Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

Ingeniería e Investigación

versão impressa ISSN 0120-5609

Ing. Investig. v.29 n.2 Bogotá maio/ago. 2009

Geraldo Lombardi1, Pedro A. Rodríguez Ramos2, Aldo Ometto3, Romeu Corsini4, Osney Pérez Ones5, Lourdes Zumalacárregui de Cárdenas6

1 Aeronautical engineer, IPT, Brazil. Titular professor, EESC- Sao Paulo University, Brazil. lombardi@sc.usp.br

2 Mechanical engineer, ISPJAE, Cuba. Ph.D. Titular professor, Higher Polytechnic Institute "José Antonio Echeverría", Cuba. pedro@economia.cujae.edu.cu

3 Production Engineer, USP, Brazil, Ph.D. Assistant professor, EESC- Sao Paulo University, Brazil. aometto@sc.usp.br

4 Electrical engineer, USP, Brazil. Aeronautical Engineer, IPT, Brazil. Ph.D. Titular professor, EESC- Sao Paulo University, Brazil. corsini@sc.usp.br

5 Chemical engineer, ISPJAE, Cuba. M.Sc. Assistant professor, Higher Polytechnic Institute "José Antonio Echeverría", Cuba. osney@quimica.cujae.edu.cu

6 Chemical engineer, ISPJAE, Cuba. Ph.D. Titular professor, Higher Polytechnic Institute "José Antonio Echeverría", Cuba. lourdes@quimica.cujae.edu.cu

ABSTRACT

The GERIPA project aimed at generating renewable energy integrated with food production has led to a beneficial option for producing ethanol and electricity. Ethanol has economic, social and environmental potential. Considering just the first one, Brazil consumes 39 billion litres per year-LD/yr of diesel oil, 18% of it being imported. The Federal Government has a recovery programme for the soybean agribusiness aimed at soybean biodiesel (SBD) production in which a 10% addition to diesel has been proposed. This 10% involves producing 10.7 million LSBD/d. Soybean biodiesel production is not self-sustainable and such proposal could require an annual subsidy of up to US$1.33 billion. Soybean plantations would need about 10 to 12 times more land than is necessary for sugarcane plantations to produce the same equivalent thermal energy (ETE). Sixtyseven GERIPA projects (GP) producing 80,000 litres of ethanol per day (GP80) could be set up with the sum of US$1.33 billion; this would substitute current Brazilian biodiesel demand by 4.28%, adding the same value for each new subsidiary. Considering ETE, ethanol-GP cost would be 37% to 50% below that for a litre of SBD on account of its raw material (RM) and region. The diesel cycle's thermal efficiency (ηt) yield is around 50% and that of the Otto cycle engine ηt is around 37%. The cost per km driven (CKD) by substituting SBD for ethanol-GP80 would thus indicate an 18% minimum and 59% maximum cost reduction for vehicle engines.

Keywords: ethanol, biofuel, distillery.

RESUMEN

La generación de energía renovable integrada a la producción de alimentos desarrollada en el Proyecto Geripa (PG) es una opción beneficiosa para la producción de etanol y electricidad. Las potencialidades del etanol son económicas, sociales y ambientales. Considerando sólo la primera potencialidad, el aspecto económico, Brasil consume 39 billones de litros de diesel LD/año, el 18% importado. El Gobierno federal tiene un programa de recuperación en la agroindustria de la soya para la producción de biodiesel de soya (SBD) adicionando el 10% al diesel. Este 10% corresponde a 10,7 millones LSBD/d. El biodiesel de soya no es sustentable por sí mismo y una propuesta como esa pudiera demandar un subsidio anual de 1,33 billones de dólares. Las plantaciones de soya para producir la misma energía térmica equivalente (ETE) requieren de 10 a 12 veces más tierra que la que se necesitaría para una plantación de caña de azúcar. Con el fin de verificar esta afirmación, con los 1,33 billones de dólares pudieran construirse 67 PG produciendo 80 000 litros de etanol por día (PG80), que sustituiría el actual biodiesel brasileño demandado en 4,28%, adicionándose el mismo valor para cada nueva subsidiaria. Considerando la ETE, el costo del etanol de la PG es 37-50% menor que el de un litro de SBD, en dependencia de su materia prima (RM) y región. La eficiencia térmica del ciclo diesel ηt es aproximadamente 50% y la del ciclo Otto 37%. Por tanto, para vehículos, el costo por km recorrido (CKD) sustituyendo SBD por etanol-PG80 indica un a reducción mínima del costo del 18% y máxima del 59%.

