1. Introduction

The supermarket sector, in a contemporary perspective, has considered customer satisfaction as something to be prioritized [1]. In this context, one of the existing challenges is the development of skills and differentiating characteristics by organizations, in order to achieve a competitive advantage [2,3]. Faced with this, in many cases, employee motivation is a determining factor for the success of organizations, since customer satisfaction is closely related to the level of service provided by their employees [4]. In the case of the expansion process of the supermarket chain, this occurred gradually, first with the participation of countries in Latin America, followed by Asia, Europe and Africa [5].

The supermarket chain was introduced in Brazil in the early 1950s, where it subsequently went through a process of structuring and maturing the market [6]. During the 1980s, the sector followed the crisis of the Brazilian economy, so that it returned to show high growth rates in the second half of the 1990s [7]. The changes in the macroeconomic environment caused an increase in demand, attracting several national and foreign organizations to the sector [5]. Within this phase of great growth, supermarkets started to use new technologies, especially commercial automation [5-7].

Service processes’ automation in the supermarket chain appears as a response to the optimization of quality standards and customer satisfaction [7]. Regarding this, quality management is responsible for incorporating a new form of management based on innovative concepts and techniques to the reality of organizations [8-10]. Among the contributions of the area, there are the Process Management and the Routine Management [11]. Process Management enables the analysis of an organization in an interconnected way, where work is dictated by the processes that compose it, in this way, activities come to be considered as vital parts for quality assurance as a whole [11,9].

Regarding Routine Management, it is based on the greater autonomy of employees to solve daily problems, providing greater effectiveness and operational efficiency [8,12]. In addition to Process Analysis and Routine Management, Process Simulation can be incorporated in this context as a complementary measure to aid in the effective diagnosis of operations [13]. In view of this, Process Simulation has applicability in the solution of real problems through the anticipation of adverse situations in the system, as well as in the performance evaluation of the system [14]. Thus, among the contents covered by the simulation, the Theory of Queues can be highlighted, in which systems with arrival, waiting and service processes are analyzed [15]. For this purpose, input variables are defined that correspond, for example, to the rate of arrival and customer service [14].

Finally, the present study carried out an analysis of the microprocesses and activities performed by cashiers at a supermarket located in the Alto Paranaíba mesoregion. In addition, its aim was to optimize the performance of the cashier's service macroprocess, by reducing the average time taken to carry out the activity. It should be remembered that the research problem was related to the recurring delays in customer service, generating long lines, with a long average waiting time. The justification for this study was based on the need for improvements in the performance of the cashier service sector and, consequently, on the level of customer satisfaction.

2. Literature review

The search for efficiency and effectiveness of productive systems is a constant practice in organizations in face of the current competitive scenario [16]. In this, the development of core business is a key aspect for organizational success, helping to expand market share, for example [16]. In this way, tools are used in order to guide the progress of organizations, providing greater effectiveness in their strategies, as well as promoting the achievement of pre-established visions [17]. In this context, the PDCA (Plan, Do, Check, Act) cycle can be incorporated into organizational processes as a foundation for reaching the final objectives and, above all, for their continuous improvement [18,19].

2.1. Quality management and process simulation

Quality Management practices improvement has become recurrent in organizations [8,20]. Thus, in addition to inspection and control to guarantee the final quality of products, there is a search for perfection and skills’ development, in order to enhance the results and financial returns of organizations [8,21]. In addition, the present scenario contemplates the introduction of new technologies and more dynamic production patterns, contributing to the effectiveness of processes and the production chain [8]. In view of this, greater employee training becomes a necessity that should be encouraged by organizations, since the progress in the level of consumer demand is progressive [10]. Another striking aspect refers to the standardization of processes that guarantees the simplification of these, as well as the reduction of costs and production lead time [21].

