of the circular economy

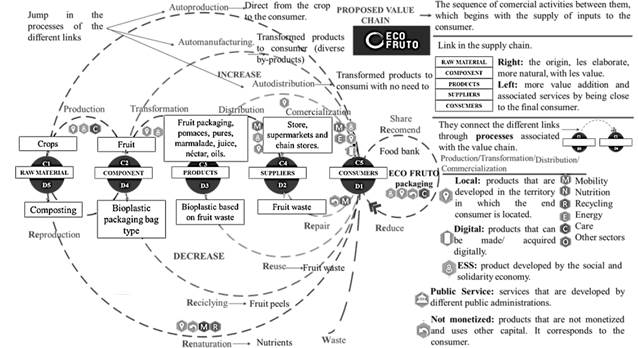

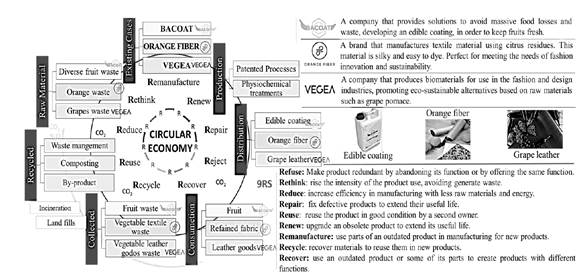

This study addressed the characterization of cases of circular economy in agriculture where companies have been formed that apply the circular economy model to their production and distribution processes, as seen in Fig. 1.

Source: The authors.

Figure 1 Triangular characterization of companies that apply the circular economy model in agriculture

The objective of the triangulation methodology is to identify the behavior of the cases, taking into account their structure, processes and bases defined in 9r.

3.1.1 Definition of the variables to be evaluated along the value chain

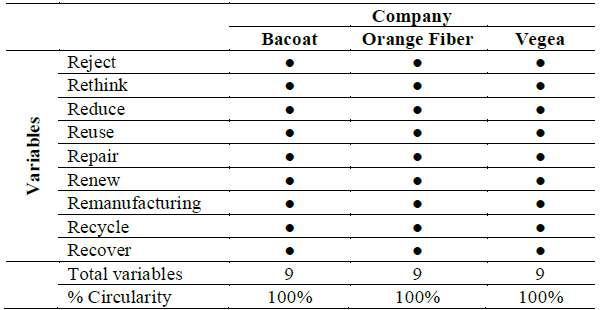

In this process, the variables established must be evaluated in relation to the 9R strategies, which allow the increase of circularity with respect to the characterization carried out previously, as seen in Table 1.

Following the methodology of multiple cases, we proceeded to make a comparative analysis of each of the models based on the results we made decisions for the construction of the proposed model, as seen in Table 2.

3.2 Phase 2. Diagnosis of the causes associated with the low recovery of fruit residues.

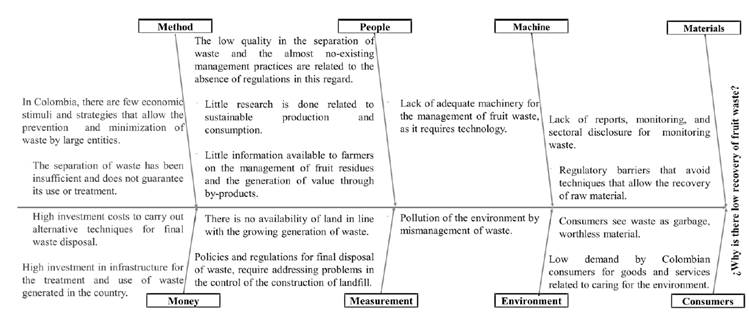

This diagram was made with respect to secondary information sources and their relationship with the 6M and 3 relevant, as seen in Fig. 2.

The relevant aspects of the causes mentioned in the Fig. 2 are specified below:

Source: The authors.

Figure 2 Ishikawa type 6M and 3 stratified diagrams of the causes of the low-value recovery of fruit waste.

3.2.1 Raw material

Lack of reports, monitoring, and sectoral disclosure for monitoring waste. The National Administrative Department of Statistics (DANE) proposed in 2018 to create an environmental and economic waste account used as an official information tool that allows better decision-making in the manufacture of by-products because the data currently available are erroneous or scattered [34].

