1. Introduction

Analyzing cement is very important for Civil Engineering because buildings must do largely with this material; therefore, it is important to know its history and evolution. Considering this, the first appearance of what is most like cement dates to 400 BC, which was made by volcanic ash used as a natural cement. Then, its composition was altered until 1824, when Joseph Aspdin patented the first Portland cement [1].

Cement is a fine granulometry material obtained from the calcination of a mixture of limestone, clay, and iron ore at ~1,450 °C. The product of the calcination process is known as Clinker (the main ingredient of cement), which must be ground with gypsum and other chemical additives, thus finally producing cement for different applications in the masonry industry for construction. Since the cement is the most widely used construction material in the world, this material provides mechanical and physical properties, such as compressive strength (the construction material with the highest resistance per unit cost), indicating the maximum compression capacity of the cement can withstand. Before reaching its failure limit, other qualities are durability and aesthetics, used for applications in the masonry industry for construction [2].

1.1. Overview of studies in concrete cobbles

Different authors have been adding different materials to concrete cobbles to improve their mechanical properties mainly, from adding recycled materials to changing their dimensions, as is the case [3], which proposed concrete cobble 500×500 mm (area = 25,000 mm2), with slopes of 1.3 and 5.0%. For this work, splash losses were considered as part of surface runoff to evaluate the reduction of surface runoff on pavements, showing the coefficient Csuperficial+Splash, which indicated data in the range of 0.74 to 0.89; these data are located close to the cement block pavement coefficient (C=0.78) and are subordinate to that of concrete pavement (C=0.95), it could be considered that if we use these dimensions for a pavement, it would be in the category of semi-permeable.

In India, the construction industry has a great shortage of its natural aggregates because they have limited availability, and the extraction of the raw material is prohibited. For this reason, Kumar et al 2020 [4] replaced the natural coarse aggregate and river sand in conventional cobble blocks by adding recycled concrete. Investigating the mechanical and durability properties, i.e., density, compressive strength, water absorption, abrasion resistance, and ultrasonic pulse velocity of the cobble blocks, they were able to conclude that coarse recycled concrete can replace up to 45% of the natural aggregate and 40% of the river sand, this without having a significant impact on the properties of the cobbles. On the other hand, authors have also used demolition and construction sediments but made 80 mm I-shaped cobbles type. The process was to replace the natural coarse aggregate of 10 mm in the proportions of (0, 15, 30, 45, 60, and 75%) with coarse recycled concrete aggregate derived from construction and demolition waste; observed that the cobble with construction aggregate replaces up to 60% of natural aggregates, obtaining great results in laboratories of resistance to compression, water absorption, and impact tests.

Peru also aims to recycle construction demolition materials, Castañeda 2014 [5] investigated the construction of a large sustainability proscenium, reducing non-renewable assets and the destructive impact on the environment for solid waste management. They supplanted the coarse and fine innate aggregate with aggregate originating from the crushing of recycled concrete. Also analyzed the flexural and compressive properties at 7, 14, and 28 days. Finally, the test indicated the possibility of using recycled concrete in terms of 70% coarse and 70% fine aggregate. Hossiney 2020 [6] also added recycled material to the alkali-activated cobbles, which came from asphalt pavements. This behavior is due to the increased expansion of roads in India, which has generated a considerable amount of recycled asphalt pavement aggregate. Alkali-activated cobble blocks were synthesized from fly ash, ground granulated blast furnace slag, NaOH solution, Na2SiO3 solution, recycled asphalt pavement aggregate, and natural aggregates. The cobble blocks developed under this methodology were analyzed by water absorption, compressive strength, and abrasion resistance by the IS 15658:2006 standard. Although the study yielded negative results in terms of compressive strength if it meets the standards for use as cobbles in pedestrian pathways, with a highly positive result in terms of cost since a maximum reduction of 25.8% in the total cost was observed. On the other hand, Saboo 2020 [7] used recycled asphalt pavement aggregates. The properties of the cobbles were characterized by measuring porosity, density, dynamic modulus of elasticity using UPV, resistance to compression, and abrasion by loss of Cantabrian. Virgin aggregates and paving aggregates were mixed in three different ratios (0-100, 50-50, and 100-0) using two different aggregate gradations (G1-coarser and G2-finer) to fabricate beveled cobbles using a method factory standard. The G1 gradation represented a force reduction of 4.23, 14.3, and 23.6%, and in the case of the G2 gradation, a force reduction of 10, 27, and 43% were observed on average for the addition of RAP of 10, 30, and 50%, respectively. Although this study had significant results in the properties of concrete, it is still noted that the compressive strength decreases with recycled aggregates from asphalt pavements.

