1. Introduction

New technologies, the demands of the markets, and the emergence of new business models have influenced and transformed production processes since the beginning of the industrialization [1]. The Fourth Industrial Revolution establishes a new paradigm for production systems. Central concepts to this new paradigm are among others: Big Data, Cloud Computing, Artificial Intelligence, Industrial Internet of Things (IIoT), and Cyber Security [2].

The Fourth Industrial Revolution gained some synonyms over time: Digital Transformation, Digitalization, Industrial Internet of Things (IIoT) and Industry 4.0. [44]

The term Industry 4.0 was derived from the German term “Industrie 4.0” and first presented at the Hannover Fair in 2011. It denotes the high technology project of the Federal Ministry of Education and Research of the German Government, intending to increase the automation of local production systems [3].

As it is a relatively new and constantly expanding theme, there is still no consensus on the enabling technologies that make up the concept of Industry 4.0. In [21], after performing a review in the databases on the technologies that allow an adequate implementation of Industry 4.0, 19 articles were found, in which 20 different types of technologies are presented. After an pareto classification, seven technologies stand out: Big Data, ‘Internet of Things’ (IoT), Cloud Computing, Autonomous robots, additive manufacturing, Cyber Physical Systems, and Augmented Reality.

We understand that there is only one phenomena of industry 4.0, but a lot of commercial and scientific communication. As industry 4.0 is characterized by a set of new technologies, it is common to find lots of interpretation for its application. Despite this, applications that suggest a maturity assessment commonly understand industry 4.0 as a set of technologies that must fit to company processes to be effective.

The number of publications on the Scopus platform, that include the term Industry 4.0 between 2001 and 2020 increased exponentially in the last years, 98 publications in the year 2012 for a total of 5218 publications in 2019 and 5294 so far in 2020, a leap of approximately 53 times.

There is wide agreement that companies must have a certain degree of maturity to engage in an Industry 4.0 environment [4,5]. That is, they must fulfill a set of requirements to be able to apply technologies and skills to further develop towards the vision of Industry 4.0. Maturity models serve scientific and practical purposes. From the scientific point of view, these models allow gathering information about the current state of the company and its strategies for Industry 4.0. From a practical point of view, maturity models enable companies to evaluate themselves within an Industry 4.0 context [6]. However, current maturity models treat maturity as a final outcome after an analysis of different structures and processes, technologies or other enablers of a company. They do not take the current maturity of company as an enabler into account.

Therefore, the purpose of this article is to present a bibliometric analysis of scientific publications containing the terms "Industry 4.0" and "Maturity" which were published from 2001 to 2020. Main journals, publications, authors, countries as well as trends of maturity models in the context of Industry 4.0 were identified. Based on the analysis of existing maturity models, a new concept for measuring companies’ Industry 4.0 Readiness in more and less technology dynamic economies as Germany and Brazil is introduced.

In Section 2, the research methodology is presented, Section 3 details the analysis of previous models and relevant literature, Section 4 presents the cube model, and its different dimensions and Section 5 concludes the paper with a summary and an outlook.

2. Methodology

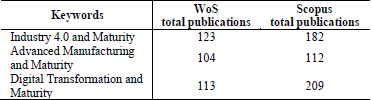

The methodology used in this study follows protocols for research, classification, and bibliometric analysis [7]. Currently, several databases use bibliometric indicators and provide a bibliometric analysis of scientific production. Two of the most common platforms among them are the Web of Science (WoS) and the Elsevier Scopus (Scopus) platform. The data presented in this study was obtained through bibliometric research of these two platforms. Table 1 presents the keywords and the number of total publications containing the keywords.

3. Results

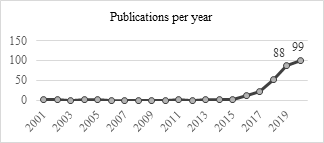

The number of publications on the Scopus platform using the term “Industry 4.0” and “Maturity”, rose drastically in the last years from 2015 (1 publication) to 2019 (88 publications) and 2020 so far (99 publications), as can be seen in Fig. 1.

Source: author’s own elaboration.

Figure 1 The number of publications per year containing the terms Industry 4.0 and Maturity (Scopus).

