Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.32 no.2 Bogotá May/Aug. 2012

A methodological approach to sugar mill diversification and conversion

Enfoque metodológico de diversificación y reconversión de ingenios azucareros

N. Aguilar1, G. Galindo2, C.Contreras3, J.Fortanelli4

1 Noé Aguilar Rivera. Affiliation: Universidad Veracruzana. PhD in Environmental sciences, Universidad Autónoma de San Luis Potosí, Mexico. MSc. in Forestal product sciences, Universidad de Guadalajara, Mexico. BSc. in Chemical Engineering, Instituto Tecnológico de Orizaba Veracruz, Mexico. E-mail: nagui-lar@uv.mx

2 María Guadalupe Galindo Mendoza. Affiliation: Universidad Autónoma de San Luis Potosi, Mexico. Doctor Philosophy and letters Faculty, UNAM, Mexico. Master in Philosophy and letters Faculty, UNAM, Mexico. Geography licentiate Philosophy and letters Faculty UNAM, Mexico. E-mail: ggm@uaslp.mx

3 Carlos Contreras Servín. Affiliation: Universidad Autónoma de San Luis Potosi, Mexico. Doctor Philosophy and letters Faculty, UNAM, Mexico. Master in Philosophy and letters Faculty, UNAM, Mexico. Geography licentiate Philosophy and letters Faculty UNAM, Mexico. E-mail: coser@uaslp.mx

4 Javier Fortanelli Martínez. Affiliation: Universidad Autónoma de San Luis Potosi, Mexico. Doctor Agronomy Faculty, Universidad Autónoma de San Luis Potosi, Mexico. Master in Colegio de Posgraduados en Ciencias Agrícolas, Montecillo, Mexico. Licenciature in Escuela de Agronomía. E-mail: fortanel@uaslp.mx

ABSTRACT

Sugar industry diversification is complex, being constrained by biophysical and socioeconomic conditions. Ongoing work has shown the sugarcane industry's potential as biorefinery or its sustainable use by offering products as raw material. However, few studies have studied how such potential could be achieved by promoting a conventional sugar mill through integrating its indicators for developing an efficient diversified processing plant which would contribute towards fossil energy saving and competitiveness. This paper presents a conceptual framework for analysis based on existing knowledge regarding sugar industry state-of-the-art for evaluating diversification, using analytical hierarchy process (AHP) as a tool for analysing complex systems, identifying alternatives to the current situation and discussing them to facilitate collective decision-making. Sugar mill AHP scores enabled discussion about the variables most affecting sugar mill diversification (0.332 factory yield, 0.327 sugar mill products and 0.121 sugarcane quality). The results serve as a useful guidance for formulating strategies for the optimum use of by-products in a sugar mill while maximising benefits to modify/convert a traditional sugar mill to a so-called bio-refinery.

Keywords: Sugar mill, AHP, analytic hierarchy process, diversification.

RESUMEN

La diversificación de la industria azucarera es compleja y se ve limitada por condiciones biofísicas y socioeconómicas. Muchos trabajos han demostrado su potencial como biorrefinería y la utilización sostenible de los subproductos como materia prima. Sin embargo, pocos estudios se ha focalizado a través de la integración de indicadores productivos de un ingenio azucarero y cómo este potencial podría lograr transformar un ingenio azucarero convencional en una eficiente planta diversificada que contribuya a reducir el consumo de energía fósil y alcanzar la competitividad. Este trabajo presenta un marco de análisis o metodología basada en el conocimiento existente sobre la industria azucarera o el estado del arte, con la finalidad de evaluar la diversificación mediante el proceso de jerarquías analíticas (AHP) como una herramienta adecuada para el análisis de sistemas complejos, la identificación de alternativas y su discusión de manera que facilite la toma de decisiones colectivas. El análisis AHP obtenido en este estudio ofrece una discusión acerca de las variables que explican la capacidad para diversificar los procesos en un ingenio azucarero (rendimiento de fábrica: 0.332, productos derivados del ingenio azucarero: 0.327 y calidad de materia prima o caña de azúcar: 0.121). Los resultados obtenidos sirven de guía en la formulación de estrategias para la utilización óptima de los recursos derivados de un ingenio azucarero, mientras que la maximización de sus beneficios, para diversificar o reconvertir ingenios azucareros en biorrefinerías.

Palabras clave: ingenio azucarero, AHP, diversificación.

