1. Introduction

The development of an artisanal process without defined operations and without any control over production parameters results in a garlic powder with deteriorated organoleptic characteristics, specifically color, odor and flavor. In addition, solid waste from this type of production process is incorrectly disposed of, which ultimately generates high levels of environmental contamination. For this reason, the objective of this research is to propose the development of an ecological and standardized process for the production of garlic powder in the region.

Currently, in the Arequipa region, there are two main suppliers of garlic and its by-products: agro-industrial companies, individual farmers and farmers' associations. With regards to the first case, the degree of processing given to garlic is limited. Aybar et al. [2] stated that the company La Joya S.A.C. has extensive experience in garlic production and is currently a supplier of garlic bulbs and peeled garlic in the Santa Anita wholesale market in Lima. It also offers other freeze-dried and dehydrated products such as basil, thyme, parsley, oregano, coriander, leeks, bell peppers, chives, tomatoes, jalapeños, ginger, dill, lucuma, and pineapple. Additionally, based on primary sources, we have found that the company, Agroganadera Universal, offers melon roots, tubers and vegetables for export, as well as garlic paste, which is produced in a more modernized manner. Other Arequipa agroindustrial companies such as Agroinka and Agropel produce, commercialize, and export various products such as avocado, pomegranate, asparagus, tangerine, cochineal, and other Andean fruits. Another company, called Nobex Agricola, produces and exports olives. The Arequipa association Agricola Pampa Baja grows and exports table grapes, paprika peppers, avocados, onions, mandarins, pomegranates, and guajillo peppers. Evidence from primary sources shows that none of the agroindustrial companies in the region, which currently have the machinery and know-how to process garlic, have an ecological and standardized process to obtain garlic powder. Secondly, for the case of farmers, [16] stated that they have low profitability in the sale and marketing of garlic. This is due to the fact that they generally sell the fresh fruit too soon after being harvested, which means they have to receive and accept the payment offered by the intermediary. Likewise, Villavicencio [18] expressed that other farmers, however, in smaller quantities, provide some type of processing prior to its commercialization once they have harvested the garlic. In some cases, they shuck the garlic bulbs and peel the cloves manually in order to bag it and put it up for sale. In other cases, the bulbs are selected according to their size and garlic-based byproducts are produced (garlic sauce, dried garlic and garlic salt).

There is research regarding the production of garlic powder, but few related to an ecological and standardized production process [15]. In this type of processing, the most relevant operations are considered to be dehydration, grinding, and sieving due to the large number of operating parameters that must be controlled [9]. In the dehydration operation, temperature, air speed, charge density, weight and humidity on a dry basis are all closely monitored and controlled [7]. This is because exposing peeled garlic cloves directly to sunlight and environmental contamination for long periods of time negatively affects the pigmentation, odor and flavor of the garlic, resulting in a final product with deteriorated organoleptic properties, resulting in a lower overall product value as perceived by consumers. [12]. Another study reports that different pre-harvest conditions, such as genotype and growing environment, and post-harvest conditions, such as storage and culinary preparation, affect the chemical composition and bioactive value of garlic. Factors such as climate, soil, irrigation, fertilization, pest and disease control, as well as the harvesting process, along with the impact of storage, drying, germination, fermentation and cooking on garlic properties are analyzed.

According to [7], in the grinding and sieving operations, the fineness modulus and uniformity index of garlic powder are evaluated through a granulometric analysis. As it is a product obtained in an artisanal way without defined processes or operations, and without properly identifying and controlling the operating parameters, there are a large number of problems associated with the quality of the final product, such as the loss of flavor and discoloration, which both originate during the drying of the garlic [15].

A study shows that steam explosion significantly increases the antioxidant activity of raw garlic compared to traditional methods. In addition, the effects of temperature, pressure, and treatment time on the extraction of antioxidants from raw garlic are investigated, concluding that steam explosion is an effective, environmentally friendly, and cost-effective method for obtaining antioxidants from this product. Similarly, there are studies of industrial dehydration processes which aim to preserve the nutritional and medicinal qualities of the raw material, and to dehydrate and encapsulate Arequipa garlic. In this process, hot air was used because it is less costly and minimizes alterations in color, odor and flavor [14]. On the other hand, there is research that has already determined the appropriate parameters for obtaining dehydrated garlic powder and evaluated its organoleptic characteristics after the packaging process [1].

