Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.33 no.1 Bogotá Jan./Apr. 2013

W. D. Fernández-Gómez1, H. Rondón Quintana2 and F. Reyes Lizcano3

1 Wilmar Darío Fernández-Gómez. M. Sc., Dr. (c) Ingeniería. Universidad Javeriana, Colombia. Affiliation: Facultad del Medio Ambiente y Recursos Naturales, Universidad Distrital Francisco José de Caldas, Colombia. E-mail: wfernandez@udistrital.edu.co

2 Hugo Alexander Rondón Quintana. Ph. D. Affiliation: Facultad del Medio Ambiente y Recursos Naturales, Universidad Distrital Francisco José de Caldas, Colombia. E-mail: harondonq@udistrital.edu.co

3 Fredy Reyes-Lizcano. Ph. D. Affiliation: Departamento de Ingeniería Civil, Pontificia Universidad Javeriana, Colombia. E-mail: fredy.reyes@javeriana.edu.co

ABSTRACT

This paper presents an extensive review of the pertinent literature regarding asphalt and asphalt mixture aging. Aging affects flexible pavement performance and is produced by intrinsic and extrinsic variables as well as exposure time. Intrinsic variables include asphalt and aggregate properties, a mixture's asphalt content, binder film thickness and air void content; extrinsic variables are associated with production (short-term aging) and exposure to environmental field conditions (long-term aging). Taken together, both variables demonstrate that aging results from three distinct mechanisms: volatilisation, oxidation and steric hardening. Temperature, pressure and photo degradation treatments are used to simulate aging in the laboratory and empirical and semi-empirical models are created to represent and study aging. Aging increases asphalt complex modulus and decreases the phase angle. Mixtures become stiffer while fatigue life becomes reduced. Carbonyl and sulfoxide group formation in asphalt are often studied as such chemical changes show oxidation in aged asphalts. The prevailing models used to predict asphalt aging are discussed, though more comprehensive research into asphalt aging is still needed.

Keywords: Asphalt aging, asphalt mixture aging, oxidation, volatilization, steric hardening, aging models, aging testing.

RESUMEN

Este artículo presenta una revisión bibliográfica del fenómeno de envejecimiento que experimentan los asfaltos y las mezclas asfálticas. El envejecimiento afecta el desempeño de los pavimentos flexibles y la magnitud de sus efectos se debe a la combinación de las características de los materiales (variables intrínsecas) y los efectos ambientales (variables extrínsecas) que actúan sobre ellos. Las variables intrínsecas incluyen las propiedades del asfalto y los agregados, el contenido de asfalto en la mezcla, el espesor de la película de asfalto y el contenido de vacíos. Las variables extrínsecas corresponden a dos momentos de la mezcla asfáltica; el primero, conocido como envejecimiento a corto plazo, se asocia al proceso de producción y colocación de la mezcla, y el segundo, conocido como envejecimiento a largo plazo, se asocia a la exposición a condiciones ambientales en el campo durante el tiempo de servicio. El proceso de envejecimiento ocurre por medio de tres mecanismos: volatilización, oxidación y endurecimiento estérico. Para simular el fenómeno en el laboratorio, se llevaron a cabo pruebas de envejecimiento acelerado mediante temperatura, presión y fotodegradación y a partir de ellas se crearon modelos empíricos y semiempíricos. Como resultado de esas pruebas, se ha observado el incremento en el módulo complejo y la reducción del ángulo de fase de los asfaltos. En el caso de las mezclas, se aprecia que la rigidez también se incrementa y las mezclas tienden a ser frágiles, por lo que la vida de fatiga se reduce. Los cambios químicos se manifiestan en la formación y aumento en el tiempo de grupos funcionales de carbonilo y sulfóxido. Finalmente, algunos modelos utilizados para predecir el envejecimiento se discuten. Todo lo anterior permite afirmar que la investigación del fenómeno de envejecimiento es una importante tarea de la ingeniería de pavimentos.

Palabras clave: envejecimiento, asfaltos, mezcla asfáltica, oxidación, volatilización, endurecimiento estérico, modelos de envejecimiento, pruebas de envejecimiento acelerado.

Received: February 27th 2012 Accepted: March 13th 2013

Introduction

Weather conditions and time lead to asphalt mixture aging due to several conditions during mixing and construction in addition to service life (Airey, 2003). These two processes are referred to as short- and long-term aging, respectively ( Bell, 1989; Scholz, 1995; Vallerga, 1981), as the former takes a few hours and occurs while the asphalt mixture is hot whilst the latter spans the years after road construction during service life.

Aging stems from intrinsic and extrinsic variables; intrinsic variables include the materials and t characteristics of a particular asphalt mixture, the asphalt, the aggregates, air void content and the asphalt binder film over the aggregates (Kandhal and Chakraborty, 1996). Extrinsic variables consist of variables external to the mixture, such as mixing temperature regarding short-term aging and environmental conditions (i.e. ultraviolet radiation, temperature, rainfall) and time in long-term aging (Abbas et al., 2002; Lau et al., 1992; Lee, 1973; Traxler, 1963). These variables' interaction throughout the life of service results in a harder, more brittle asphalt mixture; hence, the mixture may crack. Asphalt mixtures undergo chemical, physical, mechanical and rheological changes causing an asphalt binder and asphalt mixture to harden.

Nathan et al., (2013) have reported asphalt materials' aging studies, omitting the influence of granular aggregate in bitumen aging. They have also reported that mixtures' effective binder content has provided the strongest indicator as to whether the parameters of a mixture being evaluated would have a significant influence on the aging characteristics of an asphalt binder in a particular mix.