Received: February 4 th 2011 Accepted: May 16th 2012

Introduction

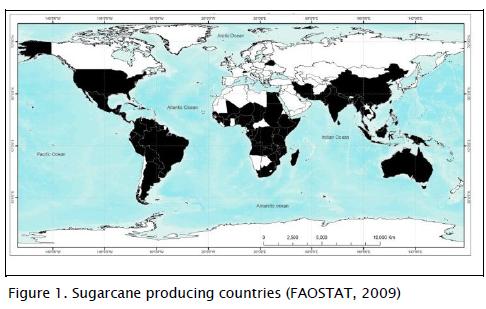

Agroindustry sugarcane represents a production sector which has worked with a single product, sucrose or table sugar, resulting from operations in a sugar mill exclusively processing a raw material, sugarcane (Saccharum officinarum L.), from a monoculture. FAOSTAT (2009) reported that sugarcane is produced in over 130 countries (having varying economic development) worldwide and is consumed locally in all of them at various levels (per capita consumption of sugar kg / inhabitant / year), the world average being 22.64 (Figure 1). The major producers are Brazil (20.8%), India (14.7%), China (7.0%), the USA (4.6%), Thailand (3.7%), Mexico (3.6%) and Australia (3.1%).

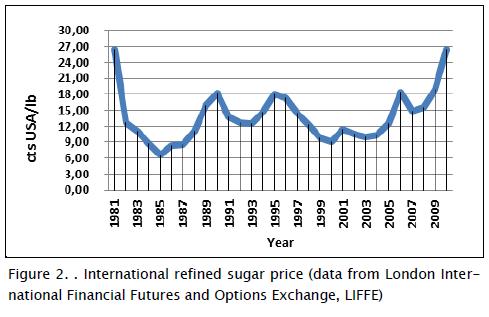

The economic challenges facing the global sugar industry are volatile world trade sugar prices (Figure 2) and the diversification of sugarcane monoculture production structure and sugar mill by-products (bagasse, molasses, vinasse, filter sludge and ashes) for improving productivity and competitiveness by using existing equipment, infrastructure and increasing the specialisation resulting from potential demand for sugarcane derivatives worldwide (Aguilar et al., 2009, 2010).

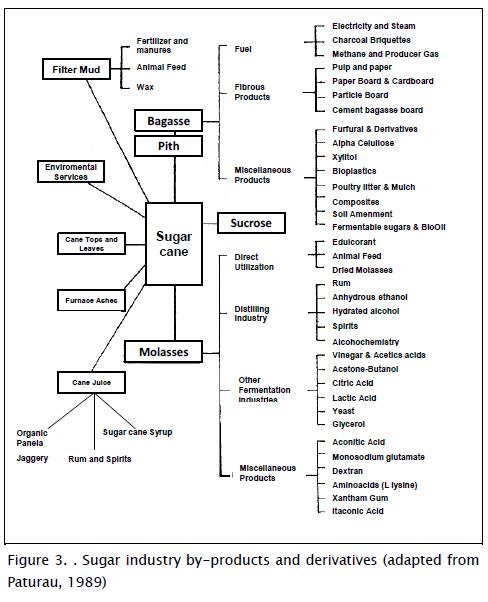

However, sugar industry diversification (Figure 3) is highly complex; it has been evaluated since 1970 as being a viable technical-economic alternative to offset international sugar price volatility by decreasing production costs and environmental impact while converting by-products into raw materials for new production cycles (Contreras et al., 2009; Renouf, 2007; Johannesburg, 2005; Lodi, 2005 and Galvez, 2000).

Analysing diversification projects must be based on scientific knowledge regarding coproducts, energy and material balance and the sugarcane derivative trade on the complexity assumed for incorporating and integrating agroindustrial factors and variables using the biorefinery concept for discussing their possible effects (D'Hont et al., 2008; Brumbley 2007; Birch, 2007; Edye, 2006; Morandini, 2006; Avram, 2005).

Such conceptualisation should form the starting point for studying diversification and identifying constraints and the specific weighting of each determining factor in sugar mills; this implies designing fresh decision-making methodologies, such as multicriteria evaluation (MCE). This study was aimed at developing a methodology for determining sugar mills' capacity to diversify their base production (sucrose), as a diversification index, by using the analytic hierarchy process (AHP) multicriteria method

Materials and Methods

MCE is based on weighting and compensating for variables and aptitudes determining decision theory-related factors (Gomez, 2006). A multicriteria problem involves a discrete number of alternatives where A is a finite set of n alternatives or feasible actions, G is the set of m evaluation functions gi, i = 1,2, ..., m associated with the evaluation criteria. If A is an alternative, gi (A) is their assessment and i criterion can be represented in a matrix P of m rows and n columns (evaluation table or impact matrix) whose elements pij (i = 1,2, ..., m, j = 1,2, ..., n) repre-sent the evaluation of alternative j in criterion i (Falconi, 2004).