Another study describes how garlic was exposed to the sun for different periods of time, recording its mass and moisture before drying. The results showed that sun exposure time significantly affects the loss of mass and moisture in garlic, with the minimum loss occurring after five hours. This suggests that this natural dehydration process is an efficient, economical, and environmentally friendly method.

The latest research on the methods of obtaining garlic powder indicates that once the garlic bulbs are prepared, there are several types of drying processes that can be used.

The first is the spray dry method, which uses a dehydrator and a chute to introduce the raw material. The dehydration process for this method is carried out by atomization with an inlet temperature of 110 ºC and an outlet temperature of 80 ºC. Finally, the garlic powder is separated by means of a cyclone system, which is part of the spray dehydrator.

The second method uses a foam bed, from which the following operating conditions were determined: drying temperature at 50 ºC, air speed 2.4 m/s and drying time determined by weight constancy. For the third method, the peeled garlic is placed in a sodium hypochlorite solution and then the raw material is placed in a multipurpose dehydrator oven for 9 hours - 6 hours at 100 ºC as a first drying stage and 3 hours at 70 ºC to reach a final humidity of 5%. Finally, the dehydrated garlic undergoes a grinding and sieving process to standardize the garlic powder [6].

Finally, during the process to obtain garlic powder, for every 189.62 kg of freshly harvested garlic, 120.37kg of waste is produced, from which 27.5 kg is solid waste - from garlic cloves, stained leaves, non-commercial heads of garlic (due to their size or ripeness), garlic skin waste, and protective cuticles. The rest of the waste is represented by water and water vapor, which is also part of the production process. In the region of Arequipa, the final disposal of the solid waste is completely inadequate since it is separated and disposed of in a designated area and/or incinerated, which directly contributes to environmental pollution [11].

2. Methodology

The methodology of this research paper proposes the development of an ecological and standardized process for processing garlic powder in Arequipa and consists of three stages: The first stage began with the elaboration of a situational diagnosis based on information gathered on the current situation of the agricultural sector, specifically related to vegetable production, garlic cultivation, artisanal methods of garlic processing and final disposal of solid waste from the process. In addition, information was gathered from bibliographic sources in order to prepare the preliminary design of the process for obtaining garlic powder by dividing it into constituent units, identifying the operations along with their operating parameters (temperature and drying time, product humidity, etc.) and corresponding control points. Furthermore, the feasibility of using the waste for composting and the availability of the technology to carry out the proposal were also investigated. During the final stage, the information gathered was evaluated and as a result, the necessary characteristics and requirements for the preliminary design of the garlic processing line were obtained.

During the second stage, the pilot line prototype was designed taking into consideration the specifications established in the previous stage. Initially, the units and operations involved in the production process were defined and, according to the requirements of each operation, the necessary equipment was selected. This was based on the operating parameters, the corresponding control points and measuring instrumentation. As a result, we were able to derive the experimental model and procedure.

Lastly, during the third and final stage, the garlic powder production process was validated and the final product obtained was evaluated through an analysis of the organoleptic properties (color, odor and flavor). Moreover, a comparison was made with the garlic powder obtained through the artisanal process in order to guarantee a safe product, suitable for sale and with superior characteristics.

