Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.32 no.2 Bogotá May/Aug. 2012

The impact of liquid drops on purple cabbage leaves (Brassica oleracea l. Var. Capitata)

Comportamiento al impacto de gotas sobre hojas de repollo morado (Brassica oleracea l. Var. Capitata)

R. D. Andrade1, O. Skurtys2, F. Osorio3

1 Ricardo D. Andrade Pizarro. Affiliation: Universidad de Córdoba, Colombia. PhD. candidate in Food Science and Technology, Universidad de Santiago de Chile. BSC. In Chemical Engineering, Universidad del Atlántico, Colombia. E-mail: ricardo.andrade@usach.cl

2 Olivier Skurtys. Affiliation: Universidad Técnica Federico Santa María, Chile. PhD in Engineering Sciences, ENSMA - Université de Poitiers, France. E-mail: oliivierskurtys@usm.cl

3 Fernando Osorio Lira. Affiliation: Universidad de Santiago de Chile. PhD. in food Engineering, Michigan University, United States. E-mail: fernandoosorio@usach.cl

ABSTRACT

Liquid drop impact on solid surfaces has been well studied due to its wide industrial application; however, there are very few studies of liquid drop impact on vegetable surfaces. The present work determined the drop impact pattern on purple cabbage leaves' surface and evaluated the influence of water drop viscosity and surface tension. The pattern of fluid impact on cabbage surface was evaluated by using a high-speed camera (1250 frames/s) at different impact heights for Weber numbers ranging from 100-800. The results showed that greater maximum spread factor was achieved with higher impact speed and lower surface tension drops. Viscosity had great influence on maximum spread factor and on dynamic impact. Maximum scaled spread factor ξmax was We1/4 for low viscosity water drops (water and Tween20-water). Fluid viscosity could be increased or surface tension decreased to prevent droplet rebound and keep them on purple cabbage surface by spraying them with an edible coating.

Keywords: drop impact, spread factor, Weber number, spraying.

RESUMEN

Debido a su importancia en varias aplicaciones industriales, el impacto de gotas sobre superficies sólidas ha sido bastante estudiado. Sin embargo, las investigaciones en impactos de gotas sobre superficies de vegetales son muy escasas. En este trabajo se determina el comportamiento del impacto de gotas en superficies de repollo morado y se evalúa la influencia de la viscosidad y la tensión superficial. El comportamiento frente al impacto de los fluidos evaluados sobre la superficie de repollo morado fue medido utilizando una cámara de alta velocidad (1250 fotos/s) a diversas alturas de impacto, para un rango de número de Weber de 100 a 800. Los resultados muestran que el factor de extensibilidad máxima incrementa con el aumento de la velocidad de impacto y menor tensión superficial de gotas. La viscosidad tiene una gran influencia sobre el factor de extensibilidad máxima y la dinámica del impacto. Además, para líquidos de baja viscosidad (agua y Tween20-agua), el factor de extensibilidad máxima (ξmax) es proporcional a We1/4. Finalmente, para lograr que la gota no rebote y se mantenga en la superficie del repollo morado, en la aplicación de recubrimientos comestibles por aspersión se puede aumentar la viscosidad o disminuir la tensión superficial del líquido

Palabras clave: impacto de gota, factor de extensibilidad, número de Weber, aspersión.

Received: August 22th 2011 Accepted: July 12th 2012

Introduction

Purple cabbage (Brassica oleracea L. var. capitata) is a native crop from Europe's Mediterranean region which now grows all over the world as a fresh vegetable for market. Purple cabbage is usually consumed in fresh-cut salad mixtures; it is a functional food and has become popular due to its high anthocyanin content levels and has particularly been reported as providing protection against human tumour development (Yuan et al., 2009).

When purple cabbage is used in fresh-cut salad its aspect may become modified; its surface may lose water and turn brownish. The use of an edible coating could extend purple cabbage shelf life. Purple cabbage crops may be affected by pests such as the mealy cabbage aphid (Brevicoryne brassicae L.), the white butter-fly (Pieris brassicae L.), the cabbage moth (Mamestra brassicae L.) and flea beetles (Phyllotreta spp.) (Hasan and Ansari, 2011; Weinberger and Srinivasan, 2009). Synthetic fungicides or natural extracts are commonly used for controlling insect pests.