When it comes to achieving customer satisfaction, Quality Management operates in organizations, based on the practice of basic aspects, such as customer focus, teamwork, decision making based on facts and data, constant search for problem solving and reduction or elimination of errors [8,21]. It is worth remembering that this management model brings benefits to the organization, in terms of improving employee satisfaction, more efficient information flow and increased productivity [8]. In this way, the production system becomes more dynamic with the development of products and services of high conformity [21]. According to the management philosophy based on the dimensions of quality, the effectiveness in satisfying internal and external customers occurs in parallel, that is, there cannot be satisfied external customers without the organization's internal customers also being satisfied [9,8,20].

The search for the improvement of productive systems is also a reality that can be understood from the perspective of Process Simulation [14]. In this sense, simulation represents a tool for analyzing scenarios and assisting organizations in decision-making processes [13]. In addition, Process Simulation is based on the creation of models that faithfully represent the basic and essential aspects of the analyzed reality [22]. The applicability of this tool is wide, both for the manufacture of products and for the service branch [14]. Among some application examples, assembly lines, automated cells, production scheduling problems, inventory analysis and logistics chains can be mentioned [13].

Thus, in the theme of service production systems, a long waiting time for customers in line to perform a type of service generates impacts on the service perceived quality [23]. In view of this, Queuing Theory emerges as a tool for analyzing the average queue, service and system times, so that it allows a careful view of the reality analyzed from the input data, in this case, the arrival rates and customer service [14,22]. It is worth mentioning that the application of intrinsic factors of Production Simulation and Queuing Theory to the cashier service contributes to the measurement of the number of jobs, as well as the efficiency of the entire process [14,13].

2.2. Process management and routine management in supermarket organizations

The supermarket sector organizations initially prioritized the service of close customers, so that aspects related to management, such as cash flow and investment capacity, were forgotten [1]. With the advancement of technologies and the globalization process, the dispute for new customers has become fiercer among organizations in this sector [2]. In view of this, aware of the client’s power of influence in view of organizational success, they dedicated themselves to incorporating new business management techniques [2]. It is worth remembering that the performance of organizations is directly related to the efficiency of their processes, so that measures to reduce costs and waste resources have become recurrent [9,10].

The Process Management methodology makes it possible to analyze the organization as an integrated system, in which work is performed through its processes [7]. Thus, for an organization's managerial functions to perform satisfactorily, its operational functions must also be effective [8]. In other words, it is necessary to make evident the role of each person within the organization, so that in fact better results are obtained [17]. In an organization, operational processes are the ones that demand the most time, making their continuous management indispensable [11]. In view of this, the concept of Process Management is approached both as continuous improvement and as a rupture, in which case new processes are inserted [24,25].

In addition, the interaction between the organization and its processes must be perceived, and the performance of each process must be measured in relation to the planned results [24]. Among the Process Management tools, process mapping is an option for improving efficiency, as it can reveal bottlenecks, the unproductive use of resources, redundant steps, as well as activities that do not add value and root causes of problems [26]. Thus, in order to leverage organizational performance, it is of paramount importance to have a process improvement study, that is, an effective management of processes and organization as a whole [7].

In order to improve service, increase quality and satisfy internal and external customers, it is significant to apply routine management in the supermarket sector as a complementary measure to Process Management [9]. This is justified since the Routine Management is managed by all hierarchical levels within the organization, and aims to train participants in daily activities, meaning a project for continuous improvement and maintenance [8]. Routine management aims to give the employee more autonomy in decision making, reducing the overhead of supervisors and managers [8]. In addition, it also seeks to increase productivity, customer satisfaction, effectiveness and operational efficiency and promote the reduction of accidents at work [10].

2.3. Contextualization of supermarket organizations in Brazil

The supermarket sector underwent a major transformation shortly after the Real Plan, where inflation rates were very high [27]. Then, this was marked by the modernization and focus on the customer, with an important growth and profitability, a fact that intensified the competition between the existing networks [27]. Authors [5] points out that the changes in this sector have an impact on several other market segments, as this sector is a great generator of jobs, as well as an important link in the production chain, generating advances in the economy.

However, the referred sector presented difficulties related to the fierce competition between local organizations and large networks, difficult access by more distant populations, heterogeneous markets and hiring qualified labor [4,5,2,28]. Thus, in addition to the quality of the products offered, it is essential to promote services with acceptable levels of quality, as a way of reaching the fullness of the market and its satisfaction [5]. In addition, organizations seek customer loyalty, since the cost of attracting new customers is five times greater than the cost of maintaining them [29].