AHP is supported by reciprocal judgments and element homoge-neity in a complex multivariable problem compared to the same order of magnitude and hierarchical structure to prioritise their relative importance in production systems (Freitas, 2006 and Saaty, 1990). It has been used in sugarcane variety selection (Zhong et al., 2009), in designing strategies to increase competitiveness (Akli, 2009; Castellanos, 2007; Nagesha, et al., 2006; Abreu, 2004), sugarcane area management (Diogo et al., 2007; Qureshi, 2003) and bioethanol and bioenergy projects (Turcksin, 2010; Hilmola et al., 2010; Lapola et al., 2010; Tienwong, 2009; Lamparelli, 2009; Junqueira et al., 2009; Silva, 2009, Quintero et al., 2008; Papalexandrou, 2007).

The study involved variables or factors according to international sugar organisation (ISO, 2005) standards for sugar industry com-petitiveness and diversification: sugar mill yield (%), sucrose recovery rate (%), total time loss (%), sugarcane quality (% su-crose), external electricity (kWh / t. cane), external fuel consumption (oil) oil L / t.cane and produced sugarcane derivatives (raw, muscovado, refined, ethanol, electricity, compost, fertirigation, rum, spirits, etc.).

Such variables or factors provide a priori information about the sector's ability to diversify, including optimal indexes for international comparative analysis (benchmarking), industry dynamics and weighting each variable or techno-economic indicator's relative importance in analysing diversification when considering sugar mill capacity, raw material quality and energy balance (ISO, 2005; Zimmermann, 2002; Banerjee, 2004).

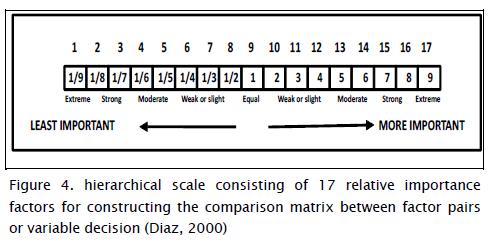

Each factor's relative importance was evaluated by building a multicriteria AHP pairwise comparison matrix and then using such matrix for assigning a different value (weighting) to individual factors or constraints. Each possible pair was compared and qualified by applying a continuous hierarchical scale of 17 relative importance factors (Figure 4).

AHP evaluates paired matrix error or inconsistency for overall sets of alternative priorities; less than 10% (CI index <0.1) is considered acceptable and robust (Sipahi 2010; Berumen 2007; Aguarón et al., 2003; Saaty, 1990).

Results and Discussion

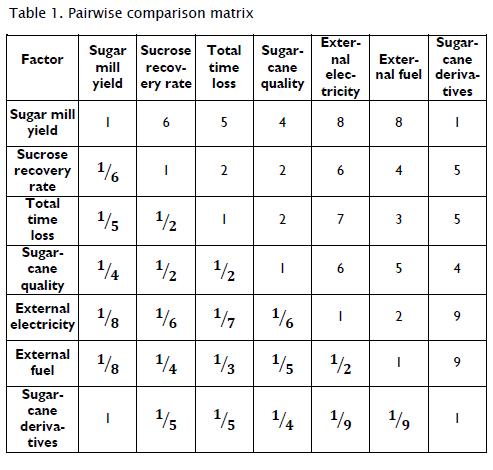

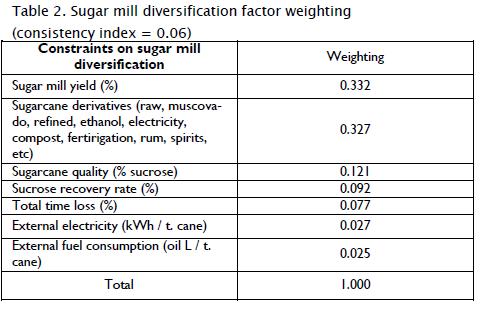

Tables 1 and 2 show the pairwise matrix and weightings obtained using Expert Choice 11.5 software AHP evaluation module for each factor.