Asphalt

Asphalt composition

Asphalt is a viscoelastic material which is derived from crude petroleum or from natural deposits; its chemical composition is complex, consisting mainly of carbon (80-88%) and hydrogen atoms (8-12%). Other elements, such as sulphur (0-9%), oxygen (0-2%) and nitrogen (0-2%) may also be present, as well as traces of vanadium, nickel and manganese (Lesueur, 2009; Petersen et al., 1994; Speight, 2007). Given such chemical complexity, it should be mentioned that asphalt's particular composition depends on its source and the distillation involved; asphalt chemistry should thus be studied regarding its molecular structure and molecular interactions.

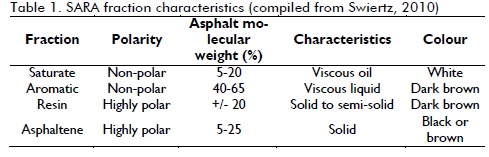

When the Strategic Highways Research Programme (SHRP 1987) began micelle modelling, this was the best available explanation for asphalt chemistry (Jones IV and T. W. Kennedy, 1991). Micelle modelling explains the how and the why of asphalt's viscoelastic behaviour; however, micelle modelling and colloidal modelling are both widely accepted today. Solid particles (asphaltenes) are dispersed within an oleaginous matrix (maltenes) in the colloidal model; asphaltene and maltene fractions are separated by elution absorption involving liquid chromatography on active alumina (Corbett, 1970). Maltenes are separated into saturate, aromatic, resin and asphaltene (SARA) fractions (Table 1). Asphaltene fractions are the solid particles responsible for aggregate adhesion and saturates and aromatics grant fluidity; thus combining saturates, aromatics and asphaltenes produces asphaltic flow conditions (Lesueur, 2009). By contrast, resins provide ductility.

Asphalts' molecular interactions are based on molecular size, composition, polarity and reactivity. Along with component distribution within dispersed polar fluids, these interactions determine asphalt's physical properties. Molecules attract and interact with each other through a variety of secondary forces which are weaker than covalent (strong) chemical bonding forces. Molecules in the fluid can form intermolecular bonds. Polar molecules are uniformly distributed throughout the fluid, but non-polar molecules serve as a matrix or solvent for polar molecules providing asphalts with their elastic properties. Bonds are brought about by temperature fluctuations and external stresses (Christensen and Anderson, 1992; Petersen, 2009) and, due to their weak nature, are constantly being broken and reformed.

Defining asphalt aging

Asphalt aging concerns the physical properties involved in asphalt change as time elapses because of changes in its chemical composition. These changes are produced by the interaction of intrinsic and extrinsic variables associated with short- and long-term aging. Aging mechanisms consist of volatilisation, oxidation and steric hardening. Whereas volatilisation and oxidation are produced by changes in molecular structure, steric hardening is produced by molecular reorganisation. Asphalt aging, also known as age hardening, describes hardening (Bell, 1989).

Mechanisms associated with asphalt binder aging

Aging is produced by three mechanisms: volatilisation of light asphalt components (Lesueur, 2009; Traxler, 1961), oxidation during service life (Petersen, 2009) and steric hardening. Volatilisation and oxidation are irreversible as they are prompted by chemical changes (Lu and Isacsson, 2000); steric hardening, though, can be reversed through heat or mechanical work (Swiertz, 2010) as it entails structural reorganisation of the molecule, produced by temperature changes (Petersen, 1984).

Volatilisation

The temperature increase during the production, storage, transport and laying of asphalt leads to volatilisation which links it to the short-term aging of the heated asphalt mixture. Temperatures reach and surpass 150oC at which point the asphalt fractions begin to evaporate. An additional 10 to 12oC could double volatile emissions (Read and Whiteoak, 2003).

Hot asphalt coats the aggregates with a thin film during asphalt mixture; this film's thickness ranges from 6 to 19 microns even though such thickness is not constant (Kandhal and Chakraborty, 1996; Petersen, 1989). When thin asphalt film comes into contact with aggregates at temperatures of 150oC or higher, aromatic fractions rapidly evaporate and asphaltenes generally increase between 1 and 4 wt% (Farcas, 1996). Steam and fumes are produced as a result of this reaction depending on the contact surface area between the asphalt film and the aggregates (Zupanick and Baselice, 1997). Although volatilisation primarily occurs during mixing, it may also occur during storage, transportation and laying.

Volatilisation's main effect is a loss of asphalt weight because of evaporation. Weight loss, in turn, reduces asphalt flow properties, i.e. viscosity is affected by volatilisation, especially given the speed with which volatilisation takes place. Researchers have found that viscosity increases from 150 to 400% (Bell, 1989; Christensen and Anderson, 1992).

Oxidation

Asphalt's complex organic components react with atmospheric oxygen and ultraviolet (UV) radiation. Atmospheric oxygen and UV radiation initially react with pavement surface. Given that the surface is harder, cracks may appear; after the cracks appear, air percolates into the asphalt layers and engenders oxidation. Oxidation penetrates up to 15 mm below the surface layer (Martínez and Caicedo, 2005). It progresses in a top-down fashion, for UV radiation increases energy levels, leading to carbon-carbon chains breaking and combining with oxygen (oxidation); this occurs naturally during a pavement's service life.

Oxidation produces changes in SARA fractions. Corbett and Mertz (1975) studied 18-year-old pavements, concluding that there was no significant loss of saturate fractions because of oxidation, while the other three SARA fractions did indeed exhibit significant variation. In addition to affecting three of the four SARA fractions, oxidation has been seen to reduce aromatics which first become resins and then asphaltenes (Farcas, 1996). Functional groups with oxygen have been formed in asphalt molecules, leading to decreased resin and aromatic fractions and increased asphaltene fractions (Lesueur, 2009). Bitumen oxidation can be explained by the formation of carbonyl and sulfoxide groups, and obeys first order kinetic reactions (Herrington, 1998).

