1. Introduction

According to Greenpeace International (2018), “every minute, one garbage truck of plastic is dumped into our oceans.” This, as a consequence of humanity’s modern “use-and-dispose” lifestyle, has unleashed an emergency that impacts the health of ecosystems and the living beings that depend on them.

The above explains why environmental sustainability has gone from being the purpose of activist groups to becoming a concern of ordinary citizens, society and its organizations, and industries and governments worldwide with the U.N.’s promulgation of the SDGs (2015). For the Global Data agency (2018), sustainability ranks second among the eight “megatrends” for industrial processes using plastic materials.

Given such a scenario, industries worldwide need to speed up their migration from a “linear economy” model, which implies producing, using, and disposing of goods, towards a “circular economy” that maximizes the use of resources and converts their waste into new raw materials (World Economic Forum, Ellen MacArthur Foundation, and McKinsey and Company, 2016).

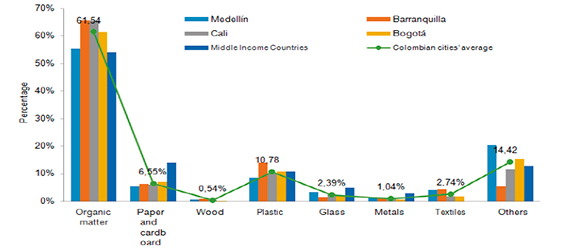

The Colombian plastics industry is in the spotlight concerning the circular economy because it has failed to invest in science, technology, and innovation to reduce its ecological impact (CONPES, 2016). Colombia produces 12 million tons of garbage per year, and plastic comprises 10.78% of these (Graph 1), making it the second-leading group of solid waste and the first of interest in the circular economy.

The reason for developing this research is that Colombia consumes about 1.2 million tons of plastic a year, of which 56% are PET containers (Procuraduría General de la Nación, 2019 - Attorney General of the Nation’s Office), more than 4,000 million PET bottles a year, and the country only 31% of those (the worldwide average is 78%) (Diario La República, 2019; Ecoembes, 2019).

Such a PET recycling problem in Colombia has led to identifying the logistics chain behind it to specifically analyze where each echelon stands within the Circular Economy, determining that the recycling problem is due to the lack of a PET “culture for recycling” by the three leading companies in the beverage sector (Postobón SA, Coca Cola FEMSA, and Bavaria S.A.). In awareness of their responsibility with sustainable development, they have entered into sustainability commitments, as is the case of Coca-Cola FEMSA’s Environmental Declaration (2018), the new Postobón Sustainability Model (2018), and the 2025 Sustainability Goals of Bavaria S.A. (2018).

Therefore, this paper aims to describe the characteristics behind implementing the Circular Economy strategy concerning Polyethylene Terephthalate (PET) and its influence on the Colombian beverage sector’s development for deployment and operation. According to DANE (2020), the beverage sector consists of Division 11, according to the International Standard Industrial Classification (ISIC), as characterized by the production of beverages packaged into PET plastics.

Among the research contributions, the PET recycling problem is analyzed, and the logistics chain is analyzed in a broader Circular Economy-based management context. The consulting firm Acceleratio, focused on transition processes towards the Circular Economy, has identified the most recurring obstacles to rapidly adopting the model, i.e., the lack of support and incentives from governments, consumers’ psychological barriers, markets’ low capacity for recycling, and costly innovation processes or new technologies (Van Eijk, 2015).

The paper is structured theoretically: state of the art, a literature review and theoretical and conceptual framework, the methodology, findings and discussion, and conclusions.

2. Theoretical Structure

2.1. State of the art

The circular economy seeks to keep materials in circular processes, preventing their discarding while promoting their reintegration into the value chain once their useful life is over so as to be converted into new raw materials (Ellen MacArthur Foundation, 2014).

Research such as that by Marcet (2018) and Greenpeace (2018) concluded that waste recycling plays a crucial role in the circular economy, not only because of its impact on the environment but rather because of the way that waste is collected and handled and the promptness and the ability to do so en masse, can lead to higher recycling rates and materials coming back into use.

The Cradle to Cradle theory sustains that the recycling process is insufficient to bring economies closer to an effective circular economy model (Braungart and McDonough, 2002). The solution is not to do the impossible to reduce, reuse and recycle waste, but to effortlessly design the products to be reused from the start, offering circular products thought of as such from the origin (Braungart and McDonough, 2002).