Seashell by-products are produced in significant quantities in France and are considered waste. Pennarasi 2019 [8], uses it as a replacement for aggregates in previous concrete cobbles in search of being friendly to the environment. The coarse aggregate fraction was replaced (20 or 40% by mass) by the by-products of the seashells obtained from the shell of Crepidula. Crushed crepidula shells of 2/4 and 4/6.3 mm were used to make new cobbles based on seashell by-products; determining the mechanical and hydrological properties of conventional cobbles and cobbles with seashells shows us that the by-products of seashells have the potential to be used as aggregates, yielding results in terms of compressive strength of 16 and 15 MPa.

Ground glass has been a source of research to be used as an aggregate in different construction areas since being a recycling material can also provide better properties than Nguyen 2013 [9] used ground glass in concrete cobbles to replace conventional coarse concrete aggregate. The proportions used were 5, 10, 15, 25, and 50% of ground glass material compared with conventional concrete cobbles. The most important tests were carried out, which are compression resistance and water absorption. Finally, they concluded that adding 50% recycled glass to the mixture increases the compression resistance of the cobble of 4.09%.

Recycled rubber has been used in construction as pavements and concrete for constructing roads and buildings. Chavarri 2020 [10] used recycled rubber to seek a better effect on the properties of the cobble and to reduce the environmental impact of unused tires. The respective tests were carried out, including the compressive strength test, which yielded data of 349.35 kg/cm2 for conventional cobbles and modified cobbles with 3, 5, and 7% recycled rubber in replacement of fine aggregate; minor variations were obtained compared to conventional cobblestone by 8.74%. This behavior does not meet the hypothesis raised at the beginning.

1.2. For the case of Colombia and the NTC standard procedures

Zegarra et al 2015 [3] proved the data obtained by partially replacing the fine aggregate in volume with GCR (recycled rubber grain) in the execution of concrete cobbles. In this way, were made four varieties of mixes, a first mix as a reference without adding GCR, the second substituting 5% of the fine aggregate for the same volume proportion of GCR, the third and fourth with the same configuration, but replacing 10 and 15%, respectively. The properties were estimated: water absorption and density, resistance to abrasion, and resistance to flex-traction. These tests were carried out 28 days after the cobbles were manufactured since it is the period for them to be hardened. Finally, it was concluded that the resistance to flex-traction was reduced due to the minimum percentage of adhesion between the GCR and the concrete paste. However, the mixtures with replacement of 5 and 10% perform correctly with the resistance required in the NTC 2017 of 2004. The density decreased with the substitution of GCR, while the resistance to abrasion and water absorption were observed to be identical to the base mix.

Every day, the world is implementing new methods and techniques that are much more feasible to determine in different fields. It is important to verify the cobbles and their respective tests; as a result, they investigated their behavior, applying the greatest number of tests to relate them and see their performance; due to this, Muñoz 2022 [11] applied different tests to identify the behavior of the cobbles under different loads, thus determining the prevailing stresses in a cobble. The environment has always been a very controversial point to which many companies and/or those in charge of executing works have neglected; as a result of this, Hernández [12] studies carried out by the Cement and Concrete Association (United Kingdom) concluding that a cobblestone pavement acts in a similar way to a flexible one; In this regard, it was sought that this article proposed, based on a bibliographical observation, the concrete cobblestone pavement as an environmental choice in the manufacture of road infrastructure in Colombia, therefore, building more sustainable roads and highways with the environment avoided of pollution.

Another author who contributed to the search for new environmentally friendly cobbles was Ussa and Poveda 2015 [13], who contributed a cobble made with construction demolitions, thus implementing a benefits system within the work without hindering parallel functions, in which they can be carried out the mixture of rubble , binders, and additives for the manufacture of a cobble model that completes with the unbeatable physical quality of resistance, impermeability, and durability, and thus has easy manufacture to achieve that it is used in pedestrian pathways, common strips, space dividing strips, etc.

On the other hand, for ecological materials Acosta and Beltran 2017 [14], investigated and manufactured cobblestones and structural blocks with the aid of unusual materials such as the ash from the shell of the African palm where they looked for what percentage of this material is the one required to be used in different constructions and buildings, they also sought to generate a decrease in damage to the environment since this material, such as cuesco, is polluting, they investigated changing an unbeatable percentage of cement for cuesco ash, precipitating the mechanical properties and its best use, producing a more resistant concrete, reducing manufacturing costs and favoring the environment. On the other hand, Reyes and Contreras 2015 [15] realized that paper was a polluting element that could not be reused; as a result, they implemented paper in the paving stones and gave an optimal contribution to the use when talking about light traffic.