Oxidative age hardening significantly contributes to pavement embrittlement in asphalt pavements, eventually resulting in excessive pavement cracking (Petersen, 2009). Non-polar molecules' real molecular weight plays an important role in pavement performance, especially at low temperatures, as thin asphalt pavements having excessive polar material will undergo fatigue cracking, thermal cracking and brittleness. Similarly, asphalts with too much non-polar material or asphalts having extremely low non-polar material molecular weight will experience fatigue cracking; moisture sensitivity and rutting have been observed in thick pavements (Jones IV and Kennedy, 1991).

Steric hardening

Steric hardening refers to asphalt hardening at room temperature as time elapses. This involves a molecular reorganisation of asphalt, affecting asphaltene fractions (Masson et al., 2005); this occurs within one day and may be reversible because of temperature fluctuations within the same day. Steric hardening effects include increased viscosity and slight volume contraction (Pechenyi and Kuznetsov, 1990; Traxler, 1961); steric hardening is mostly attributable to wax crystallisation, referring to the crystallisation of linear alkanes present in asphaltene fractions (Lesueur, 2009). This mechanism has also been called physical hardening.

Changes in asphalt binder properties

The mechanisms discussed so far produce several changes in cement asphalt properties. Regarding physical changes, laboratory results have demonstrated less penetration and ductility, as well as a higher softening temperature and ignition point (Siddiqui and Ali, 1999a, Rojas, Amado, Fernandez & Reyes, 2012). Molecular size causes these changes, ultimately reducing flow conditions. Mechanical changes have also been reported due to an increase in the moduli (mechanical and dynamic moduli) (Abbas et al., 2002; AbWahab et al., 1993; Airey et al., 2004; Al-Azri et al., 2006). These studies have shown that the moduli ratios before and after aging have reached 100% to 400%, depending on the asphalt. Stiffness alterations generate more permanent deformation and major cracking at low temperatures (Bell, 1989; Bell and Kliewer, 1995).

SARA fraction composition changes due to the interaction of intrinsic and extrinsic variables: aromatics become resins and resins become asphaltenes (Farcas, 1996; Petersen, 2009; Petersen, 1984; Qi and Wang, 2003, 2004a, 2004b; Siddiqui and Ali, 1999a, 1999b, Reyes, Daza & Rondón, 2012). These chemical changes involve larger, more polar molecular entities (Bahia and Anderson, 1995), evidenced by the formation of new functional groups, such as carbonyls and sulfoxides (Lesueur, 2009; Qi et al., 2009; Qi and Wang, 2004a; Siddiqui and Ali, 1999b). Molecular size increase forms an elastic response that is faster than the viscous response (a result of aging). Although molecular agglomeration reduces asphalt fluidity, and thus decreases the phase angle, the viscosity and complex moduli increase. Such aspects significantly alter asphalt's rheological properties.

Laboratory aging techniques

Treatments have focused on accelerating aging via temperature, oxidation and photo degradation. Myriad treatments have been used to age asphalt binders (Bahia et al, 1998; Dow, 1903; Edler et al., 1985; Griffin et al, 1955; Halstead and Zenewitz, 1961; Hveem et al., 1963; Zube and Skog, 1963; Kemp and Predoehl, 1981; Lee, 1973; Lewis and Welborn, 1940; Parmeggiani, 2000; Petersen, 1989; Qi and Wang, 2003; De la Roche et al., 2009; Traxler, 1963) and asphalt mixtures (Bell, 1989; Hugo and T. Kennedy, 1985; Kemp and Predoehl, 1981; Khalid and Walsh, 2000; Korsgaard et al., 1996; Pauls and Welborn, 1952; Von Quintus et al., 1991; Scholz, 1995). The thickness of asphalt cement film, which coats the aggregates, and asphalt mixtures' air void content have been considered regarding aging. Differing time intervals have been considered to account for both short- and long-term aging: from minutes and hours for short-term aging to days or months for long-term aging. Researchers have also studied pavement core extraction, taken after varying years of service life.

The Rolling Thin Film Oven Test (RTFOT) (Bahia et al., 1998) and the Pressure Aging Vessel (PAV) (Bahia and Anderson, 1995) test have now become the most common methods for simulating short- and long-term aging, respectively. RTFOT is a treatment in which a thin film of asphalt rolled inside a bottle is subjected to 163oC for 85 minutes with blowing air pressure. The PAV treatment involves using a chamber set at 100oC for 20 hours at 2.07 MPa pressure to reproduce aging effects. PAV treatment simulates between 6 to 8 years of pavement service life, according to USA standards. However, it should be born in mind that such aging does not necessarily correspond to the aging produced in other asphalts or weather conditions.

After aging acceleration treatment, samples are usually studied to recognise changes in their physical, chemical, mechanical and rheological properties (Table 2), based on a comparison of asphalt characteristics before and after aging treatment. Physical testing and SARA fractions paint a clearer picture of aging; physical testing alone is important for easily understanding the changes produced during asphalt aging. Penetration and ductility indicate the level of hardening, though they do not describe the phenomena so occurring. Chemical testing explains changes in molecular structure and molecular interactions after aging treatment/combinations of treatments. Changes in SARA fractions and functional groups accurately indicate aging. It would thus be prudent to consider both aspects when studying asphalt aging.

Mechanical and dynamic tests are used to ascertain performance indicators. Aging stiffens materials; stiffening is detrimental to asphalt from the very beginning of its service life (as it exacerbates fatigue, permanent deformation and cracking) and further into its service life (as it embrittles material).