Another interesting finding refers to the countries that generated these publications. Leading is Germany with 39 in Scopus. This aligns with our expectation since Germany is the nation that initially launched the term Industry 4.0. In third place is Brazil with 15 publications in Scopus. Austria, Sweden, England, China, the USA, Finland, France, Ireland, Italy, Spain, Switzerland, Taiwan, and Turkey appear in sequence. Brazil stands out in second place in the WoS and third in the Scopus ranking. This is mainly related to the high degree of industrialization in the central and southern regions of Brazil. These regions are characterized by a large number of German immigrants and researchers who completed part of their studies in Germany. Several pieces of research and studies have been carried out in Brazil in recent years to evaluate the local productive matrix and look for ways to make it more efficient by using Industry 4.0 technologies, i.e., the maturity evaluation tool developed by the National Industrial Learning Service - SENAI / CNI [8] or the work conducted by the Brazilian Industrial Development Agency - ABDI [9].

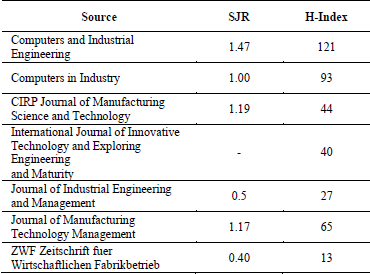

In Table 2 the main sources of the publications were listed and classified according to their SCImago Journal Rank

(SJR) and the H-Index. The SJR evaluates and ranks scientific periodicals according to the number of their citations in three years after the publication of the editions, to the origin of citations as well as to the logic of citations [10]. The H-Index expresses the journal's number of articles (h) that have received at least h citations. It quantifies the journal’s scientific productivity and scientific impact and it is also applicable to authors [11].

In addition to the main sources presented in Table 2, the IEEE 2018 International Conference on Engineering, Technology, and Innovation (ICE/ITMC) published four articles. This confirms that the examined topic is currently discussed in the scientific engineering community.

The Politecnico di Milano in Italy ranks first regarding the amount of generated publications among institutions (eight publications). Among Brazilian institutions, the Pontifíc Catholic University in Paraná, Brazil, stands out with six publications. It is important to note that different institutions work together through the collaboration of several authors, which leads to differences between the number of publications and the respective number of institutions.

The WoS and Scopus platform provide the most cited keywords, within the set of analyzed papers, after inserting the terms Industry 4.0 and Maturity. As expected, the most frequent keyword is Industry 4.0 with 13 quotes in WoS and 14 quotes in Scopus. The keyword Maturity Model appears in sequence with 7 quotes in WoS and 13 quotes in Scopus. Other keywords cited are Digitization, Digital Transformation, Smart Factory, Internet of Things, and Learning Factory, among others.

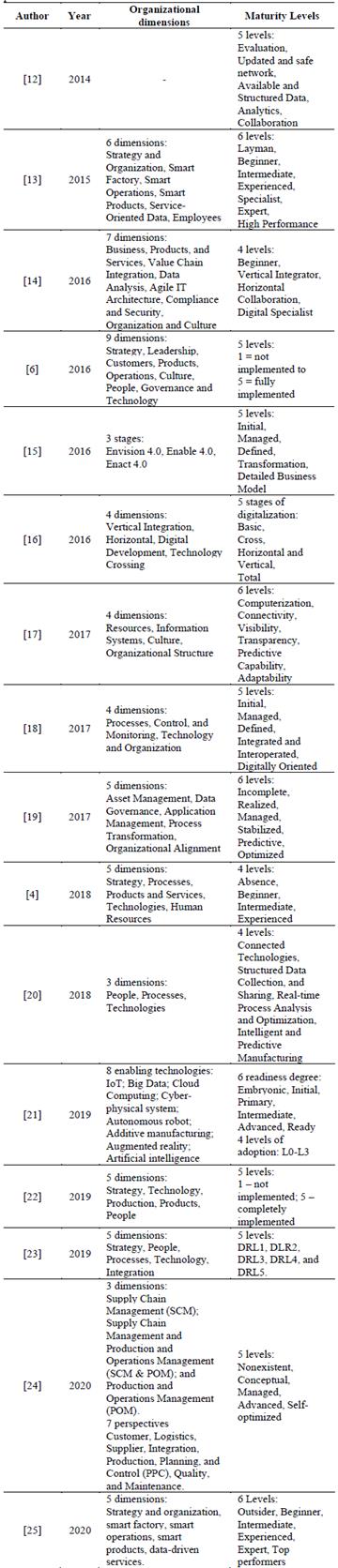

Twelve maturity models, identified in the bibliometric research, were further analyzed. Additionally, four additional models (PwC, Acatech, IMPULS, and Rockwell Automation) were included in the analysis, because of their prominence among practitioners. The results are summarized in Table 3 and further outlined in the following.