Flexible pavements are used for pedestrian use routes and low traffic volume, but they have a problem: they deteriorate before the time proposed in the design. Rodriguez 2019 [16], proposed to take advantage of the characteristics of some materials to increase the modulus of rupture in cobbles by implementing a lower layer of concrete with 7% steel chips and an upper layer of concrete with 7% fly ash. The fly ash in the dosage of 7% increased the resistance of the concrete by 9.0 MPa at 45 days of elaboration, the cobble without any type of addition in the mixture presented a modulus of rupture of 3.14 MPa at 28 days of elaboration, the which increased little until its 45 days of curing, but in the case of the cobbles with the aggregates of fly ash and steel shavings, the modulus of rupture increased to 4.13 MPa thanks to the resistance provided by the fly ash during the first 7 days. In the flexural tests, the cobbles with aggregates of fly ash and steel chips increased the resistance by 25% more than the conventional concrete cobble. as well as the modulus of rupture increased to 4.21 MPa in the cobble with aggregates, the modulus of rupture of conventional concrete cobble of 3.30 MPa.

or decades, the glass industry has manufactured more than 100 million containers, which entails a large amount of environmental pollution; even though it has a material with high amounts of silica, it is not biodegradable. Coronel and Sanchez 2021 [17] incorporated pulverized glass into the mortar, replacing it with cement, by making 50 mm mortar cubes and incorporating glass weights in percentages of 10, 20, and 30% to compare with the conventional mortar sample were able to conclude that the compressive strength of the mixtures used with pulverized glass is lower than the resistance of the pattern used, however, the sample with 10% replacement of cement by pulverized glass has a compressive strength activity index that considers the glass residue as a pozzolan that behaves like cement [18].

In this research work, concrete samples with the addition of clay from the region (northwestern Colombia) and another with residues of ash from ovens (product of firing the ceramic blocks) are obtained under different mixture percentages with the aid of an experimental design using the Stargraphics software. Furthermore, in order to evaluate the physical and mechanical properties of the different mixture samples, were considered the guidelines of the Colombian standards (NTC) that establish the minimum requirements for these masonry products for construction, providing a solution to the waste generated in the region and thus obtain economic cobbles that meet the necessary quality standards for use in the construction industry.

2. Materials and methods

The binder is a mixture of sand, gravel, and gravel materials (also known as aggregates) and cement. The concrete hardens easily just by adding water during the mixing process. Thanks to this, it can also be used in underwater construction. It is a material that can have any shape when poured into a mold or formwork and thus be transformed into prefabricated pieces for construction. It offers a solid foundation for buildings as it is a material mixed with filler and hardness aggregates, while reinforced and pre-compressed concrete resists high tensile forces in buildings.

Prismatically shaped unit made of vibro-compressed concrete, which allows the placement of pieces continuously and symmetrically to form folders for bearings or pavements, streets and avenues, squares and walkways, parking lots, etc. Although the most common dimensions of the cobbles are usually 20 long by 15 cm wide, generally prefabricated pieces of mass concrete, commonly bilayer, their sizes, and formats can be variable. For example, the definition of a cobble by the European Product Standard highlights that the entire cross-section at 50 mm of distance from the cobbled edge will not have a horizontal dimension of less than 50 mm. On the other hand, the total length divided by the thickness will be less than 4.0 [19].

2.1. Physical and mechanical characterization

The Colombian technical standards (NTC) exit a minimum quality and manufacturing parameters that govern concrete in Colombia, stipulating the appropriate characteristics for the cement to have optimal performance in construction. Another requirement associated with the quality of the concrete is the compressive strength, which is based on a test carried out employing the NTC-220 standard in cubes with edges of 5.08 cm (cobblestones). These cubes are made with a mixture made up of one part of cement for three parts of OTAWA sand, which has the highest acceptance according to the American Society for Testing and Materials (ASTM) [20]. As part of the evaluation of the physical properties of concretes, the following standards-based tests (NTC and INVIAS) were used:

2.1.1. Density or Unit Weight. (INV.E - 405 - 13) [21]

Density, also known as unit weight, is defined as the mass of a material per unit volume, using Eq. 1:

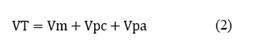

The following procedure must be carried out to calculate the densities, considering the expression for the mass: Specimen mass = Solid mass + Air mass ≅ Solid mass. For the volume there are three types of volumes that a material can present. Considering that all material is made up of a matter called compactness and several holes are known as porosity, the different volumes are classified. In this way, to calculate the total volume (VT), Eq. 2 is used:

The total sum of the mass volume (Vm) Also, adding the volume of the closed pores (Vpc) is called, usually, apparent volume (Vap) (Others call it relative volume); this means that it does not consider the open pores using Eq. 3:

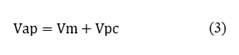

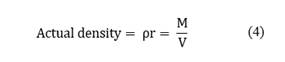

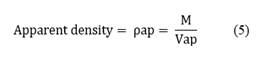

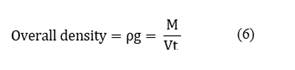

The open pores can become permeable or impermeable, which means communicated or not communicated. Due to the previous expressions and considering the definition of density (Mass/Volume) three types of densities can be defined (Depending on why the volume is divided); thus, Eq. 4 was used, and as considerations, Eq. 5 and Eq. 6. It is important to remember that the last two densities in compact materials could differ by 2.0%.

2.1.2. Water absorption. (INV.E 427 - 13) [22]

This test determines the amount of water that concrete cobbles absorb when subjected to immersion in water. As stated in the standard, concrete cobbles must have a total water absorption (Aa%) of no more than 7.0% as the average value of all specimens and no more than 8.0% for each specimen. On the other hand, the quality parameters must be considered as detailed below: Modulus of rupture 8.0 (Mr), at 28 days, minimum between 3.8 and 4.2 MPa for individual cobbles and an average of 5 samples. Likewise, the footprint length (Fh) for an average of 5 samples is a maximum of 23. The modulus of rupture (Mr) has been specified at 28 days; however, the cobbles can be used at earlier ages when there are stories about the evolution of the modulus of rupture (Mr) of cobbles with the same characteristics, indicating that the first ones can obtain the modulus of rupture and that they have the necessary resistance to be used on site. The preceding does not exempt from the direct verification of the quality of the cobbles using tests at 28 days. Higher moduli of rupture (Mr), or surface layers with characteristics, can be specified when required by service conditions such as abrasive loads, tires, and metal tracks, among others. In this case, it's important to check with local suppliers to find out the availability of this type of cobble.

2.1.3. Flexural strength (modulus of rupture). (INV.E - 415 - 13) [23]

This test method refers to the determination of the flexural strength of concrete using a supported beam loaded at its center point. Said test is used to determine the modulus of rupture of specimens prepared and cured according to the INV - E 402 or INV - 420 standards. Calculated strength may vary depending on specimen size, curing, moisture, and preparation differences. The results of this test method can be used to determine compliance with specifications or as a basis for concrete batching, mixing, and placing operations.

2.2. Samples criteria for acceptance or rejection

Considering the NTC and INVIAS standards establish the minimum requirements for analyzing the acceptance or rejection conditions of the samples based on optimization considering statistical theories. If a sample does not comply with what is specified in this standard, the control sample must be tested, and the lot must be entirely rejected [24].

2.3. Mix design

The design of experiments with mixtures is known as the empirical procedure that considers several important properties of materials (physical, chemical, mechanical), some of which are based on acquiring an adequate compressive strength for a specific age, as well as optimal workability in a specific time, which must have adequate properties so that, when used, the structures are safe [25]. In recent years, the use of the design of experiments with mixtures has been carried out through applied statistics to optimize materials and industrial processes.

2.3.1 Realization of mix design

The proportions for an optimal concrete mixture are achieved through a system based on trial and error. This procedure consists of idealizing a concrete mixture composed of water, sand, cement, and gravel, then executing it and calculating it using different methods. In addition, quality tests should be carried out on this mixture [25]. For this, it is necessary to have the data of the materials and their respective material properties to be used must be known, such as particle size, fineness modulus of the sand, maximum size of the gravel, bulk density of gravel, and sand, absorption of gravel and sand, compact unit mass of gravel, moisture of aggregates immediately before mixing, density of cement, among others.

2.3.2. Methods for calculating mix designs

The method of minimum void content is used to determine the designs of experiments with mixtures. The first thing that must be considered is determining the characteristics of the aggregates, which involve the following aspects: maximum size and maximum nominal size. From this, a correct combination between gravel and sand must be determined. Likewise, the minimum void content in the combined aggregates must be obtained. The best way to obtain this value is experimentally through the change in compact volume of the aggregates, varying at the same time the different proportions between gravel and sand to the point of obtaining a relative proportion with which the minimum void content will be obtained.