3.2.2 Machinery

Currently, there is no specialized machinery in the management of fruit waste. For this reason, traditional strategies are implemented in conventional by-products.

3.2.3 Workforce

The low quality in the separation of waste and the almost non-existing practices for its management are related by the absence of regulations in this regard. This situation has delayed the general development of alternative strategies where activities, schedules, and frequencies are stipulated in order for the population to deliver their waste separately. On the other hand, there are few investigations related to sustainable production and consumption, which point out the proper management of waste and its potential use and treatment.

3.2.4 Method

In Colombia there are few economic stimuli and strategies fostering the prevention and minimization of waste contributing to its treatment and subsequent use. This is the reason why a major portion of waste ends its cycle in sanitary landfills. If this situation persists, it can cause irreversibly damage environmental conditions because these places do not have the necessary infrastructure to dispose of all the waste. Not guaranteeing the separation, treatment, and use of waste become a problem related to education in waste management. Consequently, when a correct process is not carried out, the closest materials become contaminated and it is more expensive to submit them to exploitation mechanisms, resulting in the loss of energy potential by not being able to dispose of these wastes as raw material.

3.2.5 Monetary

In this aspect, the high investment costs to carry out alternative techniques of final waste disposal are highlighted. According to the study of the National Planning Department (DNP) and the World Bank, which have carried out financial evaluations of the different treatment techniques, final disposal or use of waste through the generation of energy, recycling, mechanical treatment, sanitary landfills and composting under real conditions of use of waste, it was found that the costs of these recovery activities are higher than the income obtained from their commercialization.

3.2.6 Environment

It is important to emphasize the pollution of the environment due to the mismanagement of waste. The way organic matter is decomposed in sanitary landfills, produces a mixture of gases composed mainly of carbon dioxide, methane, water vapor, and hydrogen, which are considered greenhouse gases. This organic matter occupies most of the capacity of the sanitary landfills where energy and nutrients are lost through the soils. It is then necessary to propose strategies that increase the use of waste.

3.2.7 Measure

There is no availability of land in line with the growing generation of waste. According to calculations made in the National Policy to Consolidate the System of Cities in Colombia COMPES 3819, by 2030 about 14.2 million tons of waste per year will be generated from rural and urban areas that may not be received since there is no installed capacity to process such increase. In other words, if there is no land for new infrastructures aimed at the use, treatment and final disposal of waste, there will not be enough space in the current sanitary landfills to handle the amount of waste and this deficit will be greater in the cities. Policies and regulations are required for the final disposal of waste, addressing the issues regarding control and execution of sanitary landfills. In Colombia, various policies are being put in the place for the closure of open dumps and exerting pollution control, but without achieving the expected progress or results. The situation is critical because among some of the problems to be solved, it has been found that 38% of the final waste disposal sites have environmental licenses for less than three years, according to the Superintendence of Home Public Services.

3.2.8 Consumer

Consumers in large cities in the country see waste as worthless material. For this reason, there is a need for an integrated solid waste management plan that brings awareness and benefits to all the actors in the process of managing waste. Studies in this sense conclude that the organic waste generated in the different stages of production, post-harvest, storage, and processing amounts to about 64% of tons of food and 36% in distribution and marketing. Similarly, there is a low demand for goods and services related to the care for the environment by the regular Colombian consumer because the sectors involved do not carry out the respective analysis of the life cycle of the products due to the limited handling of information and lack of incentives that can generate a cultural change [35].

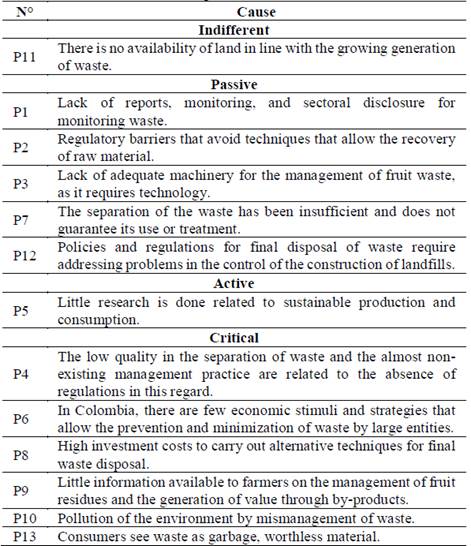

3.3 Vester matrix

Through the application of the following analysis matrix, each cause is related to its level of incidence. 13 important causes are identified that include deficiencies in the recovery of the value of fruit residues, highlighting the different general aspects as seen in Table 3. These causes were classified with respect to the percentages presented below: 7% indifferent, 31% passive, 8% active and 54% critical.