Sugar mill yield (%) and the number of goods or sugarcane derivatives produced (raw, muscovado, refined, ethanol, electricity, compost, fertirigation, rum, spirits, etc) had greater weighting than whole factors, since they implied greater sugar mill capacity to transform raw material into sucrose and by-products (molas-ses, bagasse, filter sludge, ashes and vinasse) for energy and other products (cogeneration, ethanol, compost, refined sugar, musco-vado, organic waste, etc.) along with conventional raw or refined sugar and facilities and technical knowledge (learning curve or know-how) when producing sugarcane and its derivatives. The next most important factors were sugarcane quality (% sucrose, % fibre) and sucrose recovery rate (%), their importance being directly related to sugar cane production and intrinsic productivity. Sucrose recovery rate (%) was related to core technology and/or the obsolescence of the equipment being used for handling raw materials, representing external electricity and fuel consumption both by t / cane resulting from energy diversification regarding external power.

Regarding the weighting of each factor in Tables 1 and 2, a sugar mill evaluation instrument or chart was prepared (Table 3) according to Ahumada (2009), Yamba (2008), ISO (2005), Trujillo (2002) and Zimmermann et al., 2002 determining the weighting or relative importance by hierarchical level and threshold for making technical decisions concerning diversifying the sugar industry (high, medium, low and very low diversification index).

The aforementioned methodology could be used as a tool for supporting decision-making in planning sugar mill diversification. Variables, factors and constraints needing intensive study were identified and may be reproduced in other settings and enriched by including new criteria and constraints, avoiding subjective information derived from sector statistics (restrictions on indicators traditionally used for highlighting the sugar sector's national and regional importance) and speculative action for positively and systematically managing controllable sugar production factors .

Conclusions

A <0.1 IC established that the independent variables used were sufficient for an a priori explanation of dependent variable "sugar mill diversification capacity." This method provided indicator-based synthesis (index diversification), this being an advantage since it significantly reduced the amount of data to be analysed and was not simply an aggregation of indicators, each therefore being weighted according to their relative importance and having real dimensions applicable to any sugar mill worldwide

References

Abreu Ledón, R., Asencio García, J., Marrero Delgado, F. Fabelo Lago, O. El índice de prioridad del Equipo con enfoque multicriterio para la búsqueda de oportunidades de inversión sobre el equipamiento productivo en empresas de apoyo a la industria azucarera. Centro Azúcar. No. 4, año 31, octubre - diciembre, 2004, pp. 83-89. [ Links ]

Aguarón, J.; Moreno-Jiménez, J. M. The Geometric Consistency Index: Approximated Thresholds". European Journal of Operational Research Vol. 147 No.1, 2003, pp. 137-145 [ Links ]

Aguilar.R. N., D. A. Rodríguez Lagunes, A. Castillo Morán. Azúcar, coproductos y subproductos en la diversificación de la agroindustria de la caña de azúcar. 2010, http://www.revistavirtualpro.com/files/ti02_201011.pdf [ Links ]

Aguilar R. N., G. G. Mendoza, C. Contreras S., J. Fortanelli M. ¿Por qué diversificar la agroindustria azucarera en México? Revista Globalizacion competitividad y gobernabilidad Vol 3 No. 1, 2009, pp.62-75 [ Links ]

Akli Achabou M. S. Tozanli. The institutional environment in the strategic decision of the emerging companies: the case of the Algerian sugar industry. Journal of Multi-Criteria Decision Analysis Vol. 16, No. 5-6, 2009, pp. 139-148 [ Links ]

Ahumada M.R. Diagnostico agroindustrial de la caña de azúcar. Memorias XXXII Convención de la asociación de técnicos azucareros de México. Cordoba Ver. 27-28 agosto 2009 [ Links ]

Avram P. B. Morgen. Benchmarking concept for an integrated sugar, ethanol and cogeneration plant.(ISSCT); International Society of Sugar Cane Technologists Congress, Vol.2; 0130-0204; 2005, Guatemala City(GT). [ Links ]

Banerjee S. Determinants of International Competitiveness: A Comparative Study of the Sugar Industry in Australia, Brazil, and the European Union. Thesis for Degree of Masters in Business, School of International Business, Queensland University of Technology, Brisbane, Australia, 2004,136 p. [ Links ]

Berumen, S. A, Llamazares R. Usefulness of multiple criteria decision methods (such as AHP) in an environment with growing competitiveness. Cuad. Adm., Vol. 20 No.34, 2007, pp.65-87 [ Links ]

Bojórquez, L.A. ANP modeling of complex socio-environmental systems: adaptive capacity of smallholder coffee system in Mesoamerica. Proceedings of the International Symposium on the Analytic Hierarchy Process 2009, 1-10 p. [ Links ]