Rockwell Automation [12], which has partnered with other major technology companies such as Microsoft, Cisco, and Panduit, presents a five-stage model of measures and best practices for changing technology and culture to develop a connected company. In a study commissioned by the IMPULS Foundation of the German Engineering Federation (VDMA) [13], carried out by IW Consult and the Institute for Industrial Management at RWTH Aachen University, a maturity model was developed including six key dimensions, each of which is defined on a six-level scale. Four of the six dimensions presented coincide with the necessary capabilities as required for Industry 4.0: smart factory, smart products, smart operations, and data-driven services. According to the model, the level of maturity of a given dimension is defined by the lower level of maturity of the respective areas of interest that compose it. Besides, according to the level of maturity obtained by the model, organizations can be classified into three types: “Newcomers” (level 0 and 1) companies that have done either nothing or very little to deal with Industry 4.0, “Learners” (level 2) companies that have already taken first steps in implementing Industry 4.0, and “Leaders” (level 3 and up) companies that are already further with their efforts to implement Industry 4.0, representing the benchmark group. According to the IMPULS study, only 5.6% of the evaluated companies are classified as “Leaders”, 17.9% as “Learners” and the majority, 76.5% were classified as “Newcomers”.

The PwC Model [14] is based on seven dimensions of digital capabilities, involving business, products and services, value chain integration, data analysis, agile IT architecture, compliance and security, organization, and culture. Four levels of maturity are presented: beginner, vertical integrator, horizontal collaborator, and digital specialist.

In [6], a model based on 62 items of maturity is developed concerning technology and organization. These items are grouped into nine company dimensions, each being evaluated within five levels of maturity. The model is designed for manufacturing companies and was then applied in case studies with an Austrian manufacturing enterprise that already is engaged in Industry 4.0 and possesses required basic knowledge and understanding about its basic concepts.

[15] proposes a three-stage maturity model towards Industry 4.0, which are: envision, enable and enact. The process model consisting of tool-oriented sub-models aiming at vision, strategy, and construction of actions and a 5-level scale is defined for the model, from the “initial level”, when the organization have not adopted the Industry 4.0 philosophy, to “detailed BM”, when exist a transformation of business model.

The maturity model for System Integration (SIMMI 4.0) by [16] allows companies to classify their own IT systems for the Industry 4.0 landscape. It consists of five stages of maturity. Each stage represents a corresponding level of maturity for Industry 4.0. and is divided into four dimensions that represent different areas of the company (vertical, horizontal, digital development, and technology crossing).

According to the ACATECH (German Academy of Science and Engineering), being 4.0 means generating data knowledge to transform the company into an agile, learning organization, allowing rapid decision making and flexible adaptation of processes in all business areas. The ACATECH has developed a maturity model, which includes four key perspectives of an organization: resources, information systems, organizational structure, and organizational culture. Each of these perspectives is assessed at six levels of maturity [17].

In the study called DREAMY [18], five major areas are initially structured: design and engineering, production management, quality management, maintenance management, and logistics management. Based on these areas, five levels of maturity are defined: initial, managed, defined, integrated, and interoperated as well as digitally oriented. To evaluate the digital capacity of an organization, not only technologies in use are considered. Instead, the digital capacity is evaluated by four dimensions: processes, control and monitoring, technology, and organization.

In [19] a maturity model for Industry 4.0 based on ISO/IEC 15504 is presented (also known as SPICE; Software Process Improvement and Capability Determination). The model is built on five aspect dimensions (Asset Management, Data Governance, Application Management, Process Transformation and Organizational Alignment) and six capability levels (Incomplete, Performed, Managed, Established, Predictable and Optimizing).