Spray systems are usually used for applying edible coatings and fungicides to vegetables (Andrade et al., 2012). The impact of aqueous drops on plants has been reported to involve splashing or bouncing, even for low kinetic energy drops since the upper-most layers of the cuticle (the epicuticular waxes) act as a sub-stantial barrier against wetting (Zhang et al., 2006). Rebounding or splashing may reduce the protective treatment of purple cabbages; indeed denser waxes always show more hydrophobic ability which can render spray applications ineffective. Two ways of preventing drops rebounding and keeping them on the surface have been proposed by Bergeron (2003): decreasing surface tension (adding surfactants) and increasing fluid viscosity (adding polymers and colloids).

The impact of liquid drops on solids is a very complex problem. It depends on drop and solid surface geometry as well as their physic-chemical properties. When a water drop makes an impact on a solid this can be divided into spreading, receding, splashing and bouncing. The relevant dimensionless parameters governing a drop's impact on a smooth solid are Reynolds number (Re = ρU0D0 /μ), Weber number (We=ρD0U02/) and Ohnesorge number (Oh=μ/√(ρ D0), where U0 is impact speed, D0 is initial drop diameter, ρ is fluid density, is surface tension for a fluid-air interface and μ is dynamic viscosity (Clanet et al., 2004; Yarin, 2006). Impact (spreading and receding) has been characterised by a normalised "spread factor", ξ(t), which is the ratio of drop spread diameter, D(t), on a solid surface to initial drop diameter, D0, prior to impact, ξ(t)=D(t)/D0. Plotting spread factor regard-ing time yields a key value of interest to researchers: the maxi-mum spread factor, ξmax=Dmax/D0 (Aytouna et al., 2010).

This work was aimed at investigating and describing the fluid dynamics that occur during the impact of a water drop on a purple cabbage leaf. The influence of viscosity and surface tension were determined by varying fluid properties: water, glycerol-water (50%v/v) and Tween 20-water (0.1%w/v).

Materials and Methods

Plant material

Purple cabbages (Brassica oleracea var. capitata) were purchased from a local supermarket in Santiago (Chile); the vegetables were left at room temperature (20ºC) for several hours before meas-urements were taken. Some lacking any visual signs of physical damage were then carefully selected.

Physical properties of liquids

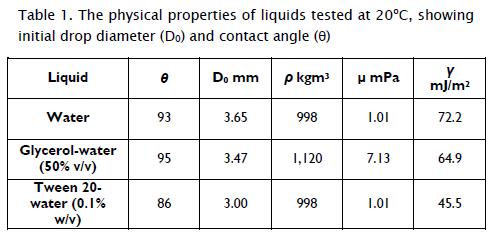

Three liquid solutions were used: water, glycerol-water (50% v/v) and Tween 20-water (0.1% w/v) mixtures. Glycerol and Tween 20 were purchased from Sigma (Sigma-Aldrich, Chile). The solu-tions' physical properties were measured (Table 1). Viscosity varied from 1 to 7.1 mPa and surface tension from 45.5 to 72.2 mJ/m2. Surface tension measurements were carried out by the pendant drop method as reported in Skurtys and Aguilera (2008). Contact angle was measured by the sessile drop method, using ImageJ software (National Institutes of Health, USA) with the plugin Drop Shape Analysis (Drop-analysis, 2010).

