1. Introduction

One of the main challenges in foundations works is ensuring that the elements inserted in the ground have an adequate quality. Uncertainties about the condition of the foundation elements can be minimized with executive (bulletin to record information) and operational control, ensuring that the design is respected during the work. Although minimized, the uncertainties are not completely eliminated, and the question remains on the integrity of the executed elements, such that inspection methods are required.

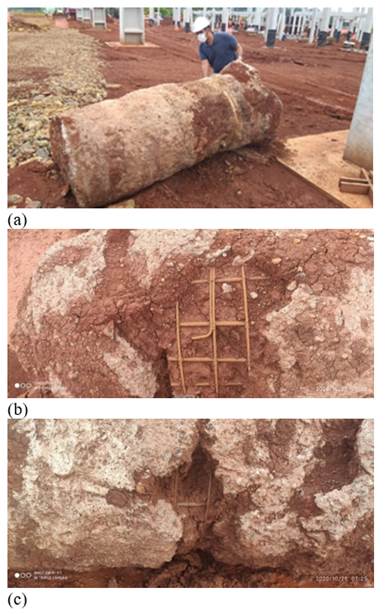

The inspection of deep foundations can be carried out based on ground excavation to directly observe the foundation element (Fig.1a). According to Wu et al. [1], the advantage of this procedure is the possibility of visually verifying the integrity of the pile and possible concreting defects (as shown in Figs. 1b and 1c). However, there are clear disadvantages, since the process is inviable for long elements, the impossibility to verify internal defects, the difficulty to excavate resistant soils, possibility of damaging the element when the process is mechanically carried out, the presence of water table, the loss of part of the lateral friction resistance, among others.

On the other hand, there are indirect or non-destructive methods based on the emission and reception of acoustic waves that allow to assess the integrity and length of deep foundations, maintaining the structural safety of the element. As an example, Pile Integrity Test (PIT), which can indicate possible execution anomalies, and also confirm the executed pile length can be considered easy-to-perform, low-cost, and reliable. Unfortunately, this method still not be standardized in Brazil.

In this scenario, this paper aims to use PIT tests in short caissons to verify their integrity and validate the results by excavating the elements. In addition, the study carried out a statistical analysis of the wave velocity and the time spent by each PIT test in the short caissons evaluated.

2. Theoretical background

The caisson foundations, commonly executed in Brazil, consist of molded in situ piles with an enlarged base [2]. The quality of the caissons depends mainly on the execution technique used. In addition, inspection of the supporting soil (base) by a Geotechnical engineer is essential and part of the executive procedure.

Chernauskas and Paikowsky [3] explained that the integrity test was developed due to the need for a method to evaluate the quality of foundations in situ. The method to assess the integrity of a pile through its response to an impact, using a transducer installed on its top, was first published by Paquet [4]. Since then, the test has received several other names such as PIT (pile integrity test), “low strain integrity test”, “sonic echo” and “impulse echo”.

Bourdet [5] reported that the Centre Experimental de Recherche et d’Etudes du Batiment et des Travaux Publics (CEBTP) made its first attempts to control the continuity of piles by the echo method in 1965. In 1972, a vibrating hammer stopped being used as a source of percussion and a hand hammer, which would impact the top of the pile, was used to generate the wave to be analyzed.

Paquet [4] also introduced notions of deconvolution of the return signal to eliminate the oscillatory return of the pile to equilibrium and also the exponential amplification of the signal in the time domain to reduce the damping effects of the ground and to facilitate the analysis of the more deeply reflected signals. It also showed that, with the analog signal processing technology available at the time, analysis in the frequency domain was the best alternative, especially when there were defects in the first few meters of the pile.

Pasqual et al. [6] showed a real case of stem reduction (“strangulation”) of an excavated pile, identified by PIT tests. Paraíso et al. (2020) [7] studied the application of the PIT for detecting problems several different pile types. The authors showed several examples of pile anomalies, with the corresponding PIT reflectograms and visual confirmation (field excavation):

i)damping of wave velocity amplitude;

ii)presence of a negative reflection after the top reflection, indicating discontinuity near the top;

iii)reflectogram with lateral area extension indicating superposition of positive reflections due to structural damage very close to the top; and

iv)reflectogram with lateral amplitude of the top peak reflection followed by negative reflection suggesting a structural damage and cross-section variation.