3. Experimental model

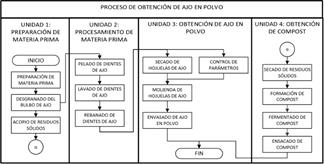

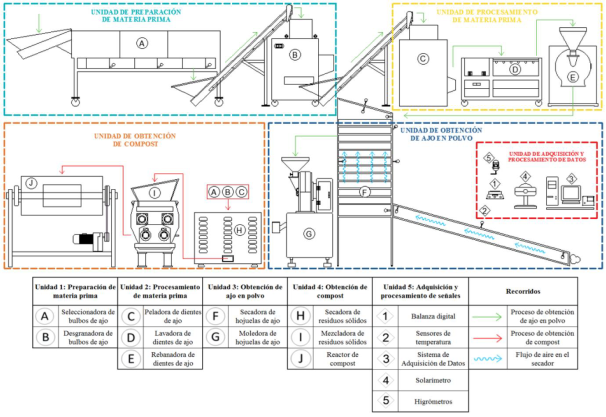

For the development of the experimental model, the process was divided into four constituent units as shown in Fig. 1:

Raw material preparation unit

Raw material processing unit

Garlic powder production unit

Compost production unit

3.1. Raw material preparation unit

This unit is responsible for the preparation of the raw material (garlic bulbs) to enable its subsequent processing and encompasses everything from the collection of the raw material to the shredding of the garlic bulbs. This unit begins with the preparation of the gathered raw material, which undergoes a brief characterization in which the external part (bulbs, stalks and discs) is evaluated. This characterization also has a pre-selection function that separates the most suitable garlic bulbs from those that do not meet the physical requirements. This is done to ensure that the best bulbs enter the sorting machine and the rest are discarded and disposed of as solid waste from the process. The pre-selection requirements used were as follows:

Physiologically developed and healthy garlic bulbs.

Stems with uniform coloration and texture.

Disks free from sprouting or bursting.

Before introducing the selected raw material into the sorting machine, the stems are cut and the roots are removed so that they have the optimum size for entry. For this reason, care must be taken that the cut in the stem is between 0.5 and 1 cm above the "head" of garlic, taking special care not to damage the garlic bulbs, the root discs or saucers with any cuts. It should be noted that garlic bulbs are stored at room temperature in such a way as to protect them from rain and humidity, and to control the presence of insects and pests so as not to negatively affect the quality of the product or cause it to deteriorate in any way.

The sorting machine is equipped with beating rollers and four-level selection mechanism that separates the garlic bulbs, with the main selection criteria being size so that only uniform bulbs larger than 25 mm in diameter are retained. In addition, the sorting machine is used to clean the bulbs in order to eliminate any remaining debris that cannot be used in the process, such as roots, soil or dry husks. Finally, once they have been properly selected and cleaned, the garlic bulbs are shredded using a garlic peeler machine with a rubber roller mechanism that imitates manual peeling. The only thing that must be checked is that the garlic cloves with cuticles are not crushed or bruised by the force of the compressor. This unit also includes the collection of solid waste (mainly straw, roots and husks) from the selection, cleaning and shelling processes, which will eventually be used to make compost.

3.2. Raw material processing unit

The purpose of this stage is to transform the raw material in order to optimize the dehydration process. It additionally involves everything from peeling the garlic cloves to slicing them. This stage begins with the peeling operation, in which the garlic cloves are peeled to remove their protective cuticle. A peeling machine is used to receive the garlic cloves and, with the aid of pneumatic technology and a removal chamber, the cuticle is extracted and the peeled garlic cloves are expelled. Once the peeled garlic cloves have been collected, the edible part is analyzed with the following evaluation criteria:

The garlic cloves in optimum condition are washed in a machine with bubble tumbling, brushing and spraying technology so that no foreign matter or residue remains attached. After they are removed from the washer, a 10-minute waiting period is recommended to allow the surface water to naturally evaporate. Afterwards, the size of the garlic cloves minus the cuticle is reduced to a thickness of 1.5 or 2 mm with the slicing machine.

3.3. Garlic powder production unit

The objective of this unit is to process the garlic flakes obtained from the previous unit in order to obtain the final product. This process begins with the drying of the garlic flakes and continues up to the packaging of the garlic powder. The third unit starts with by weighing the garlic flakes from the previous stage, which are then distributed in trays and introduced into a mixed solar dryer in which the garlic is dehydrated. In order to develop an environmentally friendly process that takes advantage of solar energy, an active solar dryer was chosen. This specific machine has a high number of parameters that need to be controlled. For this purpose, measuring instruments were installed at the different control points, both in the drying chamber and in the solar collector to control the air temperature at various points in the dryer, radiation and humidity.

