1. Introduction

Piles molded in situ are often designed to resist high design loads. The usual practice of dimensioning these loads varies in each case, taking the type of pile, soil, work, quality of the foundation's executor because all these design conditions directly interfere in the ultimate load capacity of the foundation elements. Currently, for quality control and performance, the verification of this capacity consists of estimates by set and rebound (dynamic formulas), Static Load Testing (SLT), and Dynamic Load Tests (DLT). The technical literature has already numerous articles and documents that compare and verify indirect correlations between both tests (SLT and DLT). However, these comparisons are based on the practical common of performing only one CAPWAP analysis per dynamic test performed. When comparing the DLT and the SLT, it is possible to verify a better fit between the tests when performing CAPWAP analyzes for all blows of the same test (and not just one). This method estimates with great precision, through the SLT/DLT, the rupture load of the foundation element.

The determination of a more realistic rupture load through the Dynamic Loading Test may contribute a great dynamism and good use of these tests, it happens when execution between DLT and SLT is 5 to 1, according to Foundation Brazilian standard [1].

This paper presents correlations between static and dynamic loading tests for three “in situ" molded piles widely used in Brazil, to optimize the criteria for obtaining the load failure of the pile. Four real cases were analyzed: the first on root type piles with a diameter of 310 mm, the second one on Franki Ø520mm type piles, and the other two cases on Continuous flight auger piles monitored with 400 and 700mm of diameter, respectively.

One of the tests made in a continuous flight auger was carried out with the pile instrumented by electrical extensometers at 4 different depths along the shaft. Through this instrumentation was possible to compare the resistant loads measured by the sensors with the results obtained by the CAPWAP analysis along the length of the pile that is why it evaluates the response of the analysis regarding the load distribution for this type of pile and specific soil conditions.

The comparison of the dynamic test with the static test in different types of pile, diameter, depth, concrete strength, soil conditions, and test loads allowed a careful evaluation of the response of dynamic tests for use in "in situ” molded piles in Brazil and it pretends to demonstrate the effectiveness of using Dynamic Loading Tests to determine the theoretical rupture of “in situ” molded piles.

2. Load tests

2.1 History of static load test in Brazil

According to [2], the first precise method to execute the tests of Static Load Test (SLT) in Brazil, began to be studied in 1942, by IPT, with the collaboration of Prof. Costa Nunes, engineer of the Estacas Franki Ltda company. The IPT, through a request from the Frankignoul Pile International Company, debuted in Brazil and assigned to professor Costa Nunes the responsibility for the execution and planning of a load test.

The first load test was applied to the foundations of the Estrada de Ferro Noroeste Station, in the city of Bauru, executed on Franki pile and carried out by IPT itself in 1936. In Rio de Janeiro, the first experiences of load tests on Franki type piles date from 1942 and were executed on the foundations of the Instituto de Resseguros Brasil [2].

[2] pointed out that the first works on piles or models of instrumented piles date from the beginning of 1950. However, it was after the VI Pan-American Conference on Soil Mechanics and Geotechnical Engineering in 1979, that was generated a large quantity of national and international works, on load tests in instrumented piles. This type of work is recent in Brazil; there are few research centers and companies capable of executing it. The SLT determines the characteristics of displacement and resistance of the soil or structural elements of the foundation. The tests are carried out to ensure that there will be no geotechnical or structural rupture of the foundation on service.

2.1.1 Interpretation of the load-settlement curve by extrapolation methods

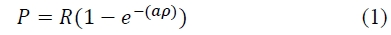

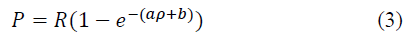

Most of the load-settlement curves do not show a well-defined rupture, so it is necessary an interpretation criterion to define the value of the load capacity of the foundation element. There are many criteria for physical rupture, but the most used in Brazil are [3], Van der Veen modified by [4], and [5]. For conventional rupture, the most used are [6], Brazilian standard [1], and [7]. In this work, original [3], Van der Veen modified by [4] and [1] methods will be required. The Van der Veen criterion associates the load-settlement curve with an exponential function:

Where:

a = coefficient that represents the form of the curve.

P = pile settlement during test (m);

R = pile loading force during test (kN);

To determine a and R, a trial and error process is used, adopting values for R and plotting the respective graphs:

[4] does not impose that the adjusted line passes through the origin of the coordinate system. The equation is modified to:

Where:

b = It is the intercept, on the settlement axis, of the straight line obtained in the semi-logarithmic scale.

