1. Introduction

The level of development of a country can be measured according to different factors, but it can be agreed that one of the most relevant elements to be used as a reference is the field of construction, mainly that corresponding to road structures [1], since the greater the mileage of properly implemented roads, the greater the access to all regions of a country. Not to mention the improvement in the quality of life of the population that has greater access to health services, education, and work. That is why it is not only enough to implement the necessary road infrastructure works, but it is also imperative to ensure that they are of high quality and last over time, for the period for which they were designed.

In road infrastructure, flexible pavements are the most commonly used structures. These are composed of 4 layers: wearing surface, base, subbase, and subgrade [1,2], these layers range from higher to lower quality, with the surface layers having the best properties [3].

The subgrade is an essential part in the design of the pavement structure, since its bearing capacity, together with the characteristics of the road surface and traffic, are basic factors that will influence the design of the pavement structure [4,5]. For the evaluation of the quality of this layer, its bearing capacity [5] or resistance to shear deformation under traffic loads is taken as a reference, in addition to its behavior in the presence of moisture. It should also be taken into account that for the structure of a pavement to rest on a subgrade, it must meet certain minimum parameters, including that the CBR (California Bearing Ratio) of the soil must be greater than 3% in subgrades for urban pavements; if this parameter is not met, it must be stabilized by means of mechanical, chemical or synthetic procedures.

Soils with a high clay content often require stabilization, especially if they are located in rainy areas or where the water table is high. This procedure consists of avoiding soil replacement by improving certain soil properties, such as bearing capacity and permeability [6], thus extending the useful life of structures supported on the subgrade [7].

At present, the most commonly used stabilizers for CL soils according to the USCS (Unified Soil Classification System) soil classification are lime and cement, the use of one or the other depending on the plasticity index of the soil [5,7,8,12]. However, the use of these conventional construction materials causes not only significant depredation of non-renewable natural resources, but also increases the existing environmental stress [9].

On one hand, the cement industry is one of the most environmentally damaging industries, contributing between 5% and 7% of global anthropogenic CO2 emissions. In addition, the pollutants emitted in cement production, as well as the extraction of raw materials, cause a degradation of environmental quality, affecting the quality of life of flora, fauna, and human beings [11-13]. Similarly, lime production is an excessively polluting process due to the high carbon emissions from its production process and the raw materials needed [14,15].

The construction sector is the economic activity that contributes most to the deterioration of the environment due to the large carbon emissions it generates [9]. For this reason, it is necessary to look for alternative construction materials that are technically, economically, and environmentally viable by replacing conventional construction materials with materials that avoid the exploitation of non-renewable resources and solve problems such as the excessive production of waste through the "cradle to cradle" philosophy.

One of the alternatives proposed in this research is the use of asphalt emulsion for the improvement of the subgrade, since both its production and application are environmentally sustainable [16]. In addition, it is known that such emulsions generate a resistance to aggregate moisture and that it is possible to some extent to solve failures in weak soils [17].

The second proposed alternative for the improvement of the subgrade is steel shavings, which is an abundant residue from the lathing of metal parts to which we are seeking to give added value by using them as an additive to analyze the changes it would cause in the mechanical properties of the subgrade.

The main objective of this research is to evaluate the changes produced by both asphalt emulsion and steel filings in the physical-mechanical properties of soil for urban pavement subgrades, as well as to perform an economic analysis to evaluate the feasibility of using each of them.

2. Methodology

This research can be defined as descriptive since the characteristics of the studied phenomenon were specified. Likewise, the design of this work is experimental, since the independent variables (asphalt emulsion and steel filings) were intentionally manipulated to analyze the modifications they caused in the dependent variable.

2.1. Field works

7 research points were carried out in the study area in order to carry out their physical characterization and obtain their mechanical properties. These had a minimum depth of 1.5 m and dimensions in plan with sufficient measures to carry out the extraction of the samples.

For the purposes of this research, from the samples obtained from the aforementioned research points, the one whose mechanical characteristics were the most unfavorable was selected.

2.2. Characterization and selection of the sample

For the physical characterization of the samples obtained, moisture content tests, granulometric analysis by sieving and hydrometer, determination of the liquid limit, determination of the plastic limit and plasticity index were performed. The samples were also subjected to mechanical tests such as the modified Proctor compaction test and the soil CBR test.

