1. Introduction

The maintenance of physical assets requires an ever-increasing set of skills and expertise, as it is directly influenced by technological development and progress in Information Technology (IT), making the collaboration of multiple experts in formal knowledge modeling indispensable, with the objective of improving decision making [1]. During the literature review carried out, a wide use of optimization tools in maintenance management was observed. However, there is no evidence of a state of the art that considers the use of these tools in specific practical study objects, as a guide and contribution for maintenance decision makers.

An efficient maintenance system implies having activities aimed at maintaining the useful life of the equipment in optimal operating conditions to avoid the occurrence of unforeseen failures. An important part of this involves Operational Reliability (OR), defined as the capacity by a system composed of equipment, processes, technology and personnel to fulfill the functions to which it has been created with certain limits and a defined operational context [2]. This Operational Reliability is made of four main components: process reliability [3], human reliability [4], equipment reliability [5] and maintainability [6].

Reliability analysis and maintenance management, in general terms, are affected by inaccurate data recording, which results in poor parameter estimates and erroneous decisions regarding replacement intervals and equipment interventions [7]. Competitive pressure and an increasingly demanding market have generated the search for the application of tools that make it possible to improve the estimation of the data required for reliability analysis [8], as well as the application of novel methodologies for the detection and diagnosis of failures, for which researchers have developed diverse approaches including the use of mathematical models, artificial intelligence and statistical approaches [9]. It becomes necessary, then, the use of tools and strategies that allow the improvement of estimates concerning the delimitation of intervention times, maintenance costs, tasks to be developed [10-12], critical components and failure rate [13], reaching the use of various optimization methods and tools as a viable alternative for this.

Therefore, optimization can be considered as the maximization or minimization of a function that depends on a set of variables and is subject to a set of constraints [14], which integrates different disciplines such as applied mathematics and computational sciences to solve it out. These optimization methods can be classified into two main groups: deterministic techniques (where the parameter values are certain) and stochastic, also called probabilistic, (which means they include a certain uncertainty in their results) [15].

This paper shows the contribution to successful maintenance decision making achieved by combining reliability and maintenance analysis of physical assets with optimization tools such as: Mathematical Modeling, Genetic Algorithms, Simulation, Neural Networks, Markov Chains and Bayesian Networks, all these, tools of artificial intelligence.

2. Methodology

The study is focused towards benchmarks to reach relevant results and conclusions related to the linkage of various optimization tools to reliability studies. The time horizon covered for the review of scientific articles covers the period between 2010 and 2021. The following keywords and their possible combinations were used for the bibliographic search: reliability, Reliability Centered Maintenance (RCM), genetic algorithms, simulation, neural networks, Markov chains, optimization, mathematical modeling and Bayesian networks.

Subsequently, the analysis of the case studies found in the literature analysis is carried out, taking into account the variables involved in the study, the optimization tool used, and the result obtained in the analysis of the reliability of the physical assets.

3. Consultation and analysis of the literature

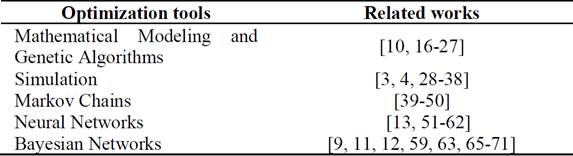

For the development of the literature consultation and analysis, as mentioned in the previous section, we resorted to the consultation in several search engines. Table 1 shows the optimization tools applied to the reliability studies of physical assets and the reference to the corresponding works.

Several researches have presented cases where mathematical modeling applied to maintenance and reliability analysis have been used. The application of integer linear programming for the selection of maintenance strategies, is a case where the tools of mathematical modeling linked to reliability are used, allowing to perform the allocation of monetary resources for each maintenance strategy, in equipment of the paper production industry, by applying Reliability Centered Maintenance [16]; shown in this article is a literature review of the use of multi-criteria decision methods, applied for the selection of the best maintenance strategies based on criteria such as: maintenance cost, safety, equipment risk, feasibility and number or level of risk priority as the most significant ones.