On the other hand, it was considered the guidelines of the ASTM-C29 standard procedure [26], which has a simple execution and is recommended with aggregates with a maximum size of 40 mm. And then, it can obtain the lowest void content in the mixture preparation at the time of its execution; inherent effects are implicitly covered, considering the shape and surface texture of the particles, as well as the maximum size and particle granulometry. Also, this method is based on finding the appropriate amounts of aggregates. This method is determined by calculating the weight of gravel and sand using the maximum volumetric weight method. These weights must be converted to absolute volumes to add them and obtain the absolute volume of the mixture.

Finally, the water and cement required for the initial mixture were considered the guidelines of the ACI 211.1-91, then find the concrete percentage required for the mixture. After having determined the percentage of air, it must be converted to unit volume; having this volume was possible to subtract it from the cement paste and include air and then obtain the paste volume.

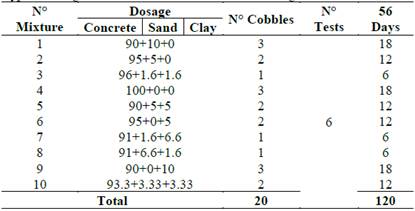

2.3.3. Experimental mixture design

The sample size calculation was carried out using Statgraphics software to conduct several executable tests during the present investigation, indicating a series of combinations and dosages for the concrete cobbles required with additions of clay and kiln ash residue. Considering the above, a Simplex-Centroid design was developed to study the effects of 3 components in 20 runs, executed in a single block [27]. Furthermore, the order of the experiments was completely randomized (random). Although this experiment will protect against the effect of hidden variables since the selected model is quadratic, the design will try to fit a model with both first and second-order terms. Likewise, the limits established for each material were considered according to the design of experiments with mixtures as detailed below: concrete (low 90 and high 100), clay (low 0 and high 10), and ash (low 0 and high 10). Finally, considering the above, the design of experiments is shown in Table 1 where is possible to observe 10 types of mixture designs with their respective dosage that will be developed in this research work based on the statistical results of the Statgraphics software. Considering the above, the cobbles number necessary for each dosage was obtained. This depended on the times the same dosage was repeated in the experimental design. For this reason, 6 types of physical-mechanical tests were considered: absorption, resistance to flexo-traction, and abrasion resistance. Subsequently, the cobbles number was multiplied by the number of tests to obtain the number of samples necessary considering the curing age of the cobbles to be tested (56 days).

The NTC-2017 standard procedure was used to determine the cobbles dimensions [28], which establishes the relationship between the nominal length (ln) and the nominal width (an). Also, the relationship between nominal length (ln), considering that the thickness of cobbles should not be greater than 4 in both cases; Following these recommendations, a cobble with a length of 200 mm, a width of 100 mm, and height/thickness of 80 mm was chosen, thus complying with the necessary parameters required for this standard method. It is the most commercial in the current market in Colombia, with a general use for light traffic, platforms, and parking, with an average weight of 3.5 kg, with a compressive strength of 2,500 PSI, which can be seen in Fig. 1.

3. Results and discussions

3.1. Experimental test results

3.1.1. Moisture content of aggregates (NTC-1776)

The moisture test was performed on all the aggregates obtained [29], resulting in the coarse aggregate having a moisture content of 2%, the fine 6.37%, the ashes 8.73%, and the clay 17.48%.

3.1.2. Granulometry test (NTC-77).

For this test, the coarse aggregate has a maximum size of ½” and a nominal maximum size of –”, the fine aggregate has a fineness modulus of 4.01, the clay a fineness modulus of 2.66, and the fly ash a fineness modulus of 3.58 [30].

Table 2 Summary of the results of laboratory tests developed with their respective standard.

| Standard | Description | Aggregate Type | Results | |

|---|---|---|---|---|

| NTC-77 | Granulometry | Fine | MF 4.013 | |

| NTC-77 | Granulometry | Thick | TM 1 ½” y TMN –” | |

| NTC-176 | Density | Thick | 4,572 kg/m3 | |

| NTC-176 | Absorption | Thick | 7.553% | |

| NTC-237 | Density | Fine | 2,660 kg/m3 | |

| NTC-237 | Absorption | Fine | 1.66 | |

| NTC-1776 | Humidity | Fine | 6.42% | |

| NTC-1776 | Humidity | Thick | 2.06% | |

| NTC-92 | unit mass | Fine | 1,579.15 g/cm3 | |

| NTC-92 | unit mass | Thick | 1,556.34 g/cm3 | |

| INV.E-218 | Abrasion | Thick | 40% of the sample |

Source: Own elaboration.