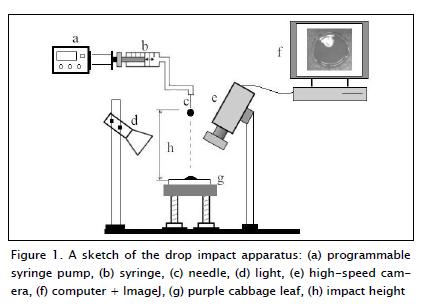

Drop impact apparatus

Figure 1 gives a sketch of the apparatus for drop impact on vege-table surfaces. It consisted of a drop production system and an image acquisition system. Water drops were generated by a 1.194 mm internal diameter precision flat-tipped syringe needle (16 gauge) (Sigma-Aldrich, USA, St. Louis) connected to a digital-ly-controlled syringe pump (Model 1000, New Era Pump System Inc., Farmingdale, NY, USA). Liquid flow rate was sufficiently low to obtain a nil initial drop speed (0.05 ml.min-1). The drop subse-quently fell a predetermined vertical height onto a purple cab-bage leaf. Drops were assumed to maintain their spherical shape throughout their free-fall since their radii were lower than capil-lary length, κ=√(γ/g) (Landau and Lifshitz, 1959).

Drop impact experiments were conducted for six different values of U0 in a 1.4 - 3.4 m.s-1 range. Drop impact kinetic energy, EK, varied from 1.4 × 10-5 J to 1.5 × 10-4 J. the speed of an impacting drop, U0, was estimated from √(2gh). The image acquisition system consisted of a high-speed camera (Pulnix, Inc., San Jose, USA) positioned with an angle fixed at 10º from the vertical. The camera's acquisition rate was adjusted to 1,250 frames per second (fps) and shutter speed to 1/4,000s for accurate capture of drop t dynamics after collision. The pixel resolution at this speed was 224 x 160.

Drop impact measurements

Drop diameter measurements (initial, D0; maximum, Dmax and final, Dend) were made using ImageJ software for all video data. The temporal evolution of the spread factor (ξ(t)) and maximum spread factor (ξmax) were determined from these measurements.

Results and Discussion

A qualitative description of the dynamics of drop spreading

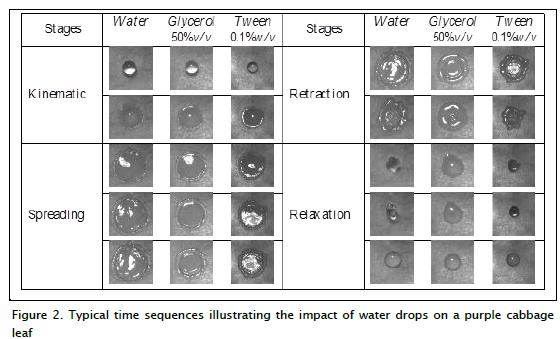

The drop's kinetic energy on impact was sufficiently high to spread (We ≥ 100) but sufficient low as not to splash (We ≤ 800) for all the tests. Indeed, fingers were observed at the end of spreading but water drop cohesion was preserved for the highest Weber numbers. Figure 2 presents typical time sequences illustrating drop behaviour after impact (We ≈ 100) on a purple cabbage leaf for each liquid (water, glycerol-water and Tween 20-water mixtures). The time sequence for each liquid can be divided into four stages: kinematic, spreading, retraction and relaxation. Each stage's time scale depended on water drop impact speed and physical properties. A large portion of the drop remained nearly hemispherical during the kinematic phase (t <1ms), then spread out radially on impact and reached maximum spreading diameter (Dmax). A thin film (lamella) bounded by a rim was observed during the spreading stage. When Dmax was achieved, surface tension forces became sufficiently important to retract the lamella. Thus, drop diameter decreased continuously, receding towards the impact point (t ≈ 8ms). Three phenomena were observed during the relaxation stage, depending on water drop properties: no rebound (glycerol-water mixture), rebound (water) and partial rebound (Tween 20-water mixture). A water drop reached an equilibrium shape at the end of the impact p (Dend).

