1. Introduction

Meat quality for human consumption is considered here from different perspectives. The first perspective has to do with sanitary quality. This is an obligation when it comes to animals for public supply that includes certification from Health Authorities raising the animals, transport, slaughter, and the commercialization stage [1]. The second perspective is the nutritional quality, related to the contribution of nutrients in the diet, represented by the content, quality, and bioavailability of proteins, fats, vitamins (mainly those of the B complex) and minerals [2-3]. The third perspective is visible aspect, represented by those characteristics that are perceived by the sense organs, like the appearance, color, smell, taste and texture [4]. Industrial quality is considered, in which the characteristics that are valued by the meat industry are grouped together and are taken into account for the design of derivative products, relative to the composition and stability of the chemical systems that compose them [5].

Among the visible aspect the shearing force is probably the characteristic most valued by consumers, since it determines the tenderness of the product [6]. This characteristic depends on aspects such as the anatomical origin of the cut, its macroscopic composition (proportion of muscle, connective tissue and fat proportion), the breed, sex, and age of the animal, and the handling of the meat once it is obtained [7-8]. There are several ways to know the cutting force of the meat. The first is through a sensory panel that, with adequate training, can respond as a reliable and reproducible instrument. The second is by instrumental methods that determine the force to be applied to a standardized portion of the material to produce a cut of meat, simulating the effect of the incisors when a bite is made [9-10].

Because of the breeds and the animal production systems (grazing) predominant in Colombia, the obtained meat cuts from the front quarter of the bovines have been regularly destined for meat products, since it is considered that the animals are slaughtered at ages higher than 4-5 years old and they do not provide tender cuts. However, this production sector has been changing based on livestock farms modernization, animals with genetic and nutrition improved which allows to obtain animals with higher slaughter weights at earlier ages with better meat quality parameters [11].

The amount of fat, protein and moisture are very important factors in the process of formulating derivative products [12], given that a special surveillance function is exercised over them through health agencies and that their relationships determine aspects of sensory quality in a wide range of products such as stability, texture and juiciness. Characteristics such as water holding capacity (WHC) and emulsifying capacity (EC) are mainly indicators of meat functionality that allows a cut to trap and stabilize water and fat when subjected to mechanical or thermal stresses such as during processing [13-14]. Quantifying each of them represents technically limiting values in product formulation in order to be able to adjust to legal realities.

In the meat dough (mixture of ingredients and additives) with which a finely chopped meat derivative is made (e.g., a Frankfurt-type sausage), several systems coexist: an emulsion, a solution, a dispersion, a suspension and even a foam. The correct balance of these depends on the stability exhibited by the product during all phases (constitution, transport, stuffing, heat treatment, packaging and distribution) [15]. In order to determine the general quality of bovine meat produced in the Urabá region (Antioquia), the bromatological, textural and industrial properties of seven new primary cuts of the forequarter of zebus and crosses with zebu males were determined. This characterization was carried out using standardized assays for the determination of protein, fat, humidity, ash, and collagen content, degree of tenderness, water holding capacity, and emulsifying capacity, so that a quality standard could be established in the region for facilitating the commerce.

2. Materials and methods

2.1 Selection and management of livestock

A total of 290 male zebus and crosses with zebu and turine cattled were fattened and castrated in the Urabá region (Antioquia, Colombia). They were slaughtered in a plant certified by the National Health Authority (INVIMA) and processed according to current Colombian legislation [16]. The carcasses were classified according to the Colombian Technical Standard (NTC 4271) as three, four and five stars, valued according to the quantitative and qualitative characteristics of the System. These values included the age of the animal, weight and length of the carcass, dorsal fat thickness, leg perimeter, and degree of finish [17] From these a number of 56 carcasses classified into three, four and five stars (18, 18 and 20, respectively) were randomly selected that were divided into half carcasses by means of a cut performed across the midline of the spine.

