1. Introduction

According to the National Accreditation Council of Colombia (CNA), formative research is considered as a pedagogical strategy, i.e. a set of actions aimed at strengthening the appropriation of knowledge in the process of training the individual as a social actor, which in no way replaces the role of university in carry out scientific research 1.

According to Díaz Villa, academic culture, as an expression of the power and control relations that underlie the division of academic work in the university, has been characterized by the division of academic work between teaching, research, and extension, thus generating a very strong separation between teaching and research 2. At university, research work is more appreciated than professional training, which translates into an excessive emphasis on scientific research to the detriment of formative research processes. This discrimination has been referred to by other authors, such as Galeana, who states that project-based learning seeks to improve the ability to solve problems and develop complex tasks, the ability to work in teams, develop higher order mental capacities, increase knowledge and skill in the use of ICT, and promote responsibility for one's own learning 3.

An integrative project is a formative research strategy that consists in carrying out a set of articulated activities, with a beginning, a development, and an end, with the purpose of identifying, interpreting, arguing and solving a problem of the context, and thus contribute to form one or several competencies of the graduate's profile, taking into account the approach to a significant problem of the disciplinary-research, social, labor-professional context 4.

The authors opted for the design and implementation of a strategy based on integrative projects with a complex approach throughout the professional training cycle, seeking continuity in the training route and its relevance. It is expected that by carrying out several successive integrative projects, students will achieve significant improvement in their professional competencies. The pedagogical approach of the proposed training project can be placed in the line of situated learning and the development of reflective critical thinking.

From these conceptions of learning, we derive an instructional approach, situated teaching, which affirms that activity and context are key to learning and recognizes that school learning is, above all, a cultural process through which students are progressively integrated into a community or culture of social practices. In this sense, situated teaching assumes that learning and doing are inseparable actions.

Teaching for understanding involves a process of meta-cognition that can be guided by three essential questions the teacher asks himself when introducing a new concept or creating new learning opportunities:

What do we really want our students to understand, and why?

How can we engage our students in constructing these understandings?

How will we and they know that their understanding is developing?

According to Perkins, understanding is not just about knowledge; it is also more than a routine automated skill. Understanding is the ability to think and act flexibly from what one knows 5. In Gardner's words, "when students can apply their knowledge to new situations or can solve problems appropriately, they can be said to have understood" 6.

Methodologically, for the implementation of the training projects, Tobóns proposal 7 on competency-based training and the methodology for planning the learning and evaluation processes of this same author [8] have been followed and adapted to adjust to the particular situation of the project.

The approach proposed by Tobón describes competencies with three components: problems, criteria, and evidence. The problems are challenges of the context; the criteria, the specific aspects to be taken into account in mediation and assessment; and the evidence, the concrete proof to analyze the criteria and determine the process of competency formation. In this approach, evaluation has only three basic axes: criteria, evidence, and learning maps (rubrics), making it simpler and more feasible to apply. In particular, we found Kennedy's methodology 9 to be very explicit. Not only as researchers, but above all as engineering teachers and trainers, we have wondered how to structure and adopt a strategy for training in engineering research that allows students to develop a critical attitude and a creative capacity to find alternatives for the advancement of science and technology in the country. Is it possible to train technical skills while developing critical thinking and a sense of social responsibility of future engineers? With these questions in mind, the authors initiated a technological appropriation project. This is a basic research project using plasma surface modification techniques for metal hard coatings that has potential application in areas such as biomedical inserts, cutting tools and the decoration. This project aims at bringing about significant improvement in the quality of the manufacturing of this type of products in the national industry. High hardness materials are very important in improving the competitiveness of the industry, since they allow a longer duration of the parts, better quality of the manufactured products, less reprocessing, shorter production cycles, and lower cost. Similar advantages are obtained in the jewelry and costume jewelry sector.

During the design of the proposal, one of the strategies to develop this technology and at the same time create a new line of research for the development of new materials was to involve students from the beginning, that is, from the design and construction of the necessary equipment and prototype.

The technology chosen for appropriation is Physical Vapor Phase Deposition and according to one of the authors, different Universities use the sputtering technique, and there are different studies applied to improve the mechanical, tribological, morphological and corrosion properties. The coatings obtained by using these techniques show advantages in the improvement of the said properties in relation to other surface modification techniques, especially when working with stainless steels.

The commercial cost of a deposition system of this technique is high, since investment of the order of 100,000 to 200,000 dollars is required. This constitutes an important financial justification to undertake technological appropriation and build a low-cost system with an investment of no more than $10,000.