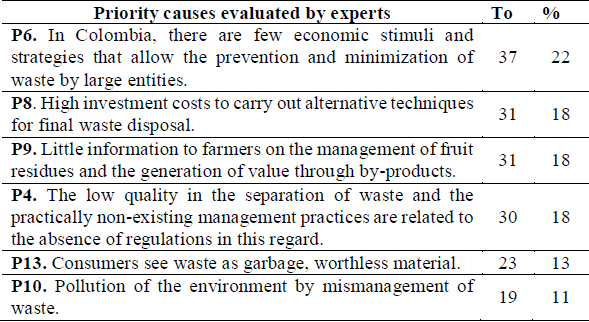

3.4 Primary sources

With the results obtained previously, a validation of the critical causes is carried out through a semi-structured interview directed to experts with the aim of ratifying the identified causes for their analysis of the qualitative data through the Atlas program Ti, as seen in Table 4. This is a program developed by Thomas Muh to segment data into units of meaning.

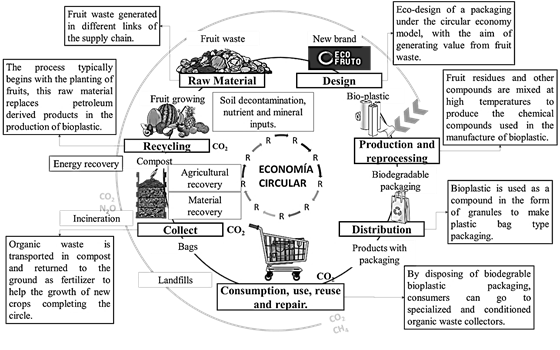

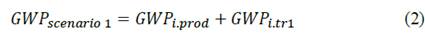

3.5 Circular economy proposal

The manufacture of packaging is exposed below where its main raw material is the fruit waste generated throughout the supply chain, applying the circular model in its production processes, as seen in Fig. 3.

The generation of value to fruit residues was then established through the proposed structure, the different strategies considered relevant in the exploratory phase were evaluated focused on the solution of the aforementioned causes, as seen in Fig. 4.

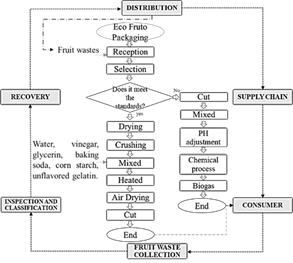

3.5 Logistics for fruit waste processing

A major axis of the circular economy is reverse logistics. The reverse logistics process may be defined as a supply chain that is redesigned to efficiently manage the flow of products destined for reprocessing, reuse, recycling or destruction, using all its resources correctly, as seen in Fig. 5.

Next, the economic, environmental, and social benefits that the implementation of the packaging production proposal would have under the circular economy model are presented:

3.6 Economic benefits

3.6.1 Higher economic growth

This would be the result of the combination of income from activities driven by the circular economy model proposed by the researchers and the reduction of manufacturing costs due to the more productive use of inputs (fruit wastes), accelerating the growth of the sustainable packaging market in Colombia.

3.6.2 Growth of employment opportunities

Employment is a positive effect of the circular economy due to lower prices and increased labor intensity on activities involved in fruit waste management, remanufacturing and sustainable innovative entrepreneurship.

3.7 Environmental benefits

3.7.1 Lower greenhouse gas emissions

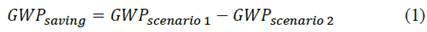

Under the proposal, greenhouse gas emissions could be reduced by a quarter. This is because waste does not end up in landfills; on the contrary, it is about taking advantage of it to a great extent by manufacturing not only packaging but also producing biogas. Next, a global warming potential algorithm is presented in order to follow up on the proposal and evaluate the different strategies.