The application of mixed integer linear programming, to minimize maintenance delay and costs [10], is also used to model and optimize a shop-flow scheduling problem integrated with multiple maintenance activities in a mixed integer programming with input variables involving the costs of unavailability and maintenance-related activities, optimized by a lower bounded genetic algorithm (LBGA), in which the algorithm parameters are first tested through a factorial experiment to identify the statistically significant parameters. The LBGA self-tunes these parameters to improve its performance based on the solution gap from the lower bound. The genetic algorithm takes into account the number of machines in the shop and the maintenance levels applied to each one of them based on the assigned maintenance strategy. To generate the lower limit, an objective function is created which consists of minimizing maintenance and delay costs. The Genetic Algorithm for the presented problem is proposed by using an experimental design to identify the significant parameters of the algorithm and then adjusting those parameters based on the identified lower bounds. Genetic Algorithms have been applied to different research areas, including several applications in machine scheduling; they have also been used to solve the integrated production and maintenance scheduling of a single machine [10].

On the other hand, Hameed et al. consider reliability and maintenance costs as conflicting objectives. They develop a decision support model for risk-based maintenance in a liquefied natural gas plant, where they integrate genetic algorithms and simulation to optimize maintenance scheduling, considering minimizing costs and maximizing reliability [17]. The decision support tool presents a nonlinear combinatorial optimization model using genetic algorithm for maintenance scheduling. The proposed simulation-based approach presented in the study provides feasible schedules for inspection, maintenance and replacement activities to achieve system reliability performance and cost optimization. In general, the methodology used helps to develop effective resource utilization planning. The Pareto optimal model that is developed provides flexibility for engineers and planners to develop maintenance programs considering different conflicting objectives.

Improving existing techniques or developing a new optimization procedure remains an interesting research task. One way to generate this optimization in mathematical modeling is through the use of Genetic Algorithms, as we have seen in previous cases. Genetic Algorithms are metaheuristics that aim to emulate the process of natural selection. They use a population of chromosomes to represent possible solutions to a problem, with each chromosome consisting of a set of genes that describe the solution. To create a new generation of chromosomes, the chromosomes of the current generation are randomly combined in proportion to their fitness.

In the case of the mining sector, where the cost of maintenance represents between 30 to 60% of the operating costs of a mine, it is of vital importance to ensure the scheduling of weekly maintenance activities. The combination of Mixed Integer Linear Programming and Genetic Algorithms allows to generate a weekly maintenance program with the objective of minimizing maintenance costs, guaranteeing thus equipment reliability [18], taking into account the availability of equipment, the availability of maintenance personnel and the maintenance activities to be performed.

In railway companies, the case is no different. However, their maintenance costs are primarily focused on the repair and replacement of tracks, hence the need to optimize the activities related to these through the design of a mathematical model in conjunction with genetic algorithms [19]. The input variables of such model are maintenance indicators such as mean time between failures, mean time for repair and maintenance activities. The results obtained in this study show that planned maintenance and renewal management systems can be developed and used successfully instead of resorting to corrective maintenance activities.

They also play an important role in the modeling of operating conditions, such is the case of the application of a genetic algorithm to model the operation of a hydroelectric power plant, by modeling its reservoir parameters, inflow, generation head, power generation, water level and plant coefficient. In these optimization models the objective functions are formulated maximizing efficiency (current), survivability and sustainability capability, taking into account economic, social and environmental criteria [20] to achieve sustainable decision making.

Similarly, genetic algorithms can be used to optimize offshore wind farm operation and maintenance assets [21]. In this study, the reliability characteristics of offshore wind turbines and the composition of the maintenance fleet are simultaneously considered in the optimization problem, in order to minimize the operating costs of the offshore farm while maximizing its reliability and availability. Optimized road maintenance planning is another application where genetic algorithms coupled with multi-objective particle swarm optimization (MOPSO) show good solutions that allow minimizing the life cycle cost while maximizing the pavement conditions [22].