Rheological changes reflect the viscoelastic properties of asphalttic material subjected to aging treatment. Rheological testing provides information about the stress-strain relation in viscoelastic materials, thereby helping to establish the constitutive equations of asphalt and asphalt binders used in different parts of the world, including Colombia. Allen et al., (2012) have evaluated aging through asphalt binder micro-rheological properties using atomic force microscopy.

The effects of different UV absorbers (octabenzone and bumetrizole) on bitumen's physical properties and photostability have been investigated by Feng et al., (2013); they used thin-layer chromatography with flame ionisation detection to analyse the likely mechanism of UV absorber on bitumen chemical transformation and ageing properties. The results indicated that bitumen ductility was significantly enhanced by adding a small amount of UV absorbers, especially by adding octabenzone, mainly attributed to an increase in bitumen's aromatic content. The influence of UV absorbers on bitumen photostability was seen to be dependent on bitumen origin and the type of UV absorber. Bitumen from different origins showed specific selectivity for different UV absorbers.

Aging models

Researchers have developed a wealth of models to tackle questions regarding asphalt behaviour related to the material's chemical, physical, mathematical and rheological aspects. Models have either been empirical, based on laboratory results or semi-empirical, based on a combination of laboratory results and constitutive equations concerning material behaviour.

One of the first mathematical expressions for asphalt hardening was the Aging Index (AI) (Griffin et al., 1955). It represented the asphalt viscosity ratio of a 5 micron asphalt sample before and after being subjected to a 2-hour aging treatment at 107oC:

where hA was viscosity after aging and hB was viscosity before such process (original asphalt viscosity).

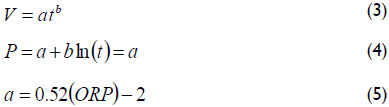

Another mathematical expression stemmed from a study of eight asphalt cements over 48 months conducted by Lee (Lee, 1973), using both temperature and oxidation treatments. The results led to a hyperbolic function being established for estimating the evolution of physical properties:

where T1 was the amount of time required to reach a certain property in the laboratory, Tf was the amount of time in the field (expressed in months) required to reach the same property and a and b were constants. The results showed that 46 months of laboratory aging equalled 60 months of aging in the field.

As opposed to Lee's hyperbolic model, Benson (Benson, 1976) established an exponential model; stronger correlations for penetration (P) and viscosity (V) were found. Constant a was a measure of short-term aging and b was the model's curvature:

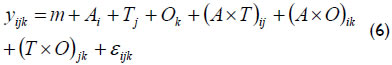

Shiau et al., (1992) developed a linear empirical model that included asphalt (A), temperature (T), oven (O) and these three variables' interactions. Shiau et al., arrived at the following expression by studying 20 asphalts using two ovens and three temperature levels:

This affirmed that viscosity was affected by temperature. The TFOT or RTFOT procedure performed at 185oF represented three months of Marshall specimens' natural weathering. Six to nine months of pavement aging would also have produced roughly the same hardening effects in typical paving grade asphalt used in Florida.

Huang et al., (Huang, Tia, and Ruth, 1996) applied Shiaus's model to modified asphalts in 1996. The RTFOT aging treatment at 185oC for 75 minutes seemed to simulate one year of field aging in typical Florida conditions, while 168 hours of California tilt oven durability treatment seemed to simulate eight years of field aging in typical Florida conditions.

Huh and Robertson's model (1996) spanned 800 hours, using a pressure aging vessel (PAV) having 2.07 MPa chamber pressure at 60oC, 80oC and 100oC. They adapted Arrhenius' chemical model which considers the speed of the chemical reaction based on particle collision, in addition to activation energy from diffusion:

where k(t) was the number of collisions in a reaction per second, A was a frequency or pre-exponential factor, Ea was the activation energy from diffusion, R was the gas constant and T was temperature. The exponential factor was the probability that any collision could turn into a reaction. Sulfoxide formation dominated the initial phase of oxidative aging (0-200 hours), having a concomitant increase in viscosity. Viscosity became constant during the following hours but then began to rise owing to carbonyl formation. Sulfoxide and carbonyl formation during oxidation thus increased viscosity.

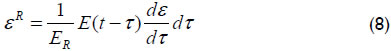

Daniel et al., (1998) used a mechanical model to investigate the effects of aging on asphalt aggregate mixtures; Schapery's elastic-viscoelastic correspondence principle was used to validate such effects. The researchers analysed changes in the viscoelastic properties and obtained dynamic moduli, relaxation moduli and the phase angle:

where εR was uniaxial strain, ER the arbitrary constant used as reference modulus, E(t) the uniaxial relaxation modulus, t the amount of time elapsed from specimen fabrication to the time of interest and τ was the time when loading began.

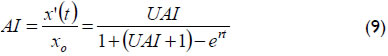

Chen and Huang (2000) studied the oxidative effect on asphalt using an empirical model. They used RTFOT and PAV treatments to simulate field aging and an experimental road was constructed for this study which allowed them to investigate real aging. Field and laboratory binders yielded comparable data when aged at 60oC under 20 kg/cm2 of pressure. Asphalt aging time regarding the PAV treatment depended on the amount of time pavements were used in the field. As the road test project demonstrated a strong correlation between field and laboratory aging, an aging model was proposed to predict changes in paving binder properties during field hardening. Chen and Huang developed a chemical- mathematical model including the aging rate and the changes of binder properties in terms of molecular association:

The Ultimate Aging Index (UAI) concerns the ratio of the maximum value to the initial value of x(t). The UAI represents the final increase in x as time elapses. As time became indefinite, the x value equalled the UAI. The r parameter was the aging rate indicating the increased rate in x over the range of UAI. These two parameters, r and UAI, can be used to compare pavements' aging rate and aging magnitude, respectively. The results closely agreed with experimental data from both laboratory and field aging tests.