[1] standard recommends that the rupture load correspond to the intersection of the load versus settlement curve (extrapolated if necessary) with the line of the following equation:

Where:

D = Pile diameter (m);

A = Cross-sectional area of the shaft (m2);

L = Pile length (m);

E = Modulus of elasticity of the pile material (kN/m2).

[8] evaluated the load test results in order to provide important information for the foundations design The results of these tests allowed us to learn how shaft and base resistances were mobilized when the test pile was subjected to axial loads.

In addition, methods for load vs. settlement prediction were studied by [9], where the curve tends to follow elastoplastic behavior but the load test curve is more rigid. Also, those methods allow obtaining to predict settlement. On the other hand, [10] developed a mathematical model using the finite element method to estimate the load-settlement curve, where obtained values near the values of the static load test.

2.2 History of the dynamic load test in Brazil

The Dynamic Load Test was made to improve the dynamic driving formulas, and its theoretical basis was developed from the propagation of the wave generated by the impact of the hammer, in consequence exciting the foundation element. The test execution principle is relatively simple, so it consists only of generating an impact at the top of the pile, which propagates to the tip, where there is a reflection of the stress wave, which returns to the top, where it is monitored. The wave is affected by several interferences along with the pile, the main ones being the soil-pile interaction and the impedance variations (cross-sectional area, modulus of elasticity, etc.).

The analysis through the wave equation consists of the quantification of all these interactions. One of the milestones in the evolution of DLT was the principal work of [11] that was put into practice through technological development and information processing capabilities. The name of the equipment most used today in the world scenario to perform the DLT is the Pile Driving Analyzer, or PDA [12]. Fig. 1 shows a detail of the equipment needed for the test.

The main aim of the PDA equipment is to determine the static load capacity mobilized from the pile-soil system. The test estimates the total resistance and permits to obtain the dynamic component, using a damping factor, so, the static component was evaluated by the difference between total resistance and dynamic component.

Also, the test can still provide the pile integrity condition, the efficiency of the driving system, the stresses applied to the pile during driving, and stress versus strain curves evaluated from static tests. This last feature will be analyzed in this article by comparing stress-strain curves of static load tests and curves obtained by dynamic tests through CAPWAP analyzes on all blows.

In Brazil, the current practice of the dynamic loading test consists of an increasing energy test [13]. It is carried out after the end of driving and uses sequential blows where the applied energy is gradually increased (blow by blow), varying the hammer drop height.

The main objective of this testing modality is to obtain the maximum resistance mobilized of the pile [14]. Data collection for different hammer drop heights allows sufficient displacements to be achieved to fully mobilize this resistance.

2.3 Brazilian methods for estimate load capacity

Several Brazilian researchers have proposed methods to relate the determination of the load capacity of piles to the index of resistance to penetration of the SPT test (NSPT). Among them, the Brazilian classic methods of [15-18]. A comparative analysis between the proposed load capacity methods is very important, comparing the results with those obtained from the static and dynamic load tests, and verifying the efficiency of the methods for the piles in the study area.

3. Case Studies

In this section, the case studies will be analyzed for different piles. All the tested piles are of the “in situ” type molded, where one case in a root pile, the second in a Franki type pile, and two other cases in Continuous flight auger piles.

3.1 Case 1: root pile

The dynamic load test was carried out in the North Zone of Rio de Janeiro / RJ, where the soil profile is made by layers of fine sand and clayey silt, with an average NSPT value of 18.8. The pile was molded “in situ” and it is root type, with a diameter of 310 mm and 15.04 m in depth. Likewise, it was designed to resist an axial compression load of 700 kN.

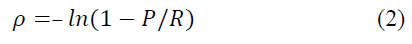

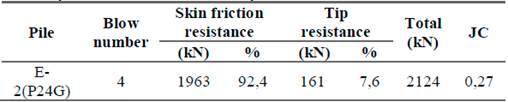

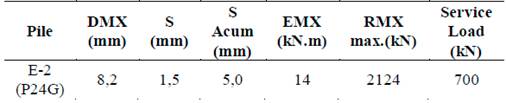

The usual dynamic load test procedure was performed successfully, with a mobilized resistance (RMX) of 2124 kN being obtained through CAPWAP analysis. The proportion between shaft load (lateral friction) and tip load is shown in Table 1.