2.2. Obtaining the different meat cuts

After refrigerated storing the carcasses for 24 hours, the forequarters of each half carcass were produced by making the commercial cut called a gun before proceeding to execute the wholesale cuts as described below. Shank cut: initially the pectoral and rhomboid muscles were sectioned, later the separation of the thoracic portion of the trapezius muscle was performed by inserting the edge of the scapula and retracting the muscle caudally, then bordering the scapular cartilage and the caudal edge of the scapula, the great dorsal muscle was sectioned, leaving the forelimb free.

For the neck cut, an incision was made from the atlas to the third thoracic vertebra along the cranial edge of the scapula, descending towards the distal area, looking for the shoulder joint (scapulo-humeral), carving against the vertebrae and removing the entire mass of the muscle. For the foreshank cut, the flexor and extensor muscles of the fingers were separated at the junction with the ulna and radius. The loin cut involved a deep dissection between the third and thirteenth thoracic vertebrae up to the vertebral processes and against the corresponding ribs in their joint.

The brisket cut was produced starting in the apophysis xiphoid, making the cut close to the sternum to separate the pectoral ascendant muscle; then the pectoral descending muscle was separated from its attachments to the manubrium of the sternum and from there the muscle bundle with the pectoral muscles was removed. The rib-flank cut was obtained by cutting the parietal pleura of the ribs to promote the separation of the bone from the muscle mass. It was removed by pressure from the ventral end, executing this operation one by one, so that the ribs appear as white bone after fracturing or sawing the joint to the vertebra. For the diaphragm cut, the cut was followed through the entire edge of the muscle that bears the same name.

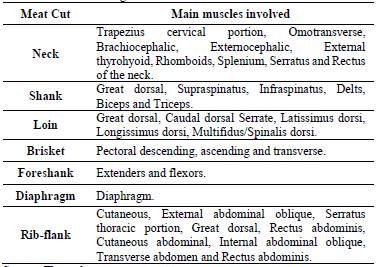

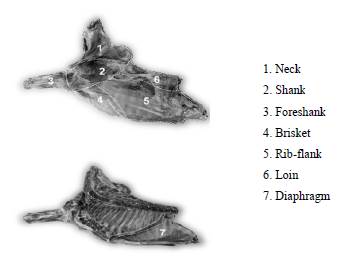

Each of the wholesale meat cuts obtained in this way were properly labeled, vacuum packed, and refrigerated at 4 °C until tests were carried out. Fig. 1 shows the areas of the carcass where the cuts were obtained and Table 1 shows the main muscles involved in each cut.

Source: The authors.

Figure 1 Delimitation of the forequarter cuts of bovine carcass from Uraba region.

2.3 Proximal analysis

A compositional analysis of the different meat cuts was carried out using the Official Method of the AOAC 2007.04 [18]. The samples were ground and placed on the sample chamber of a near infrared spectrophotometer (FoodScan, FOSS NIRsystems, Inc., Laurel, MD, USA), and 16 zones of the sample were sub-scanned, that were then integrated to obtain a total spectrum, that was compared with a chemical analysis database and the relationship between the spectral characteristics and the constituent values of the sample was quantified. Through this analysis, the content of fat, moisture, ash, protein and total collagen was determined. The results were expressed as g of each component per 100 g of meat.

2.4 Determination of meat cuts shear force

The method used to evaluate the shear force of the samples was a hardness analysis. For the evaluation, the meat samples were brought to a cooking temperature of 75 °C in a convection oven and then cooled to 4 °C. Pieces of 6 cm long, 1 cm high and 1 cm wide, were cut, cutting parallel to the muscle fibers. The force necessary to cut the meat sample was measured on a TA.XT texturometer coupled with a Warner-Bratzler blade (Texture Technologies, Hamilton MA, USA) at a cutting speed of 5 mm/s and the average of six readings was the final value; the results were reported in Newton (N) [19]. The textural analyses of all the cuts were carried out at three and twelve days after butchering animal, with the aim of observing the effect of time on tenderness.