Currently, in the supermarket sector there is a restructuring of organizations, with the objective of adjusting and adapting companies to the scenario of intense competition, resulting from changes in the Brazilian economy [30]. The increase in competition exposed the sector's difficulties in rapidly changing its focus of action and adapting to the new competition scenario [29]. The greater structuring and adequate use of information related to the consumption pattern, combined with the concentration of the sector, place organizations in a privileged position in relation to suppliers [30]. It is worth mentioning that adapting to new scenarios has been important to accompany the transformations that have occurred in this market, and thus to outline new strategies, being fundamental for the organization's survival [5].

When it comes to the quality of services offered to consumers, their guarantee for increasing productivity, reducing costs and increasing profit is of great importance [5]. According to authors [17], for some customers the speed and quality of service in supermarkets often override the lowest price. As stated by authors [5] there is a need for new investments to improve the human capital of organizations in the supermarket sector, contributing to a better performance of the organizations' human resources strategies. Authors [5] also argue that studies indicate that in the future, the supermarket employee will act as a product and service advisor, starting to play a role closer to the customer.

3. Materials and methods

The research methodology corresponds to a detailed analysis based on scientific procedures in order to solve a specific problem [31,32]. In addition, this is considered as an unfinished process and in constant change, being possible its adaptation and intervention in the studied reality [31]. Authors [33] complement that scientific research is a systematic and intensive process aimed at analyzing the real facts. It is worth remembering that the scientific method allows the ordering of thoughts in systems, in addition to drawing action plans to reach the pre-established objectives [31].

Thus, the present study was supported in some areas of Quality Management, in this case, Process Management and Routine Management, and Process Simulation based on Queuing Theory for its development and obtaining results. In addition, the Process Simulation was also present in the representation of the Activity Cycle Diagram (Diagrama de Ciclo de Atividades - DCA) performed with the aid of the Simul8 software, complemented by the process mapping built in the Bizagi Modeler software and in the validation of the collected data. In this study, first a systemic analysis of the internal processes of the supermarket considered was developed, according to the Process Management approach.

In view of this, through the brainstorming sections and direct observations made by the team members, the cashier service process was defined as the object of study, since it presented greater inefficiency compared to the other existing processes, in relation to the formation of a longer queue waiting for customers. Brainstorming corresponds to a group technique carried out with the objective of enhancing the emergence of innovative ideas for the solution of a predefined problem [34]. Another important aspect corresponds to the democratic acceptance of ideas in a group of people, a fact that contributes to the generation of innovative solutions for processes [35].

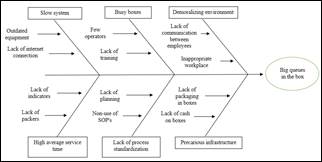

In this way, a processes’ mapping was carried out referring to the macroprocess of service of cashiers, in order to obtain greater knowledge about the activities that comprise it. Then, the present study was based on the construction of an Ishikawa diagram, which made it possible to understand the probable causes of the problem inherent in the cashier's macro service process, in this case, the formation of long queues for customer service. According to authors [9], the Ishikawa diagram helps to understand the main causes of the problem addressed, as well as to monitor and continuously improve operations. Also, according to authors [9], this tool is divided into six categories of primary causes (6Ms), they are, machine, method, material, environment, measure and labor.

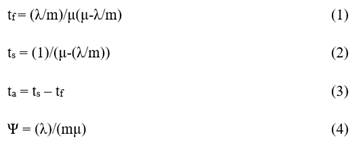

As a way of analyzing the current process, from direct observations, the average intervals between arrivals, the average service time and the average waiting time for customers in line for both conventional and priority cashiers were estimated. From that, arrival rates were calculated (λ), attendance (μ) and use of the system (Ψ), in addition to the average waiting time for customers in line, according to the analysis method adopted. The formulas referring to the average time of customers in queue (tf), average customer time in the system (ts), average service time ( t 𝑎 ) and rate of use of the system correspond to the equations (1), (2), (3) e (4).