Minimizing total costs, while maintaining a defined level of availability and reliability remains one of the purposes of the application of this tool, a mathematical model of nonlinear integer binary programming is proposed in a sodium chloride factory, and the Genetic Algorithm is adopted to solve the model, capable of obtaining a very good solution for maintenance scheduling. Availability, reliability and resource, labor and spare parts constraints are required. Total maintenance costs take into account the costs of unplanned failures, repair/replacement costs, and planned downtime costs [23]. Another similar case is given for water dispensers on an academic campus, where with the same input variables as the previous example, an optimization model is formulated by integrating Dijkstra's algorithm, simulated annealing and a genetic algorithm to identify the shortest maintenance path. The results of the application revealed that maintenance strategies aimed at determining the optimal dispatch time of maintenance personnel could be established based on the minimum unit cost criterion [24].

Genetic Algorithms are widely used to solve production and maintenance problems, a model to minimize costs for production and maintenance planning is proposed, taking into account process quality constraints, i.e., normal process operation (with the specified percentage of defect) and the percentage out of control. In order to obtain the mathematical model that minimizes total costs, it is essential to establish the production levels, production capacity and maintenance budget. As solution methods the genetic algorithm and the tabu search algorithm are employed, being a successful heuristic that is based on the evaluation of neighboring points and repeatedly moves from the current point to the best non-taboo solution until a stop condition is met. The problem is modeled as a nonlinear program and its various peculiarities are discussed. In addition, two metaheuristic methods, (a genetic algorithm and a tabu search) as well as a non-integrated solution approach are proposed [25]. The design of a reliable communication network is a well-known optimization problem to produce a network with maximum reliability. The integration of genetic algorithms with the Branch and Bound method [26] is another case of application of this tool.

It has been proven that when production planning takes maintenance into account, better yields are obtained for the system. In addition to maintenance costs, unavailability rates and failure probabilities have been used as input for the formulation of multi-objective models [27].

Not only multi-objective programming and Genetic Algorithms are alternatives to improve reliability and contribute to the activities that involve maintenance; In recent times, Simulation has also been used as a complementary tool for reliability studies, for example, through Monte Carlo Simulation it is possible to detect optimal maintenance intervention intervals [4], in addition to determining operating parameters, taking into account small samples of failures and multiple failure modes in the presence of uncertainty, seeking to map the reliability response surface of the system [28]. Other applications have allowed maximizing the travel time reliability of a transportation network by solving a dynamic congestion pricing problem, through simulation-based optimization (SBO) [29], or using simulation as a tool to evaluate the support structural reliability of offshore wind turbines, the distribution of failures by generating their predictions [30] or to achieve maintenance manpower planning, seeking to minimize customer waiting time [31], and even to model the risks involved with the human factor [3]. This is achieved since discrete event simulation, combined with multi-objective optimization with system dynamics, allows us to identify the maintenance activities to be performed within the production system, generating less reactive workload in the maintenance organization [32].

In [33] a study is presented to optimize maintenance actions through the analysis of stochastic scenarios based on a simulation model, seeking to minimize the total maintenance cost. Downtime probabilities and uncertainty in the supply of spare parts have been considered in the mathematical model. The model could also be used to predict failure patterns of a specific system, consequently improving the optimization of the stochastic solution.

Simulation using system dynamics has also been used to investigate problems involving multifaceted elements that interact and evolve over time, as found in Total Productive Maintenance (TPM) [34], or by showing how changing interrelationships between fleet management, human resources and subcontractor capability areas are likely to counteract management policies, thus generating performance deterioration [35].

Nowadays, Simulation is increasingly exploited in a wide variety of application domains, although not yet in its entirety [36,37]; however, current virtual simulation platforms provide several tools that allow the generation of non-immersive processes in maintenance, being adopted for analysis, presentation, demonstration and verification of the process, with corresponding time savings in the performance of maintenance activities [38]. This type of study is limited by time, due to the complicated human operations and the logical relationships involved in the processes, so that Simulation still represents a field of opportunity to be optimized.