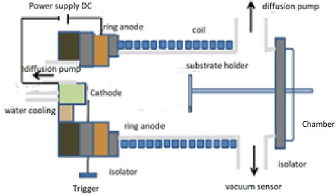

A non-commercial PVD benchmark is constituted by a vacuum system applied to a chamber and inside it an evaporator formed by an anode and a cathode, both cooled and connected to a 18Kv power source 10. Fig. 1 shows the system diagram 11. the chamber is surrounded by a cooling system, blue dots, output for vacuum extraction, input to sense the vacuum and insulation for the cathode and anode.

Source: the authors.

Figure 1 Scheme of the experimental setup: evaporation chamber and connections.

In these systems, the discharges are generated in high vacuum, which is obtained by means of diffusion pumps assisted by a mechanics that reaches a base pressure of 0.01Pa.

The evolution of the technological appropriation of the PVD technique will be shown below.

2. Experimental procedure

Initially, low-cost technological appropriation was sought. (Technological appropriation takes place when the individual feels that the technology no longer belongs to a third party, but is also his own, and demonstrates it in practice, through the use and handling of it). To this end, a first phase of the project is elaborated to design and build the vacuum system applied to a deposition chamber. This first phase involved the design of an elective course for the students who were going to participate in the construction of the prototype seeking to develop specific competences: 1) Knowledge of cathodic arc deposition techniques. 2) Design and construction of an equipment or device for a sputter evaporator system used for the production of nanostructured coatings.

The one-semester course was designed for students from different programs of the Faculty of Engineering: Industrial Engineering, Bioengineering, and Electronics Engineering. It began with the description of the vacuum and arc system operation and the physical principles involved in each of the devices included in the equipment. Considering the skills of the students in each program, the parts or devices of the equipment that the students could design at low cost and with project resources were agreed upon. The main activities of the first phase of the project included the following:

System design

Design and construction of the deposition chamber

Design and construction of a diffusion pump

Design and construction of a gas sensor

Selection and procurement of a mechanical pump

Selection and procurement of complementary parts

Assembly and set-up of the vacuum system

To begin with, we chose to build a diffuser pump, considering its high commercial cost compared to our budget. For this, the Reverse Engineering methodology was used; a diffuser was disassembled, and low-cost options were sought to use stainless steel parts that are commercially easy to acquire and that require the least machining work, with measurements not necessarily equal to those of the commercial equipment, since the conceptual principles are applied in the same manner.

The design and construction of the prototype chamber considered the dimensions according to the applications and materials that are commercially available and allow the least amount of metalworking. The accessories such as valves, ducts, dividers, and adapters, were obtained commercially in similar designs, but of lower cost than those used in the laboratories.

In this phase of the project, the students participated in the design and construction of other devices such as the Hall probe, magnetic concentrator and gas sensor. Once the student teams had defined the device to be designed, they had to present a work plan in three stages: In the first stage they made a literature review on the operation of the device to be built and its commercial offer. The second stage consisted in designing and implementing the device, while the last stage focused on verifying its proper functioning. Therefore, each project, although on a smaller scale, went through the different stages of a real engineering project.

In a second phase of the project, the students are linked to the faculty's research group. The methodology of the seedbed consists in a reflection seminar with sessions of 2 hours per week. At a first moment the professor presents different topics on strategic management of technology and development of new products related to the current project. At a second moment, a debate is opened with the students, using reflective dialogue and didactic questioning as a key strategy. This consists in the teacher making explicit the procedure he/she is working with the students are given a task (for example, to explain how the device they designed works), the procedure (how they did it) and the justification (the function the device fulfills in the total system, the products that can be derived from this technology, its applications, potential markets, etc.). The teacher stimulates the learning process through questions. The answers to the doubts that remain in each session must be investigated and the results brought to the next session. A document is progressively constructed with the knowledge built collectively. The idea is to guide students to explore opportunities for knowledge transfer or business creation, making explicit the purpose of teaching (18).

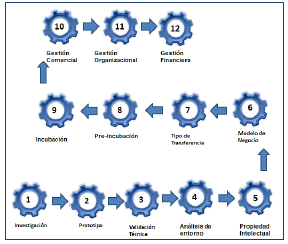

In order to adequately address this second phase of the project, a bibliography search was conducted on the processes of university technological innovation. The group's attention was drawn to the "Basic methodological guide for the creation of business plans in technology-based companies" Universidad Nacional de Colombia, which is a compendium of the development of concepts and the transformation of knowledge into the creation of companies that are born as a product of the research processes carried out by the academic sector during the last two decades around the world. The innovation cycle for the creation of technology-based companies is shown in Fig. 2.

Source: Adapted from Guía metodológica básica para la creación del plan de negocio en empresas de base tecnológica, Universidad Nacional de Colombia.

Figure 2 Innovation cycle for the creation of technology-based companies.