Where:

λ = Customer arrival rate.

μ = Customer service rate.

m = Number of cashier stations available.

It is worth remembering that the analysis method adopted corresponded to the M/M/1 model with FIFO priority service (First In First Out), with the calculations being made for seven parallel and independent cashier stations, that is, five normal and two priority ones. In the case of Routine Management, continuous improvement was designated by the PDCA cycle. In the Plan (P) stage, after identifying the root causes of the macroproblem, strategic measures were structured with a view to the effectiveness of operations. In the Do (D) stage, the average time of the customer in line was calculated according to the model presented. In the Check (C) step, the values referring to the average waiting times of customers in line were compared, that is, the actual value verified with the estimated value, using the model described, being calculated the percentage variation based on real time observed. Such variation can be considered as a performance indicator of the flow of operations for the service macroprocess. As for the Act (A) stage, the creation of Standard Operating Procedures (SOPs) was suggested, in order to standardize the services provided, based on the improvements previously proposed. To achieve continuous improvement, being the pillar of Routine Management, the PDCA cycle must be constantly monitored through the performance indicator already established. Fig. 1 represents the Activity Cycle Diagram (DCA) implemented in the Simul8 software.

In view of this, when making purchases, the customer has the option of going to a priority service station or to a conventional one, if the quantity of goods exceeds the quantity allowed in the priority cashier station. In addition, the system has among its resources, cashier operators, packers, cashier and an available space of 2 customers, per regular cashier and 5 customers, per priority cashier.

It is worth mentioning that this study was characterized as hybrid research, with the presence of quantitative and qualitative analyzes. The quantitative analysis was responsible for generating numerical data in relation to the observed average times, whereas the qualitative analysis corresponded to an interpretation of these data, in order to propose improvements and appropriate solutions to the problems observed in the cashier service macroprocess [36]. The present study was also configured as a case study, since according to authors [33] the case study is convenient when it has the objective of investigating the how and why of a set of contemporary events. It is worth remembering that the case study is an empirical investigation that allows a contemporary phenomenon within a real-life context [33].

4. Results and discussion

The analyzed company in this study is located in a municipality in the Minas Gerais region of Alto Paranaíba. Besides, it is a company in the supermarket sector, in addition to having a familiar character in its formation. Currently, the company counts on the efforts of approximately 90 employees, who are distributed among the different departments of the organization. Among these, the department of stocks, stationery, butcher, bakery, administration and cashier services. The company has a wide range of suppliers located in the middle of the city. Regarding to the sector analyzed, the cashier sector, it has a reduced number of employees, who carry out shift changes, in order to facilitate compliance with the imposed workload. Finally, the company serves a diverse audience, including consumers of different economic classes and age groups in the municipality.

In the case of Management by Processes, it aims to detect the interaction between the various activities and processes carried out by a company, through a totalitarian and integrated view of it. In Process Management, the first necessary measure is the total mapping of the company's processes, making it possible to identify all the integration between the operations, as well as the singularities and needs of each one of them. However, the study only contemplated the mapping of the cashier service macroprocess, since it was inefficient above other sectors. Thus, Fig. 2 represents an outline of the analyzed macroprocess.

The team responsible for the macroprocess is formed by 13 cashiers, who are divided between shifts throughout the week at the seven existing workstations. When these are admitted, the cashier undergoes training of just one week, so that the person learns the function activities and acquires contact with the system used. The one that is easy to understand, however, presents problems a few times a month, requiring the help of technicians to resolve such adversities. In order to complement the study and promote a greater understanding of the causes related to the formation of long queues, an Ishikawa diagram was developed, in which these causes are arranged by categories. It is worth remembering that the brainstorming and direct observation sections were fundamental for the construction of this. Fig. 3 represents the diagram where possible causes for the identified problem are listed.