In Brazil, the application of dynamic tests based on the wave propagation theory equation was first introduced in 1981 in offshore pilings and the first PIT test took place in 1989 [8]. The PIT is usually applied to cast-in-place and precast concrete piles without seams [9]. A series of PIT tests were applied on different types of piles [10-11], highlighting the potential of the PIT methodology. However, there is still no specific standard for the low strain integrity test in Brazil, and the method is not required by the Brazilian standard NBR 6122 [12].

Souza et al. [13] performed pile integrity tests (PITs) tests in long caisson executed in a sandy clay soil with increasing resistance with depth. The length evaluated by the PIT was in the range from 7 to 9m, whereas the design indicated a length of 8m.

Thus, this paper contributes to disseminating the use of PIT tests in the geotechnical community, especially in Brazil. The foundation excavation has been adopted as an alternative to validate the PIT test results.

3. Materials and methods

3.1. Area Characterization

The case study was carried out during the expansion of a substation of Concessionária Eletrosul, on Linha Santa Cruz, km 20, in the municipality of Itá, Santa Catarina. Fig.2 shows the substation during the foundation work.

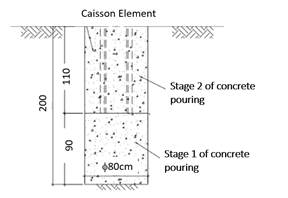

The caissons were designed with diameters of 0.8 m and lengths of 2 m (Fig.3), consisting then of short caissons. The integrity checks were carried out on some of the caissons belonging to new structures built to expand the substation. In order to speed up the execution, the caissons were built using an unconventional executive process.

The excavation was done with a mechanical auger and without tip cleaning and manual base opening. Usually, the process of excavation would be manual, and there would be a base opening.

Although advantageous in terms of execution time, the mechanical excavation of a caisson requires a lot of care to minimize break up of the soil structure during mechanical excavation and the fall of loose soil into the hole, which makes the base soil soft.

3.2. Geotechnical characterization

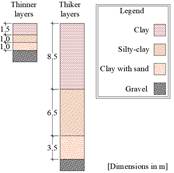

For the substation extension, thirteen Standard Penetration Test (SPT) boreholes were drilled at the locations shown in Fig.4. The number of boreholes was determined according to our national standard (NBR 8036 [14]), considering the projected area of the structure. The borehole locations were randomly selected. The boreholes were advanced until reaching the impenetrable to percussion level, which occurred at depths of approximately 2.55 m to 13.10 m, for SP 12 and SP 09. Fig.5 shows the soil profile according to the SPT tests.

Table 1 shows the boring depth reached by each standard penetration test and the respective water level.

3.3. Excavation of caissons

Among all caissons executed, nine were fully excavated. Fig.1 shows an example of caissons that was fully excavated and extracted from the ground for visual assessment. In total, nine caissons were partially excavated (Table 1).

Source: Authors’ own production

Figure 5 Soil profile according to the SPT boreholes. The is a presence of a surficial red clay layer, medium to hard in consistency, with thickness varying from 1.45 to 8.45 m, followed by 1.00 to 6.00 m of a brown silty clay, medium to hard, and by a layer of brown clay with sand, medium to hard, 1.00 to 3.00 m in thickness. Further down, a hard gravel layer was found, determining the impenetrable to percussion.

Table 1 Caissons inspected with excavated lengths.

| Caisson | Excavated length (m) | |

|---|---|---|

| B1B-06* | 1.30 | |

| B1B-08* | 1.45 | |

| B2D-01 | 1.41 | |

| B2D-04 | 1.37 | |

| B2D-07 | 1.42 | |

| B2D-11 | 1.46 | |

| B2D-12 | 1.58 | |

| B3C-2 | 1.47 | |

| B3C-8 | 1.40 | |

| * caisson with exposed reinforcement | ||

Source: Authors’ own production

Table 2 Depth reached by each sounding and water level.

| SPT | Depth (m) | Water level depth (m) |

|---|---|---|

| SP 01 | 5,90 | 3,60 |

| SP 02 | 5,80 | - |

| SP 03 | 6,75 | 3,00 |

| SP 04 | 12,20 | 9,70 |

| SP 05 | 8,70 | 3,50 |

| SP 06 | 12,95 | 4,30 |

| SP 07 | 12,10 | 8,90 |

| SP 08 | 7,10 | 6,60 |

| SP 09 | 13,10 | 5,90 |

| SP 10 | 5,70 | 2,30 |

| SP 11 | 8,40 | 11,20 |

| SP 12 | 2,55 | 3,00 |

| SP 13 | 4,97 | 3,00 |

Source: Authors’ own production

3.4. Integrity test

For the integrity tests, the equipment utilized was a Profound brand device with the following characteristics: IP65 rating according to DIN 40 050/ IEC 529. High quality full color TFT - LCD transflective display.

