Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.31 no.1 Bogotá Jan./Apr. 2011

Studying asphalt binder fatigue pattern by using a dynamic shear rheometer

Oscar Javier Reyes Ortiz1, Félix E. Pérez Jiménez2

1 M.Sc. Civil Engineering, Universidad de los Andes, Colombia. Ph.D., Universidad de Cataluña, ña. Associate professor, Universidad Militar Nueva Granada, Colombia. oscar.reyes@unimilitar. edu.co

2B.Sc. Paths, Canals and Ports Engineering, Escuela Técnica Superior de Ingenieros de Caminos, Canales y Puertos, Spain. Ph.D., Universidad Politécnica de Madrid, Spain. Professor, Universidad Politécnica de Cataluña, Spain. feduardo.perez@upc.es

ABSTRACT

This article was aimed at determining fatigue test results regarding different types of binder when using a dynamic shear rheometer (DSR). The tests were carried out in stress conditions at 20°C. The stress input signal was a constant amplitude, 1.59 Hz frequency sine wave. Asphalt binders B-13/22, B-40/50, B-60/70, B-80/00, B-150/200 and BM-3c (modified asphalt) were studied. The test measured strain, complex modulus (G*), dissipated energy and dissipated energy ratio (DER) with the number of cycles. Strain criteria were used for determining binder fatigue failure (DER). Failure was defined as the point at which (DER) dropped 10% after peaking. Laws of asphalt fatigue were obtained from the strain and failure cycle results.

Keywords: fatigue, asphalts binder, DSR, dissipated energy, strain failure.

Received: November 9th 2009. Accepted: Feuary 7th 2011

Introduction

Fatigue is one of the main causes of damage in bituminous mixtures; its study is therefore of the utmost importance. Several authors have defined its behaviour and have evaluated it via strain-controlled, stress and displacement laboratory tests (Baren et al., 2002, Mihai et al, 2005, Di Benedetto, 1997). However, few authors have studied bitumen's role in fatigue failure. The Superior Performing Asphalt Pavements (Superpave) system proposes that a dynamic shear rheometer (DSR) be used for determining fatigue crack patterns by analysing G* sine δin a strain-controlled test at 1.59 Hz frequency. On the other hand, some authors say that Superpave specifications do not provide sufficient information (Kennedy et al., 1998); different hypotheses have thus been proposed for analysing bitumen's behaviour and its fatigue failure (Anderson et al., 2001, Cho and Bahia, 2007, Shen and Carpentier, 2005, Pérez-Jiménez et al., 2008).

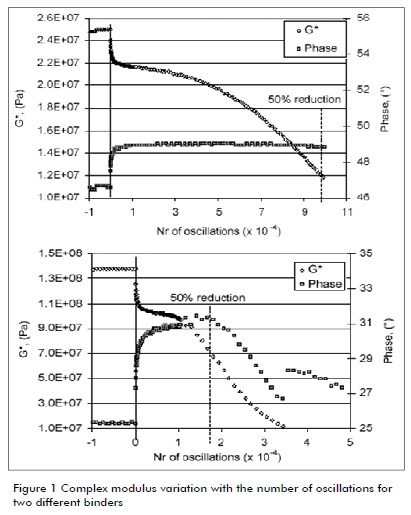

H. Soenen, De la Roche and Redelius (2004) have determined fatigue laws for different binders using a DSR. Such fatigue laws were computed with bitumen samples measuring 8 mm in diameter and 2 mm in height. Bitumen samples failed at 50% initial complex modulus using the controlled stress method (the classic criterion for bituminous mixture fatigue failure in controlled displacement testing) (Figure 1)

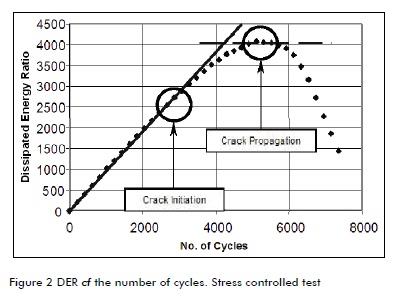

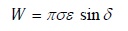

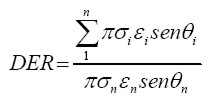

Delgadillo and Bahia (2005) have studied fatigue using a DSR focusing on dissipated energy (w) (equation 1) and dissipated energy ratio (DER) (equation 2). DER compared to cycle representation obtained by the stress controlled test showed that the curve began with a constant upward slope until a number of cycles had been achieved, after which point the slope began to decrease (Figure 2). The authors have claimed that this point is where cracks began to appear; from that point on values continued increasing until reaching a maximum value when fatigue occurred. When the curve deviates upward from its initial path in strain-controlled testing, micro-cracks appear. The authors established fatigue failure at 20% deviation (Figure 3).