Thus, the cause attributed was the slowness of the system, and as possible sub-causes, the existence of outdated equipment and the lack of internet connectivity were considered. A large part of consumers makes payments by credit card, so it is necessary to connect to the internet for the software to receive purchases; when the network is unavailable, the operator must receive it by manual card machines, generating delays in the service. As strategic measures, it was suggested to increase the network speed and replace old hardware.

In the Labor force category, the fact that cashiers are always busy was considered as the main cause, and their probable sub-causes were related to the operators’ reduced number and their lack of training. In addition, it is worth remembering that most of the customers when making the payment for their purchases opt for the division of the account, this process is slow, since it needs information on how many people there are, and how each one is going to pay. Based on the observations made, it was evident that operators are poorly trained to perform this task, since in these situations large queues are formed. Therefore, as strategic measures, more intensive training for new operators was suggested, as well as the expansion of the number of these during times of greater service flow.

In the case of the Environment category, the main cause identified was the demotivating environment, its sub-causes being the lack of communication between employees and the existence of poorly designed jobs. In view of this, the lack of an adequate flow of information prevents activities from being carried out with greater dynamism, hampering the work of employees. In addition, it is worth remembering the issues related to the poor projection of the cashier's workstations, which are subjected to undesirable positions and a continuous exposure to the luminosity of computer monitors. Therefore, as strategic measures, it was suggested to carry out an ergonomic analysis of the cashiers’ jobs, the use of cash management tables and continuous feedback from the operators with the cash management and inspector.

In the Measure category, the occurrence of a long average service time was adopted as the main cause. With regard to possible sub-causes, the lack of indicators that assist in monitoring and controlling the performance of the analyzed macroprocess was considered, as well as the lack of employees at the cashiers to carry out the packaging. The packaging activity can be understood as one of the reasons for the formation of long lines, since in the absence of packers, such activity ends up being performed by the operators themselves, which generates delays in service. In order to propose improvements to the process, it was suggested to increase the number of employees to carry out packaging at times of greater customer flow and to monitor the service macroprocess through performance indicators such as the average customer service time (ta) and the average waiting time for customers in queue (tf).

Regarding the Method category, the main cause corresponded to the lack of standardization of the service macroprocess. This fact presents as sub-causes the lack of planning and use of Standard Operating Procedures (SOPs). This reveals a flawed organizational culture marked by the lack of efficient strategic planning. It is worth mentioning the dependence of the operators in relation to the cash supervisor to carry out some activities, a fact that also results in service delays when he is not around. In view of this, as strategic measures, periodic meetings were held with the existing staff, in order to align the strategic objectives of the organization; in addition, it was suggested the documentation of the microprocesses inherent to cashier service from the use of SOPs.

Finally, in the Material category, poor infrastructure was considered as the main cause, and the lack of packaging and cash in the cash register as sub-causes. Both sub-causes develop disorders in the service macroprocess, meaning production stops and increased service time. Therefore, as an strategic measure, it was suggested the continuous intervention of the cash supervisor to carry out the replacement of packaging and cash when necessary. In view of this, once the macroprocess was mapped and the problem causes of formation of large queues were identified, the average service times were estimated (ta), average time of customers in queue (tf), average system time (ts) and system usage rate (Ψ). It is worth mentioning that these values were obtained from samples collected at the supermarket during times of greater customer flow, in this case, from Monday to Wednesday, from 7pm to 8pm, as described in Table 1.

Table 1 Average arrival times, attendance and waiting for customers in line

| Box | Average time between arrivals (min) | Average service time (min) | Average waiting time for customers in queue (min) |

|---|---|---|---|

| 1 | 5,57 | 3,83 | 7,42 |

| 2 | 6,13 | 4,26 | 8,27 |

| 3 | 5,90 | 3,95 | 7,93 |

| 4 | 6,18 | 4,07 | 8,46 |

| 5 | 6,40 | 3,98 | 8,78 |

| Overall Average | 6,04 | 4,02 | 8,17 |

| Standard deviation | 0,32 | 0,16 | 0,52 |

| 6 | 4,24 | 2,36 | 1,98 |

| 7 | 4,12 | 2,04 | 1,74 |

| Overall Average | 4,18 | 2,20 | 1,86 |

| Standard deviation | 0,08 | 0,23 | 0,17 |

Source: The authors.