2.3. Additive preparation

2.4. Characterization of soil - steel chip mixture

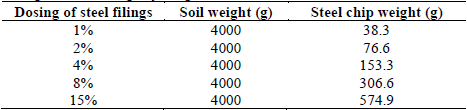

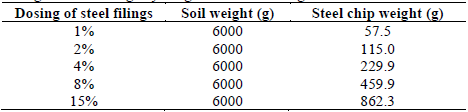

The soil mixture with the addition of steel filings was subjected to modified Proctor tests to determine its optimum moisture content and maximum dry density (MDD). The aforementioned mixture was mixed with the dosages shown in Table 1.

After the aforementioned test, the CBR test was carried out, for which the soil mixture was mixed with steel filings and water to achieve the optimum moisture content. This dosage is specified in Table 2.

2.5. Characterization of soil-asphalt emulsion mixture

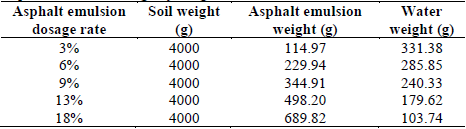

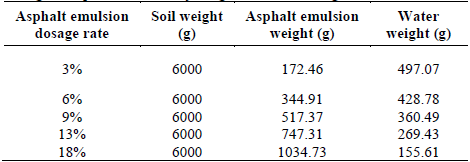

For the characterization of the soil mixture with the addition of asphalt emulsion, tests were carried out to determine the liquid limit, plastic limit, and plastic index. Likewise, the modified Proctor tests were carried out using the dosages shown in Table 3 and the soil CBR test with the dosages shown in Table 4. For the calculation of the quantities in the dosages with asphalt emulsion, the water content, and asphalt residue in the emulsion had to be taken into account to calculate the water necessary to reach the optimum moisture content of the soil.

3. Results and discussion

3.1. Physical classification of natural soil

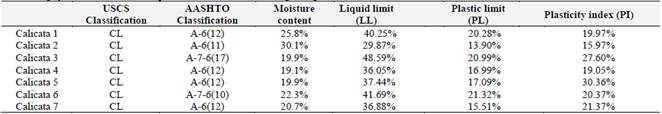

After the soil physical tests were carried out, it was found that all the soil samples obtained from the 7 research points belong to the CL type according to the USCS classification. As for the AASHTO classification, it was observed that 5 of the samples belong to group A-6, while the remaining two belong to group A-7-6.

The moisture content of the samples is quite variable, the sample with the lowest moisture content is the one from pit 4 with 19.1% and the one with the highest moisture content is the one from pit 2 with 30.1%.

As for the liquid limit obtained from the tests, there is also a great variation among the samples, obtaining a liquid limit from 29.87% to 48.59% for test pits 2 and 3, respectively. On the other hand, the plastic limits obtained are between 13.90% and 21.32%, and the plasticity indexes are between 15.97% and 30.36%; results that can be observed in Table 5.

3.2. Mechanical testing of natural soil

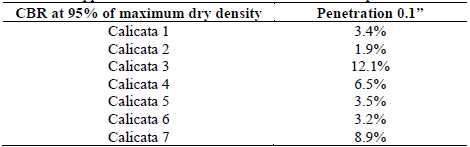

With the results of the California Bearing Ratio test shown in the Table 6, it was determined that the research point whose CBR value is the lowest is that of test pit 2, whose subgrade is classified as "poor" by obtaining a CBR of 1.9% at 95% of the maximum dry density.

Table 6 California support ratio test results to the 7 natural soil samples.

Source: Own elaboration

For the purposes of this research, the sample of test pit 2 was selected as the standard sample for the tests with the addition of steel filings and asphalt emulsion.

3.3. Soil testing with the addition of steel filings

3.3.1. Modified Proctor test on soil with added steel filings

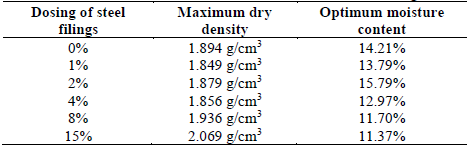

The trend of the optimum moisture content of soil mixtures with steel filings is decreasing, meaning that as the dosage of steel filings increases, less water is needed to reach the maximum dry density of the soil.

On the other hand, it can be noted that as the dosage of the additive increases, the maximum dry density increases. This means that, with the maximum dosage of steel filings, 15%, a higher maximum dry density of the soil is obtained with a lower optimum moisture content in comparison with the natural soil sample, data found in Table 7.

3.3.2. California to soil support ratio test with addition of steel filings

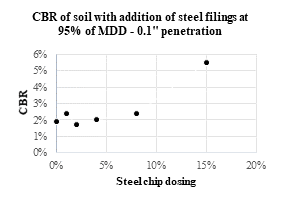

It is notorious that the CBR increases as the dosage of steel filings increases, obtaining the highest CBR value with 15% addition, increasing the CBR of the natural soil by 189.47%. It is important to emphasize that soil stabilization is only achieved with the 15% dosage, since with lower dosages the subgrade is still considered a poor subgrade, as shown in Fig. 1.