2.5 Determination of the emulsifying capacity (EC)

The ability to form an emulsion in meat cuts was analyzed according to a proposal of Carpenter and Saffle (1964) [20] with some modifications [21]. The different cuts were ground to form a uniform paste and 100 g were weighed and mixed in a blender with 750 mL of a cold solution of NaCl (1M) for 60 s. Finally, a 10 g portion of the mixture was poured into another blender and homogenized again with 60 mL of the cold NaCl solution. A 50 mL portion of corn oil (previously containing 0.03% Sudan III lipid dye) was added to the previous mixture and homogenized at high speed. Additional aliquots of oil were added at a rate of 1.0 mL/s until the solution changed phase, observed by the appearance of a darker color and the decrease in the mixing speed in the blender jar. The total amount of oil used was recorded and the emulsifying capacity was expressed as the volume of oil emulsified per gram of meat protein (mL/g).

2.6 Determination of the water holding capacity (WHC)

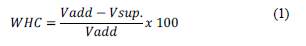

The water holding capacity in meat cuts was carried out according to the following procedure. Portions of 10 g finely ground meat were placed in centrifuge tubes together with 15 mL of NaCl solution (0.6 M). For 15 min they were kept at 5 °C and then centrifuged at 10,000 rpm (4 °C) for a further 15 min. Finally, the water supernatant was measured. The water retention capacity was expressed as a percentage according to eq. 1 [22].

Where, Vadd is the volume in mL of NaCl added to the tube and Vsup is the volume in mL that remains as supernatant after centrifugation process.

2.7 Statistic analysis

All analyses were performed in triplicate and the results were presented as a mean ± SD. Statistically significant differences were determined by one-way analysis of variance (ANOVA) with a F test, and p<0.05 were considered statistically significant. Statistical analyses were performed with Statgraphics Centurion XIV software (Statgraphics Technologies Inc., Virginia, USA).

3. Results and discussion

3.1 Proximal composition of meat cuts

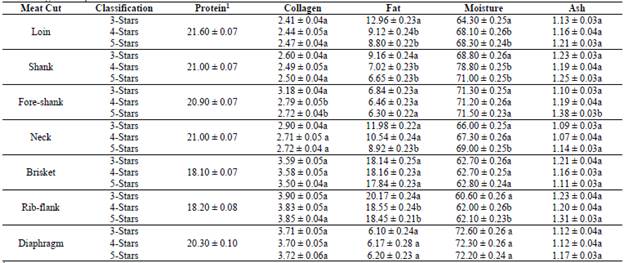

The bromatological composition of the meat cuts obtained are shown in Table 2. The different samples had protein, collagen, fat, moisture and ash values that are within the ranges reported for meat cuts of the forequarters of cattle produced in other places throughout the world, some of them are even classified as Premium Category [23-26].

Table 2 Bromatological composition of meat cuts.

1For protein values, there were no statistical differences between the cuts according to the classification of the carcass. Values with different letters showed significant differences.

Source: The authors.

The protein content was similar in almost all the cuts except in brisket and rib-flank, for which it was slightly lower without being statistically significant (p>0.05). In the case of the protein minus collagen ratio (calculated from the data), the effect of the classification in the neck cut in the four- and five-star categories was evident. In the foreshank cut, there were significant differences (p<0.05) between classifications.

The fat variable presented the expected behavior because the carcass classification system considers their finish (degree of fat coverage) as one of the determining characteristics. Cuts from five-star category carcasses are leaner than those of category four and three stars, although not all were statistically significant. Rib-flank, diaphragm and brisket cuts, were significant different (p<0.05) to loin, shank, fore-shank and neck cuts.