[4] developed a model based on 36 questions divided into five areas: strategy, processes, products and services, technology, and human resources. Based on the questions four different levels of maturity are derived: absence, beginner, intermediate, and experienced. As a result, a radar-type graph is generated and the mean of the company's general maturity level, based on the five dimensions, is calculated.

In [20] five case studies are analyzed and the challenges and key steps required to implement a smart factory are identified. A model is then built based on three principles: people, the introduction of agile processes, and configuration of modular technologies. These principles are classified into four maturity levels. The benefits of implementing a smart factory are analyzed as well and are the following according to [20]: greater process efficiency, lower operating costs, higher product quality as well as greater safety and sustainability.

In [21], a literature review was performed, and 19 articles, from 2015 to 2018, describing 20 enabling technologies that encompass Industry 4.0 were identified. To select the most relevant qualifying technologies, those most frequently cited in the literature were considered and an ABC classification concept was used to select eight enabling technologies. The evaluation of readiness is performed by identifying four possible answers to each statement: Level 0 until Level 3, where L0 - the component is not present or there are major inconsistencies in its implementation; and L3 - the component is fully present. The company selected for this study was a multinational diesel engine manufacturer located in the state of Sao Paulo in Brazil and employs approximately 1200 persons. The degree of readiness of this diesel engine manufacturing company is 0.7569, or 75.7%, that is, the company has about three quarter of the technologies in place that are required to support an adequate I 4.0 implementation.

[22] provides a maturity scale that could support SMEs in their Industry 4.0 assessment and implementation. Five dimensions were proposed through the review of eleven maturity models: Strategy, Technology, Production, Products, and People. The items of each dimension are posed as a Likert-type scale ranging from 1 to 5, where 1 is “not implemented/not present” and 5 “completely implemented/present”. Data from a survey with 11 items were then analyzed and a radar chart was designed to support practitioners in visually understanding the organization’s maturity. The radar chart is calculated as the average of the items for each dimension.

[23] propose a tool called The Digital Readiness Level 4.0 Model (DRL 4.0) to overcome some limitations of existing maturity models whose monolithic structures do not always fit SMEs’ organizational forms. The five dimensions (Strategy, People, Processes, Technology, and Integration) have been chosen based on the most used dimensions in Industry readiness assessments present in eleven sources. The final DRL 4.0 model comprises 46 questions. In the first section, 12 closed-ended questions concerning the firm’s vital statistics aim to identify the enterprise’s size in terms of employment and turnover, the industry, and general features of the production process. The second section includes 24 five-point Likert-scale questions concerning Industry 4.0 technological implementation within the enterprise, encompassing five different dimensions. The final section includes ten single-choice questions concerning investments that the examined firm is undertaking or intends to evaluate in the short term.

[24] develop a fuzzy logic-based I4.0 Maturity Model (MM) for Operations and Supply Chain Management (OSCM) following four steps: Comparison of existing I4.0 MMs; iterative procedure; MM implementation; and MM evaluation.

[25] carried out a review of maturity models from 2011 to 2019 in Google Scholar and Web of Science databases, analyzing their features with regard to behavioral criteria considered of interest for their application in Machine Tools companies, especially SMEs. Starting from 96 documents and after some discussion by research team and filtering, 35 maturity models was identified. The IMPULS model [13] has been selected as a reference model for the development of a model adapted to the particularities of Machine Tools. The six dimensions established for Machine Tools organizations are also equivalent to those in IMPULS. After a critical review of its adaptability to the sector characteristics, the research team adapted the boundary conditions of other sub-dimensions in five of the six IMPULS dimensions.

According to [32], maturity models must have some requirements, such as the development of some entity, represented by a number, that the organization must achieve, called maturity levels (usually four to six). Levels are ordered sequentially, from an initial level up to an ending, and highly well systematized process level.

In addition to the models shown in the Table 3, other models present in the bases are also noteworthy, such as [40] model with 3 maturity levels; [35] with 4 levels; [33, 36, 38, 39, 41, 44] that present their frameworks with 5 maturity levels. The [42, 37, 34] models have 6 levels. Regarding the enterprise type, [35] applies to retail sector, [36] applies to SME, [42] to Automotive Industries and [43] to Bank enterprise.