2.1.1. State of the art on the impact of PET plastic

The study by Gómez (2016) entitled “Diagnosis of the impact of plastic bottles on the environment: A state of the art” identified 60 research articles published between 1993 and 2016. It is highlighted that Colombia is the second country in PET impact studies. The search was 10-year scoped due to the lack of available information about the impact of PET (Tables 1, 2).

Table 1 Information Collection Distribution in Database

| Database | Descriptor | Years | N° papers found | N° relevant papers | Language |

|---|---|---|---|---|---|

| ProQuest Ebrary | Polyethylene terephthalate its impact on the environment | 2004 | 20 | 3 | Spanish |

| 2008 | |||||

| Packaging and environment | 2006 | 25 | 3 | Spanish | |

| 2009 | |||||

| Waste and PET plastics | 2009 | 12 | 3 | Spanish | |

| 2011 | |||||

| PET containers | 2013 | 16 | 1 | English | |

| 2015 | |||||

| Scielo | Biodegradation of PET | 2005 | 20 | 3 | Spanish |

| 2007 | English | ||||

| Google Scholar | Plastics in Spain | 2001 | 10 | 1 | Spanish |

| 2003 | |||||

| Plastics | 2007 | 9 | 2 | Spanish | |

| 2010 | |||||

| Problems with PET | 2010 | 13 | 3 | Spanish | |

| 2012 | |||||

| PET plastics | 2009 | 26 | 3 | Spanish | |

| 2013 |

Source: Gómez (2016).

Table 2 Information Collection Distribution in EBSCO HOST

| Database | Descriptor | Years | N° papers found | N° relevant papers | Language |

|---|---|---|---|---|---|

| EBSCO HOST | Environmental pollution | 1993 | 20 | 4 | English |

| 1999 | |||||

| Impact of PET | 2003 | 15 | 5 | Spanish English | |

| 2005 | |||||

| Environment impact and PET | 2004 | 6 | 1 | English | |

| 2007 | |||||

| Ecological Plastic | 2005 | 15 | 2 | Spanish | |

| 2008 | |||||

| Studies on PET | 2005 | 20 | 1 | Spanish | |

| 2007 | |||||

| Use bottle | 2007 | 5 | 1 | English | |

| 2009 | |||||

| Packaging Plastics | 2007 | 10 | 1 | Spanish | |

| 2011 | |||||

| PET bottle Chain | 2008 | 7 | 1 | English | |

| 2010 | |||||

| Bottles | 2009 | 14 | 4 | Spanish | |

| 2011 | |||||

| Contaminants from PET bottle | 2009 | 27 | 3 | English | |

| 2013 | |||||

| Increase of PET | 2009 | 20 | 4 | English | |

| 2013 | |||||

| Stress-cracking of PET bottle | 2010 | 13 | 1 | English | |

| 2014 | |||||

| Environment and PET | 2011 | 15 | 6 | Spanish | |

| 2014 | English | ||||

| PET plastic | 2012 | 18 | 2 | Spanish | |

| 2014 | |||||

| Bottles of PET | 2013 | 11 | 1 | English | |

| 2015 | |||||

| PET bottles a case Study of Beijing | 2013 | 4 | 1 | English | |

| 2015 |

Source: Gómez (2016).

Of the 60 baseline papers reviewed, 63% (38) came in Spanish and 37% (22) in English. According to the range of years, the production of the papers is distributed, as shown Table 3.

Table 3 Distribution of the number of paper by year range

| Year range | Number of papers | (%) |

|---|---|---|

| 1993-1999 | 4 | 7 |

| 2000-2009 | 25 | 42 |

| 2010-2015 | 31 | 52 |

| Total | 60 | 100 |

Source Gómez (2016).

The importance gained by the publishing articles on the impact of plastic on the environment during the 21st century is palpable (92% of last decade papers were published between 2000 and 2015).

Regarding the studies’ country origin (Table 4), its distribution indicates that the American continent (the United States, Colombia, and Mexico) leads the publication of papers in indexed journals: Journal Arbor, Pro Quest ebrary, Environmental, Water, Air, and Soil Magazine, and Industrial Engineering Magazine.