The test presented an accumulated set (permanent deformation) of 5.0 mm and a relation between mobilized load and service load is three, as shown in Table 2.

Table 2 Summary table of the results obtained by the CASE method, with Jc from the CAPWAP analysis.

Source: The authors

Where:

EMX: maximum transferred energy to the pile calculated in the dynamic load test

DMX: maximum pile displacement after stroke calculated in the dynamic load test

s: Set. Permanent (plastic) displacement per blow

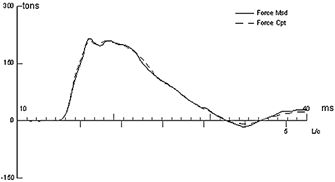

The weight of the hammer used to generate the impact was 2140 kg, that is to say, 3% of the service load. Fig. 2 shows the good correlation between the measured force and the calculated force by the CAPWAP analysis.

3.2 Case 2: Franki pile

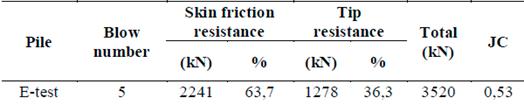

The test was carried out in the West Zone of the city of Rio de Janeiro / RJ, where the soil profile is made of a superficial layer of an embankment, followed by a layer of very soft organic clay (14.0 m) and a subsequent layer of dense fine sand resulting in an average NSPT value of 11.0. Franki pile was molded “in situ” with 520 mm in diameter and 25.00 m deep, designed to withstand an axial compression load of 1700 kN. The dynamic load test was performed 36 days after the static test and the mobilized load (RMX) of 3520 kN was obtained through CAPWAP analysis, being divided into shaft load (lateral friction) and tip load, as shown in Table 3. The test showed an accumulated set of 6.0 mm and a relation between mobilized load and service load with a value of more than two, as shown in Table 4. The weight of the hammer used to generate the impact was 7400 kg, likewise, 4.4% of the service load.

3.3 Cases 3: Continuous flight auger piles

The test was carried out in the city of Serra / ES, where the soil profile is made of a superficial layer of an embankment and a layer of silty clay, distributed with fine sand, with clayey silt, resulting in an average NSPT value of 17.6. This pile has 400 mm in diameter and 19.0 m deep and 17.5 m below the ground. It was designed to withstand an axial working load of 900 kN.

The dynamic load test was performed six days after the static test. This pile was previously instrumented with electrical resistance extensometers at four previously defined levels. At each level, four opposed extensometers were used, connected in a complete bridge, and glued to the steel bars.

During the dynamic test, the event responses of the electrical extensometers were measured and recorded in the ADS 2000 system, manufactured by LYNX Tecnologia Eletrônica LTDA, controlled by a Notebook. This system provided in real-time and with a data frequency of 100 Hz the values of the specific deformations of the instrumented points.

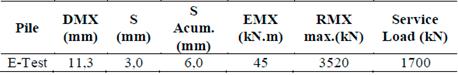

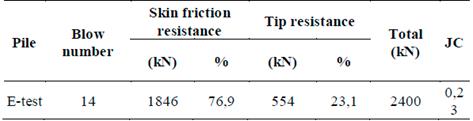

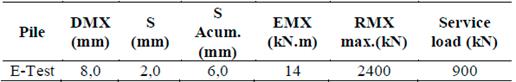

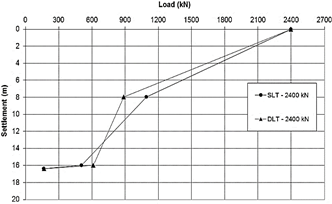

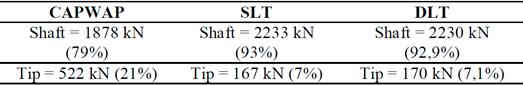

The mobilized load (RMX) on the helical pile obtained by the CAPWAP analysis was 2400 kN, being divided into shaft load (lateral friction) and tip load as shown in Table 5. The test showed an accumulated set of 6.0 mm and a ratio between mobilized load and service load of 2.66, as shown in Table 6. The weight of the hammer used to generate the impact was 4000 kg, likewise, 4.44% of the service load.

3.4 Case 4: continuous flight auger piles

The test was carried out in the city of Itaboraí / RJ, where the soil profile consisted of a superficial layer of an embankment, followed by 8.5m of sandy clay and a subsequent layer of dense coarse sand, resulting in an average NSPT value of 19.2. The pile has a diameter of 700 mm and 11.00 m in depth. It was designed to resist an axial compression load of 1600 kN.