|

[1] |

|

[2] |

where

DER = dissipated energy ratio

W = dissipated energy

σ = stress applied

ε = strain obtained

θ = phase angle

This research was thus aimed at analysing the behaviour of both modified and conventional binders in fatigue conditions. The researchers used a DSR in stress controlled testing. The authors determined that bitumen fatigue occurred with DER, dissipated energy and deformation.

Experimental

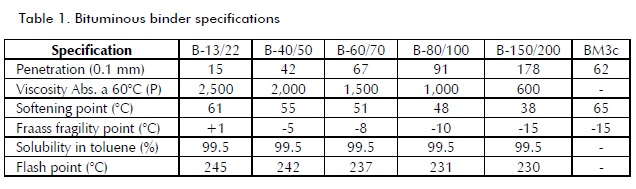

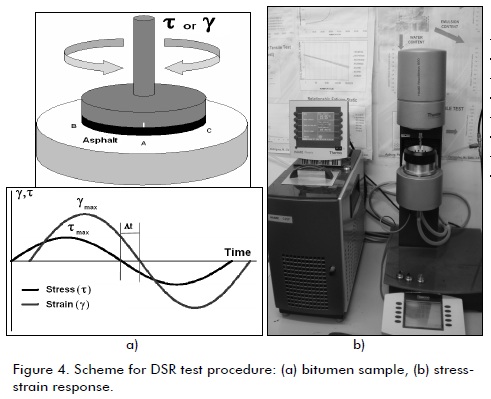

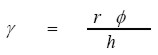

The tests were carried out using a dynamic shear rheometer DSR in stress controlled mode. Several conventional binders were tested together with polymer-modified bitumen. Conventional bitumen had different penetration ranges (B-13/22, B-40/50, B- 60/70, B-80/100 and B-150/200). The modified binder was a BM-3c. Bituminous binder specifications are shown in Table 1. The samples consisted of 8 mm diameter and 2 mm height cylinders. The specimens were fixed between two parallel plates and a sine torque was applied at 1.59 Hz frequency. Test temperature was 20°C (Figure 4). The applied stress varied between 1,000 Pa and 9,000 Pa. The variables recorded were change strain, complex modulus, dissipated energy and dissipated energy ratio. Strain, dissipated energy and DER were calculated using equations 3 and 4 (Figure 5).

|

[3] |

|

[4] |

Where

τ= torque applied

G*= complex modulus

γ = strain obtained

r = ratio

Φ = phase angle

h= height

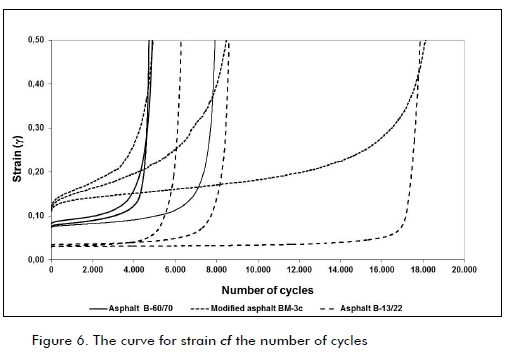

Figure 6 shows that strain was plotted with the number of cycles for a conventional B-80/100 binder. The test was continued until the slope increased sharply.