Once the garlic flakes reach a constant weight and the data obtained have been recorded, they are extracted and placed in a garlic grinding machine to obtain the final product.

According to [17], there are two types of powder products derived from garlic that depend on the particle size (garlic powder and granulated garlic).

Garlic Powder (Type I): 95% of the product passes through a sieve with a mesh opening of 0.250 mm (NOM-24 M, No. 60 U.S.).

Granulated Garlic (Type II): 95% of the product has a particle size between 0.250 mm (NOM-24M, No. 60 U.S.) and a mesh size of 1.25 mm (NOM-5 M, No. 16 U.S.).

For the development of the experimental model, the process was divided into four constituent units as shown in Fig. 1.

The particle size range of the garlic powder obtained must be controlled to ensure that it is suitable for marketing (between 0.250 mm and 1.25 mm). Once this requirement has been verified, the final product is packaged and ready for sale.

3.4. Composting unit

The primary function of this unit is to produce compost from the solid waste collected throughout the process of garlic powder production. This ranges from drying the waste to bagging the compost. After the waste has been collected from the first and second unit, compost can be produced from the solid waste. First, the solid waste, which is composed mainly of internal and external shells, roots, stalks and garlic in poor condition, are dried in a solid waste dryer at 70°C. This is subsequently ground in a mixer that performs a double function: shredding the waste and producing the optimal compost mixture with water in the following proportion: 80 g of dry garlic straw with 40 ml of water at approximately 37°C. Once the process of compost and water homogenization has been carried out, the mixture is fermented in a rotary drum reactor for approximately 10 days, which will improve the insecticidal, nematicidal, fungicidal and phytotoxic properties of the compost. Finally, once the compost has been fermented for the appropriate amount of time, it is bagged and ready to be marketed.

Source: Authors.

Figure 1 Diagram of the garlic powder production process divided into its constituent units and components.

For practical purposes, we included an additional data acquisition and processing unit, comprising a total of four measuring instruments. An Oharus Traveler TA501 digital scale with a maximum capacity of 500 grams was used to control the weight variation throughout the entire process prior to drying, thereby making it possible to determine the amount of solid waste and water lost from the raw material at each stage. For the measurement of temperatures at strategic positions in the dehydrator, 10 K-type thermocouples (Chromel-Alumel) with a temperature range between -55 °C and 100 °C were used. Each one was installed at different points of the solar dryer: at the inlet and outlet of the solar collector, at the inlet and outlet of the drying chamber, on the collector glass, on the internal translucent and opaque walls, on the external translucent and opaque walls, and finally a sensor that will measure the ambient temperature. Additionally, a Kippzonen brand solarimeter, model Cmp6, was used to record solar radiation and a Campbell CR800 SAD Campbell Data Acquisition System was used to record the temperature and radiation signal values. Finally, two Extrech hygrometers, model Modulo 42270 with an integrated matrix that stores up to 16000 readings (8000 temperature and 8000 %RH), were used to record the temperature and humidity inside the drying chamber of the dehydrator.

4. Experimental procedure

The experimental procedure was developed with the production of garlic powder as its primary objective, and during operations, to register and determine the optimum values of each identified operating parameter. For practical purposes, the protocol was segmented into two types of tests: laboratory level testing and pilot line level testing. Furthermore, the following initial considerations were made: the type of garlic, which was Napurí, since it is produced and marketed in large quantities throughout the Arequipa region, and the cultivation period, which goes from December to July and harvested after 6 months. The study began with the harvesting and collection of garlic and concluded with production of garlic powder as the final product. The drying and milling stages were considered critical operations because they generate several operating parameters that must be rigorously controlled. Finally, the daily drying time was determined to be between 9 a.m. and 5 p.m., since the highest level of solar radiation was recorded during this period, also considering the amount of water lost during the night.

Five tests were carried out at the laboratory level in order to determine the amount of solid waste (in Kg) generated from the first two units of the garlic powder production process. The objectives of these tests were: to obtain the material balance of the process, to check if the amount of solid waste varies according to the change in proportion of the raw material and, if so, to determine the trend of the behavior, and additionally, to know the total percentage of waste lost in each operation throughout the process.