Palabras clave: etanol, biocombustibles, destilerías.

Recibido: octubre 6 de 2008

Aceptado: junio 16 de 2009

Introduction

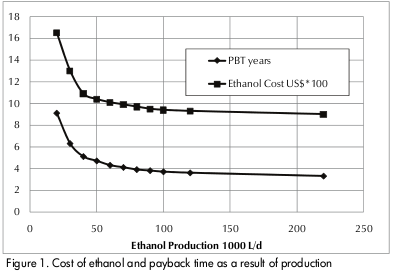

Integration in agribusiness currently means competence, feasibility and survival; this is still in its infancy in traditional sugar-ethanol agribusiness (SEA), when practised. The integration concept includes the entire productive sector in the GERIPA project (geracao de energia renovavel integrada a producao de alimentos) (Ramos and Lombardi, 2000). It presents 9.1 to 3.3 years' economic payback time for producing around 20 to 240 thousand LE/d. GERIPA project (GP) GP-80 ethanol costs US$ 0.108/LE compared to the US$0.18/LE for present day SEA (i.e. it is 40% cheaper). Compared to diesel fuel it is 40% less per km driven (KD). It cogenerates 10.4 MW electricity and produces 9,500 tons of varied food annually, including 2,270 tons of dehydrated yeast, 5,600 cows, 3.7 million litres of milk, etc. (Ramos and Lombardi, 2000). Associating sugar cane and saccharine sorghum allows work to be extended throughout the whole year, having 315 days worked (DW) and 45 set aside for preventative maintenance.

It represents economic, social and strategic development in line with the Kyoto Protocol's sustainable concept. It fulfils the basic needs of a city having 34,600 inhabitants. The social, environmental and economic benefits are significant; social benefits obtained with the GP are related to jobs, education and health.

The GP currently provides 482 permanent jobs; this number may rise in an unprecedented way if planting conterminous agroforests is considered as part of the GP. It would be supported by 42,020 Kyoto quota/year revenue which was not taken into account when economic calculations were made for the GP (Ramos, Lombardi, 2000). Agroforests become selfsufficient in 7 years (Santos, 2000) and a new cycle may be started. However, such procedure's sustainability must be studied.

In terms of education, the community and social installations have been designed to include a residential district, nursery, kindergarten, elementary school up to high school provision, adult literacy courses, family counselling, etc. Attention has been paid to sports, discourse development, ethics and citizenry. Fundamental learning within the GP pertains to well-being and mankind represents its most important product.

The GP has medical and dental assistance having a well-equipped out-patients' health post to administer small-scale medical intervention. Transfer facilities are foreseen for specialised medical attention. The post operates according to basic educational, prevention, medication and rehabilitation principles.

Different fuels are compared in this paper to demonstrate that GP ethanol is an energy solution worth considering.

GP procedure

A GP uses up-to-date equipment. Regenerating and recycling are used; animal waste products and other materials retaining nutrients resulting from the plantation are mixed to the vinasse, treated and bio-digested, thus becoming transformed into methane-rich gas to be used as fuel in the boiler and neutral fertiliser which is ideal for cane and sorghum. Such material is recycled via irrigation by dripping onto sugarcane roots and localised spraying on sorghum. Electric motors set the equipment in motion and electricity is generated by a high output turbo-generator (Ramos and Lombardi, 2000). Keeping in mind expenditure on transport and RM sufficiency, a GP operates on its own property, being 90.80 km2, with 31.80 km2 devoted to sugar cane and 36.30 km2 to sorghum (for 8 months and 4 months, respectively). The sugarcane produces 0.012t/m2 from an average of 8 crops (Netafim, 2004); 0.007 t/ m2 standard was adopted in this project, the same as the local value. Harvesting is manual and the fields are left unburned. The tops of RM are separated, receive protein adjustment and it is stored in silos for making the organic food for 5,600 cows raised in semiconfinement. Bagasse at 50% relative humidity is dried to 35% in a fluidised drier suspended by combustion products from the boiler, in the best GP regenerative process. The integrated procedure has significant cost reduction per revenue unit ($0.361/1$ for GP80) and 64% profit balance. Figure 1 shows the cost of ethanol and GP payback time (PBT) as a function of its production.