Source: Own elaboration

Figure 1 Trend graph of the California bearing ratio according to steel chip dosage.

3.4. Soil tests with addition of asphalt emulsion

3.4.1. Soil liquid limit test with added asphalt emulsion

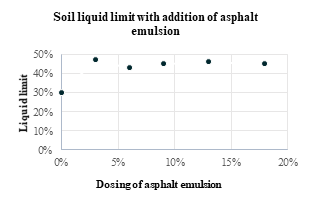

Fig. 2 shows the graph with the results of the liquid limit test of the soil added with asphalt emulsion, showing an increase with respect to the result obtained from the natural soil sample. It should be emphasized that in all the dosages of asphalt emulsion, a higher liquid limit was obtained than the sample that had not been added. From the above, it can be concluded that a greater amount of water will be required, compared to the natural soil sample, for the added soil sample to pass from a plastic solid state to a viscous liquid state.

3.4.2. Plastic limit test to soil with addition of asphalt emulsion

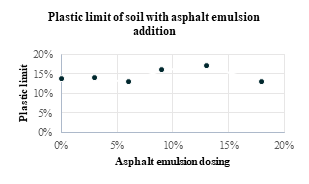

Similarly, in the results of the test of the plastic limit of the soil with the addition of asphalt emulsion, Fig. 3, a maximum value can be observed in the dosage of 13% of asphalt emulsion; however, a noticeable decrease in the plastic limit is observed in the dosage of 18%, which is below the plastic limit of the natural soil. According to this, it can be said that only for this dosage, the water required for the soil in a rigid solid state to pass to a plastic solid state will be even less than that required by the natural soil sample.

Source: Own elaboration

Figure 3 Trend graph of the Plastic Limit according to the asphalt emulsion dosage.

3.4.3. California stand to soil ratio test with addition of asphalt emulsion.

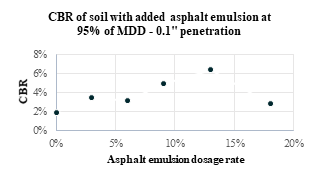

The tendency of the CBR of the soil with the addition of asphalt emulsion, shown in Fig. 4, is to increase up to the dosage of 13%, achieving soil stabilization since the CBR exceeds 3%. However, later it can be seen that in the soil with the dosage of 18% of asphalt emulsion the CBR decreases notoriously, obtaining a CBR lower than 3%.

3.5. Economic analysis of proposed solutions

3.5.1. Additive production costs

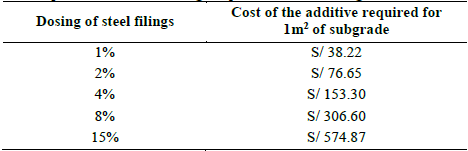

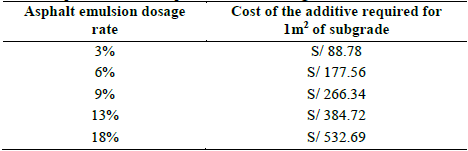

The costs for obtaining and producing the steel filings were much higher than those of the asphalt emulsion, as can be seen in Tables 8 and 9. If a comparison is made between the higher dosages of both additives, it can be noted that adding 15% of steel filings is more expensive than adding 18% of asphalt emulsion to the soil. This is because the cost of processing the filings from their raw state to their final state for use as an additive is expensive. However, if methods could be found to make this more efficient, the costs would be significantly reduced, thus making its use more economically feasible.

3.5.2. Flexible pavement design and construction cost

The pavement design and cost analysis of the execution of each of these structures was performed when the subgrade soil has been added with both steel filings and asphalt emulsion.

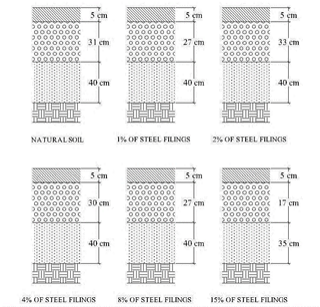

The base and subbase thicknesses calculated for the natural soil sample were significantly reduced and consequently a reduction in pavement structure costs was obtained. According to the analysis carried out, it can be said that with the highest percentage of steel filings studied, a reduction of 79.2% was obtained, as shown in Fig. 5.