Table 4 Distribution of the number of articles by country of origin

| Country of origin | Number of papers | Country of origin | Number of papers |

|---|---|---|---|

| USA | 13 | Australia | 1 |

| Colombia | 9 | Bolivia | 1 |

| Mexico | 8 | Chile | 1 |

| Spain | 5 | China | 1 |

| Brazil | 4 | Costa Rica | 1 |

| Cuba | 2 | Croatia | 1 |

| Italy | 2 | Ecuador | 1 |

| Peru | 2 | India | 1 |

| Panama | 1 | Kenya | 1 |

| Venezuela | 1 | Poland | 1 |

| Salvador | 1 | Uganda | 1 |

| England | 1 | Total | 60 |

Source: Gómez (2016).

Gómez’s study accounts for the importance of PET studies in Colombia, as it is the second-leading country on studies about the impact of PET plastics. The author maintains that, given the increase in the use of PET plastic, it is necessary to take appropriate measures to mitigate the environmental impact in the industries that package their products using plastic. A strategy to mitigate the environmental impact of plastic is shifting to the circular economy, which companies have undertaken under the SDGs.

2.1.2. State of the art of the Circular Economy

Geisendorf and Pietrulla (2017) ascertain that the roots of the notion about the circular flow of material go back decades. Boulding (1966) stated that circular systems framed in the global economy are inevitable to guarantee human life in the long term. Pearce and Turner (1989) relied on Boulding’s ideas that the traditional linear economy is unsustainable if not for recycling and, consequently, must be replaced by a circular economic system. Their reasoning is grounded in the second law of thermodynamics (Georgescu-Roegen, 1986) inasmuch as the entropy of an isolated system will increase over time and will devalue the energy or higher-order material. The Circular Economy’s waste management policies’ roots go back to Germany in 1972, where a waste disposal law was enacted, and the notion of extended producer responsibility developed (Geisendorf and Pietrulla, 2017).

These policies are considered the earliest steps to promote the implementation of the Circular Economy (Andersen, 2007). Another inspiration for the Circular Economy is research on industrial ecology (Preston, 2012) and general systems theory (Von Bertalanffy, 1968) under the notion that an economy can be analyzed through a holistic and complex systemic thinking approach. Industrial ecology is a root for investigating the Circular Economy through industrial systems and operational optimization analysis.

Park, Sarkis, and Wu (2010) and Stahel (2016) assert that the Circular Economy was born in Europe with the definition of sustainability that has transcended to date, which originated in the analyzes derived from environmental summits and the very statement of growing environmental deterioration problems, such as the Brundtland report (1987) and the concept of sustainable development: “meeting the needs of the present generation without compromising the ability of future generations to meet their own needs.”

By defining the circular economy, the author is referring to a “closed cycle economy” that “does not produce waste in excess and whereby any waste becomes a resource” (Wysokińska, 2016, p. 1). The closed-loop means that the materials remain in the cycle and can be continuously reused. In the Circular Economy, materials remain in the system, and “waste” can only exist by being reused (Wysokińska, 2016).

The Circular Economy is interpreted as a new business model (Ghisellini, Cialini, and Ulgiati, 2016) for a sustainable and healthy economy. It tries to incorporate several relevant aspects of sustainable development: social, environmental, economic, and technological (Ghisellini et al., 2016). The Circular Economy concept is an opportunity to transition the economy and develop new and different business models.

The Circular Economy addresses micro-processes in companies, as well as macro-level processes in the economy (Birat, 2015). Through its principles, the Circular Economy encourages an economy’s agents to foster a more respectful use of environmental resources (Planing, 2015). Innovators and explicit decision-making tools for the Circular Economy are considered of the essence to facilitate its implementation (Golinska, Kosacka, Mierzwiak, and Werner-Lewandowska, 2015). Lastly, measu-ring circularity is considered a crucial task, but there is no prevailing opinion on which operation to use. Many different approaches are discussed, most of which refer to the classic eco-efficiency indicators (Shou-feng, 2006) or alternatives such as the “reuse potential” indicator of Park and Behera (2014).

According to Ghisellini et al. (2016), the Circular Economy is misinterpreted as just “an approach to more adequate waste management” (p. 2). Such a perception is enhanced through prevailing principles such as the 3Rs (Reduce, Reuse and Recycle), cited to summarize the core of the Circular Economy. However, this waste-oriented view of the 3Rs is too narrow. The actual notion of the 3Rs within the Circular Economy encompasses a much broader perspective of the economic system, and they can play a more prominent role in its design and implementation in many other areas.