Results

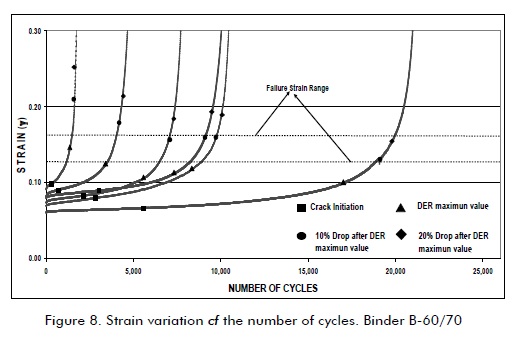

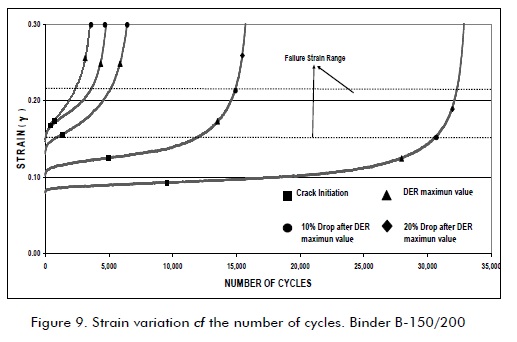

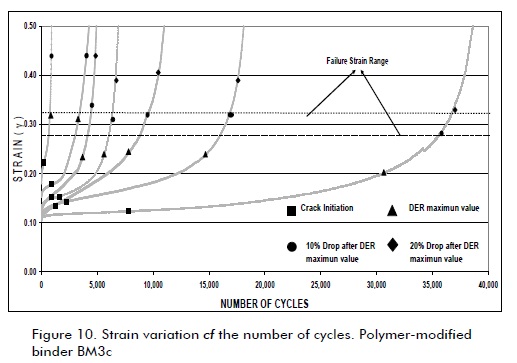

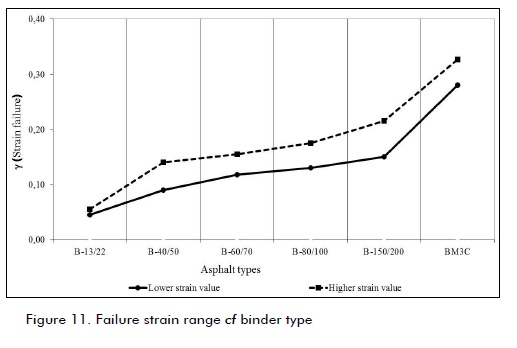

Figures 7, 8, 9 and 10 show variation in strain throughout load cycles for all bitumens. Each curve shows different stress values. Strain increased slowly during the first part of the test until a certain number of cycles when strain began to increase dramatically. The tests showed that samples from the same type of bitumen failed in the same strain range (defined as failure-strain range). Such strain range increased with penetration of binders. Polymer-modified binders had the highest failure strain range for all binders tested. Figure 11 shows the strain range in which samples failed. The strain at which failure took place was higher for binders having a higher penetration range and was even higher for polymer-modified bitumen.

New failure criterion (DER and strain evolutions)

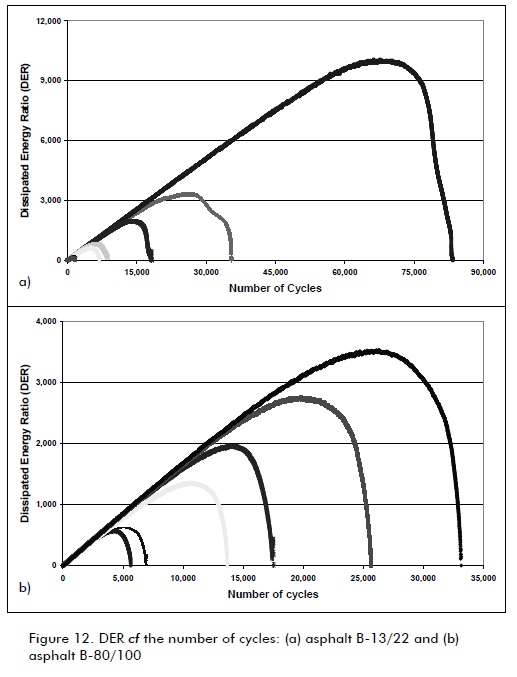

Figure 12 shows DER variation throughout load cycles for the same binders. Based on these curves, the number of cycles at which failure occurred was computed using four different criteria:

- DER deviation from the path;

- DER 's maximum value;

- 10% and 20% drop from DER 's maximum value

The values for these criteria have been plotted on the graphs shown in Figures 7, 8, 9 and 10. When DER deviation from the path proved to be too conservative, strain established by the criterion had a much lower value than the failure strain range (i.e. it appeared much earlier than actual fatigue failure occurred).The DER's maximum value and 10% and 20% drop from DER’s maximum value were more suitable for soft and polymer-modified binders, or, more precisely, when a high number cycles was required to produce significant damage. DER’s maximum value criterion was best suited to few cycles. Given that a high number of cycles is necessary for a reliable fatigue test result, a 10% drop from DER's maximum value should be the parameter used for determining failure.