3.1.3. Density and absorption test (NTC-176)

The coarse aggregate has a density of 4,579 kg/m3 and an absorption rate of 7,554 [31], considering Eqs. 1 to 6.

3.1.4. Density and absorption of fine aggregate (NTC-237)

Considering this test, it was concluded that the fine aggregate has an absorption percentage of 1.66 and a density of 2.66 kg/m3 [32].

3.1.5. Unit mass and voids between aggregate particles

Carrying out the process described in NTC-92 [33] and based on the experimental procedure, it is concluded that the unit mass of the fine aggregate is 1,579.510 g/cm3 and that the unit mass of the coarse aggregate is 1,556.343g/cm3.

3.1.6. Abrasion and wear on coarse aggregate

For this test, the guidelines described in the INV.E-218 standard were followed [34], which concludes that the percentage of losses is 44.51%.

Table 2 summarizes the results obtained in the different experimental laboratory tests carried out with the respective technical standard implemented as part of the experimental procedure.

3.2. Mix design

According to the experimental data obtained for the physical characterization of the aggregates, a maximum resistance of 21 MPa is expected, with a settlement of 5 cm, since this settlement is recommended for hand-vibrated concrete and pavements, establishes a dosage of 1:2:3, this being a national standard for cobbles. Therefore, the corresponding dosages for the different cobbles are calculated after determining the main dosage, as shown in Table 3. This way, a total amount of 120 cobbles were obtained considering the experimental design (Multiplication between cobble amount and number of tests) to develop the tests based on NTC standard procedures and then obtain the main mechanical properties of the cobbles with different dosages.

The conventional cobble is one whose concrete mixture is made only with cement [28]. This mixture was considering the dosage in Table 4, and it was considered to carry out compression and bending tests at 14 and 28 days, although due to problems in the universal machine, it was only possible to carry out the tests once, at 56 days, to determine the behavior of the modulus of rupture by increasing the curing time. Each sample was stripped 24 hours after processing and placed in a pool of water for proper setting and curing until the required age. Considering the above, 120 concrete cobble samples were made in 10 dosages with different percentages of aggregate: brick kiln residue ash and clay. In addition, mixtures were verified that have a settlement of 5.0 cm, correctly forming each cobble to contain the mixture adequately.

3.2.1. Raw materials obtention

The materials used as additives were extracted from a brickyard in the North Santander region in Ocaña-Colombia. First, the ash was extracted from inside the oven, then sifted to ensure that it did not come with other additional materials and thus could take maximum advantage of its properties. Likewise, the clay was extracted from the mountain, and used for bricks and blocks.

3.2.2. Molding for the cobble samples

Fig. 8 shows the cobble molds made of cedar wood. This wood has very useful characteristics regarding hardness, lightness, and resistance to rot, fungi, and insects. This mold was used properly to use the formwork or molds for the cobbles, which must perfectly comply with the previously mentioned assigned dimensions. For the casting of the mixture, burnt oil was applied to the entire mold. This is to ensure that the cobbles do not adhere so much to the wood and to be able to remove them better without changing their dimensions.

3.2.3. Paving preparation

For the elaboration of the cobbles considering the mixture design, the steps shown in Fig. 2 were considered. The first thing that was carried out was to thoroughly clean the surface where it was going to be done so that it did not have contact with any other material or solid residue and thus obtain an optimal elaboration of this, then proceed to stir the materials together so that the clay and ash are well dispersed. Finally, add water and stir until it is completely compacted. After having all the mixture stirred according to the type of dosage, the slump cone test is carried out, which involves filling a frustoconical metal mold with standardized dimensions, in three layers rammed with 25 strokes of the rod. This removes the mold, and the settlement experienced in the upper part of the concrete mass is measured, to verify the settlement between 5 and 10 cm. Subsequently, the concrete is poured over the molds, making it into two layers, each layer rammed with a metal rod 25 times, ensuring that the mixture is well compacted and avoids gaps between it.

After leaving the samples for 24 h of their preparation, they were removed, so they did not lose the assigned dimensions. They were introduced into the pool with water from the laboratory designated for the development of the experimental tests for a correct setting and curing until approximately the required age (54 days), in which flexural strength and compression tests were performed. It is important to consider that the NTC-2017 standard [28] establishes the requirements for unreinforced concrete cobbles and their pieces, which must be suitable for constructing concrete cobble pavements. The absorption test is important to know the behavior of the cobbles when exposed to saturation. For this test, the different cobbles were tested according to the proposed dosages to identify the difference in absorption between them, considering the weighing with a conventional scale, whose data were summarized in Table 4. Notice that the tests were replicated at least six times to validate the experimental results obtained.

