Introduction

The objective of this investigation was to characterize from the technological and socioeconomic point of view the production system of the sweet chili pepper (Capsicum chinense) in the Caribbean Region of Colombia.

The statistics of the Ministry of Agriculture and Rural Development of Colombia (MADR) present that the largest producers of this crop are the departments of Bolívar, Sucre, and Córdoba. Further, the department of Bolívar has the highest production with 6381 tons and with an average yield of 7 t h-1 (Agronet, 2018).

There are studies of characterization of agricultural production systems (Agreda, 1991); of the typification of production systems (Escobar, 1990), and some contributions of the International Center for Improvement of Maize and Wheat (CIMMYT) in 1988, through a manual of economic evaluation of agricultural technologies, in addition to the socio-economic evaluation techniques applied to agricultural production systems developed by Agreda (1991).

In Colombia, Duarte (1990) carried out a study of analysis of production systems in San Gil Santander. Ríos (2004) analyzed the production systems of lulo (Solanum quitoense Lam) in the coffee region of Colombia, and, Martínez et al. (2019) carried out a characterization work of the long beans and the eggplant in the Caribbean Region of Colombia.

Concerning the commercialization margins, Martínez and Hernández (2007) calculated the marketing margins and the direct participation of the producer for dry cassava within the poultry chain, with a generated result of a gross margin of 27 % and the direct participation of the producer of 73 %. The low participation of farmers in the benefits generated along the production-consumption chain is evident (Martínez et al., 2019) In the case of the eggplant in two regions of the Caribbean, the researchers’ conclusion related to the commercialization margins was that it exists little integration of the production chain. The disadvantage of the producer in favor of the marketer is evidenced by the inequality when distributing the surplus.

Materials and methods

The study of local production technology was carried out in the influential area of the Caribbean region, and the analysis of the economic returns, in two specific locations of the same territory: San Juan del Cesar, in the department of La Guajira, and Ponedera, in the department of Atlántico.

According to Rodríguez (2005), the simple random sampling method was used for this study. It started from an ensemble of 1428 farmers. The destination of the production was taken as a sampling variable: 62 % destined for the market and 38 % for household consumption. The original data was obtained from the agricultural evaluations and Agronet (2018).

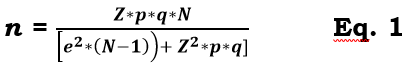

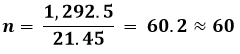

The following equation was applied to calculate the sample size:

Where:

p: the proportion of the population that cultivates less than one hectare, i.e., 524 farmers.

q: the difference between the total population and the proportion of the population that does not meet the characteristic, in this case, units larger than one hectare (i.e., 321 farmers).

e: maximum error (i.e., 14.7 %)

N: population size (i.e., 846 productive units)

The structured survey, with 30 questions related to the technological and socio-economic aspects of the production, was applied to agricultural experts in cultivation. The data was organized and there were applied techniques such as frequency analysis, contingency tables, descriptive statistics, and correlation analysis of the variables.

The economic returns considered the local production technology, the cost patterns built using the consensus technique, and two workshops: one in San Juan del Cesar and the other in the town of Ponedera. According to Molina (2005), the results included production costs, unit cost, gross income, net income, equilibrium point, and production efficiency.

The value of labor was calculated by the price they pay for a wage in the region. The value of the inputs was made with the field price, as suggested by CIMMYT (1988), that is, the price in the agricultural warehouse plus the cost of transportation to take it to the farm. For the components of the cost, the statistical concept of fashion was used (Add, 1991). The product was calculated with the field price, that is, what they pay the farmer on his farm minus the cost of taking it to the consumption center. Net income is the difference between gross income and production costs, plus the minimum amounts that must be produced to equalize income with costs as estimated as the break-even point.

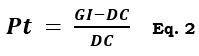

Efficiency was analyzed following Forero et al. (2013) who, in addition to economic efficiency, consider the technical profitability of the crop, net profitability, and technical efficiency. Technical profitability was determined by establishing the relationship between the difference in gross income and direct costs. For net profitability, the difference between gross income and direct and indirect costs was related to the total costs. The difference between gross income and direct cost was related to the cultivated area to calculate the technical efficiency of the crop. The technical profitability indicator was calculated establishing the relationship between the difference between gross income and direct costs, as follows:

Where:

Pt: Technical profitability

GI: Gross Income

DC: Direct costs

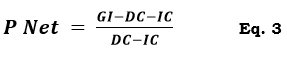

Regarding net profitability, which is obtained by relating the difference between gross income and direct and indirect costs to the total costs, it is the same concept of profitability that is traditionally used and is expressed as follows:

Where:

P Net: Net Profitability

GI: Gross Income

DC: Direct costs

IC: Indirect costs

For this study, the Gross Margin of Commercialization (GMC) was calculated following Espinosa et al. (2008), in where it is defined as the difference between the price paid by the consumer and the one received by the farmer. This was calculated using the following equation:

Besides, the Direct Participation of the Producer (DPP) was estimated, indicating the share that the producer receives for what the consumer pays:

The Net Margin of Commercialization (NMC) is an indicator that shows the proportion of the price paid by the consumer, which is the profit for the intermediary:

NMC allows estimating the differences of the values in terms of prices paid to the producer and those paid by the consumer for the product, i.e., sweet chili pepper.

Results and discussion

The farmers who cultivate sweet chili pepper manifest certain characteristics, such as average age of 51 years old and 11 years of experience with the crop. This information is similar to the results found in studies carried out in the production systems of vegetables such as tomato, long bean, eggplant, and tomato in Colombia where farmers count with average age of 50 years old (Perilla, 2011; Martínez et al., 2019; Orozco et al., 2019). Thus, it is allowed to infer that most of the horticultural production systems in the country are in charge by a population categorized between adulthood and old age. However, for that same matter, there is a risk that ancestral knowledge and the same productive systems tend to disappear due to the inexistence of a relay generational situation. This is different at the international level. For example, in countries like Bangladesh, the average age of the producers of the horticultural production system is 20-35 years old, that is, a young population (Mahamuda, 2017).

The mean area dedicated to sweet pepper is 0.6 hectares, and therefore, the farmers are considered small producers. This result coincides with that reported by Páez Redondo et al. (2004), where it presents that 33.3 % of respondents in the Department of Cesar plant less than one hectare. 90 % of the production is destined for the market in the nearest consumption centers, such as Barranquilla and Cartagena. This coincides with what was reported by Ruíz (2016).

The farmers report the following production technology tasks:

Batch selection

Batches are selected according to different risk elements, such as susceptibility to flooding, and proximity to a water source.

Soil preparation

At least 50 % of the farmers perform adaptation work with equipment (machinery) to plow once and then rake (once). 29 % prepare the soil manually, while 21 % combine manual and mechanical methods. It should be noted that farmers always carry out some manual activity.

Sowing

80 % of farmers carry out seedbed preparation or purchase seedlings in nurseries, as well as weed control; in transplanting they use about 5 wages per hectare at a cost of COP 25.000. The amount of seed is 35 g per hectare. 83 % of the surveyed farmers use non-certified seeds, and 17 % use certified seeds that are purchased in agricultural stores.

The predominant production or arrangement system is monoculture (82 %), followed by far by the rotational system (12 %), and only 6 % regularly form partnerships under family farming or miscellaneous crop schemes.

Irrigation

40 % of the surveyed do not use irrigation and depend on the rains. 34 % of those who use irrigation use the systems by gravity, 11 % drip irrigation, and 15 % use manual showers. Water sources are diverse, usually using water from natural sources such as a river or stream in 65 % of the cases studied, as well as a dam or well in Jagüey (22 %); only 13 % use other sources of water. Ruíz (2016), in his study on the Implementation of a sweet pepper production project as a model of agricultural development for small producers in the municipality of Córdoba, Bolívar, relates that these producers do not have innovative “agricultural systems such as irrigation systems that allow mitigate the effect of drought”.

Fertilization

Of the farmers surveyed, 75.8 % apply chemical synthesis fertilizers, being urea (46 % nitrogen), triple 15 (N-P-K), and ammonium diphosphate (DAP), the most widely used. Further, 9.1 % combine chemical and organic fertilization methods, 4.5 % do not fertilize, and 10.6 % apply solely organic fertilization. The latter includes composting with crop residues that are incorporated into the system. In the first two fertilization methods, while the production cycle of the crop progresses, its nutritional demand is higher; therefore, farmers increase the doses of fertilizers applied.

Phytosanitary management

Regarding weed control, chemical products are used in 41.4 % of the respondents surveyed. However, 52.5 % of the farmers perform manual control, and 6.06 % carry out mechanical control. For the control of insect pests, the farmers state that they mostly use chemical synthesis products (91.94 %), while a very low percentage (3.23 %) use biological control; moreover, the same proportion (3.23 %) of farmers apply a mixed control, and 1.61 % perform other types of control method combinations.

Other agronomic tasks

Other agronomic tasks performed are reseeding, pruning, waste collection, and earthing up. The latter is done twice during the crop cycle, using an average of 60 wages h-1.