On the other hand, seven tests were carried out at pilot line level. Of the total number of tests carried out, five of them were from the drying operation present in the garlic powder production unit. The first two tests were carried out to establish the optimum temperature in the drying chamber to ensure that the organoleptic characteristics (color, odor and flavor) of the garlic flakes do not deteriorate. The main objective of the two subsequent tests was to determine and verify the value of the unit energy consumption in the drying chamber and the efficiency of the solar collector. Finally, the last drying test was carried out for practical purposes in order to determine the total drying time from the time the garlic bulbs are harvested until the dehydrated garlic flakes are produced. The remaining two pilot line tests, pertaining to the milling operation, were carried out to validate the optimum particle size of the garlic powder using a manual mill and a 0.25 mm sieve in the mesh opening.

5. Organoleptic evaluation

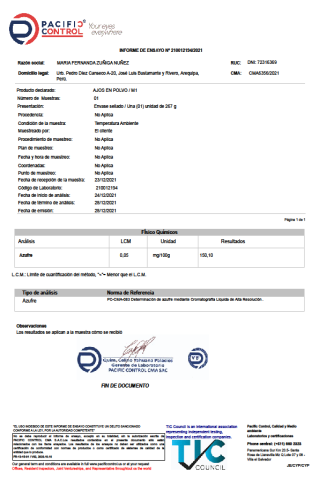

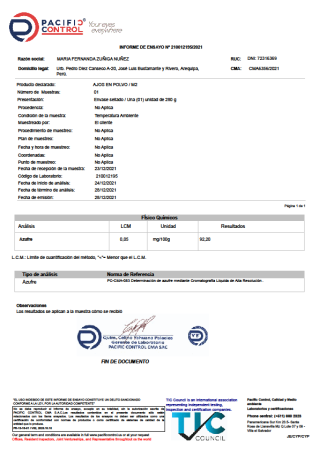

To validate the superior quality of a product obtained by a standardized and controlled process, the organoleptic characteristics (color, odor and flavor) of garlic powder obtained by the standardized and organic method (Sample 1) and by the artisanal/manual method (Sample 2) were compared. For the color comparison, the Pantone chromatic scale in Fig. 2, between the range PMS 7499 C to PMS 7505 was used.

Conversely, to compare odor and flavor, the percentage of sulfur was considered as the main indicator. Block [4] stated that the distinctive flavor of garlic is mainly due to its nitrogen and sulfur compounds (specifically isoaliin since it is the precursor of garlic's characteristic allylic compounds), while allicin is the sulfur compound that gives garlic its characteristic odor. According to [3], in his research article, noted that the sulfur compounds of garlic depend on the processing conditions, the gentler the technique and/or method, the better they are preserved. Under this premise, it is considered that the garlic powder with the highest percentage of sulfur in its composition is that which has been obtained from an optimal, controlled and efficient process as this improves the preservation of its odor and flavor. As a reference point for comparison, the sulfur content of garlic obtained by Lawson [8] was considered. He stated that the total sulfur content is approximately 1.0% of its dry weight or 0.35% of its fresh weight. Finally, taking into account the aforementioned premises, the samples obtained in the experimental tests (1 sample of the manual processing and 1 sample of the proposed processing) were sent to the Pacific Control Laboratory, accredited by INACAL and the Ministry of Production, to be analyzed for sulfur content, using PC-CMA083: Determination of Sulfur by High Performance Liquid Chromatography as a reference standard.

6. Results

The proposal to design and validate an ecological and standardized process to obtain garlic powder in the agricultural sector of Arequipa has bibliographic support since it is corroborated by both research articles and graduate theses. Secondly, this proposal can be validated by the number of success stories that have been recorded at the national level. As a result of the design, a process divided into four units with sequential constituent operations and specific functions was obtained, as shown in Fig. 3.