The Profound brand sensor has the following characteristics:

Sensor Light-weight, high quality acceleration part no.: SIT.20800

Delta shear with thermal spiral

Nominal sensitivity: 10mV/g

Resonat frequency: 32kHz

Accelerometer range: +- 500m/s2

The Profound brand hammer has the following characteristics:

The non-destructive PIT verification was performed on all caissons, including the nine caissons that were visually inspected (Table 2). This allowed verifying if the PIT results showed the presence of the anomaly.

3.5. Statistical analysis

This study also statistically analyzed the wave velocity and the time taken for the wave to come and go through the concrete of the caissons. As only nine caissons were examined, the study used Student's t-distribution analysis, which is appropriate for a normally distributed population with a small sample size and when the population standard deviation is unknown. Eq. 1 shows how to calculate the Student's t-variable (t).

Where

is the mean value of the parameter of interest; μ, the population mean; S; sample standard deviation; and n is the sample size.

is the mean value of the parameter of interest; μ, the population mean; S; sample standard deviation; and n is the sample size.

Results and discussion

4.1. Visual assessment of caissons by means of extraction

From the excavated caissons, the pathologies found were either joints in the concrete or exposure of the reinforcement. In fact, the exposure of reinforcement in the caissons belonging to the new structure was the initial motivation for carrying out PIT as a method of integrity assessment, followed by the visual inspection. Two examples of reinforcement exposure are shown in Fig.1b and 1c, and identified in Table 2.

It is understood that the reason for this pathology may be that some caissons were executed during the intense rainy season, with the soil saturated and with disturbance from the mechanical excavation. Unfortunately, that lacks results from PIT tests carried out in caissons, which harms to compare the results obtained with the literature. Kormann [15]) have excavated long piles and have observed damage in the pile’s stem.

Evaluation of caissons with the PIT Test

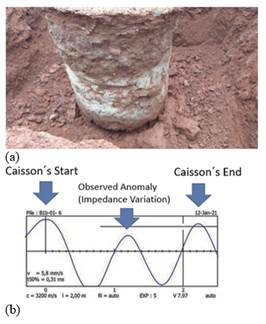

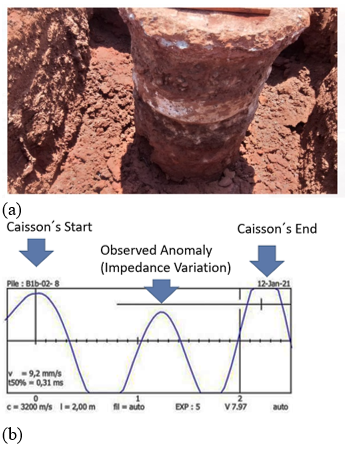

After the blows are applied, a curve is generated, showing the wave speed variation with time (related to the depth of the pile). Initially, there is a positive inflexion resulting from the blow generated, and then there are oscillations in the wave speed over time. Positive or negative inflexions indicate variations in the pile cross-section associated with anomalies such as cracks or other structural issues within the material. Figs. 6 and 7 show the photographic records of the visual inspection and the PIT reflectograms for the caisons B1B-06 and B1B-08, with exposed reinforcement.

It can be seen from the two PIT reflectograms that there is a large variation in impedance in both cases, which is characteristic of a pathology. Based on the results of the PIT test and the visual inspection, B1B-06 and B1B-08 were required to be treated and foundation reinforced.