Table 4 Cobble absorption calculation.

| Cobble Mixture | Saturated weight (g) | Dry weight (g) | % Absorption Average |

|---|---|---|---|

| M1 | 3969.8 | 3613.1 | 9.87 |

| M2 | 3951.1 | 3689.0 | 7.10 |

| M3 | 4202.4 | 3905.1 | 7.61 |

| M4 | 4090.5 | 3823.8 | 6.97 |

| M5 | 3802.2 | 3505.9 | 8.45 |

| M6 | 3954.2 | 3685.0 | 7.30 |

| M7 | 3815.5 | 3535.1 | 7.93 |

| M8 | 4017.2 | 3731.7 | 7.65 |

| M9 | 3884.3 | 3592.8 | 8.11 |

| M10 | 4248.0 | 3939.9 | 7.82 |

Source: Own elaboration.

Source: Own elaboration.

Figure 3 a) Morphology, b) compression test, and c) bending test on cobbles.

Then, compression and bending tests were developed for each of the dosages obtained through the previously described design of experiments with mixtures. Note that, for all the samples obtained, the morphology was obtained, as shown in Fig. 3a. The cobbles were removed from the setting process 56 days after they were introduced, it had been planned to carry out the respective tests at 14 and 28 days, but due to technical problems in the compressive strength machine of the material strength laboratory of the Universidad Francisco de Paula Santander Ocaña, it was not possible to comply with the proposed schedule. Notice that, according to Khare et al 2013 [35], compression and flexion brick properties at 45 days or more aid in coupling the additives to the samples developed. In this way, to determine the final resistance to compression and the modulus of rupture in flex-traction, which establishes which will be the most efficient mixture to contribute to the improvement in the mechanical properties of the cobbles, applying a constant load of 0.5 MPa/s in the universal machine for compression and flexural testing until failure of the specimen as shown in Fig. 3b and 3c.

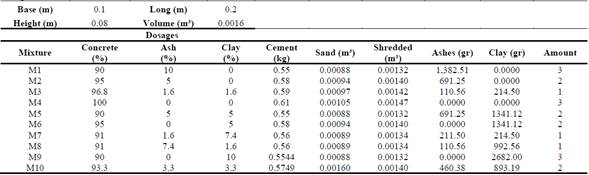

The data of each specimen, such as width, length, height, and appearance, were taken to determine the morphological characteristics of the cobbles developed experimentally [36], whose results are summarized in Fig. 4. The mechanical characterization of concrete covers all kinds of characteristics that it has and how it contributes to the contribution of resisting different applied forces. When conducting a study, it was found that the mechanical properties of the different types of concrete are subjected to tests to determine the properties. Considering the experimental results found, correlations were proposed to predict concrete's different physical and mechanical properties. In said study, recommendations were proposed on the minimum resistance the concrete should have and the optimal age for stripping. These recommendations could be implemented in low-rise and low-cost housing constructions [37].

Fig. 4a shows the height values for all the mixtures evaluated, obtaining an average value of ~80 mm, with a maximum and minimum value of 80.36 and 79.86 mm, respectively. In the case of length dimensions, the results are shown in Fig. 4b, where an average value of ~199 mm in length can be seen in general, with a maximum and minimum value of 199.78 and 200.26 mm, respectively.

Fig. 4c shows the width results for the entire mixtures, obtaining an average value of ~100 mm in general, with maximum and minimum values of 99.90 and 100.22 mm. In the case of the weight of the cobbles (see Fig. 4d), it can be observed that in the mixtures with the highest content of additives (clay and ash), the cobbles are lighter with average values of ~4.0 Kg of weight in general, with a value maximum and minimum of M1=4.12 Kg and M3=3.99 Kg. Finally, as shown in Fig. 4e, the behavior of the cross-sectional area of the different mixtures presents values between 19,940 and 20,033 mm2 for the maximum and minimum values, respectively. It can be observed for all the cases in general that the morphology properties of the mixtures developed under different dosages do not differ by more than 10%.

Source: Own elaboration.

Figure 4 Graphical results of a) high (H), b) Length (L), c) width (A), d) weight (W), and e) cross-sectional area (AT).