Comparing GP-80's energy with that of biodiesel and diesel

Comparing the cost-benefit of ethanol-GP with that of biodiesel (BD) and diesel, in terms of equivalent thermal energy (ETE) and cost per km driven (CKD), it becomes interesting to consider the GP context and the editorial published in the Folha de São Paulo newspaper (11/06/06) where it mentions that the Federal Government has a soybean agribusiness salvaging programme aimed at soybean biodiesel (SBD) production which is aimed at adding 10% to currently available diesel fuel. Brazilian diesel consumption is 39 billion LD/yr; 10% of this goes to producing 10.7 million L/d of BD. (LBD). SBD production is not energy sustainable and if that goal is met annual subsidy can reach up to almost US$1.33 billions (Leite, 2006). A soybean plantation occupies 10 to 12 times more land to produce sugarcane ETE. US$1.33 billion would enable setting up 67 GP 80/year, at a cost of US$20*106 each.

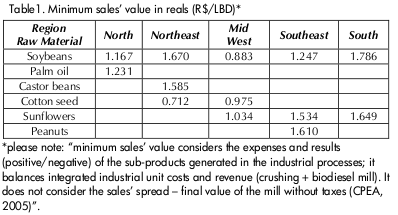

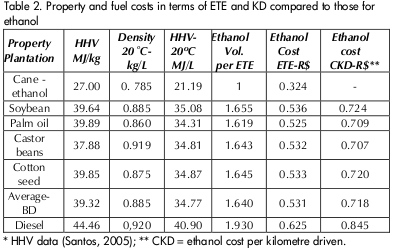

Table 1 shows the costs per litre of BD from different Brazilian raw material (RM) and regions (CPEA, 2005). Table 2 gives the calculations for this section based on high heating value (HHV) (Santos, 2005). US$0.108 cost is considered for ethanol-GP80, with 1US$ =3R$ (09/2003), thus giving R$0.324/LE.

Table 1 shows that SBD from the Southern region has the highest cost per litre and the lowest comes from cotton seed (CBD) from the Northeast region (60% difference). The lowest SBD cost is from plantation in the Midwest, even so, with a higher cost of 19.4% than the Northeast CBD.

Table 2 shows the cost in ETE and CKD of ethanol-GP80 and BD.

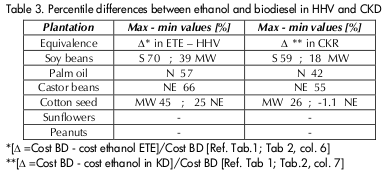

Table 3 shows that the cost of ethanol is about 25% to 70% lower than ETE for a litre of BD due to its RM and region. The CKD mode must be considered if ethanol is used in vehicle engines. The reduction in cost (when ethanol GP-80 replaces SBD) gives 18% minimal and 59% maximum reduction. Only CBD from the Northeast is cheaper than ethanol by 1.1%.

Ethanol versus diesel

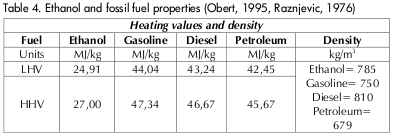

Table 4 shows different fuels' heating values and densities.