There were collagen differences between the cuts and classifications, as well as in the interaction between them. In general, the cuts from carcasses of the three-star classification were those with the highest collagen content, followed by those from four stars and those from five stars. Rib-flank and brisket cuts were significant different (p<0.05) to neck and loin cuts and to shank, fore-shank and diaphragm cuts. The interactions of meat cut by classification of the carcass from which they come were seen in loin and the neck.

The moisture content of the analyzed cuts was between 60.6% and 78.8%. The loin, shank, neck and rib-flank cuts showed significant differences (p<0.05) with respect to the classification of the carcass by stars, showing a slight increase in humidity for cuts from five-star carcasses. Diaphragm, shank, fore-shank, loin and neck cuts were significant different (p<0.05) in humidity to rib-flank and brisket cuts. Moisture in meat, as a raw material, is related to the contribution of succulence, juiciness, and the ability to incorporate water-soluble ingredients, as well as the ability to form dispersive systems, emulsions and increased yield in the formulation of meat products [27].

The meat cuts presented similar ash content among them and all above 1%. There were no differences between cuts or between the carcass classification. The presence of ash in the samples is important from the nutritional point of view thanks to the contribution of essential elements such as Fe, Se, Mn, I, Zn and Cu that are naturally more bioavailable than the contribution of other food sources and that are also transferred to meat products [28].

The cuts that had the best bromatological characteristics according to the carcass classification system were, for the most part, those that came from the five-star classification (p<0.05).

3.2 Shear force

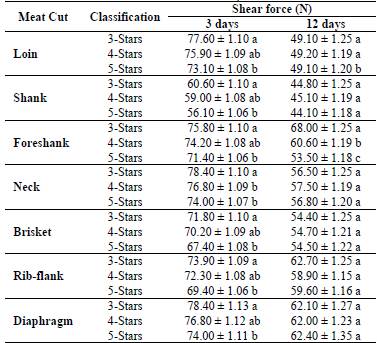

The shear force of the analyzed samples is presented in Table 3. The meat cuts classified as three stars had a higher value of cutting force (lower value of tenderness) than the samples classified as four and five stars; the latter had the lowest values. The effect of time caused a decrease in the shear force of all the samples; this clearly reflects an increase in tenderness caused by the physicochemical reactions that occur in the maturation process [29].

Table 3 Shear force behavior for the different meat samples

Differences in the letters that accompany the values for shear force in meat cuts indicate significant differences.

Source: The authors

According to the magnitude of the shear force in the analyzed samples, shank and loin are suitable cuts for consumption at the table under traditional cooking methods due to their greater tenderness. Brisket and neck cuts could become an alternative, especially after 12 days of maturation, since their values are very close to the limits established by regular and demanding consumers of these products [30], while rib-flank cuts, diaphragm and foreshank, must undergo more severe cooking methods or be used preferably as raw material in industrial processes to make meat derivatives products. Similar results have been found in muscles of the forequarters of Mexican beef [31].

Chriki et al. (2013) proposed that the tenderness of meat depends directly on the biochemical characteristics of the muscles, such as the content of total and insoluble collagen, intramuscular fat, glycolytic muscle fibers and the activity of some enzymes such as isocitrate dehydrogenase and lactate dehydrogenase. This complex interaction allows us to understand the great variability of texture that these studied cuts of meat show [32].