Another technique used is the Markov Chains, which allow the optimization of maintenance processes, minimizing the total expected cost, including inspection and maintenance costs. Systems deteriorate at a faster rate as they get older, and executing the right maintenance policies is critical. Finite-horizon Markov decisions are used to define optimal maintenance policies, taking into account the time elapsed since the last maintenance intervention, the level of the last intervention performed, and the age of the physical assets [39]. The Markov chain can be seen as a decision support tool for managers concerning the organization of equipment maintenance [40]. It also takes advantage of the traditional probabilistic birth-death approach of Markovian models by using a probabilistic approach to analyze the performance of a system (power plant); performing reliability and availability studies on the plant [41].

Continuous-time Markov decision processes are used for the probabilistic verification of models that allow analyzing the reliability of failures in a multistate system, obtaining flexible and effective results regarding failure times [42]. An example of this is to use the continuous-time Markov chain to describe the degradation process of Traction Power Supply Equipment (TPSE). In this study, the state of the equipment is classified into four levels and the transition probabilities between different states are calculated by equating the failure times in the statistical period. The risk of TPSE failure after maintenance is quantified to optimize both the economic cost and reliability of the maintenance strategy [43]. Furthermore, in [44], in order to address this problem, a Condition-Based Maintenance (CBM) model based on the Partially Observable Markov Decision Process (POMDP) that is continuous in time is established. Considering the maintenance cost and the risk of failure, the optimal maintenance method and inspection period are determined based on this model.

In other cases, these chains are used as a predictive model for intervention intervals, helping to reduce the deterioration rate and the total operating cost, in facilities as important as offshore structures, where the consequences of failures can cause a negative environmental impact, loss of human lives, catastrophic effects and even the collapse of the structure [45]. This is achieved by calculating the transition probabilities between equipment failure states, and determining, by means of an algorithm, the expected number of transitions between these states, which yields optimal results in the determination of the mean time between failures [46]. In [47], Markov chains are used to study the deterioration of roads, mainly by means of the Linear Transition Probability (LTP) matrix method and a Median Life Expectancy (MLE) algorithm. The model developed in this study is ideal for projecting the average life of assets, and the LTP matrix presents a feasible approach for defining a new maintenance regime when more certain deterioration data are available.

Further works addresses pavement maintainability with an optimization approach by simultaneously considering future pavement conditions and the ability to search for and determine optimal pavement maintenance strategies. This is achieved through the application of Markov chain and a particle swarm optimization algorithm that aims to consider the predicted pavement condition and optimize maintenance strategies during operation when applied in the maintenance management of a road pavement section. The results obtained, compared with the linear program, show that the integrated approach is effective and reliable in determining the maintenance strategy that can be employed to promote pavement sustainability [48].

The stochastic Markov Chain model is more flexible and capable of quantifying the uncertainties associated with the deterioration process than the deterministic model approach commonly used to predict offshore health conditions. Some models even allow the inclusion of environmental variables for asset planning [49]. For this purpose, maintenance activities are represented as a semi-Markov decision process and environmental time series are obtained, allowing to find the optimal set of decisions and corresponding maintenance plans, including replacement costs and revenue losses for facilities where uncertainty of operations is present. In addition, this type of studies has come to demonstrate the need for inspections and replacements [50], giving way to formulate new maintenance policies that ensure long-term availability, identifying the factors with the highest incidence that cause the occurrence of a failure.

In modern approaches, to effectively improve fault tolerance, a basic requirement is to perform a reliability analysis aimed at identifying crucial components and thus predicting behaviors that lead to failure. A very useful tool for this purpose has been Neural Networks [51,52], with which reliability and availability indexes are increased, and the economic impact is reduced through the prevention of failure events [53]. The use of a Neural Network is proposed for the prediction of parameters in a machining process to avoid vibrations in the process, thus obtaining a reliable prediction model of the studied parameters [51]; as well as for the evaluation of the reliability of wireless sensor networks that allow monitoring, supervising, controlling and managing a wide range of conditions [52].