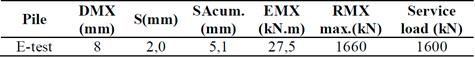

The dynamic load test was performed 21 days after the static test and a mobilized load (RMX) of 1660 kN was obtained through the CAPWAP analysis, being divided into shaft load (side friction) and tip load, as shown in Table 7.

The test showed an accumulated set of 10.0 mm and the relation between mobilized load and service load great than 1.03, as shown in Table 8.

Table 8 Summary table of the results obtained by the CASE method, with JC from the Capwap analysis.

Source: The authors

The weight of the hammer used to generate the impact was 5,000 kg, likewise, 3.1% of the service load.In the specific case of this test, the geotechnical rupture occurred during the Static Load Test, performed by the conventional method, with the maximum load reached 182 tons. That is why to calculate the geotechnical rupture and compare it with the static and dynamic results.

4. DLT versus SLT

4.1 Root Pile

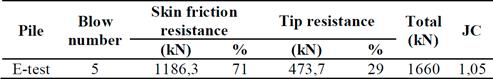

The static test was performed 44 days after the dynamic test, with loading until twice the service load. For a comparison between the types of tests, the results of the static test were extrapolated to the mobilized load of the dynamic test, as shown in Fig. 3. The load versus settlement curve obtained by the dynamic test showed deformations higher than those presented by the static test. An important factor in the analysis of the dynamic test in root type piles is the monitoring of the accumulated set that must be up to 5.00 mm, so it is possible to mobilize a tip load capacity similar to that designed for this type of pile. When the tested piles exceed this value of accumulated set, the CAPWAP analysis tends to exhibit an increase in the load related to the tip of the pile higher than that adopted in the project and different from the group of piles made in the work. Thus, in the case of accumulated set greater than 5.00 mm for root piles, it is suggested that the CAPWAP analysis be performed on the blow that generated a compatible accumulated set, thus maintaining the ratio of toe resistance and lateral friction of the group of piles made in this period.

It was verified that the dynamic loading test safely reproduced the static test.

4.2 Franki pile

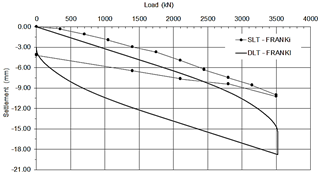

The static test was carried out and results were obtained using the maximum test load, 3500 kN, which was reached in the last loading stage and showed stabilization of settlements after 12 hours, with an accumulated displacement of 10.25 mm. The unloading was carried out normally in four stages, obtaining at the end a residual settlement of 4.08 mm.

The dynamic test allowed a simulation of the load versus settlement curve of the static test for the mobilized load of 3520 kN, with a maximum displacement of 15.7 mm and an accumulated displacement of 18.6 mm. In the simulated unloading, a residual settlement of 3.0 mm was obtained. Fig. 4 shows the comparison of the load versus settlement curve between the two tests.

Source: The authors

Figure 4 Comparison of load x settlement between dynamic test (DLT) and static test of the Franki pile.

It was observed that in the dynamic load test the pile mobilized practically the same load as the static load performed. Analyzing the simulation of the static test performed by the dynamic test, great deformations were verified compared to the static load.

4.3 Continuous flight auger piles

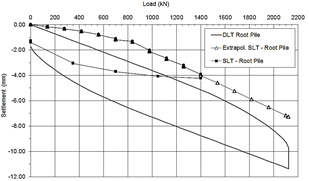

The static and dynamic tests were performed with the pile instrumented by electrical extensometers at 4 points along the pile shaft: point P1 (+0.10 m above the ground); point P2 (-7.95 m); point P3 (-16.00 m) and point P4 (-16.40 m). Fig. 5 shows the P1 deformations during the test.

The static test was performed before the dynamic, with the maximum test load of 2400 kN, which was successfully reached and stabilized in the last load stage, for which maximum stabilized displacement was measured after 12 hours of 11.89 mm. Unloading was carried out normally in six stages, resulting in a 6.00 mm residual settlement.

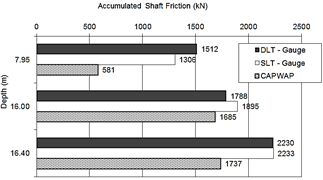

Based on the loads calculated at the points measured by the instrumentation, an accumulated lateral friction resistance up to a depth of 16.40 m of 2233 kN was obtained for the 2400 kN static load applied on top of the pile.