In the operations of the raw material preparation unit, which consist of garlic bulb shelling, peeling, washing and slicing of garlic cloves, only the physical characteristics of the raw material were controlled in each operation. The operations with the greatest number of operational parameters that determined the quality of the final product obtained were: drying and grinding. The variation in weight during the entire process was controlled to calculate the moisture content of the garlic (66%) and the proportion of solid residues (18.3%). In the drying operation, a mixed solar dehydrator was used (Fig. 4), which consists of a solar collector and a drying chamber with ten trays inside, where the product to be dehydrated is placed. The chamber has four opaque walls made of galvanized steel and a translucent glass wall at the top that functions as a direct type dryer since it receives solar radiation and directly affects the garlic. The flow of hot air is additionally a type of natural convection circulation, and the trays containing the garlic, which come into direct contact with the opaque walls of the drying chamber, are subjected to heat exchange by conduction. Finally, it should be noted that the chamber is fully insulated with a rubber seal to reduce heat loss.

The flat plate solar collector gathers heat from radiation and conducts it to the drying chamber using fans (forced convection heat transfer). In addition, it consists of a cover or top plate made of a 3mm half-double glass which is a translucent material sensitive to thermal radiation that generates a greenhouse effect inside. It also uses mineral fibre as insulation material for its low thermal conductivity and has a galvanized steel plate at the bottom painted black to attract more radiation. This allows the air flow to enter through the bottom of the collector and exit through the upper part that connects directly to the drying chamber.

The parameters controlled in the drying process were the following: the temperature at different points of the drying chamber and the solar collector, solar radiation, wind speed and humidity. The final result was a solar collector efficiency of 61.38% and a unit energy consumption (UEC) of the drying chamber of 3076.47 W/kg.

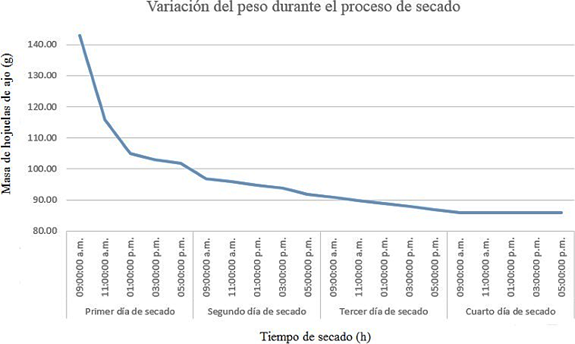

Furthermore, we determined that the optimum drying temperature range was between 50 and 60 °C, since it preserves the organoleptic characteristics of garlic (color, odor and flavor). The drying time was 72 hours for 202.9 g of garlic flakes with an initial humidity of 66%, finally yielding the values of weight variation in two-hour intervals during the drying time, data expressed in Table l.

Table 1 Weight variation of garlic flakes during the drying process.

| Weight variation during drying process | Time | Weight (g) | |

|---|---|---|---|

| Initial weight of garlic flakes | 6.6 | ||

| First day of drying | 9:00 a.m. | 142.9 | |

| 11:00 a.m. | 115.9 | ||

| 13:00 p.m. | 104.9 | ||

| 15:00 p.m. | 102.9 | ||

| 17:00 p.m. | 101.9 | ||

| Second day of drying | 9:00 a.m. | 96.9 | |

| 11:00 a.m. | 95.9 | ||

| 13:00 p.m. | 94.9 | ||

| 15:00 p.m. | 93.9 | ||

| 17:00 p.m. | 91.9 | ||

| Third day of drying | 9:00 a.m. | 90.9 | |

| 11:00 a.m. | 89.9 | ||

| 13:00 p.m. | 88.9 | ||

| 15:00 p.m. | 87.9 | ||

| 17:00 p.m. | 86.9 | ||

| Fourth day of drying | 9:00 a.m. | 85.9 | |

| 11:00 a.m. | 85.9 | ||

| 13:00 p.m. | 85.9 | ||

| 15:00 p.m. | 85.9 | ||

| 17:00 p.m. | 85.9 | ||

| Final weight of garlic flakes | 85.9 | ||

Source: Authors

It is evident from the dehydration curve in Fig. 5 that the drastic change in the mass of the garlic flakes occurs in the initial stage of the drying process, due to the fact that garlic contains 66% water and that the greatest amount of vaporization occurred on the first day. Once this time period of 48 hours has ended, the drying curve assumes an almost linear shape in which the drying rate becomes almost constant. This is a direct result of the decrease in the amount of water lost. Consequently, the line of the drying process is maintained for a certain period of time (between 48 and 72 hours) until reaching the critical point, where a small curvature in the drying line is evident, indicating that the equilibrium weight has been reached and the dehydration process is therefore finished.