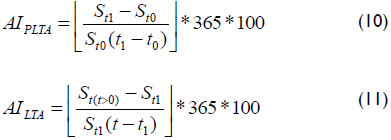

Said (2005) developed an Aging Index (AI) for comparing mixture patterns. AI was defined as the relative increase in stiffness moduli per year, expressed as a percentage:

where AI PLTA preceded the long-term aging index, representing the first year of service, while AI LTA was long-term aging, representing the pavement after the first year of service. S was the stiffness modulus at different times, t was time in days, t1 was the first year (365 days) and t0 time (15 to 30 days). This model demonstrated that stiffness increased by about 27% during the first year after laying and only 3.5% per year from year two to year four after laying, with a continued decline after four years of expected service.

Models have studied asphalt before and after aging; they have analysed the chemical, mechanical and rheological pattern of asphalt subjected to aging, but they cannot be reproduced in the field as they are based on isolated analysis of variables. For example, the Aging Index (Griffin et al., 1955) evaluated a sample's rheological changes after several temperature variations. Daniel's mechanical model evaluated the strain changes of a sample subjected to different loads. These models cannot be effectively compared and there is still no model that reproduces aging pattern taking into account both the intrinsic and extrinsic variables involved in asphalt aging. Only Said's Aging Index proposed a stiffness performance test for pavement after four years' service. However, this study was specifically designed for a specific asphalt, one supplier and one climatic zone. Researchers must thus establish a model which can analyse the intrinsic and extrinsic variables affecting asphalt mixtures to obtain a general model.

Xiao et al., (2012) developed an Artificial Neural Networks (ANN) model to simulate the long-term aging of three asphalt binders regarding seven aging variables such as aging temperature and duration, m-value, mass loss of pressurised aging vessel (PAV) samples, percentages of large and small molecular sizes of high pressure-gel permeation chromatographic (GPC) testing, and binder stiffness. They stated that ANN-based models are more effective than regression models and can easily be implemented in a spreadsheet. The proposed models cannot reproduce the reduction in performance brought about by aging and aging has not been included as an input variable in the aforementioned methods. Further research must study aging and its implications and also how this variable can be introduced into design guidelines. It is worth mentioning that aging depends on the characteristics of the materials and that each asphalt and aggregate is different, hence addressing the problem becomes quite difficult. The intrinsic goal is to produce asphalt pavements having higher performance and durability; this research would seem to pave the way towards such goal.

Anti-aging techniques

When polyethylene waste and rubber powder is added to asphalt as modifiers, they absorb the asphalt's light oil which can reduce free radical content and improve asphalt aging properties. Antioxidant- and anti-ozone agent-containing waste rubber power effectively improves asphalt anti-aging properties (Fang et al., 2013). Reed (2010), Dong and Tan (2011), Punith et al., (2012), Shatnawi (2012) and Ali and Sadek (2013) have reported an improvement in crumb rubber-modified asphalt resistance to short-term aging. Warm mix asphalt (WMA) technology is another way of decreasing aging in asphalt mixtures; according to Kim et al., (2013) using WMA technologies are effective in reducing polymer-modified asphalt (PMA) mix aging level. Jamshidi et al., (2013) mentioned that reduced WMA asphalt binder aging was due to reduced volatilisation and oxidation because of lower construction temperatures. Ying et al., (2013) used gel permeation chromatography (GPC) for analysing SBS-modified asphalt, showing that small molecules become larger one in asphalt and SBS polymer molecules become degraded during aging. SBS polymer may lose its modifying function after aging for a long time.

Pan et al., (2012) have stated that the current state of knowledge regarding asphalt oxidation and antioxidant evaluation has focused on determining the degradation of asphalt's physical properties, mainly viscosity and ductility. Such practice does not contribute towards fundamental understanding of aging and anti-oxidation mechanisms and thereby hampers anti-aging strategies being developed.

Conclusions

Asphalt aging is complex and causes functional damage to asphalt. The aging mechanism negatively affects pavement flexibility (performance) after years of service life. The most important damage engendered by aging is cracking and a reduction of asphalt fatigue life due to asphalt binder stiffness. Aging can be understood in terms of two stages: short-term and long-term aging; the former takes place during mixing in a plant, during production and during the storage, transport and laying of an asphalt mixture, volatilisation and, to some degree, oxidation during short-term aging, making it the more severe type of aging. Long-term ageing is produced throughout asphalt's service life, resulting from oxidation due to UV radiation, humidity and rain; steric hardening happens during long-term aging at room temperature.

Environmental conditions and the characteristics of a hot asphalt mixture cause asphalt aging. Aging consequences include chemical changes in the asphalt binder (i.e. modifications in molecular structure and molecular relations). Chemical changes come from volatilisation of the resin fractions due to mixture temperature, oxidation due to humidity and water vapour and steric hardening due to room temperature; binder mass decreases as a result of volatilisation. Oxidation leads to increased carbonyl and sulfoxide groups, as carbon bonds break. Steric hardening alters binder volume and stiffens the top of the pavement. Because a stiffer binder can crack under traffic load and cracks can develop inside pavement (up to 15 millimetres deep), steric hardening is a significant cause for concern in aging studies.

Many (empirical or semi-empirical) models have been proposed for predicting aging. Current models cannot reproduce the effects of aging in asphalt and asphalt mixtures, instead resorting to simulation and prediction. Some flexible pavement design guidelines do not even consider aging. Future research must be orientated towards discovering the characteristics of aging and the effect it has on asphalt mixtures to formulate an aging model which is close to real conditions.