In the dynamic test, the load distribution was also determined using the instrumentation along with the pile. The computations were made from the variations in deformations at the points measured in the blow that mobilized the load of 2400 kN.

The calculations were performed for comparison with the static test, as well as, that obtained one along with the pile by the CAPWAP analysis.

The load distribution along the pile shaft measured by the sensors during the static and dynamic tests had a high correlation, as shown in Fig. 6.

Source: The authors.

Figure 6 Correlation in the load distribution measured by the sensors during the static and dynamic tests.

Fig. 7 and Table 9 show comparatively the load distribution in the static and dynamic tests measured by the sensors and that obtained by the CAPWAP analysis.

There was not a good correlation in the load distribution found in the CAPWAP until the point P2 (7.95 m) compared to the value measured in the sensor. However, the correlation improves significantly along the length of the pile, reaching very close values at a depth of 16 m.

Through Table 9, it is observed that the load at the tip of the CAPWAP analysis was relatively higher than that obtained by the instrumentation in the analyzed blow

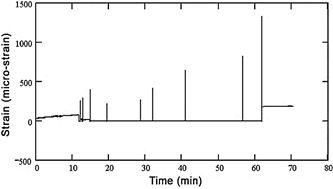

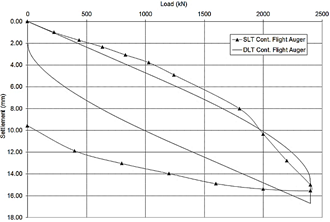

The load versus settlement curve between the static and dynamic tests were also compared, as shown in Fig. 8.

Source: The authors.

Figure 8 Comparison of load versus settlement between dynamic test (DLT) and static test of the monitored propeller pile.

It was observed that the dynamic load test reproduced for a load of 2400 kN a total displacement greater than the static load, but showed a smaller residual settlement that was obtained by the static test.

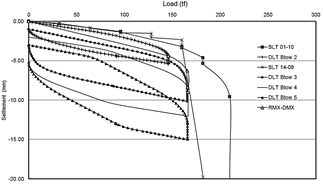

4.4 Continuous flight auger piles

In this pile, the static test was carried out before the dynamic test and the pile broke, reaching the maximum test load, of 1820 kN, which was reached in the sixth loading stage, by the slow method of the Brazilian standard [19]. The maximum measured displacement, calculated by the average of the deflectometer readings, was 19.80 mm, but it was not stabilized, characterizing a clear geotechnical rupture.

The dynamic test was performed 21 days after this result and enabled a simulation of the load versus settlement curve of the static test, mobilizing 1660 kN, with the maximum total displacement being 14.0 mm and with an accumulated permanent displacement of 15.0 mm. In the simulated unloading, a residual settlement of 5.1 mm was obtained. Fig. 9 shows the comparison of the load versus settlement curve between the two tests.

It was observed that in the dynamic load test the pile mobilized practically the same load as the static load performed. Analyzing the simulation performed using the dynamic test, great deformations were verified compared to the static load test, despite the very similar loads.

Fig. 9 shows that for a correct simulation of the Static Load Test through the Dynamic Load Test, it is necessary to carry out CAPWAP analyzes for all blows of the same and not only the one with the greatest load mobilized, as is the usual procedure. Thus, a curve that encompasses all blows - like an envelope - would design much closer to the static test than the pure analysis of blow number 5.

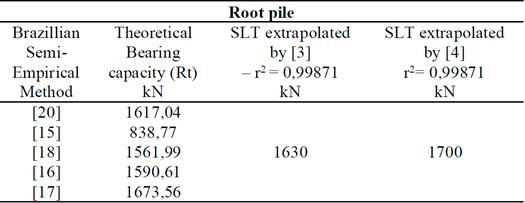

5.2 Real interpretation results of the load - settlement curve

In the case of the root pile (Table 10), the Dynamic load tests and the Static Load Tests could not be compared because they were not completed in close loads. The theoretical load capacity, computed by [18] methods, was slightly below the rupture calculated by the NBR 6122: 2019 standard, with the curve, extrapolated through the method of Van der Veen.