The Circular Economy is broader and can include a detailed regenerative aspect, which refers to recovering materials, as well as using renewable energy solutions (Ghisellini et al., 2016; Ellen MacArthur Foundation, 2014; European Union, 2015). For recovering materials, these are reclassified into technical materials and nutrients. These are two flows of materials: biological nutrients that can be reintroduced into the natural system and artificial, technical ingredients that should be recoverable through industrial recycling mechanisms. The Circular Economy notion comprises Cradle to Cradle, Closed Supply Chain, Industrial Ecology, Reverse Logistics, Blue Economy, Regenerative Design, Performance Economy, Natural Capitalism, and Biomimicry.

Theoretical Framework

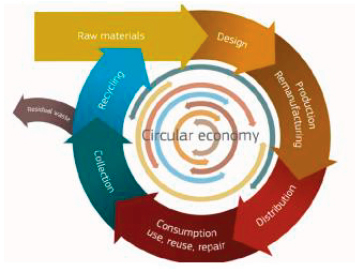

The linear economy model is based on the ‘extract-use-discard’ pattern. The Ellen MacArthur Foundation (2014) sums it up like this: companies extract raw materials, manufacture products that they then sell to the consumer, and, at the end of the chain, consumers discard the product that no longer serves them. A representation of the linear economy model is given in Figure 1.

Organización de Naciones Unidas (2015) and Greenpeace (2018), as well as the theories by Braungart, McDonough, and Ellen MacArthur Foundation (2014), indicate that this model is coming to an end. The U.N. has warned about the scarcity of natural resources, and the planet will not have the capacity to supply its needs if the same rates of consumption have kept up by 2050.

In this regard, Greenpeace (2018) points out that the linear economy is accountable for the so-called ‘comfort crisis,’ as it promotes branded products in single-use containers and packaging1, encourages mass production and hyper-consumption, significantly prompting the waste crisis accounting for over 2.1 billion tons of solid waste a year.

The circular economy model is studied through two theoretical perspectives: that of the Ellen MacArthur Foundation (2014), which published the study ‘Towards a Circular Economy: Business Rationale for an Accelerated Transition’; and the ‘From cradle to cradle’ theory, posted by McDonough and Braungart (2002). Per the Ellen MacArthur Foundation, the circular economy “is a restorative or regenerative industrial system by intention and design. It replaces the concept of “expiration” with that of “restoration” (…) and seeks to eliminate waste through optimized materials, products, and systems design and, within these, business models” (2014, p. 4).

It is based on three principles: 1) the circular economy as a systematic process to ‘end waste’: Products are designed and processes optimized to achieve a reuse cycle. 2) Items are designed for reuse. The circular pattern differentiates the consumable and durable components of a product. 3) The invested energy is renewable to reduce the need for new resources and increase the ability for recovery.

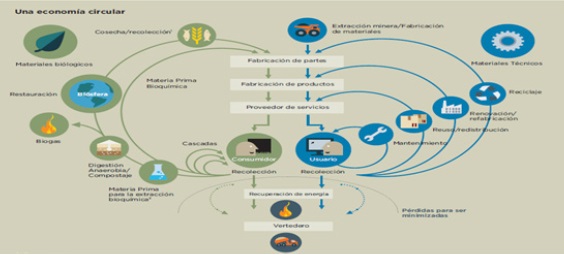

The circular economy process is subjected to biological and durable components (Figure 2). The above-described model is effective provided that the concepts developed in the ‘Cradle to Cradle’ theory are integrated from the birth of the products. Products are conceived in closed production circles under sustainability strategies, thereby mitigating the environmental impact (Braungart and McDonough, 2002).

International and Domestic Contextual Framework

By 2019, globally speaking, the Circular Economy leading country with the most public policies, most research, and patents was China, which has developed Circular Economy policies for about 20 years, perhaps under other names. However, nowadays they are number one, followed by the union of the Nordic countries and the Netherlands (the third-leading country on the issue); lastly come the countries of Latin America, which very soon will begin to stand out (Diario La República, 2019).

In Latin America, the circular economy is a hybrid issue that is just beginning to gain strength; there has been a boom since 2018. The Diario La República (November 22, 2019) interviewed Petar Ostojic, the first Circular Economy promoter in Latin America, according to the World Economic Forum (WEF). He asserts that Chile has adopted public circular economy policies through Corpo with programs that have already identified ventures and the creation of a Circular Economy Center worth USD 22 million. In Colombia, strategies driving several entrepreneurs and initiatives, such as Dow, have been recorded. Uruguay and Mexico are developing an economy on this issue.