When analyzing the innovation process presented by Universidad Nacional and comparing it with the competencies of the Industrial Engineering program of the Universidad Santiago de Cali -USC- (to which most of the students of the seedbed belong) it was seen that up to this second phase of the project the basic research stage, the construction of a prototype and the technical validation were covered, being oriented to develop the competency "Capacity to design in Engineering", a competency of the Faculty component. The three specific global competencies of the program were also analyzed (i.e.: 1. Manage the production of goods and services with quality, productivity and timeliness criteria; 2. Manage the company or functional areas, with strategic, administrative, economic and social criteria; 3. Innovate processes, products and services based on organizational competitiveness criteria) and it was seen that a particular competency, "Innovate processes, products and services based on organizational competitiveness criteria" encompassed the specific competencies of Industrial Engineering innovation and its development implied moving towards the subsequent stages of the technological innovation process: analysis of the environment, intellectual property, business model, type of transfer, pre-incubation and incubation of a technology-based company based on the new technology and the training of the human capital necessary to carry out an entrepreneurial project of this nature.

From here it was clear to the project working group that by going through the whole innovation process it was possible to develop the competencies "Ability to design in Engineering" of the Faculty component and the competency "Innovate processes, products and services based on organizational competitiveness criteria" of the specific component of the program and also to create a line of research that would allow the promotion of applied research in Industrial Engineering itself. As a result, in October 2016, the research line "Technological development and innovation in materials" was formally created. The advantage offered by this line of research was that in addition to promoting the development of new materials, it would foster technological innovation.

The students were directed towards two electives: Technological Innovation and Technological Surveillance (Competency to be developed with these electives: to manage technology based on the strategic direction of the organization). The coursework focused on specific topics of the project.

3. Results

In the first phase of this project, five proposals were presented at the XIII internal formative research meeting (The proposals presented by the students were: "Design, construction and testing of a magnetic concentrator"; "Characterization of a vacuum system"; "Construction of a prototype of a high voltage ion implantation source at variable frequency"; "Technological surveillance on surface modification of hard materials"; "Construction of a Hall probe").

In the second phase of the project, the preliminary degree projects were elaborated as a result of the work of the seedbed with students of:

1) Industrial Engineering: "Technological surveillance in nitriding processes", "Technical-economic feasibility study for the design of a coating process based on the physical vapor deposition (PVD) technique applied to the metal-mechanical sector", and "Business plan for the structuring of a company dedicated to the nitriding of parts". 2) With two Electronic Engineering students: "construction of a power source for a sputtering system".

These proposals were presented at the XIV Internal Meeting of Formative Research.

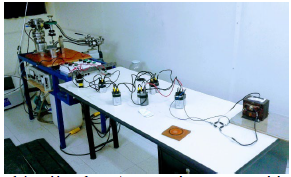

At the end of the first phase of the project, with the participation of all the students, the vacuum system was assembled, obtaining a cost reduction in respect to commercial values between 60-70%. The assemblage of this system is shown in Fig. 3.

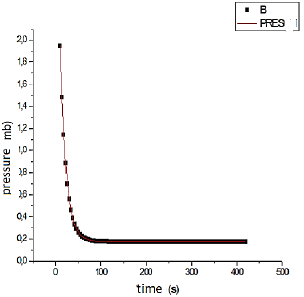

The vacuum characterization allows to go down to 10-1 mb in 2 minutes with the mechanical pump; with the diffusion pump built up to 10-4 mb in 15 minutes.

The vacuum characterization for the mechanical pump is shown in Fig. 4.

For phase II, the deposition chamber for the continuous arc technique is built and the system assemblage is shown in Fig. 5.

In parallel, a sputtering source is built, and the same vacuum system is used to assemble the magnetron sputtering system. The second phase (design and construction of the arc sources) starts with the construction of the sputtering source. The corresponding assemblage is shown in Fig. 6.

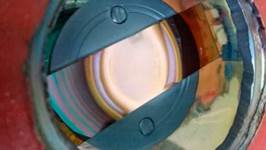

The equipment set-up and validation allowed for copper coatings to be made, using a commercial copper foil. One of the films obtained is shown in Fig. 7.

4. Conclusions

Learning based on formative projects facilitates the development of professional competencies in engineering because students have the opportunity to face relevant problems of their context, analyze them, and propose solutions.

The fact of facing a real engineering problem, such as the appropriation of a technology, promotes meaningful learning, reflection on action and the ability to formulate strategies for technological innovation, as evidenced by the collective knowledge built throughout the project.

In situated learning, the interaction between project participants and other external actors dynamizes the training process because the exchange of information between individuals who have different levels of knowledge (peers, teachers and experts in the environment) promotes a modification of the student's schemas, who ends up generating learning, as well as improving motivation to the extent that student discovers that he/she can build a professional life project.

It is possible to build low-cost cathodic arc deposition equipment, functional for formative research.