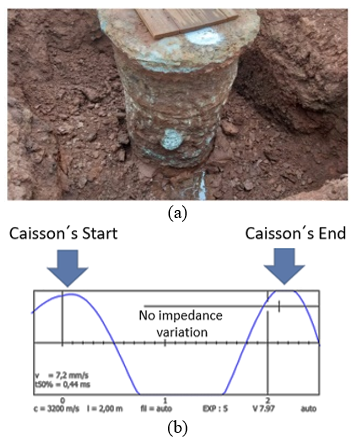

For comparison, Fig.8 illustrate the visual inspection and PIT reflectogram for caisson B2D-12, which was in intact condition (without pathology). The reflectogram did not show impedance variation, consistent with a caisson in good state of integrity. The other caissons tested showed a similar type of PIT signal.

Source: Authors’ own production

Figure 6 B1B-06 caisson joint evaluation: a) visual inspection and b) PIT signals.

Source: Authors’ own production

Figure 7 B1B-08 caisson joint evaluation: a) visual inspection and b) PIT signals.

Source: Authors’ own production

Figure 8 B2D-12 caisson joint evaluation: a) visual inspection and b) PIT signals.

Table 3 Wave velocity and time spent to come and go through the concrete of the caissons

| Caisson | Velocity [mm/s] | Time [ms] |

|---|---|---|

| B1B-06* | 5.8 | 0.31 |

| B1B-08* | 9.2 | 0.31 |

| B2D-01 | 6.7 | 0.55 |

| B2D-04 | 4.3 | 0.57 |

| B2D-07 | 6.2 | 0.54 |

| B2D-11 | 4.0 | 0.58 |

| B2D-12 | 5.6 | 0.56 |

| B3C-2 | 7.5 | 0.51 |

| B3C-8 | 5.3 | 0.62 |

| Mean | 6.1 | 0.51 |

| Standard deviation | 1,60 | 0,11 |

| Interval | 4.83 - 7.30 | 0.42 - 0.59 |

Source: Authors’ own production

Statistical analysis results

Table 3 shows the wave velocity and time spent on the wave coming and returning from the caisson's concrete. The mean and standard deviation values are also shown in the table. Although the standard deviation showed a small value, the coefficient of variation (CoV) calculation resulted in values over 20% (26.4% for the velocity and 22.7% for the time). This significant variability can be related to the intensity of the blows generated at the top of the caissons at the beginning of the test once all caissons exhibited the same wave velocity propagation (3200 cm/s). This last evidence indicates that the concrete was in a similar condition for all the caissons. The changes in the PIT signals are, therefore, directly related to the anomalies in the structure.

Source: Authors’ own production

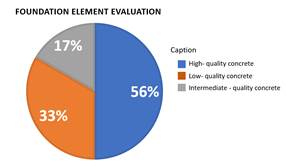

Figure 9 Concrete quality assessment through PIT (Pile Integrity Testing).

Considering the statistical analysis, a confidence interval of 95% was used to obtain the confidence interval of the parameters of interest. Considering the results of the nine caissons, the value of the t-student variable is 2.306. In this way, the confidence levels were calculated (shown in Table 3), and it can be seen that three caissons were outside the confidence interval. The high variability obtained justifies these results: i) the wide confidence interval of the properties of interest and ii) some values outside this interval.

Based on the assessed PIT test results, a chart was generated with the primary diagnosis of the findings. Fig.9 shows the percentage of concrete quality found for the piles evaluated.

It can be observed that a significant portion of the piles have good-quality concrete (56%), whereas 33% displayed poor-quality concrete, and 11% had inconclusive diagnoses, necessitating retesting or foundation reinforcement.

Conclusion

The present study performed pile integrity tests in short caissons in Itá, SC, Brazil. After performing the in-situ non-destructive test, nine foundation elements were fully excavated to evaluate the efficiency of the PIT test in identifying anomalies. A statistical analysis was carried out, and the results of the study helped to draw the following conclusions:

The PIT showed that two caissons (B1B-06 and B1B-08) had critical anomalies, more specifically a reduction in their cross-section over a specific length;

Visual inspection of the caissons, which was exceptionally possible to perform in this case, revealed that the same caissons with anomalies in the PIT test results had reinforcement exposure; and

The majority of the caissons at the site were found to be intact.

Overall, the PIT method is effective in detecting anomalies in short caissons constructed by a non-conventional mechanical method. Dynamic or static load testing is highly recommended when the acceptance of foundation elements cannot be accurately diagnosed using PIT or non-destructive tests.