According to Ostojic, the circular economy promotes development because it entails a three-fold benefit: economic, social, and environmental development. The waste produced in Latin America is far from what developed countries in Europe produce; however, when it comes to recycling, Europe’s rates are around 40% or 45%, whereas no Latin American country surpasses the 10% mark (Diario La República, 2019). There is still 30% or 35% to go to create more recycling-related jobs and entrepreneurship, which entails economic development. If taken the leap from the linear to the circular economy, entities such as the International Labor Organization have recorded that circular economy models can create up to six million in Latin America alone (Diario La República, 2019).

Regarding implementing the Circular Economy in Colombia, Ostojic sustains that it has been quite fast since it began in 2018 as Journals publications have it. Currently, it is part of the government strategy, which will be a before and after for Colombia, thus becoming a circular economy example due to the volume it represents and the importance of its market and industries (Diario La República, 2019). Of the 78 million tons of plastic produced per year, only 2% is reused, while developed countries’ average is 40% and Latin America’s 10%.

One of the factors holding the Circular Economy back in Colombia is the culture: people have begun to understand the difference between circular economy and recycling, and the importance of maintaining materials’ worth for the longest time, rather than living a linear economy that thrives in planned obsolescence; the industry: this sector is regarded as an opportunity that allows developing environmentally-friendly industries (Diario La República, 2019).

3. Methodology

A qualitative study with descriptive features was conducted. The Qualitative Study methodology makes an intensive and holistic description and analysis of a phenomenon given by an organization, group of people, or a process (Merriam, 1988; Yin, 1994). Based on research-research theoretical foundations, the methodology included structured interviews and document analysis as a secondary source of information to characterize the implementation of the Circular Economy on PET containers.

Structured interviews were administered to nine executives from companies in the PET circular economy logistics chain in Colombia: a general manager of a PET recycling warehouse; a vice-president and a country manager for the two most crucial recycled-PET transformer plants in Colombia; a PET and recycled PET raw materials supplier’s general manager; and five executives from PET-demanding companies: three sustainability managers, a sustainability director, and a Marketing director. Each interview lasted one hour on average to describe the comments of each manager and then move on to characterize the circular economy on PET.

Below is the structured interview administered to all managers:

What does Circular Economy mean to you?

State your point of view on Resolution 1407 of July 26, 2018 (Extended Producer Responsibility - REP)

State your point of view on the ANDI’s efforts to comply with the REP.

What do you consider to be the main obstacles to adopting the circular economy model in Colombia?

What is the status of companies such as Bavaria SA, Postobón SA, and Coca-Cola FEMSA?

What is your point of view on the production of PET containers in Colombia regarding quantity, quality, price, and the number of suppliers?

What do you know about PET-containers recycling in Colombia regarding the number of companies, capacity, quality, pricing, and challenges?

What circular economy ecosystem variables and stakeholders can be applied in Colombia concerning PET containers?

What are the PET-containers circular economy ecosystem variables restricting its implementation in Colombia?

Five documents were consulted, the analysis of which allowed characterizing the Colombian legislation on the Circular Economy concerning PET (CONPES and MADS), identifying the REP whereby producers are more strongly responsible for the implementation of the circular economy on PET by undertaking new functions. Furthermore, 26 documents about sustainability and circular economy issues and eight documents concerned with the circular economy in Colombia and PET in Colombia were reviewed. In this sense, the documents were described and analyzed for characterizing the circular economy on PET.

4. Results and discussions

In Colombia, public policy guidelines led by the Ministry of Environment and Sustainable Development (MADS per its acronym in Spanish), such as CONPES Document 3874 of 2016 and MADS Resolution 1407 of 2018, have been issued regarding the integral management of solid waste and the circular economy.

4.1. CONPES Document 3874 of 2016

Document CONPES 3874 outlines the national policy for the integral management of solid waste. Solid waste management articulates an environmental outlook with the public service component, a priority in national public policy. From solid waste as an integral process, progress is made towards the circular economy, “… which seeks to maintain the value of products and materials for as long as possible in the production cycle” (CONPES, 2016, p. 3). Products and materials tend to maximize use over time, reducing their impact on the environment and mitigating climate change.