It is worth remembering that the values corresponding to the standard deviations were estimated based on the samples and the values of the calculated general averages. Thus, for regular cashier stations, an average interval between arrivals of 6.04 minutes, an average service time of 4.02 minutes and an average waiting time for customers in line of 8.17 minutes were verified. For the priority ones, an average interval between arrivals of 4.18 minutes, an average service time of 2.20 minutes and an average waiting time for customers in line of 1.86 minutes were verified. In view of this, Table 2 shows the arrival rates (λ), attendance fees (μ) and use of the system (Ψ) calculated based on the average values obtained in Table 1.

Table 2 Estimated arrival and customer service rates

| Box type | λ (customers/min) | μ (customers/min) | Ψ = λ/mμ (%) |

|---|---|---|---|

| Normal | 0,83 | 0,25 | 67% |

| Priority | 0,48 | 0,45 | 53% |

Source: The authors.

In addition, the service rates for regular and priority were 0.25 and 0.45 customers per minute, respectively. Finally, the rates of use of the system were estimated (Ψ), 67% for regular ones and 53% for priority stations. Then, according to eq. (1), the average waiting times of customers in line were estimated and compared with the actual values observed for the same variable. Table 3 corresponds to the values obtained for regular cashier stations.

Table 3 Estimated variation based on the average waiting time of customers in queue verified for regular cashiers

| Model [M/M/1]5 | Value verified in the sample | |

|---|---|---|

| Average number of consumers in the system | 10,82 | - |

| Average number of consumers per box | 2,16 | - |

| Average waiting time for customers in line (min) | 8,00 | 8,17 |

| Variation (%) | 2% | - |

Source: The authors.

In addition, the variation is due to issues related to the lack of training or the reduced number of employees at the time of sample collection, which generates delays in customer service time. Table 4 shows the values obtained for priority cashier stations.

Table 4 Estimated variation based on the average waiting time of customers in queue verified for priority cashiers

| Model [M/M/1]2 | Value verified in the sample | |

|---|---|---|

| Average number of consumers in the system | 2,34 | - |

| Average number of consumers per box | 1,17 | - |

| Average waiting time for customers in line (min) | 2,44 | 1,86 |

| Variation (%) | -31% | - |

Source: The authors.

This fact can be interpreted as a variation resulting from the reduced number of items purchased by each customer, which reduces the average service time and, consequently, the average waiting time for customers in line. In addition, another possible aspect of influence corresponds to the reduced number of customers at priority workstations, a fact that intensifies the flow of operations. Finally, the issue related to the greater preparation of priority cashier operators can be mentioned, since the purpose of this type of service is to add greater agility to the analyzed macroprocess.

5. Conclusions

The purpose of this study was to analyze the cashier service macroprocess in a supermarket located in the mesoregion of Minas Gerais. In view of this, after the observations made in its different sectors, the inefficiency of the cashier service sector was proven, given the delays in service and queuing times of customers. In addition, it is a family-oriented organization that has little openness to carry out efficiency monitoring methods. In this way, there were no Process Management and Routine Management practices in the supermarket.

This study performance was satisfactory, since it combined qualitative aspects, making explicit the impacts of inefficient management and possible improvements to be implemented, with quantitative aspects, which represented the current situation of the organization. In this way, the use of the model based on the Theory of Queues had its importance in the quantification of the percentage variation of the average waiting time of customers in queue, indicating the need to make adjustments. It is worth remembering the cyclical nature of this study, that is, the importance of frequent macroprocess monitoring and related indicators, in order to constantly raise the standards for quality maintenance.

When it comes to the application of quality tools, in this study the use of the Ishikawa diagram was fundamental for pointing out possible causes for the problem of forming long lines. Thus, the suggestion for improvements was made in order to complement the tool analysis. Among the measures, the use of cash management frameworks, providing feedback, more consistent training and process documentation through SOPs were identified by the organization as appropriate actions with short-term returns, in addition to providing excellent cost-benefit.