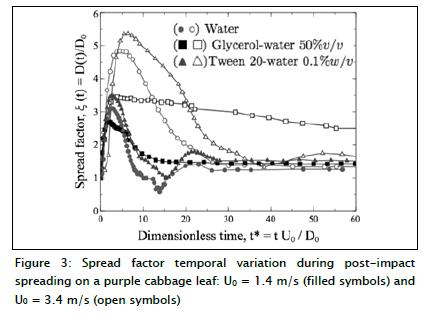

Spread factor temporal variation

Figure 3 describes the impact on purple cabbage leaves in more detail and accuracy by showing spread factor temporal evolution (ξ(t*)=D(t*)/D0). Two drop impact speeds were tested: low U0=1.4m.s-1 (filled symbols) and high 3.4m.s-1 (open symbols); We thus varied from 100 to 800. Unusually for inertia-governed impacts, time t was made non-dimensional (t*) using impact speed U0 and initial spherical drop diameter D0 (Sikalo et al., 2002). Figure 3 shows that for t* < 5 (or dξ/dt* > 0) that ξ(t*) depended on water drop impact speed and physical properties. Clearly, increased impact speed for a fixed water drop would modify the impact pattern since there would be an increase in the maximum spread factor value (ξmax) with the kinetic energy. Furthermore, for a fixed impact speed, ξmax increased when liquid viscosity or surface tension decreased since: ξmax(glycerol−water)<ξmax(water) or ξmax(water) < ξmax(Tween20−water).

Indeed, glycerol-water viscosity was six or-ders of magnitude greater than that of water whereas water and Tween 20-water had similar viscosity values even though Tween 20-water surface tension was about a third that of water. For t*>5, the receding and relaxation stages also depended on water drop properties (i.e. viscosity and surface tension). A water drop at low impact speed showed pronounced oscillations, slowly dying out due to viscous damping, whilst a glycerol-water drop showed no oscillations after receding since viscosity was higher. Kinetic energy was quickly dissipated by viscous forces. A Tween 20-water drop showed intermediate behaviour, undergoing half an oscillation. At high impact speed, ξmax was greater than the latter; receding energy was thus progressively damped and oscillation disappeared. However, even if the behaviour of water drop impacts was distinct, the drop tended towards a final drop diameter Dend of around 1.5D0.

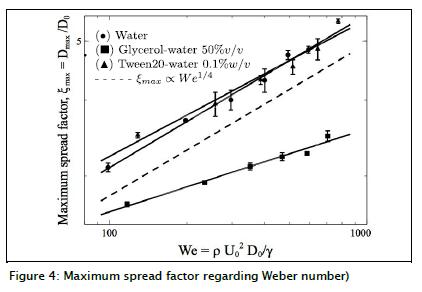

Maximum spread factor

Figure 4 shows the maximum spread factor (ξmax) on a purple cabbage leaf or a large range of Weber numbers (100-800) and the three liquids considered here. ξmax values increased with We for all liquids due increased drop impact speed (or kinetic energy). This result confirmed previous observations stating that inertia controls spreading (Bolleddula et al., 2010; Sikalo et al., 2002). Clearly, viscosity had an effect on ξmax. values; indeed, ξmax increased by 55% for water and Tween 20-water drops but only 35% for a glycerol-water drop when We became increased from 100 (U0 = 1.4m.s-1) to 800 (U0 = 3.4m.s-1). Higher viscosity liquid, such as water-glycerol, produced higher viscous dissipa-tion of the kinetic energy on impact since ξmax(water) or ξmax(Tween 20−water) were greater than ξmax(glycerol−water), the differ-ence being greater than 20%. Moreover, the data revealed ξmax ∝ We0.25±0.02 for lower viscosity, whereas this was ξmax ∝ We0.16±0.02 for higher viscosity. The lower viscosity exponent obtained in this work had good agreement with that reported by Clanet et al., (2004) for drop impact on a super-hydrophobic surface: ξmax ∝ We1/4. The Dmax relationship must contain D0 water drop surface tension and viscosity properties for explain-ing the difference between both exponents. It should be noted that Rein (1993) reported ξmax ∝ Re1/5 for highly viscous fluids.