The Strategic Axes of the national policy for the integral management of solid waste as an economic and environmental purpose (CONPES, 2016, p. 4) are: 1) adopting measures on (i) prevention regarding the waste generation; (ii) the minimization of those wastes that go to final disposal sites; (iii) promoting solid waste reuse, use, and processing; and (iv) avoiding the generation of greenhouse gases; 2) improving citizen culture, education and innovation in comprehensive solid waste management to increase rates of separation at the source, use, and processing. The two additional axes account for the creation of an institutional environment for stakeholder coordination. 3) assigning specific, clear roles to all participating entities to have them lead organic waste processing activities and urban inclusive recycling systems strengthening, among other things; 4) implementing actions to improve monitoring, verification, and dissemination.

4.2. MADS Resolution 1407 of 2018

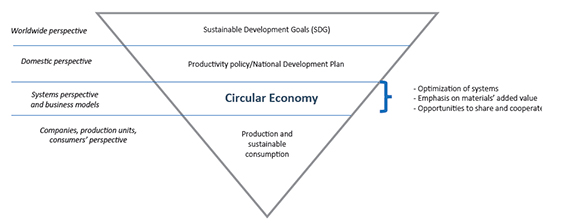

In Colombia, the Circular Economy model is still incipient. The National Circular Economy Strategy was only approved in 2018, wherein the Government encourages producers, suppliers, and consumers to develop and implement new business models that incorporate waste management and efficient material handling (MADS, 2018). The structure of the National Circular Economy Strategy is based on the SDGs to achieve efficiency through systems optimization, added value, and seizing opportunities (Figure 3).

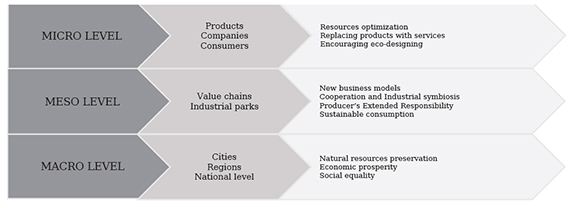

The objective of the National Circular Economy Strategy is to maximize the added value in production and consumption systems in economic (profitability), environmental (climate change), and social (employment) terms, with circularity in the flow of materials, energy, and water; fixing action fronts (Figure 4).

The MADS designed mechanisms such as regulatory adjustment, development and innovation, knowledge and research, cooperation scenarios, financial instruments management, and the incentives for transitioning to the circular economy. The National Circular Economy Strategy developed lines of action regarding industrial materials and products, container and packaging materials, biomass optimization and use, water circulation, energy sources and use, and consumption of materials in cities.

MADS and the Ministry of Commerce, Industry, and Tourism structured the National Circular Economy Strategy, which will transform the country’s production and consumption chains through efficient materials, water, and energy management. The strategy encourages producers, suppliers, consumers, and other stakeholders to the production and consumption systems to implement new business models that incorporate waste management, efficient material handling, and a change in lifestyles (MADS, 2018).

By mid-2019, MADS worked on disseminating the Circular Economy Strategy, holding regional workshops throughout Colombia. The workshops’ objectives were to disseminate the National Strategy, commit the regions to its implementation, identify regional initiatives for inclusion in a national portfolio, make them visible, and identify the barriers hindering the shift to business sustainability (MADS, 2019).

Furthermore, some Circular Economy Strategy goals have been set for 2022, which aim to increase recycling and waste use rates, which today stand at 8.7%, to 17.9% by 2022. The solid waste rate made the most out of is expected to climb from 17% to 30% by 2030. An increase in hazardous and special waste tons subject to post-consumption management is estimated to jump from 218,427 to 565,995 tons made the most out of by 2022 ( MADS, 2019).

MADS (2018) Resolution 1407 provides that the business sector must make the most of use out of 30% of the material used for containers and packaging by 2030, in abidance by the sustainability strategies for the business sector and citizens’ expectations. To take on the challenge, the ANDI Magazine (November 2019) prepared an issue entitled “Circular Economy: ANDI’s Grand Bet.” According to Ibarra (2019), deploying the circular economy on containers and packaging attests to Colombia’s transition towards it.

4.3. Entrepreneurs’ perspective on the Circular Economy Strategy

Developing the National Circular Economy Strategy entailed consultation among several stakeholders from the public and private sectors, academia, and civil society, regarding the transformation of production systems. Regional workshops and sectoral consultation sessions were held in different cities to publicize the strategy. Thus, productive guilds such as ANDI were in charge of leading the articulation of the strategy.