In most cases, economics is included as an input variable, represented by the costs involved in maintenance, operations and reliability, which together with the failure rate allow the construction of a Fuzzy Neural Network. As results of this application, maintenance cost and failure rates for a given time period are predicted and optimal maintenance decisions are provided [13]. The combinations of Artificial Neural Networks with Genetic Algorithms allow evaluating the seismic reliability of structural networks, avoiding failures in structural components, increasing the use of these tools in the Civil Engineering domain [54]. Optimal planning for the renewal of water distribution networks, a key infrastructure for the supply of this vital liquid to communities, benefits from the development of a model using a combination of Artificial Neural Networks and the Ant Colony Algorithm, which minimizes operating costs and maximizes the reliability of this network during its life cycle [55]. The combination of Neural Networks with Fuzzy Logic is proposed to support decision making in circuit breaker maintenance management [56].

Other applications of the use of neural networks and genetic algorithms have provided timely prediction of accidents caused by repair and maintenance in oil refineries, classifying the main factors that affect the occurrence of these in six categories: external, internal, executive, behavioral, situational, labor characteristics, type of accident, prediction of the type of consequence and population density; and which are considered as input variables in models with this type of objective [57]. A paper is reviewed that proposes to evaluate the reliability of multi-state manufacturing systems based on an extended state task network, taking into account the operational quality data considering the quality of the work in process. The proposed manufacturing system also takes into account the relationship between the execution of the production task, the state of wear of the equipment and the quality of the product obtained [58]. Likewise, Neural Networks have had great application in the field of human-machine error detection [59] and in structural reliability analyses [60], taking into account reliability in the operational context of the assets [61]. When dealing with very large and complex decision model structures, the focus is on the parameters and values under conditions of certainty assumed by the decision criteria. In modern manufacturing systems, repair and maintenance operations are the cornerstone to keep industrial equipment in optimal conditions of use. In [62] the use of Convolutional Neural Networks (CNN) is proposed for the automatic generation of maintenance and repair instructions, using digital augmented reality (AR) technology.

One tool within the Artificial Intelligence family is Bayesian Networks (BN). These models have different applications for diagnosis, classification and decision making, providing relevant information on how the variables under study are related [63]. They contribute to the improvement of modeling, quantification and analysis of human reliability by taking into account performance factors including complexity, stress, experience, training, work procedures, ergonomics and equipment-related factors as the most significant [59]. The P-F interval, potential failure - functional failure, is implemented as a dynamic Bayesian network allowing to improve the reliability of physical assets [63]. The P-F interval will define how often the condition tasks should be performed on the asset. If we want to detect the potential failure before it becomes a functional failure, the interval between checks should be less than the P-F interval [64]. The deterioration of manufacturing equipment and assets in general is also affected by the maintenance activities carried out, the observation and follow-up of failures, the operating conditions and, ultimately, the operational context in which they are located.

Several works point to Bayesian Networks as a tool that allows the integration of qualitative knowledge when there is insufficient data [65] and when there is a high complexity of the system, allowing the assignment of conditional probabilities of occurrence for each state of the network [66]; However, when considering this qualitative knowledge, based on experts, it provides a data deviation, the extent of which will depend on the experience of those involved in the study and the knowledge of the system [67]. An example of this type of case is the application of the methodology known as Fault Detection and Diagnosis (FDD), based on the knowledge and experience of the process, generating an 80% success rate in the identification and diagnosis of faults [9]. In addition, these models allow the identification of critical components prior to their failure, not initially considered in maintenance planning.

Other works present models that seek to dispel operational uncertainties regarding accidents caused by the man-machine relationship, including human and organizational factors and performance indicators [68], or present a quantitative approach seeking to establish causal interdependencies and reasoning in risk conditions in processes, caused by human and organizational failures, which result in accidents [69]. The activities related to maintenance are a vital point, especially in the last decades, facing two important barriers, one, the high costs that poor management brings with it, and the other, the prolonged downtime. Faced with this problem of insufficient and excessive estimates for the maintenance time interval, Bayesian Networks offer an option for adjusting these time intervals and their associated probabilities [11, 70], model multiple maintenance interventions within the life cycle of the physical asset [71], and are also a resilient tool with a high capacity for adaptation [11].