Brumbley F. Developing the sugarcane biofactory for high-value biomaterials. International Sugar Journal Vol. 109, No.1297, 2007, pp. 5-15 [ Links ]

Castellanos Abella E. A. C. J. Van Westen. Generation of a land-slide risk index map for Cuba using spatial multicriteria evaluation. Landslides Vol. 4, 2007, pp. 311-325 [ Links ]

Contreras A.M., E. Maylier Pérez, H. Van Langenhove J. Dewulf. Comparative Life Cycle Assessment of four alternatives for using by-products of cane sugar production. Journal of Cleaner Production Vol 17, No. 8, 2009, pp.772-779 [ Links ]

D'Hont D.A., G. Mendes Souza, M. Menossi. Chapter 21 Sugar-cane: A Major Source of Sweetness, Alcohol, and Bioenergy Springer, Moore, R. Ming (eds.), Genomics of Tropical Crop Plants, 2008, pp. 403-513 [ Links ]

Díaz S. J., J. L. Blanco. Evaluación del potencial para acuacultura costera de camarón en el entorno de la laguna de Mar Muerto, mediante la aplicación de técnicas de análisis multicriterio con un SIG. Investigaciones Geográficas, Boletín del Instituto de Geografía, UNAM, Vol. 41, 2000, pp. 62-80 [ Links ]

Diogo F. P., T. D. P. Lucas, F. B. de Lima Neto. How to Obtain Fair Managerial Decisions in Sugar Cane Harvest Using NSGA-II,2007, pp.186-191, 7th International Conference on Hybrid Intelligent Systems. [ Links ]

Edye, L.A. The sugarcane biorefinery: Energy crops and processes for the production of liquid fuels and renewable commodity chemicals. International Sugar Journal 2006, Vol. 108, No.1285, 2006, pp. 19-27. [ Links ]

Falconi F., Burbano R. Instrumentos económicos para la gestión ambiental: decisiones monocriteriales versus decisiones multicriteriales. Revista Iberoamericana de Economía Ecológica Vol. 1, 2004, pp.11-20 [ Links ]

FAOSTAT. 2009. Estadísticas de producción. http://faostat.fao.org/site/567/DesktopDefault.aspx?PageID=567#ancor [ Links ]

Freitas, A.; Marins, C.; Souza, D. A metodologia de multicritério como ferramenta para a tomada de decisões gerenciais: um estudo de caso. Revista GEPROS - Gestão da Produção, Operações e Sistemas Vol. 2 No.3, 2006, pp. 52-60. [ Links ]

Gálvez T.L. Manual de los Derivados de la Caña de Azúcar". Instituto Cubano de Investigación de los Derivados de la Caña de Azúcar, La Habana Cuba. 3era edición, 2000, 458 p. [ Links ]

Gamarra E. E. Silva Lora. Techno-economical evaluation of Diversification in sugarcane industry. (ISSCT); International Society of Sugar Cane Technologists Congress Vol.2; 2005; Guatemala City(GT) [ Links ]

Gómez D. M. Barredo C. J.I., Sistemas de información geográfica y evaluación multicriterio en la ordenación del territorio. "da edición. Edit. Alfaomega RaMa. México, 2006, 279 p. [ Links ]

Hilmola O.P., J. Saranen, F. Padilha Location Criteria and Strategic Factors of Biodiesel Factory Establishment in Finnish Context, Lappeenranta University of Technology Department of Industrial Management Kouvola Research Unit Research Report 219, 2010, 66 p. [ Links ]

International Sugar Organization. An International Survey of Sugar Crop Yields and Prices Paid for Sugar Cane and Beet. Market evaluation consumption and Mecas (05)05 Statistics Committee 2005, 49 p. [ Links ]

Lodi E. O Novo Ciclo da Cana : Estudo sobre a Competitividade do Sistema Agroindustrial da Cana-de-açúcar e Prospecção de Novos Empreendimentos. Brasília: IEL/NC; SEBRAE, 2005, 337. [ Links ]

Junqueira A. C. Identificação do potencial de contaminação de aquíferos livres por vinhaça na bacia do Ribeirão do Pântano, Descalvado (SP), Brasil. Revista Brasileira de Geociências Vol. 39 No. 3, 2009, pp. 507-518. [ Links ]

Lamparelli, R. A.C, Dias, H. S.. Methodological development of a quality index for agricultural operations, for corn cultivation using multicriterion analysis. An. Acad. Bras. Ciênc. Vol.81, No. 4, 2009, pp. 849-859 [ Links ]