References

Abbas, A., Choi, B. C., Masad, E., Papagiannakis, T., The influence of laboratory aging method on the rheological properties of asphalt binders., Journal of Testing and Evaluation, Vol. 30, 2002, pp. 171-176. [ Links ]

Ab Wahab, Y., Sosnovske, D., Bell, C., Ryus, P., Evaluation of asphalt-aggregate mixture aging by dynamic mechanical analysis. Transportation Research Record., 1993, pp. 22-30. [ Links ]

Airey, G., State of the art report on ageing test methods for bituminous pavement materials., International Journal of Pavement Engineering, Vol. 4, 2003, pp. 165-176. [ Links ]

Airey, G., Rahimzadeh, B., Collop, A., Linear rheological behavior of bituminous paving materials., Journal of Materials in Civil Engineering, Vol. 16, 2004, pp. 212. [ Links ]

Al-Azri, N. A., Jung, S. H., Lunsford, K. M., Ferry, A., Bullin, J. A., Davison, R. R., Glover, C. J., et al., Binder oxidative aging in Texas pavements - hardening rates, hardening susceptibilities, and impact of pavement depth., Bituminous Materials and Nonbituminous Components of Bituminous Paving Mixtures 2006, Transportation Research Record, 2006, pp. 12-20. [ Links ]

Allen, R. G., Little, D. N. Bhasin, A., Structural characterization of micromechanical properties in asphalt using atomic force microscopy., Journal of Materials in Civil Engineering, Vol. 24, No. 10, October 1, 2012, pp. 1317-1327. [ Links ]

Ali, B., Sadek, M., Experimental analysis of the influence of crumb rubber addition on the short-term aging of Syrian asphalt., Arabian Journal of Geosciences, Vol. 6, No. 1, January, 2013, pp. 85-90. [ Links ]

Bahia, H. U., Anderson, D. A., The Pressure Aging Vessel (PAV): a test to simulate rheological changes due to field aging., Physical Properties of Asphalt Cement Binders, 1995, pp. 67-88. [ Links ]

Bahia, H. U., Hislop, W. P., Zhai, H., Rangel, A., Classification of asphalt binders into simple and complex binders., Journal of the Association of Asphalt Paving Technologists, 1998, pp. 67. [ Links ]

Bell, A., Summary report on the aging of asphalt-aggregate systems., Transportation Research Board, Vol. 10, 1989, pp. 1-121. [ Links ]

Bell, C. A., Kliewer, J. E., Sosnovke, Investigation of the relationship between field performance and laboratory aging properties of asphalt mixtures. G. A. Huber, D. S. Decker. (Eds.), Engineering properties of asphalt mixtures and the relationship with their performance. ASTM STP 1265., Philadelphia, American Society for Testing and Materials. [ Links ]

Benson, P. E., Low temperature transverse cracking of asphalt concrete pavements in central and west Texas., Texas Transportation Institute, Texas A & M University, 1976. [ Links ]

Chen, J., Huang, L., Developing an aging model to evaluate engineering properties of asphalt paving binders., Materials and Structures, Vol. 33, 2000, pp. 559-565. [ Links ]

Christensen, D. W., Anderson, D. A., Interpretation of dynamic mechanical test data for paving grade asphalt cements (with discussion)., Journal of the Association of Asphalt Paving Technologists, Vol. 61, 1992. [ Links ]

Corbett, L. W., Relationship between composition and physical properties of asphalt., Proceedings of the Association of Asphalt Paving Technologists, Vol. 39, pp. 481. [ Links ]

Corbett, L. W., Merz, R. E., Asphalt binder hardening in the Michigan Test Road after 18 years of service., Transportation Research Record, No. 544, 1975. [ Links ]

Daniel, J., Kim, Y., Lee, H.-J., Effects of aging on viscoelastic properties of asphalt-aggregate mixtures., Transportation Research Record: Journal of the Transportation Research Board, Vol. 1630, No. 1, 1998, pp. 21-27. [ Links ]

Dong, Y., Tan, Y., Mix design and performance of crumb rubber modified asphalt SMA., Geotechnical Special Publication, Vol. 212, ASCE, 2011, pp. 78-86. [ Links ]

Dow, A. W., Asphalt experiments at Washington., Engineering News Record, Vol. 47, 1903, pp. 18-25. [ Links ]

Edler, A. C., Hattingh, M. M., Servas, V. P., Marais, C. P., Use of aging tests to determine the efficacy of hydrated lime additions to asphalt in retarding its oxidative hardening., Asphalt Paving Technology, Association of Asphalt Paving Technologists, Vol. 54, 1985, pp. 118-139. [ Links ]

Fang, Ch., Wu, C., Yu, R., Zhang, Z., Zhang, M., Zhou, S., Aging properties and mechanism of the modified asphalt by packaging waste polyethylene and waste rubber powder., Polymers for Advanced Technologies, Vol. 24, No. 1, January, 2013, pp. 51-55. [ Links ]

Farcas, F., Etude d'une methode de simulation du vieillissement sur route des bitumes., Laboratoire Central des Ponts et Chausses, 1996. [ Links ]

Feng, Z. G., Yu, J. Y., Kuang, D. L., The physical properties and photostability of bitumen with different ultraviolet absorbers., Petroleum Science and Technology, Vol. 31, 1996, pp. 113-120. [ Links ]

Griffin, R. L., Miles, T. K., Penther, C. J., Microfilm durability test for asphalt., Association of Asphalt Paving Technologists Proceedings, Vol. 34, 1955, pp. 31. [ Links ]

Halstead, W. J., Zenewitz, J. A., Changes in asphalt viscosities during thin-film oven and microfilm durability tests., Public Roads, Vol. 31, No. 11, 1961, pp. 211-218. [ Links ]

Herrington, P. R., Oxidation of bitumen in the presence of a constant concentration of oxygen., Petroleum Science and Technology, Vol. 16, No. 9, 1998, pp. 1061-1084. [ Links ]