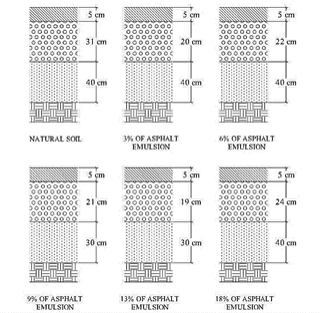

On the other hand, it can be observed that with the use of asphalt emulsion as a soil stabilizer, quite favorable results are obtained, since the base and subbase thicknesses are notoriously reduced as shown in Fig. 6, and the construction costs decrease in great proportion compared to the cost of execution without the use of additives. By reducing the costs of the base and subbase layers of the unimproved subgrade to 58.5%, these results were obtained with the use of 13% asphalt emulsion. However, if lower dosages were used, a significant reduction in costs would still be achieved.

4. Conclusions

- In the present study, a series of experimental tests were carried out to determine the influence of both steel filings and asphalt emulsion on the subgrade.

- The characterization of each of the samples obtained from the research points was carried out, from which it can be concluded that all the samples analyzed, according to the USCS classification, belong to a CL soil type.

- After the mechanical tests were performed on the 7 natural soil samples, the CBR test results were obtained for each one of them, which varied between 1.9% and 12.1%. For the purposes of this research, it was decided to carry out the studies with the soil sample belonging to test pit No. 2 and with which the different tests were carried out with the addition of steel filings and asphalt emulsion.

- The natural soil sample from test pit No. 2 yielded results after the Modified Proctor compaction test with an optimum moisture content of 14.21% and a maximum dry density of 1.894 g/cm3. Similarly, after the California Bearing Ratio test, the CBR of the soil sample at 95% and 100% of the maximum dry density was 1.9% and 1.9%, respectively, which qualifies it as a "POOR" subgrade and therefore requires a stabilization process.

- With the addition of asphalt emulsion, it was observed that with the 3% dosage the stabilization of the soil sample was achieved, obtaining a CBR of 3.5% at 95% of its maximum dry density, improving by 84.21% with respect to the results of the natural soil.

- The asphalt emulsion dosage that achieved the maximum improvement in CBR was 13%, with which a CBR of 6.4% was obtained at 95% of the maximum dry density, obtaining an improvement of 236.84% with respect to the natural soil sample studied.

- With the dosages of 1%, 2%, 4%, and 8% of steel filings, the stabilization of the subgrade soil was not achieved, that is, the 3% CBR was not reached. On the other hand, with 15% of steel filings an improvement of 189.47% was achieved with respect to the natural soil, obtaining a CBR of 5.5% at 95% of the maximum dry density; in addition, the maximum dry density increased by 9.14% reaching 2,069 g/cm3 and the optimum moisture content was reduced to 80.01% with respect to the results obtained from the natural sample.

- The optimum dosage of asphalt emulsion with which the greatest increase in CBR was obtained was 13%, with which an improvement of 236.84% was obtained.

- The optimum dosage of the addition of steel filings according to the results obtained is 15%, since it is the only one with which soil stabilization is achieved and with which the highest CBR value was obtained.

- After carrying out the structural design of the pavement using the AASHTO 93 methodology, it was found that, under natural conditions, the pavement surface is 5 cm, the base is 31 cm and the subbase is 40 cm. If the comparative analysis is made with the addition of asphalt emulsion at 13% and with the addition of steel filings at 15%, it can be concluded that in both cases the base and subbase layers are reduced to 19 cm and 30 cm in the first case and 17 cm and 35 cm in the second. The reduction of the thicknesses of both the base and the subbase, represents a cost reduction in the execution of these layers of 58.5% and 79.2% with respect to the pavement designed with the subgrade in natural conditions.

- After the cost analysis of obtaining the asphalt emulsion and the production of steel filings, the use of asphalt emulsion is more economical, since with a lower dosage and therefore a lower cost, similar CBR values are obtained compared to the use of steel filings.

Recommendations

- It is recommended to use the slow-breaking CSS-1H asphalt emulsion for the stabilization of clayey soils, because the CBR increases significantly.

- It is suggested to continue with the study of the addition of steel filings in higher percentages, because, according to the results, the CBR increases linearly.

- For further research, it is suggested that a combination of dosages of both additives be carried out in order to evaluate the results.

- It is advisable to perform tests not specified in this research work to evaluate mechanical and/or strength characteristics on which the asphalt emulsion and steel filings may have an effect.

- Consider that the use of both proposals as an additive for the improvement of the CBR of the subgrade soil does not harm the environment.

- Field trials are suggested in order to evaluate the behavior of the additives against agents present in the environment.