3.7.2 Global warming potential (GWP)

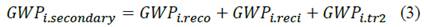

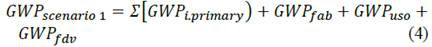

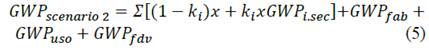

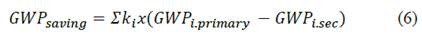

Global warming potential algorithm for the proposal to manufacture packaging based on fruit residues under the circular economy model, eq. (1)-(6).

Where:

GWPi.secondary= GWP for the production of the amount of material i required, assuming 100% virgin material.

GWPi.prod = GWP for the production of the amount of material i required, assuming 100% virgin material.

GWPi.tr1= GWP to transport the amount of material i required, from its place of production

GWPi.secunda= GWP for the amount of material i required for manufacturing, assuming 100% secondary material.

GWPi.reco= GWP for the selection of waste equivalent to the amount of material i required, for the manufacture of the product.GWPi.reci = GWP for recycling the amount of material i required.

〖GWP〗_(i.tr2)= GWP For the transport of the amount of secondary material i required, from the recycling facility.

For the entire product, we have:

Which leads us to:

3.7.3 Lower consumption of raw materials

Materials used throughout the supply chain for fruit waste management such as fertilizers, pesticides, agricultural use of water, soil, fuel and non-renewable electricity could be reduced.

3.8 Social benefits

4. Discussion

The bioplastics industry is gaining momentum. It is estimated that the industry of these bio-based plastics currently represents 0.2% of the 350 million tons that are consumed each year in the world, but that volume can be mitigated, thanks to the growing demand for ecological packaging and other products that use biomass as raw material. Therefore, the circular economy model focused on the production of packaging based on fruit residues allows to fulfill the offer and achieve benefits by mitigating the negative effects mentioned throughout this article. The final result is then proposing a model that contained the studied variables and functions of triangulation, aiming at a solution focused on costs and the reduction of the carbon footprint.

5. Conclusions

According to the review of secondary sources, it was identified that there is no proposal to manufacture packaging in Colombia, where its raw material consists of fruit waste and its processes are presented under a circular economy model.

Through the case study tools, the characterization of 3 companies related to fruit residues that promote their processes under the circular economy model in the manufacture of products through the triangulation methodology was carried out. The study companies were Bacoat, Orange Fiber, and Vegea, which were selected according to a qualitative 9R evaluation proposed by the researcher. On the basis of this, the circular economy model of each of the companies was outlined since it did not exist.

The main causes that produce low recovery of fruit residues throughout the supply chain were identified through secondary sources of information. Due to their impact, the following main reasons stand out: the country does not provide economic incentives or strategies that allow waste to be minimized, investment costs to carry out alternative techniques for the final disposal of waste are high, there is little research related to processes and sustainable consumption, and finally there is not a well-established culture of correct waste management by consumers. In the same way, the previous causes were prioritized.

The methodology used was successful since it allowed structuring a circular economy model that provides a solution to the causes associated with the low recovery of fruit residues. In addition, the fact of having obtained a sustainable product allows ratifying the qualitative variables evaluated in relation to the 9Rs. This allows us to achieve expected results, and provide economic, social, and environmental benefits. The fact of structuring the proposal related to waste management allowed the reduction of costs and increase of strategies in favor of direct and indirect actors intervening in the supply chain of the fruit sector.

The structural proposal of the manufacture of packaging allows for the entrance into new potential markets and to identify variables and parameters that allow the undertaking of sustainable businesses; therefore, it is important to involve actors in new economic models that allow growth in the country.

For the structure of the model to be carried out correctly, it is important to propose new economic and social policies with greater access to education that make it possible to make visible the current problems that arise from the low recovery of fruit residues by managing to address new societies focusing their efforts on the circular economy. Thus, it is important to influence society towards the changing of habits, preferences, needs, with the aim of attaining a greater consumer awareness.

The circular economy proposal presented above goes beyond a simple management of fruit waste. It is an effort to implement and facilitate the creation of strategies that are capable of creating a new closed industrial system based on the use of renewable energy. Only then, all resources involved in this process will become the nutrients adding value to Colombian specialty crops.