The 30/30 vision proposed by ANDI will develop in stages: Firstly, creating a democratic multisectoral organization, with market representation and a collective outlook to lead start-up actions; secondly, regional at-source separation, collection, and use models will be identified and implemented to enable the future scaling up of harvest rates as required under Resolution 1407 of 2018; thirdly, progress will be made in strengthening the value chains of packaging materials and in promoting new solutions; fourthly, eco-design practices will be encouraged, facilitating decisions that increase investments and alternatives to close the materials cycle, generating knowledge (ANDI, 2019).

4.4. Field research results

The description and comments from managers of companies in the recycler, deposit, transformer, and producer echelons of the Colombian PET circular economy chain yielded that:

ANDI’s business sector-oriented efforts to abide by the Extended Producer Responsibility are positively viewed since it is a collective, guild, sectoral, integrating effort, which facilitates the MADS’s work towards Colombian industry sustainability in the short, medium, and long term through the return of packaging materials. On the other hand, some producers believe that neither the government nor the ANDI are clear on circular economy affairs.

The leading PET producers in Colombia are Coca-Cola, Postobón, and Bavaria. The latter has played as a plastic containers producer for 15 years, and some of its specific characteristics are that it currently produces about 14,000 tons worth of amber PET a year for Pony Malta, which is much more complex to produce and recycle than other types of PET due to its manufacturing and processing requirements.

Colombian PET materials suppliers and demanders (transformers and producers) have shown their gradual adaptation and adherence to their new sustainable development-imposed responsibilities; however, they are aware that there is still much to be done. Some market players, such as San Miguel and Enka, were observed to perform as offerors in volume and technology, thereby serving a non-neglectable market share.

Virgin PET is not produced in Colombia; however, there is an adequate imported supply in terms of quantity, quality, price, and the number of suppliers, meaning that there are no supply problems. Nevertheless, the price depends on macroeconomic factors such as oil and a 10% tariff with which this product is taxed.

4.4.1. Main obstacles to the Circular Economy on PET in Colombia.

The main obstacles were accounted for by describing the logistics, recycling, deposit, transformer, producer, distribution, consumption, reuse chain. Concerning recycling, Colombia lacks a home-instilled culture of at-source separation, wherefore it is up to the recycler to fulfill that function; furthermore, some packaging companies fail to incentivize the recycler.

The producers regarded different political actors’ competencies as disarticulated and mixed-up, be it municipalities, governorates, or superintendencies, which go beyond the Producer’s Extended Responsibility.

Per the transformers, there are three obstacles: public policies that fail to encourage the implementation of recycling initiatives; an incipient civic culture on the issue of recycling and sustainability (because there is no awareness on separation at the source); and the economic and technological barriers, which go hand in hand, for such initiatives demand substantial investments and they lack such financial leverage.

Moreover, some other obstacles were listed, such as recyclers not being welcomed everywhere, inadequate supply of good-quality recyclable materials, and end consumer awareness that they need to do things correctly right at the separation at the source.

4.4.2. Market formation and advancements.

The companies involved in the Colombian PET plastic production chain sustain that they are working faster than the Government. Companies such as Postobón SA and Coca Cola assure that they already implemented circular economy models, wherein 46% and 36% of their materials and packaging come from recycled material (Postobón, 2018; Coca Cola, 2018).

Bavaria is working together with the industry to move forward on implementing the standard on return above seizing issues, working closely with Postobón and Coca-Cola - Femsa. Bavaria is especially concerned with amber PET because Malt is sensitive to light due to its components. Moreover, amber PET undergoes a complex transformation process, a disadvantage for reuse.

Transformers partly drive sustainability through initiatives that help secure Circular Economy processes and favor the articulation of all actors into the chain.

Those most favored by the PET issue are Coca-Cola and Postobón. San Miguel, the owner of Apropet, is serving Bavaria; it is the one that delivers the recycled material for Pony Malta preforms, those are Amber PET.

For its part, Postobón is using Iberplast material and making its own preforms using ENKA material.

4.5. Colombian PET Circular Economy Ecosystem Description

The actors to the PET packaging circular economy ecosystem in Colombia base their Cradle to Cradle design on the application of eco-design and industrial production (Figure 5). Describing the logistics recycling, deposit, transformer, producer, distribution, consumption, collection, reuse chain.