4. Results and discussion

Eighteen percent of the articles presented in this research correspond to works related to Mathematical Modeling and Genetic Algorithms, Simulation accounts for 18% of the literature consulted, Markov Chains participate with 17%, Neural Networks with 18%, and finally Bayesian Networks with 17%. Likewise, the application areas where this research was developed include studies linked to the productive sector where the reliability of networks, systems, components and physical assets is vital, such as electric power production plants, liquefied gas plants, oil refineries, mines, electronic networks and components, communication networks, water distribution networks and structural engineering.

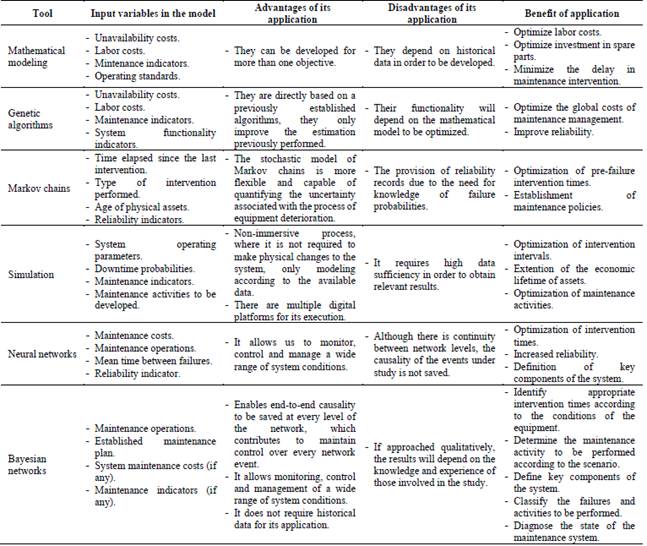

Through the analysis of the references presented in this research, it is possible to identify the input variables, the advantages and disadvantages of each tool, as well as the benefits achieved with their application (Table 2). The application of optimization tools to physical asset maintenance management, leads to:

A better predictive capacity in terms of maintenance times, types of interventions to be performed on physical assets, and maintenance policies to be applied.

The reduction of the economic impact of maintenance interventions, including unavailability costs, to the minimum.

The confirmation of the fact that the maintenance intervention interval, as well as times and costs associated, are the main variables used in the works consulted.

The optimization of reliability and availability of physical assets. Quality in productions is guaranteed, as well as early detection of potential failures, allocation of accurate and effective maintenance policies, reduction of processing time and data analysis in the processes.

5. Conclusions

The review carried out allows us to realize the benefits that the application of the optimization tools presented to the maintenance management studies brings with it; In addition, it enables to identify the strongest aspects of each tool according to the objective pursued, as well as the input variables that are most frequently used in this type of models.

Multi-objective Mathematical Modeling, together with the application of Genetic Algorithms, allows us to obtain positive results in terms of reducing operating and maintenance costs.

Genetic Algorithms allow modeling of operating conditions, minimization of total maintenance costs and timely fault detection at pre-established levels of reliability and availability.

Markov Chains prove to be optimal decision models with respect to the estimation of intervention times.

Simulation is important in the determination of maintenance intervention intervals, and in failure distribution studies for their prediction and contribution to extend the economic useful life of physical assets; however, it requires sufficient data to be used.

Neural Networks establish relationships graphically, allowing to improve pre-failure intervention times of physical assets and to improve reliability.

Bayesian Networks have the advantage of modeling quantitative-qualitative events and are ideal for establishing causality in reliability studies.

According to what has been presented throughout this research, it is shown that the integration of optimization tools to maintenance management allow obtaining satisfactory results, especially in terms of maintenance cost reduction and reliability improvement.