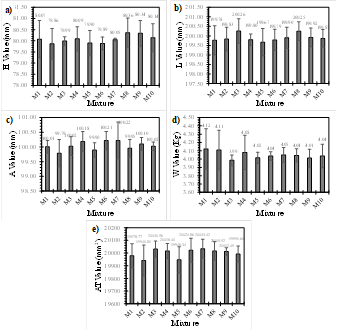

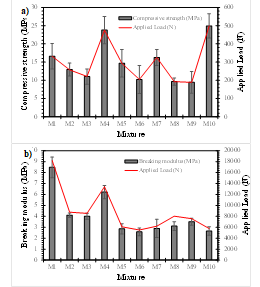

Fig. 5a shows the general results of compressive strength to the results obtained in the laboratory. According to Rodriguez 2019 [16], the resistance in concrete cylinders using said dosage for cobbles was 22.68 MPa at 45 days of setting. Considering the results obtained by Valcuente et al 2009 [38] expected compressive strength at 28 days of setting is 25 MPa for normal or fast-hardening cement. Considering Fig. 5a, it is observed that the mixture M4 (100 - 0 - 0) had a compressive strength of 23.79 at 56 days of setting, this dosage being the mixture without any addition. Therefore, the mixture M10 (93.33 - 3.33 - 3.33) obtained the most relevant compressive strength of the laboratory carried out, at 56 days of setting its resistance was 24.93 MPa, taking into account each of the data obtained in the laboratory tests for the physical characterization of the aggregates, expecting a concrete compressive strength of 3,000 PSI (21 MPa) we can say that this requirement was met, clearly with more days of setting, although the difference between the compressive strength of the cobbles with concrete without the type of addition and those of additions of clay and residue of kiln ash, the objective of the degree work was fulfilled, which is to look for different materials from the concrete mix to improve its s property and compressive strength.

The concrete cobbles must meet the minimum flex traction resistance or modulus of rupture of 5.0 MPa at 28 days of setting, according to (Clays and prefabricated concrete), to ensure an excellent useful life and that they comply with the specifications necessary for industrial applications. As was observed in Fig. 5b, the mixture M4 (100 - 0 - 0) obtained a modulus of rupture of 6.22 MPa at 56 days of setting, this dosage being without any additions. On the other hand, the M1 mix (90 - 10 - 0) obtained the highest breaking modulus was around 8.48 MPa at 56 days of setting, validating that if we add 10% clay to the concrete mix, this will have a fairly significant improvement in its modulus of rupture, thus validating our objectives, which were to be able to find an addition to the concrete to improve its mechanical properties.

Fig. 6 shows the summary of the compression and flex-traction tests for each type of dosage in a condensed manner, where it can be seen that, for the compressive strength test, the M10 mixture obtained a result of 24.93 MPa, this being the most favorable, but in its breaking modulus test its result was 2.66 MPa, this being a value below that expected by the standard [28]. For its part, for the breaking modulus, the mixture M1 obtained the result of 8.48 MPa, this being the most favorable, even though the value of the compressive strength was 16.62 MPa, which was not what was expected by the standard [28], results near from the average value. Then, the dosage that meets both specifications would be the

M4 mixture with compressive strength results of 23.79 MPa and a modulus of rupture of 6.22 MPa, this being the concrete without any additions. Likewise, a relationship could be found between the mixture M1 and M10 to find a dosage that obtains a high modulus of rupture and, at the same time, meets the expected compressive strength, thus taking advantage of the kiln residue ashes and clay as additions to the mix [16].

Source: Own elaboration.

Figure 5 Results of a) Compressive strength and b) Breaking modulus versus the applied load for all the mixtures.

4. Conclusions

It can be seen as an adequate dosage of clay and fly ash combined with the concrete (M10 = 93.3% concrete, 3.33% clay, and 3.33% fly ash), with more relevant compressive strength values of the laboratory developed at 56 days of the set, its resistance was 24.93 MPa, it can achieve the same compressive strength capacity) as a 100% concrete dosage, this is important, because by creating this dosage on a large scale we could considerably reduce the environmental impact that exists due to the production of concrete, complying with the requirements established by the Colombian technical standard NTC.

Regarding the modulus of rupture, calculated mainly with the flexural strength, a mixture with a dosage of 90% concrete and 10% clay (M1) obtained the highest modulus of rupture. On the other hand, almost All the proposed mixtures obtained a higher modulus of rupture than concrete (100%), this being a considerable improvement since a cobble could be proposed combining the dosages and reinforcing them that can supply the need for compressive strength and modulus of rupture.

Finally, the use or replacement of recyclable materials to mix them with concrete for industrial use in the construction sector is an efficient alternative considering the improvement of the mechanical properties of the materials, as well as the morphological properties that aid the sustainability of environmental resources and the economy of civil constructions nowadays.