Harvest

Fruit collection is carried out manually. On average, farmers employ 15 wages h-1 that include internal transport from the collection site to the collection point. Regarding yields, farmers mentioned that they obtain an average of 15 t ha-1 with a maximum of 20 t ha-1. The sale of the harvested product is carried out in the plot. These results coincide with those reported by Agronet (2018) where for the department of Córdoba the yield obtained is 15.62 t ha-1, while for Cesar and Sucre they are less than 8 ton ha-1. This difference may be related to the implementation of the local production technologies of each region, productive niches (environment), and cultural aspects as described by Pinto et al. (2013) where it considers that low yields are due to the low technology implemented in the production system.

Economic evaluation of the sweet chili pepper production system

The economic evaluation was carried out in two representative producing locations of the region: San Juan del Cesar, in the department of Guajira, and Ponedera, in the department of Atlántico.

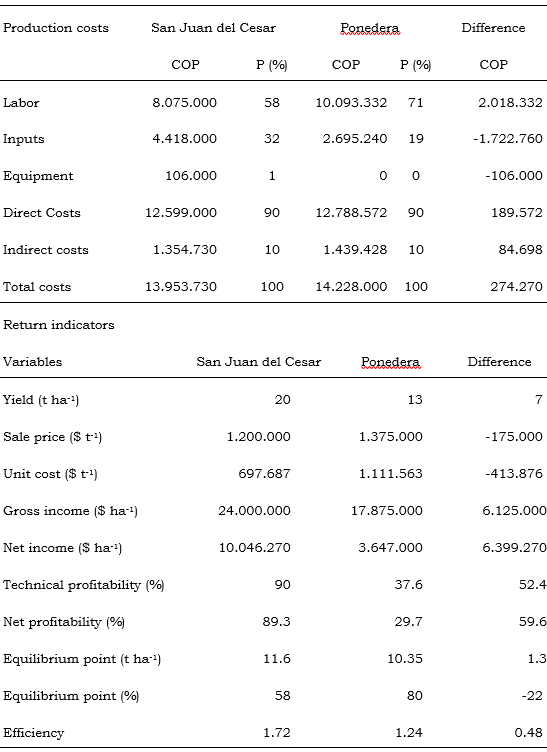

With the cost patterns for one hectare, a comparative analysis of the different elements involved in the production was carried out and can be observed in Table 1. This table shows that the net income is higher in San Juan del Cesar. This is explained by the difference in yields, obtaining a higher yield of 20 t ha-1 in this locality compared to Ponedera, that attained a value of only 13 t ha-1. This makes the profitability also higher in San Juan del Cesar.

Table 1 Comparative analysis of production costs and economic returns of one hectare of sweet chili pepper in San Juan del Cesar and Ponedera, the Caribbean region of Colombia in 2018.

Source: elaborated by the authors (the data used was obtained in the participatory workshops with producers). COP: Colombian pesos; P: participation (%).

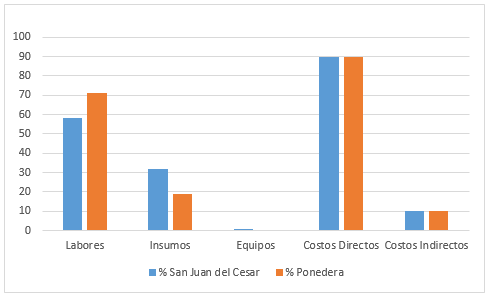

Regarding production costs for San Juan del Cesar, the total production cost is COP 13.953.730 ha-1, of which 90 % corresponds to direct costs, 10 % to indirect costs, 58 % to labor, and 32 % to inputs (Table 1). In the case of the locality of Ponedera, total production costs are COP 14.228.000 ha-1, of which 90 % corresponds to direct costs, 10 % to indirect costs, 71 % to labor, and inputs participate with 19 % of the total costs (Table 1). This situation can be observed in Figure 1.

Figure 1 Comparison of the constituent elements of the production costs for sweet chili pepper in the localities of San Juan del Cesar and Ponedera, in the Caribbean region of Colombia.

The average costs of the production process corresponded to COP 1.082.500 per hectare, being the item harvest (labor) and transport the heaviest with 26.7 % (COP 290.000). The preparation of the land and planting (mechanics and labor) constituted 22.2 % of the total costs (COP 240.000), while the labor force for applications of inputs and manual weeding represented 19.8 % (COP 216.000). Inputs such as herbicides, fertilizers, and pesticides accounted for 17.3 % of total costs (COP 190.0000), and 14.0 % (COP 146.500) corresponded to land and unforeseen leases.