Conclusions

Water drop impact on a purple cabbage leaf was studied in detail in this work; in particular, no rebound, partially rebound or rebounds were observed during the relaxation stage. Significant differences regarding spread factor pattern were reported when water drop physical properties (viscosity and surface tension) of the varied. It was shown that lower water drop surface tension promoted greater spreading and damped oscillations during the relaxation stage whilst higher viscosity damped both spreading and receding stages. Moreover, this work verified that maximum spread factor ξmax scaled with We1/4 for low viscosity water drops (water and Tween 20-water mixture). Fluid viscosity can be increased or surface tension decreased to prevent droplet rebound and keep them on purple cabbage surface by spraying them with edible coatings. It was also shown that water drop impact on purple cabbage leaves is a very complex phenomenon meriting further investigation regarding how to control it.

Acknowledgements

The authors would like to thank CorfoInnova (Project 08CT11PUT-20) for financing the project. RA is a recipient of a grant for PhD studies (Program for Foreigners, CONICYT, Chile) and grant for supporting research (VRID-USACH, Chile).

References

Andrade, R.D., Skurtys, O., Osorio, F.A. Atomizing spray systems for application of edible coatings. Comprehensive Reviews in Food Science and Food Safety, Vol. 11, No. 3, 2012, pp. 323-337 [ Links ]

Aytouna, M., Bartolo, D., Wegdam, G., Bonn, D., Rafai, S. Impact dynamics of surfactant laden drops: dynamic surface tension effects. Experiments in Fluids, Vol. 48, No. 1, 2010, pp. 49-57. [ Links ]

Bergeron, V. Designing intelligent fluid for controlling spray applications. C R Physique, Vol. 4, 2003, pp. 211-219. [ Links ]

Bolleddula, D., Berchielli, A., Aliseda, A. Impact of a heterogeneous liquid droplet on a dry surface: Application to the pharmaceutical industry. Advances in Colloid and Interface Science, Vol. 159, No. 2, 2010, pp. 144-159. [ Links ]

Clanet, C., Béguin, C., Richard, D., Quéré, D. Maximal deformation of an impacting drop. Journal of Fluid Mechanics, Vol. 517, 2004, pp. 199-208. [ Links ]

Drop-analysis,2010. http://bigwww.epfl.ch/demo/dropanalysis/ soft. Accessed March. [ Links ]

Hasan, F., Ansari, M. Population growth of Pieris brassicae (l.) (lepidoptera: peridae) on different cole crops under laboratory conditions. Journal of Pest Science, Vol. 84, 2011, pp. 179-186. [ Links ]

Landau, L., Lifshitz, E. Fluid Mechanics, Course of Theoretical Physics, Vol. 6. Addison-Wesley, Reading, 1959. [ Links ]

Rein, M. Phenomena of liquid drop impact on solid and liquid surfaces. Fluid Dynamics Research, Vol. 12, 1993, pp. 61-93. [ Links ]

Sikalo, S., Marengo, M., Tropea, C., Ganic, E.N. Analysis of impact of droplets on horizontal surfaces. Experimental Thermal and Fluid Science, Vol. 25, No. 7, 2002, pp. 503-510. [ Links ]

Skurtys, O., Aguilera, J. Structuring bubbles and foams in gelatine solutions within a circular microchannel device. Journal of Colloid and Interface Science, Vol. 318, No. 2, 2008, pp. 380-388. [ Links ]

Weinberger, K., Srinivasan, R. Farmers' management of cabbage and cauliflower pest in india and their approaches to crop protection. Journal of Asia-Pacific Entomology, Vol. 12, 2009, pp. 253-259. [ Links ]

Yarin, A. Drop impact dynamics: Splashing, spreading, receding, bouncing... . Annual Review of Fluid Mechanics, Vol. 38, No. 1, 2006, pp. 159-192. [ Links ]

Yuan, Y., Chiu, L.W., Li, L. Transcriptional regulation of anthocyanin biosynthesis in red cabbage. Planta, Vol. 230, 2009, pp. 1141-1153. [ Links ]

Zhang, Y., Zhang, G., Han, F. The spreading and superspeading behavior of new glucosamide based trisiloxane surfactants on hydrophobic foliage. Colloids and Surfaces A: Physicochemical and Engineering Aspects, Vol. 276, No. 1-3, 2006, pp. 100-106. [ Links ]