4. Readiness: a new concept for maturity

The different maturity models generally cover two distinct dimensions, (1) enablers (i.e. Strategy, Leadership, Culture [6] /Envision 4.0, Enable 4.0 [15] /Processes, Organization [18] /Organizational Alignment [19] /Strategy, Processes, Human Resources [4] /Processes, People [20] /Organization and Culture [14] /Culture, Organizational Structure [17] /Strategy and Organization [13]) and (2) technologies (i.e. Technology [6] /Enact 4.0 [15] /Control and Monitoring, Technology [18] /Digital Development, Technology Crossing [16] /Products and Services, Technology [4] /Technologies [20] /Data Analysis, Agile IT Infrastructure [14]).

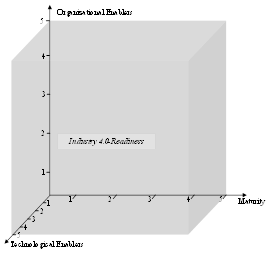

Based on the characteristics of the dimensions’ variables, the maturity regarding Industry 4.0 is evaluated. Thus, current models consider maturity as an outcome instead of an independent dimension. From our perspective, however, maturity is rather an independent dimension on its own instead of an outcome determined by enablers and technologies. In our experience, companies often lag behind in their Industry 4.0 approach since they may have the necessary enablers and technologies but lack in their organizational maturity regarding Industry 4.0. Hence, maturity is no longer seen as an outcome of evaluating enablers and technologies. Instead, a new concept to evaluate companies is introduced, namely Industry 4.0 Readiness. Readiness takes into account the dimensions of organizational enablers, technological enablers as well as the maturity of a company and shows how ready a company is to engage in an Industry 4.0 environment.

Therefore, a new conceptualization and approach for measuring the Readiness for Industry 4.0 are proposed, in which maturity is understood as an independent dimension among the other two dimensions organizational enablers and technological enablers. For each dimension, four different levels are set. The lowest level refers to a company that is not yet ready about the respective dimension. The highest level implies that a company is fully ready to engage in an Industry 4.0 environment. However, there are no levels to Readiness itself. The different dimensions (organizational enablers, technological enablers, and maturity) set up a three-dimensional Industry 4.0-Readiness space in which a company is categorized (see Fig. 2).

In the following, the different dimensions and the variables of the dimensions will be presented. The factors were chosen based on their relevance in the scientific literature. Whereas numerous variables of organizational enablers and technological enablers could be found based on the literature analysis conducted in part III, variables for maturity were elaborated based on the Capability Maturity Model Integration (CMMI).

4.1 Organizational enablers

Organizational enablers for Readiness are differentiated into the following three variables (following [6,18,16]):

These variables were chosen based on the enablers mentioned in Table 3. However, the enablers in the maturity models differ in their granularity (i.e. Organizational Alignment [16] compared to Strategy, Leadership, and Culture [6]). Therefore, they were aggregated into variables with a similar level of granularity. Organizational Culture refers to people’s shared basic assumptions about transformation at all levels of the company. How strategy, market perspective, and value constellation benefit a company in its readiness will be assessed by the variable Business Model. Lastly, Human Resources point at the digital competency of employees and their strategic development.

4.2 Technological enablers

The technology dimension is of great importance for industry 4.0 and at the center of the scientific community’s discussions [26]. To consider ongoing developments, Industry 4.0 design principles instead of specific technologies were chosen based on [27] and the technology components of the aforementioned maturity models. Additionally, contributions from the authors´ practical experiences were taken into account. The following variables have been included:

Interconnection

Information Transparency

Decentralized Decisions

Technical Assistance

Network-based Production

Interconnection refers to the connection of all members of an organization in the Industry 4.0 era. Objects as well as people are connected. Information Transparency is based on the collection of data from connected objects and people in real-time. Linking this data to digitalized models makes it possible to create a virtual copy of the physical world. Hence, all objects and people have access to all relevant data. Therefore, they are empowered to make informed Decentralized Decisions (concerning the company’s overall goal) as autonomous as possible. Technical Assistance refers to the idea of supporting humans in accomplishing their increasingly complex work processes. The last variable, Network-based Production, comprises technologies like additive manufacturing, which enable not only the main manufacturer to produce the entire product or parts of it but various actors in the value chain as well, even if an actor is a final consumer himself.