Huang, S. C., Tia, M., Ruth, B. E., Laboratory aging methods for simulation of field aging of asphalts., Journal of Materials in Civil Engineering, Vol. 8, 1996, pp. 147. [ Links ]

Hugo, F., Kennedy, T., Surface cracking of asphalt mixtures in Southern Africa., Proceedings of the Association of Asphalt Paving Technologists, 1985, pp. 454-501. [ Links ]

Huh, J., Robertson, R., Modeling of oxidative aging behavior of asphalts from short-term, high-temperature data as a step toward prediction of pavement aging., Transportation Research Record: Journal of the Transportation Research Board, Vol. 1535, 1996, pp. 91-97. [ Links ]

Hveem, F. N., Zube, E., Skog, J., Proposed new tests and specifications for paving grade asphalts., Proceedings of the Association of Asphalt Paving Technologists, Vol. 32, 1963, pp. 271-327. [ Links ]

Jamshidi, A., Hamzah, M. O., You, Z., Performance of warm mix asphalt containing sasobit: state-of-the-art., Construction and Building Materials, Vol. 38, 2013, pp. 530-553. [ Links ]

Jones IV, D. R., Kennedy, T. W., The Asphalt Model: Results of the SHRP Asphalt Research Program., Transportation Research Board VTI Rapport 372A, Part 4, 1991. [ Links ]

Kandhal, P. S., Chakraborty, S., Effect of asphalt film thickness on short-and long-term aging of asphalt paving mixtures., Transportation Research Record: Journal of the Transportation Research Board, Vol. 1535, No. 1, 1996, pp. 83-90. [ Links ]

Kemp, G. R., Predoehl, N. H., A comparison of field and laboratory environments on asphalt durability., Proceedings of the Association of Asphalt Paving Technologists, Vol. 50, 1981, pp. 492-537. [ Links ]

Khalid, H. A., Walsh, C. M., Relating mix and binder fundamental properties of aged porous asphalt materials., Proceedings of the 2nd Eurasphalt and Eurobitume Congress, Vol. 1, 2000, pp. 398-405. [ Links ]

Kim, H., Lee, S.-J., Amirkhanian, S. N., Jeong, K., Quantification of oxidative aging of polymer-modified asphalt mixes made with warm mix technologies., Journal of Materials in Civil Engineering, Vol. 25, No. 1, January, 2013, pp. 1-8. [ Links ]

Korsgaard, H. C., Blumensen, J., Sundahl, J., Gonzales, C., Accelerated ageing of asphalt in pressure ageing vessel., Proceedings of the 1st Eurasphalt and Eurobitume Congress, European Asphalt Pavement Association, 1996, pp. 11. [ Links ]

Lau, C., Lunsford, K., Glover, C., Davison, R., Bullin, J., Reaction rates and hardening susceptibilities as determined from pressure oxygen vessel aging of asphalts., Transportation Research Record, Vol. 1342, 1992, pp. 8. [ Links ]

Lee, D., Asphalt durability correlation in Iowa., Transportation Research Record, Vol. 468, 1973, pp. 43-60. [ Links ]

Lesueur, D., The colloidal structure of bitumen: consequences on the rheology and on the mechanisms of bitumen modification., Advances in Colloid and Interface Science, Vol. 145, No. 1-2, 2009, pp. 42-82. [ Links ]

Lewis, R. H., Welborn, J. Y., Report on the properties of the residues of 50-60 and 85-100 penetration asphalts from oven tests and exposure., Proceedings, Association of Asphalt Paving Technologists, Vol. 11, 1940, pp. 86-157. [ Links ]

Lu, X., Isacsson, U., Artificial aging of polymer modified bitumens., Journal of Applied Polymer Science, Vol. 76, No. 12, 2000, pp. 1811-1824. [ Links ]

Martínez, G., Caicedo, B., Efecto de la radiación ultravioleta en el envejecimiento de ligantes y mezclas asfálticas., Master Thesis, Universidad de Los Andes, Bogotá- Colombia, 2005. [ Links ]

Masson, J.-F., Collins, P., Polomark, G., Steric hardening and the ordering of asphaltenes in bitumen., Energy and Fuels, Vol. 19, No. 1, 2005, pp. 120-122. [ Links ]

Nathan, M., Hajj, E. Y., Sebaaly, P. E., Significance of mixture on binder aging in HMA mixtures. In: 92nd Annual Meeting of Transportation Research Record, Washington D.C., January, 2013. [ Links ]

Parmeggiani, G., Nitrogen Rolling Thin Film Oven Test., Proceedings of the 2nd Eurasphalt and Eurobitume Congress, Session 2: Development in Bituminous products and Techniques, 2000, pp. 432-437. [ Links ]

Pan, T. Y., Sun, L., Yu, Q., An atomistic-based chemophysical environment for evaluating asphalt oxidation and antioxidants., Journal of Molecular Modeling, Vol. 18, No. 12, December, 2012, pp. 5113-5126. [ Links ]

Pauls, J. T., Welborn, J. Y., Studies of the hardening properties of asphaltic materials., Transportation Research Board, Washington, DC, Vol. 21, No. 18, 1952. [ Links ]

Pechenyi, B. G., Kuznetsov, O. I., Formation of equilibrium structures in bitumens., Chemistry and Technology of Fuels and Oils, Vol. 26, No. 7, 1990, pp. 372-376. [ Links ]

Petersen, J. C., Robertson, R. E., Branthaver, J. F., Harsenberg, P. M., Duvall, J. J., Kim, S. S., Anderson, D. A., Christiansen, D. W., Bahia, H. U., Binder characterization and evaluation. Strategic Highway Research Program., Vol. 1, 1994. [ Links ]