The differences concerning the participation of the labor share of 13 % between both localities can be observed with higher participation of this component in the case of Ponedera. These cost structures share the direct costs and differ in the participation of agronomic management work. Regarding inputs participation, the situation is inverse: the highest proportion is found in San Juan del Cesar with a difference of 13 % compared to Ponedera.

It is less expensive to produce sweet chili pepper in San Juan del Cesar. This is explained because the proportion of labor in the production costs is higher in the case of Ponedera with a participation of 71 % of the total costs, which means that sweet chili pepper cultivation is more labor-intensive in this location. On the contrary, in San Juan del Cesar labor participates with 58 % of the total production costs. The most significant difference is that the purchase of inputs is more intensive in the case of the sweet chili pepper production in San Juan del Cesar. On the other hand, net income is higher in the case of San Juan del Cesar with COP 10.046.270 ha-1 and a difference of COP 6.399.270 ha-1 with the value obtained in Ponedera. Finally, the production unit cost is higher in Ponedera with a value of COP 1.111.563 t-1 which explains why yields are higher in San Juan del Cesar with a difference of 7 t ha-1 in relation to Ponedera. This makes the profitability also higher for San Juan del Cesar.

The efficiency of the production system (Forero, 2013) gave a coefficient of 90 % in the case of the production of San Juan del Cesar and 40 % in the case of the town of Ponedera. This difference in favor of the locality of San Juan del Cesar is explained by the low lower unit cost at COP 413.876 / t-1 in relation to the locality of Ponedera, which means that production in San Juan del Cesar is technically more efficient.

The net profitability generated a value of 89.35 % for the case of San Juan del Cesar and 32.13 % for the case of the town of Ponedera, as in the previous case, favorable for San Juan del Cesar. this is explained by the effect of the returns that make the unit cost lower for this location in relation to the town of Ponedera.

In this case, a coefficient of COP 11.401.000 was obtained for the case of San Juan del Cesar and only COP 5.086.428 for Ponedera. This is explained by the fact that the yields are higher in the first locality, and the costs per hectare and tons of sweet chili pepper produced are lower. Similarly, in both cases, there is a technical response to the resources used in the crop.

The economic efficiency calculated with values 1.71 for the town of San Juan del Cesar, in the department of La Guajira, and 1.23 for the case of the town of Ponedera. These values are related to technical efficiency and total profitability, the town of San Juan del Cesar being favorable. In both cases the production costs are exceeded by a wide margin with the yields obtained.

Commercialization margins

GMC is the proportion the consumer pays to cover the expenses and profits of the final seller or the total intermediation, i.e., for every COP 1 the consumer pays, the intermediation collects COP 0.69.

For this calculation (Eq. 8), the commercialization cost was assumed as COP 393.7 per kilogram of sweet chili pepper. The result reveals that for every COP 1 paid by the consumer, COP 0.59 are profits that are distributed in the intermediation chain. The above allows us to observe that the commercialization margin is very high because of the proportion the consumer pays for the product, i.e., 59 %. Furthermore, the intermediation takes 41 % of the price paid by the consumer, and is also the link that least risks takes in the process. Similar results were found in agricultural production systems, such as the dry cassava production system for balanced food. In this work, the same indicators were calculated, obtaining a gross margin of 27 % and direct producer participation of 73 % (Martínez & Hernández, 2007). Additionally, the results obtained in the case of long beans coincide with the fact that the gross margin for commercialization is 25 %, and the direct participation of the producer is 50 %.

The techniques used here are similar to those of the study carried out in Nigeria by Ayodele et al., 2016. The variables: Farmers’ age, 42 years old, and for this work, 51 years; the experience is similar in both cases, around 12 years; the planted areas are smaller in the case of Nigeria with 0.09 hectares, in the case of the study of the Caribbean Region, 0.6 are larger. The economic returns in the two cases analyzed are positive; however, they are higher in the case of Ayodele’s work for Nigeria with a profitability of 64 % and a ratio of benefits / cost of 1.65, while for this study it reports an average profitability of 48 %, however, the town of San Juan del Cesar presented superior profitability.

Conclusions

The sweet chili pepper production system in the Caribbean region of Colombia is sustainable to the extent that with average yields, it allows recovering production costs and generating profit surpluses.

Differences in production efficiency can be seen, being greater for the town of San Juan del Cesar, which is explained because the yields are higher by 7 t/ha-1. The net income is also higher with a difference of COP 6.399.270 ha-1 in relation to the town of Ponedera.

The low integrity of the production chain was demonstrated by the high margin of commercialization (69 %), with a very high participation of the intermediaries in the surpluses, being the farmer the one who participates the least and the one who presents the most risks.