Where:

r2: coefficient of determination (linear regression)

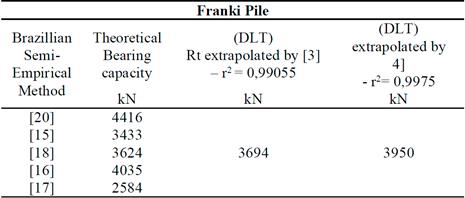

In the case of the Franki pile (Table 11), the correlation between the static simulation of the DLT and the Static Load Test was not good, everything indicates that there is a mistake in the graph of the Static Load Test, because its rigidity and its stabilization were below expectations.

However, the theoretical load capacity, calculated by the method of [18], was slightly below the rupture calculated by the method of the NBR 6122: 2019 standard, with extrapolation by Van der Veen, in the DLT static simulation. Theoretical load, calculated using the Decourt - Quaresma method, was slightly above the rupture calculated by the NBR 6122: 2019 method, with extrapolation by Van der Veen (modified by Aoki), in the DLT static simulation.

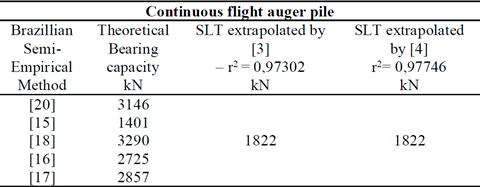

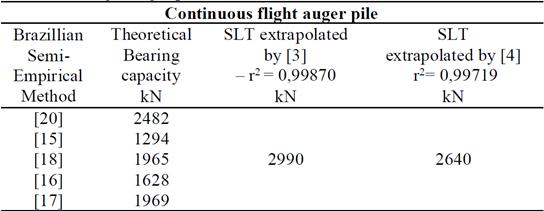

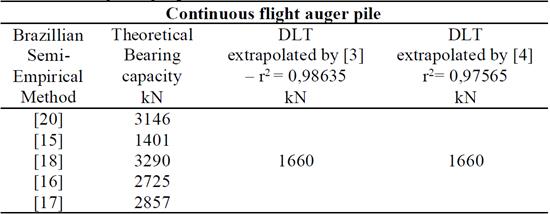

For the tests carried out on Continuous flight auger piles (Table 12), both the dynamic load test and the static load test behaved in a very similar way. In the case of continuous flight auger piles, the theoretical load capacity, calculated by the Pedro Paulo Velloso method, was slightly below the rupture calculated by [1], with extrapolation by [4], in the static simulation of the DLT.

In the case of the Continuous flight auger piles without monitoring, we can observe a more interesting fact, as this pile broke during the Static Load Test (Table 13), being tested by the Dynamic Load Test (Table 14) 21 days after the static test.

Table 13 Analysis of load capacity and rupture of the Static Load Test of the Continuous flight auger piles.

Source: The authors

Table 14 Analysis of load capacity and rupture of the Dynamic Load Test of the Continuous flight auger piles.

Source: The authors

In an investigation carried out by the consultants of the work in which the incident occurred, it was discovered that the problem that caused the geotechnical rupture of the pile was induced for the building of the pile and not design. Therefore, the theoretical load capacity will be very different from the rupture calculated by the methods of the [1], both DLT and SLT.

On the other hand, the geotechnical rupture of the pile allows using of the Dynamic Load Test to calculate a rupture in the foundation.

Thereby demonstrating the ability to calculate the theoretical rupture of a pile, in a real case, through an analysis of the Dynamic Load Test.

6. Conclusions

It concludes in this research that the Dynamic Load Test can be used to determine the load capacity of “in situ” molded piles as much as the SLT if it was analyzed by the CAPWAP method in all its blows, with good match quality’s. Theoretical dimensions vary according to the region that is applied and the pile type. Dimensioning foundations depends on the designer's knowledge to choose the best method. It was also evident that DLT SLT can only be compared if carried to similar loads; otherwise, extrapolation cannot be interesting for the assessment of the rupture load, regardless of the method to be used.

The execution methodology presented is based on executive technical criteria which must be followed scrupulously to provide good quality signals and under ideal conditions of interpretation through the wave equation theory. The concept has been defined innovative standardized potential energy, from which a new proposal for determination of the necessary potential energy according to the resistant capacity to be mobilized.

The interpretation methodology presented based on CAPWAP numerical analyzes for each stroke of increasing energy, allows the tracing of the curves around the lateral tip and total depending on displacements. This methodology provides a whole set of relevant information that makes it possible to clearly assess the transfer mechanisms load and the proposal of a displacement that corresponds to a conventional rupture load, defined from the elastic shortening and displacement of the tip of the pile.