Finally, the parameter that was controlled in this milling stage is the particle size of the garlic powder obtained. 95% of the product must pass through a sieve with a mesh opening of 0.250 mm as indicated by NOM-24 M, N°60 U.S.

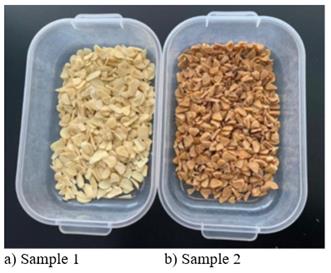

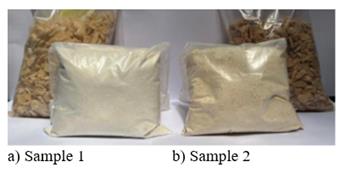

With respect to the organoleptic characteristics, the color was compared according to the Pantone scale (Fig. 2). Sample 1 is the color PMS 7499 C, which is a light shade of yellow composed of 90.2% green, 69.8% blue and 94.51% red. Additionally, it has a tone of 50° degrees, 69% saturation and 82% brightness. This is in contrast to Sample 2, which belongs to the color called PMS 7504 C. This color is a shade of brown composed of 45.1% green, 30.98% blue and 56.08% red It also has a shade of 34° degrees, 29% saturation and 44% lightness.

As a result of analyzing the color in Fig. 6 and 7, it was determined that, due to the temperature, the garlic powder obtained by the standardized and ecological method (in the mixed solar dryer) has a lighter color within the color chart than garlic from conventional drying. When the drying temperature control is set to a maximum of 60 °C, the garlic pigmentation is preserved, which is evidence of a controlled process.

Additionally, the comparison of odor and flavor obtained from the Pacific Control Laboratory results is shown in Figs. 8 and 9. As a premise, [8] established that sulfur compounds represent 350 mg for each 100 grams of fresh garlic; therefore, it is assumed that the sample with a sulfur ratio closer to 350 mg is the one that has better preserved its organoleptic characteristics of color and odor. Sample 1 contains 150.10 mg of sulfur/100 g of garlic powder while Sample 2 contains 92.20 mg of sulfur/100 g of garlic powder. This means that the proposed drying process in the solar dehydrator is more efficient and controlled than the conventional one since it better preserves the sulfur content (the compound that gives garlic its characteristic flavor and odor).

7. Conclusions

Based on the research conducted, we have concluded the following:

An ecological and standardized process was designed for the elaboration of garlic powder in the agricultural region of Arequipa, where the operative parameters were identified and controlled, a proposal was made to take advantage of its solid residues and solar energy was used as an eco-friendly alternative.

The process of producing garlic powder was designed, establishing four constituent units and a control unit for operating parameters aimed at the drying operation, since it is the most critical one.

After undergoing the following procedures: selection, shelling, peeling, washing, slicing, drying and grinding, 202.9 g of freshly harvested fresh garlic was able to yield 65.88 g of garlic powder. The composition of the initial raw material (freshly harvested fresh garlic bulb) was determined to be 15.7% garlic pulp, 18.3% solid residues and 66% water.

The drying process was controlled by identifying its operating parameters. The total drying time and the organoleptic characteristics of the final product depended on a maximum temperature of 60 °C inside the drying chamber.

The process design for obtaining garlic powder was verified through the development of experimental tests and the product obtained was validated through analysis in a High-Performance Liquid Chromatography laboratory.

A process with differentiated operations was designed at a theoretical level to make use of the solid waste derived from the process of obtaining garlic powder.