Lapola D.M., R. Schaldach, J. Alcamo, A. Bondeau, J. Koch, C. Koelking, J. A. Priess. Indirect land-use changes can overcome carbon savings from biofuels in Brazil. PNAS Vol. 107 No. 8, 2010, pp.3388-3393 www.pnas.org/cgi/content/full/0907318107/DCSupplementa [ Links ]

Morandini Paoliello J.M. Aspectos ambientais e potencial energético no aproveitamento de resíduos da industria sucroalcooleira, Dissertação (mestrado) - Universidade Estadual Paulista. Faculdade de Engenharia, Bauru, 2006,180 p. [ Links ]

Nagesha, N., and Balachandra, P. Barriers to energy efficiency in small industry clusters: Multi-criteria-based prioritization using the analytic hierarchy process", Energy, Vol. 31, 2006, pp. 1969-1983. [ Links ]

Papalexandrou M. A., P. A. Pilavachi,A. I. Chatzimouratidis. Evaluation of liquid bio-fuels using the Analytic Hierarchy Process. Proceedings of European Congress of Chemical Engineering (ECCE-6) Copenhagen, 16-20 September 2007 [ Links ]

Paturau, M. J. By-products of the cane sugar industry can introduction to their industrialization. 3ª. Edition. Elsevier Science Publishing Company Inc. New Cork City, N. Y., 1989, 436 p. [ Links ]

Quintero J.A., M.I. Montoya, O.J. Sánchez, O.H. Giraldo and C.A. Cardona. Fuel ethanol production from sugarcane and corn: Comparative analysis for a Colombian case. Energy Vol. 33 No.3, 2008, pp. 385-399 [ Links ]

Qureshi M.E. Application of the Analytic Hierarchy Process to Riparian Revegetation Policy Options 2003, http://espace.library.uq.edu.au/eserv/UQ:8658/n09_Ejaz.pdf [ Links ]

Renouf M.A. M.K. Wegener. Environmental life cycle assessment (LCA) of sugarcane production and processing in Australia. Proceedings of the Australian Society of Sugar Cane Technologists, Vol. 29, 2007, pp. 1-15. [ Links ]

Saaty, T.L. How to make a decision: The analytic hierarchy process. European Journal of Operational Research, Amsterdam, Vol. 48, 1990, pp. 9-26 [ Links ]

Silva JR. A. G. da, Perez, R., Martins, E.L. Análise de investimento em unidade de produção de óleo vegetal utilizando a metodologia "Analytic Hierarchy Process" com o software "Expert Choice". In. 7° Congresso Brasileiro de Agroinformática. Viçosa - MG. 2009, pp. 21-25 [ Links ]

Sipahi, Mehpare T. The analytic hierarchy process and analytic network process: an overview of applications", Management Decision, Vol. 48 No. 5, 2010, pp.775 - 808 [ Links ]

Tienwong Kanlaya, Songkot Dasananda, Chalie Navanugraha. Integration of land evaluation and the analytical hierarchical process method for energy crops in Kanchanaburi, Thailand. ScienceAsia Vol. 35, 2009, pp. 170-177 [ Links ]

Turcksin L. A Multi-Actor Multi-Criteria analysis to assess the stake-holder support for different biofuel options, 2010, http://wwwa.vito.be/bioses/pdf/BIOSES-MAMCA.pdf [ Links ]

Trujillo Murcia E, L. R. García Chávez. Un análisis de la eficiencia en la industria azucarera mexicana en las etapas pública y privada. Prospectiva Económica, No. 1, Julio - Diciembre, 2002, pp.137-150 [ Links ]

Yamba L. Bioenergy for Sustainable Development and Global Competitiveness: the case of Sugar Cane in southern Africa, Thematic Report 3: Markets 2008, http://www.carensa.com/CARENSA_TR3_Markets.pdf [ Links ]

Zhong Min, Tang Yao-ping. Economic Benefit Evaluation for Agricultural Products Based on Analytic Hierarchy Process, 2009, http://en.cnki.com.cn/Article_en/CJFDTOTAL-HNNK200909041.htm [ Links ]

Zimmermann B and Jürgen Zeddies. International competitive-ness of sugar production. 13th International Farm Management Congress, Wageningen, The Netherlands, July 7-12, 2002 Institut für Landwirtschaftliche Betriebslehre, Universität Hohenheim, D-70593 Stuttgart. [ Links ]