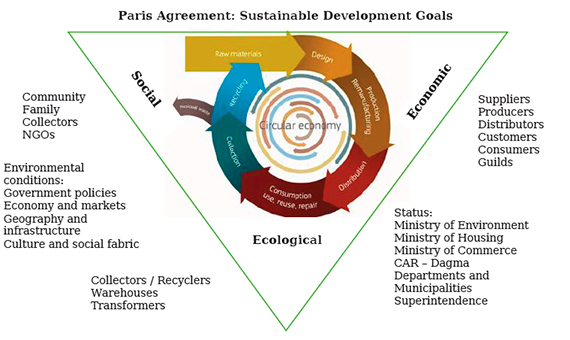

A PET Circular Economy Ecosystem for Colombia was built as a result of the research description and induction (Figure 6). The formation of the Colombian ecosystem for the circular economy strategy is grounded, in the first instance, in the Paris Agreement and the Sustainable Development goals, which some countries committed to support and further with a view towards 2030 when global warming would reach a 2ºC maximum (United Nations, 2015).

In the second instance lie sustainability components: the social component consisting of the community, the family, collectors and/or recyclers, NGOs, and national bodies such as the social fabric; the economic component, made up of producers, suppliers, distributors, clients, consumers and production guilds, characterized by exchange relations within the economy; and the ecological component that consists of collectors/recyclers, warehouses, and transformers, characterized by interactions for a circular flow (EMF, 2014).

In the third instance, the State and its many executive and control agencies take charge of formulating regulations on ecological and/or environmental matters to achieve sustainability for social, economic, and environmental activities in the short, medium, and long term.

Finally, environmental conditions shaped by government policies, the economy and the markets, culture and social fabric, and geography and infrastructure constitute the environment for sustainability (EMF, 2014).

5. Conclusions

As seen from Colombian producers’, processors’, and recyclers’ perspectives, the current state of the PET circular economy possesses particular characteristics, not because of the number of competitors, but because of the complexity inherent to the various exchanges within a PET packaging logistics chain. This chain becomes more complex under the Producers’ Extended Responsibility since the government is no longer tasked with collecting packaging waste but rather the PET packaging producers themselves.

The various exchanges within the Colombian PET packaging logistics chain account for a series of actors such as recyclers, recycling depots, processors, producers, distributors, clients, consumers, and households, who must coordinate and align themselves so that PET material undergoes the proper, desired return. The problem is that there is no such coordination that enables the expected return and efficient recycling because the logistics chain lacks the culture and social fabric that foster return.

There are approximately 60,000 recyclers in Colombia and 4,400 recycling warehouses, making the supply of recycled PET dynamic. The EKORED recycling plant suggests the need to integrate the recyclers and to have the producers incentivize them so that the recycler-deposit logistics chain will effectively transform the PET in the bottles. Since recyclers are paid per kilogram for of material collected, they seek out the heaviest PET containers they can collect en masse in order to increase their income, preferring virgin PET over Bavaria’s Pony Malta bottles amber PET (the company only recycles a small amount of it in just one of its plants).

Transformers demand recycled PET for transformation; however, not all PET material or waste is capable of transformation due to the risks it entails for the machinery. At present, there are PET transformers in Colombia (ENKA and Apropet), which produce about 100,000 tons of virgin PET per year as an additional offer to bottle-to-bottle recycling. Regarding amber PET, its conditions deteriorate due to collection/recycling times, wherefore some favorable conditions are needed for its recycling and transformation.

The Colombian PET container market is complemented by PET-requiring beverage producers’ demand for containers, including FEMSA, Postobón, and Bavaria. The first two have been producing beverages in the Colombian market for 25 years and are the ones that demand the most PET containers. As for Bavaria, it entered the amber PET container market ten years ago, and its production is limited compared to its competitors.

The lack of articulation between the circular economy logistics chain echelons, before and after MADS Resolution 1407 of 2018, whereby the circular economy strategy is implemented, is at present one of its development problems due to interpretation. Due to it being enacted until recently (in 2018) and limited dissemination, a waiting period is suggested for effective implementation; ANDI has taken up a relevant yet lacking leadership, as it waits for other institutions to show up and complement it and undertake the commitment. For adherence to Resolution 1407 on PET Producers’ Extended Responsibility, investment is needed to continue strengthening the logistics chain regarding waste management and innovation in identifying new materials.

Finally, it should be noted that the Colombian population lacks a culture for recycling as the starting point that allows the Circular Economy Strategy to be applied appropriately. In that regard, environmental population-aimed education campaigns on recycling are needed.