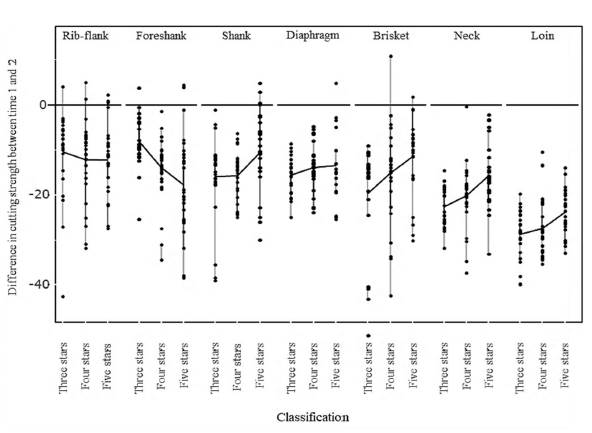

The most tender cuts at two evaluated times was shank, and the one that presented the greatest fall in the value of shear force after ripening was loin (Fig. 2). It is precisely these two cuts that show a higher value for the protein minus collagen characteristic (calculated from the data in Table 2), allowing the suggestion that the action of proteolytic enzymes is more intense on myofibrillar proteins than on stromal proteins, coinciding with that reported by Kim 2018) [33].

1Vacuum packed and kept at ± 4.0 °C. Source: The authors

Figure 2 Relative decrease of the shear force value during the wet maturation process1 of the meat samples, by cuts and classification.

The meat cuts of muscles that are more exercised or have a higher collagen content from lower-rated carcasses, had higher values for shear force measurements at 3 and 12 days of maturation.

The infraspinatus muscles produced the hardness of the shank cut, a result similar to that of Motter et al, 2020 [34], who identify this muscle as the most tender, even when comparing to muscles of the anterior quarter. The was associated with a higher proportion of fibers type I and IIA that together with the composition (protein and collagen content), anatomical location and muscle function allowed us to understand this characteristic [35]. In the case of the loin cut, we observed that it had low shear force values at twelve days of slaughter, a behavior that can be explained due to the joint softness exhibited by some of the muscles that comprise it (Table 1). The brachiocephalic muscle, together with the deltoid and external cephalic muscles are reported by Von Seggern, et al, (2005) within the group with greater hardness [36].

3.3 Techno-functional quality of meat cuts

3.3.1 Water Holding Capacity (WHC)

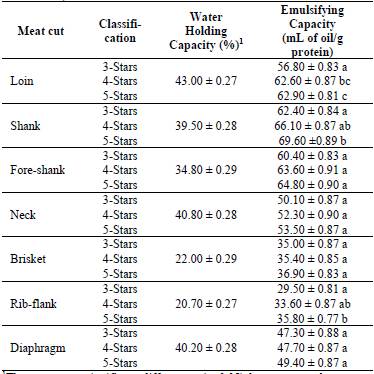

Table 4 summarizes the values obtained in the determination of WHC and EC for the analyzed meat cuts.

Table 4 Functionality of the different meat cuts.

1There were no significant differences (p>0.05) between cuts by carcass classification.

Source: The authors.

The WHC values were significantly different between cuts (p<0.05). The cut that showed the highest WHC was the Loin, responding to the functionality of the myofibrillar protein (protein minus collagen), followed by the shank, neck, fore-shank and diaphragm cuts between which there was no significant difference (p>0.05).

These results are explained by the ability of the myofibrillar protein to form a stable gel thanks to the different chemical forces that coexist there; among them, hydrogen and disulfide bonds as well as electrostatic and hydrophobic interactions [37].

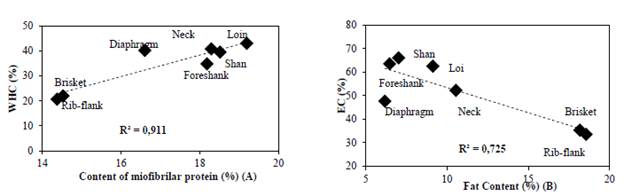

The myofibrillar protein present in the evaluated meat cuts was correlated more than 90% with the water retention capacity shown by the different samples analyzed (Fig. 3). The Rib-flank cut presented the lowest WHC value, which may be due to the high fat content (Table 2) that prevents proteins from being able to bind water molecules due to hydrophobic interactions between fat molecules.

Source: The authors.

Figure 3 Ratio of myofibrillar protein (total protein minus collagen) with respect to the water holding capacity of the meat cuts (Figure A) and ratio of the fat content with respect to the emulsifying capacity of the meat cuts (Figure B).