The fatigue laws for each binder have been determined using such new criterion (Figure 13). The relationship between the vertical position of the fatigue law and failure strain has been observed. The fatigue laws for binders having higher failure strain were in a higher position on the graph while bitumen having higher complex modulus had less slope for their fatigue laws.

Conclusions

The main conclusions were that:

The proposed fatigue failure criterion using DSR when cracks appeared was very conservative. According to the analysis of deformation curves in loading cycles, asphalt had significantly lower deformation than that corresponding to its failure by rupture;

The fatigue failure criterion in asphalt, when the DER curve reached its maximum value, was valid when the asphalt had few loading cycles or high stresses. However, fatigue occurred with a large amount of loading cycles and stress value lower than their maximum strength;

A new fatigue failure criterion was proposed after analysing the deformation curves with loading cycles and DER, as well as rupture strain; this occurred when maximum DER value became reduced by 10%; and

Future research will correlate asphalt fatigue pattern with the fatigue pattern for asphalt mixtures made from these asphalts.

References

Anderson, D., Nir, L., Yam, M., Mihai,M., Planche, J., Martin, D., y Gauthier, G. Evaluation of fatigue criteria for asphalt bidners. Tansportation research record., Journal of the transportation research board, N. 1766, TRB. Washington, D.C., 2001, pp 48-56. [ Links ]

Cho, D., Bahia, H., Effects of aggregate surface and water on rheology of asphalt films. Tansportation research record., Journal of the transportation research board, TRB. Washington, D.C., 2007, pp 10-17. [ Links ]

Delgadillo, R., Bahia, H., Rational fatigue limits for asphalt binders derived from pavement analysis., Asphalt paving thechnology: Journal of the association of asphalt paving technologics, Vol 74, 2005, pp 1-42. [ Links ]

Di Benedetto, H., De la Roche, C., Francken, L., Fatigue of bituminous mixtures: Different approaches and RILEM interlabointerlaboratory test. Mechanical test for bituminous materials. A.A. Balkema, Rotterdam, Brookfield. 1997. pp 15-26. [ Links ]

Karen, B., Kitwe, N., Kitae, N., Bahia, H., Measuring and defining fatigue behaviour of asphalt binders., Washington, D.C., Transportation Research Record. Journal of the transportation research board, N. 1810, TRB. 2002. pp. 33-43. [ Links ]

Kennedy, T., Weng, T., Mansour, S., Effect of reclaimed asphalt pavement on binder properties using the superpave system., Research report 1250-1, Center for transportation research, The university of Texas at Austin, September 1998, pp 51-59. [ Links ]

Mihai, M., Clyne, T., McGraw, J., Xinjun, L., Velásquez, R., Higttemeprature rheological properties of asphalt binders., Transportation Research Record. Journal of the transportation research board, N. 1901, TRB, 2005, pp. 52-59. [ Links ]

Perez-Jimenez, F., Reyes-Ortiz, O., Miro, R., Martinez, A., Between the fatigue bahavior of bitumines and bituminous mixtures., 4th Euroasphalt & Eurobitume congress, Cophenaghe, 2008, pp 1-8. [ Links ]

Shen, S., Carpentier, S., Application of the dissiped energy concept on fatigue endurance limit testing., Tansportation research record, Journal of the transportation research board, N. 1929, TRB. Washington, D.C., 2005, pp 165-173. [ Links ]

Soenen, H.,De la Roche, C., Redelius, R., Predict mix fatigue test from binder fatigue properties, measured with a DSR., 3th Euroasphalt & Eurobitume congress, Vienna, 2004, pp 1924 -1934. [ Links ]

text in

text in