4.3 Maturity

According to [28], “a maturity model conceptually represents phases of quantitative or qualitative enhancement of the capacity changes of a maturing element to evaluate its advances to defined focus areas". The capability of a process, however, is defined as competencies, or sets of actions and know-how, applied by an organization, which are subordinated to coordinated activities and make use of the organization’s assets [31].

In the Capability Maturity Model (CMM), a methodology created in 1986 to improve organizational processes and capabilities in managing the development, acquisition, and maintenance of software products and services, the maturity concept is defined as the necessary path to achieve the improvement of organizational processes within a set of areas, called levels of maturity. In [29] the Software Engineering Institute expanded the CMM concept by adding hardware integration and thereby forming the CMM Integration as a guideline for process integration and product improvement.

The original proposal of the CMMI maturity model encompasses four bodies of knowledge: systems engineering, software engineering, integrated product, and process development, and supplier sourcing. Our proposal combines this approach with [17] and takes into account that new business models are produced under a concept of product-service system (PSS) [30].

The maturity of an organization should be assessed by analysing four areas:

Product-service development addresses the effort to meet customer requirements that are currently based on customization and product-service systems. Production and Logistics are the main value-adding chains in manufacturing companies and must be structured systematically. Marketing and sales have to be integrated into production planning and control as well as sales and distribution planning to realize the potential of technologies and enablers of Industry 4.0.

5. Conclusion

5.1 Summary

Maturity is a concept, which offers important solutions to companies from a competitive point of view in face of the fast and changing environment of Industry 4.0. This bibliometric study analyzed a total of 168 publications on the Web of Science and the Elsevier Scopus platform. Initially, the terms Industry 4.0, Advanced Manufacturing, and Digital Transformation were combined with the term Maturity to identify scientific publications ranging from the year 2001 to 2020. A total of 20 publications were identified. The analysis of these publications shows a drastic increase in scientific publications in 2017 with Germany and Brazil being one of the main contributors. Out of the 20 publications, twelve publications introduced a maturity model for Industry 4.0. Additionally, four more practice-oriented publications covering maturity models were identified and included for further analysis. These maturity models evaluate the maturity of a company regarding Industry 4.0 based on different enablers and technology dimensions of a company. They do not target maturity as a dimension on its own.

Addressing this gap, a new concept for maturity is introduced. The main difference of the concept to previous models and concepts is that maturity is no longer seen as a dependent dimension and, thus, as an outcome of evaluating a company’s enablers and technologies. Instead, the concept introduces Industry 4.0 Readiness consisting of three different dimensions, namely organizational enablers, technological enablers, and maturity itself. Industry 4.0 Readiness is assessed by diagnosing the level of the company in each of the dimensions.

5.2 Limitations and outlook

The newly introduced concept for maturity has limitations. First, even though the variables and levels of the concept’s dimensions were carefully selected, there is a risk that they are too generic or not suitable for practical application. If a variable is too generic, an accurate assessment of the variable is difficult. If a level is too generic, a clear distinction between the levels of a dimension is missing. Hence, a valid and reliable assessment of the Readiness of a company becomes challenging. Therefore, the variables have to be reviewed regarding their suitability and level of detail and have to be adjusted accordingly. To address this point, a focus group with industry experts is planned. Within the focus group, the dimensions and variables of the concept will be discussed and updated consequently.

Second, the concept lacks operationalization. For the operationalization of the concept, a situational judgment test will be developed. Consequently, for each level of the three dimensions, a situational description is needed. Furthermore, the situational descriptions will be discussed within a focus group of experts and revised.

Third, the concept is based on the existing literature and therefore solely theoretical, even though part of the existing maturity models have already been applied in practice. Since maturity models fulfil a practical as well as a scientific purpose, the practical purpose needs of the new concept to be validated. For the practical validation of the concept, it is intended to pre-test the operationalized concept with Brazilian and German companies to show the practical applicability of the concept and possible deficits. The results of the pre-test are used to update the concept and apply it in practice. Based on its application in practice, the model will be evaluated regarding its practical usefulness.

Future work will further focus on the application of the model in practice. It will be evaluated in which form (i.e. interview or questionnaire) its application delivers usable results, and how it can be improved for a better evaluation and precise diagnosis.