An interesting case was the diaphragm cut, since it had a considerable WHC, but did not have a comparatively high content of myofibrillar protein. This suggests that the proteins that make up this muscle have functional properties that are even better than those of the other cuts. However, more extensive studies are needed to clarify this behavior.

The results of WHC in cuts of the forequarter agree with those previously reported by Leal-Gutierrez et al. (2014) [38], who studied the Longissimus dorsi and semitendinosus muscles of cattle produced in the department of Cesar (Colombia). Compared to Mendoza-Carrillo et al. (2015) [39] with mean WHC values of 28.13% (measured by the filter paper method) for Longissimus dorsi in Holstein cattle of different body conditions; the loin, shank, foreshank, neck and diaphragm cuts of this work had higher values (Table 4)

3.3.2 Emulsifying Capacity (EC)

The EC of the studied meat cuts are presented in Table 4. It can be noted that fore-shank, loin and shank cuts were significantly different to neck and diaphragm cuts and to rib-flank and brisket cuts. It is underlined here that there was no relationship of this variable with the WHC. This means that the myofibrillar protein is not the only parameter involved in this functional property and therefore the fat and moisture values of the samples must be taken into account true, for example, with the diaphragm cut.

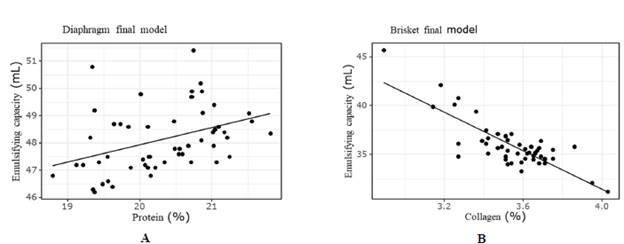

In Fig. 4A the total protein content was positively related to the EC, while in the brisket cut showed how the individual effect of collagen indicated a negative relationship with the EC (Fig. 4B) that from the techno-functional point of view would be detrimental to its use; for this reason, this tissue is usually removed from the cuts (represented in the tendons, fasciae and vascular system) before producing meat products. There is consequent nutritional loss caused since collagen provides some non-essential amino acids, including proline and glycine, important because they are precursors of different substances and their function at the level of the central nervous system [40].

Source: The authors.

Figure 4 Emulsifying capacity for the diaphragm cut, in terms of total protein (Figure A) and emulsifying capacity of the brisket cut in terms of collagen content (Figure B).

The EC is also closely related to the fat content of the cut. In Fig. 3 this relationship can be seen. The cuts that are at the top left (foreshank, shank and loin) stand out, as they are leaner cuts than the others and therefore they are able to trap and stabilize more fat in a biphasic system. In contrast, cuts such as brisket and rib-flank, have a low emulsifying capacity. This phenomenon can be explained because they are cuts that have a higher collagen content than the others (Table 2), and an increase in the amount of collagen in an emulsion-type formulation can lead to phase separation [41].

4. Conclusions

The cuts of loin, shank, foreshank, neck, brisket, rib-flank and diaphragm, from bovine carcasses of cattle produced in the Urabá region (Colombia), had bromatological characteristics that were within the ranges reported for these types of cuts produced in other places in the world, some even classified as premium category. The tenderness of the cuts showed dependence with respect to the classification system used and was higher in those cuts of five-stars, followed by those of four and three-stars. The cuts of loin and shank were identified as more suitable for home consumption, while the other cuts can be used in formulations of derived meat products. The water holding capacity and emulsifying capacity of all cuts were heterogeneous and depended directly on the analyzed meat cut. The water retention capacity increased along with the myofibrillar protein content, while the emulsifying capacity decreased in the meat cuts that contained higher fat content. With proper management of the bovine carcass, front cuts can be obtained with important quality characteristics that bring benefits for both the producer and the end consumers.