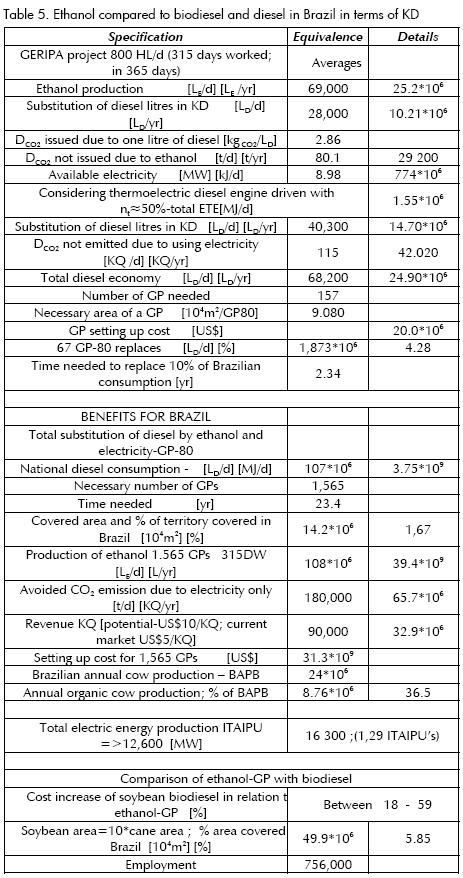

An average 80,000 LE/d value for 365 days of the year is considered in terms of low heating value (LHV), 315 days worked (DW) and km driven (KD) in which the diesel cycle's higher ηt over the Otto cycle is 50% to 37%, substituting 27,960 LD /d. The 67 GP-80 replace 1,873*106 LD/d, thus representing 1.75% of Brazilian diesel oil consumption (107*106 LD/d). Cogeneration works 365 days/yr; however, it has ultimately worked only 315 with bagasse. The 315 DW standard has therefore been adopted. An equivalent of 1.8*106 MJ/d substituted diesel will be consumed with 10.4MW of available electricity if generated by thermal electricity using diesel engines having ηt = 50% (Heywood, 1988), meaning an average 40 270 LD/d for 365 DW. The 67 GP80 electricity replaces 2.70*106 LD/d or 2.53% of Brazilian diesel consumption. The total amount substituted by both renewable energies would then be 4.28%. The time for attaining 10% substitution of the diesel so consumed will be 2.33 years, with an investment of US$3.14 billions in 157 GPs. A new cycle of GPs is set up with every new subsidy, resulting in increased substituted diesel. Considering the equation's linearity, then all diesel used in Brazil would be substituted by ethanol and electricity produced by 1,570 GPs in a maximum of 23.3 years. The additional benefits would be:

-Social: permanent jobs for 757,000 people, organic food provided for 54.3 million inhabitants, including 8.79 million cows, housing, education and medical-dental and social assistance for all employees; and

-Environmental: 65.9 million KQ/year per GP corresponding to cogeneration. Revenue from KQs, due to market uncertainties, were not computed in the financial calculation and could be used in agroforests, thus generating countless new jobs in view of sustainability 7 years after being set up. In fact, the main benefit of ethanol lies in the far-reaching potential for reducing the emission of vehicle pollutants and particulates in cities by substituting fossil fuel, especially diesel. Health costs in the city of São Paulo alone will be US$ 4.2 to 6.7 billions between 2000 and 2020 (Pinheiro et al., 2004) (Lombardi, Ramos, Orsini, 2004; Lombardi, 2004, pp. 179-193). More details are given in Table 5.

The ethanol production process shows a reduction in CO2 emission when comparing ethanol emission with that of diesel. Ethanol does not contain sulphur; some pollutants' emission shows an order of greatness smaller than that of diesel. Using diesel adds on long-term emissions (e.g. greenhouse effect due to CO2 gas).

Brazil consumes 107*106 LD/d. Diesel is a solution made up of light and heavy hydrocarbons. The average C13H28 formula (Taylor, 1976) has thus been adopted. The amount of CO2 emitted is 2.86 kgCO2/LD of LD burned. Thus national CO2 emission, due to using diesel, reaches 306,000 tons per day (tCO2/d). Using renewable energies such as GP thus minimises contamination of the atmosphere and the ground.

Table 5 gives a summary of the potential benefits of GP-80 for Brazil by completely substituting diesel for alcohol and electricity-GP for equal KD. Values corresponding to reduced transport of ethanol, electricity from already established thermal electricity, road maintenance, public health costs, international policy, etc have been adding to the fixed ones. 24 million cows are slaughtered in Brazil (IBGE, 2004). Indeed, 36.6% of organic cows entering the market provide GP with the ability to reduce deforestation, aiming at new applications in agriculture and even new short-duration crops.