Petersen, J. C., A review of the fundamentals of asphalt oxidation: chemical, physicochemical, physical property, and durability relationships., Transportation Research E-Circular, Vol. 1, Transportation Research Board, 2009. [ Links ]

Petersen, J., Chemical composition of asphalt as related to asphalt durability: state of the art., Transportation Research Board, Vol. 999, 1984, pp. 13-30. [ Links ]

Petersen, J., A thin film accelerated aging test for evaluating asphalt oxidative aging., Transportation Research Board, Vol. 58, 1989, pp. 220-237. [ Links ]

Punith, V. S., Suresha, S. N., Sridhar, R., Sunil, B., Veeraragavan, A., Laboratory investigation of open-graded friction course mixtures containing polymers and cellulose fibers., Journal of Transportation Engineering, Vol. 138, No. 1, January, 2012, pp. 67-74. [ Links ]

Qi, L., Zhang, Z. Q., Sho, A. M., Yang, H. J., Research on relationship between aging state and low-temperature performance of asphalt mixture., Journal of Testing and Evaluation, Vol. 37, 2009, pp. 486-489. [ Links ]

Qi, Y., Wang, F., Study and evaluation of aging performance of petroleum asphalts and their constituents during oxygen absorption. I. Oxygen absorption behaviors and kinetics., Petroleum Science and Technology, Vol. 21, No. 1, 2003, pp. 283-299. [ Links ]

Qi, Y., Wang, F., Study and evaluation of aging performance of petroleum asphalts and their constituents during oxygen absorption. II. Chemical group composition and structure changes., Petroleum Science and Technology, Vol. 22, No. 3, 2004, pp. 263-274. [ Links ]

Qi, Y., Wang, F., Study and evaluation of aging performance of petroleum asphalts and their constituents during oxygen absorption. III. Average molecular structure parameter changes., Petroleum Science and Technology, Vol. 22, No. 3, 2004, pp. 275-286. [ Links ]

Von Quintus, H. L., Scherocman, J. A., Hughes, C. S., Kennedy, T. W., NCHRP Report 338: Asphalt Aggregate Mixture Analysis System (AAMAS)., Washington, DC, Transportation Research Board, National Research Council, 1991. [ Links ]

Read, J., Whiteoak, D., The Shell Bitumen Handbook., Thomas Telford, 2003. [ Links ]

Reed, J., Evaluation of the effects of aging on asphalt rubber pavements., MSC thesis, Arizona State University, December, 2010. [ Links ]

Reyes, F. A., Daza, C. E., Rondón, H. A., Determination of SARA fractions of environmentally aged Colombian asphalts using liquid chromatography column., Revista EIA, No. 17, 2012, pp. 47-56. [ Links ]

Rojas, J., Amado, H., Fernández, W., Reyes, F., Efectos de la radiación ultravioleta en asfaltos colombianos., Revista Cientifica Universidad Distrital, Vol. 15, 2012, pp. 96-104. [ Links ]

De la Roche, C., Van de Ven, M., Gabet, T., Dubois, V., Grenfell, J., Porot, L., Development of a laboratory bituminous mixtures ageing protocol., Advanced Testing and Characterization of Bituminous Materials, Vol. 331, 2009. [ Links ]

Said, S. F., Aging effect on mechanical characteristics of bituminous mixtures., Bituminous Binders 2005, Transportation Research Record, 2005, pp. 1-9. [ Links ]

Scholz, T. V., Durability of Bituminous Paving Mixtures., University of Nottingham, 1995. [ Links ]

Shatnawi, S., Superior aging characteristics of asphalt rubber. In: Asphalt Rubber Conference 2012, Munich, October 23rd, 2012, pp. 1-27. [ Links ]

Shiau, J., Tia, M., Ruth, B., Page, G., Evaluation of aging characteristics of asphalts by using TFOT and RTFOT at different temperature levels., Transportation Research Board, Vol. 1342, 1992, pp. 58-66. [ Links ]

Siddiqui, M. N., Ali, M. F., Studies on the aging behavior of the Arabian asphalts., Fuel, Vol. 78, No. 9, 1999, pp. 1005-1015. [ Links ]

Siddiqui, M. N., Ali, M. F., Investigation of chemical transformations by NMR and GPC during the laboratory aging of Arabian asphalt., Fuel, Vol. 78, No. 12, 1999, pp. 1407-1416. [ Links ]

Speight, J. G., The chemistry and technology of petroleum., 4th ed., Springer, 2007. [ Links ]

Swiertz, D., Asphalt aging characteristics, rheological implications and laboratory techniques., Madison, University of Wisconsin, 2010. [ Links ]

Traxler, R. N., Relation between asphalt composition and hardening by volatilization and oxidation., Proceedings, Association of Asphalt Paving Technologist, Vol. 30, 1961, pp. 359-372. [ Links ]

Traxler, R., Durability of asphalt cements., Association of Asphalt Paving Technologist, Vol. 32, 1963, pp. 44-63. [ Links ]

Vallerga, B., Pavement deficiencies related to asphalt durability., Association of Asphalt Paving Technologist, Vol. 50, 1981, pp. 481-491. [ Links ]

Xiao, F., Amirkhanian, S. N., Juang, H., Hud, S., Shen, H., Model developments of long-term aged asphalt binders., Construction and Building Materials, Vol. 37, 2012, pp. 248-256. [ Links ]

Ying, G., Fan, G., Li, Z., Thermal oxidative aging characterization of SBS modified asphalt., Journal of Wuhan University of Technology-Mater, Vol. 28, No. 1, February, 2013, pp. 88-91. [ Links ]

Zupanick, M., Baselice, V., Characterizing asphalt volatility., Transportation Research Record: Journal of the Transportation Research Board, Vol. 1586, No. -1, 1997, pp. 1-9. DOI:10.3141/1586-01. [ Links ]