Conclusions

Many conclusions are to be drawn considering the significant benefits of the GP integration concept. However, seven are considered essential:

-GERIPA is an environmental, ecological, social and strategic energy solution for Brazil which can be extrapolated to other sugarcane producers;

-Ethanol-GP cost is about 25% to 70% lower than that correspondding to equivalent thermal energy (ETE) for a litre of biodiesel, depending on the raw material and region;

-Ethanol-GP cost per km driven (CKD) is between 18% and 59% below that corresponding to soy bean biodiesel (SBD). Only cotton seed biodiesel (CBD) from North-eastern Brazil is cheaper than ethanol by 1.1%;

-Renewable energies from 67 GP-80 replace 4.28% of Brazilian diesel consumption; 157 GP-80 should be set up to replace 10% of Brazilian diesel consumption;

-Using renewable energy such as GP-80 minimises contamination of the atmosphere and the ground compared to diesel emission;

-Government participation is very important in setting up the GERIPA project as social policy aimed at benefitting least favoured Brazilians; and

-GERIPA's main products are people who can be provided with health care, family orientation, ethics and instruction.

Nomenclature

BD: biodiesel

CBD: cotton seed biodiesel

CKD: cost per km driven

DW: days worked

ETE: equivalent thermal energy

HHV: high heating value

KD: km driven

KQ: Kyoto quotas

LHV: low heating value

LBD: litres of biodiesel

LD: litres of diesel

LE: litres of ethanol

GP: GERIPA project

GP80: GERIPA 80 000 LE/d project

RM: raw material

SBD: soy bean biodiesel

SEA: sugar-ethanol agribusiness

ηt: thermal efficiency

Bibliografía

CPEA. Centro de Estudos Avançados em Economia Aplicada (Center for Advanced Studies in Applied Economy)., ESALQ, Piracicaba, Sao Paulo, Brasil, 2005. Disponible en: http://www.cpea.esalq.usp.br, 2005 [ Links ]

Heywood, J. B., Internal Combustion Engines Fundamentals., New York: McGraw-Hill, 1988 [ Links ]

IBGE., Indicadores del desarrollo sustentable., 2004. Disponible en: http://www.ibge.gov.br. [ Links ]

Leite, R.C., Por Fora Bela Viola - Editorial Folha de São Paulo 11/06/2006, http://www.folha.com.br, 2006. [ Links ]

Netafim Brasil Sist. de Irrigação Ltda., Ribeirão Preto-SP., 2004. Disponible en: http://www.netafim.com.br/. [ Links ]

Obert, E.F., Internal Combustion Engines., Scranton: N.Y: Int. Textbook, 1955, pp. 596. [ Links ]

Pinheiro, F. C, Prado, L. T. S., Braga, A. L. F., Pereira, L. A., Amador, M. S. E., Saldiva, P. H. N., Böhm, G. M., Andrade, M. F., Integrated Environmental Strategies (IES) in São Paulo-Brazil., Final Report, June, 2004. Disponible en: http://www.ibama.gov.br/proconve). [ Links ]

Lombardi, G., Ramos, P. A. R., Corsini, R., Potencial Economico, social e ambiental da produção integrada de alcool eletricidade e alimentos., In: Carlos Roberto Sanquetta e Marco Aurélio B. Ziliotto. (Org.). Carbono - Ciência e mercado global, Curitiba: UFPa e Instituto Ecoplan, Brasil, 2004. [ Links ]

Lombardi, G., Potencial Econômico Social e Ambiental da Produção Integrada de Álcool, Eletricidade e Alimentos., Carbono, Ciência e Mercado Global: Instituto Ecoplan - Universidade Federal do Paraná, 2004, pp. 179-193. [ Links ]

Ramos, P. A. R; Lombardi G. Projeto Conceitual, Viabilidade Econômica e Projeto Dimensional da MAUI., São Carlos: Relatório FAPESP, Proc. Nº 1999/10913-4, 2000. [ Links ]

Raznjevic, K., Handbook of Thermodynamics Tables and Charts., New York: McGraw-Hill, 1976, pp. 392. [ Links ]

Santos, A M, Relatório Interno., LETeF-EESC-USP, 2005. [ Links ]

Santos, M. J. C., Avaliação Econômica de Quatro Modelos Agroflorestais em Áreas Degradadas por Pastagens na Amazônia Ocidental., Dissertação de Mestrado, Escola Superior "Luiz de Queiroz" USP, Piracicaba, SP, dezembro, 2000. [ Links ]

Taylor, C. I., Análise dos Motores de Combustão Interna., Ed. USP, 1976. [ Links ]