Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.33 no.1 Bogotá Jan./Apr. 2013

D. Vargas1, D.Chaves2, M. Trujillo3, J. Piñeres4 and J. Barraza5

1 Diana Vargas. M. Sc. Candidate, Ingeniera química, Universidad del Valle, Colombia. Affiliation: Universidad del Valle, Colombia. E-mail: diana_isa85@hotmail.com

2 Deisy Chaves Sanchez. Ingeniería de Sistemas, Universidad del Valle, Colombia. Affiliation: Escuela de Ingeniería de Sistemas y Computación, Universidad del Valle, Colombia. E-mail: deisy.chaves@correounivalle.edu.co

3 Maria Patricia Trujillo Uribe. Ph. D. Estadística, Universidad del Valle, Colombia. Affiliation: Escuela de Ingeniería de Sistemas, Universidad del Valle.

E-mail: maria.trujillo@correounivalle.edu.co

4 Jorge Luis Piñeres Mendoza. Ph. D. Ingeniería Química, M. Sc. Ingeniería Química, Ingeniero Químico. Affiliation: Escuela de Ingeniería Química, Universidad del Valle, Colombia. E-mail: luispin@univalle.edu.co

5 Juan Manuel Barraza Burgos. Ph. D. Ingeniería Química, M. Sc. Ingeniería Química, Ingeniero Químico. Affiliation: Escuela de Ingeniería Química, Universidad del Valle, Colombia. E-mail: juan.barraza@correounivalle.edu.co

How to cite: Vargas, D., Chaves, D., Trujillo, M., Piñeres, J., Barraza, J., Beneficiated coals' char morphology., Ingeniería e Investigación Journal, Vol. 33, No.1, Apr., 2013, pp. 13-17.

ABSTRACT

This work evaluated the char morphology of beneficiated and original coal (without beneficiation) from four Colombian coalmines: Cerrejón (La Guajira), La Jagua (Cesar), Guachinte (Valle del Cauca) and Nechí (Antioquia). Column flotation was used to obtain beneficiated coal, whereas a drop tube reactor at 1,000oC, 104 oC/s heating rate and 100 ms residence time was used to obtain char. The chars were analysed by image analysis which determined their shape, size, porosity and wall thickness. It was found that char morphology depended on coal rank and maceral composition. Morphological characteristics like high porosity, thinner walls and network-like morphology which are beneficial in improving combustion were present in vitrinite- and liptinite-rich lowest-ranking coals. Beneficiated coals showed that their chars had better performance regarding their morphological characteristics than their original coal chars.

Keywords: morphology, char, devolatilisation, beneficiation, image analysis.

RESUMEN

Este trabajo evaluó la morfología de carbonizados beneficiados y sin beneficiar (originales) de cuatro carbones colombianos: El Cerrejón (Guajira), La Jagua (Cesar), Guachinte (Valle) y Nechí (Antioquia). Los carbones beneficiados se obtuvieron usando un proceso de flotación en columna, mientras que los carbonizados, en un reactor tubular de caída a 1000 oC, con una velocidad de calentamiento de 104 oC/s y un tiempo de residencia de 100 ms. Los carbonizados se analizaron usando análisis de imagen, con la cual se determinó su forma, tamaño, porosidad y espesor de pared. Se encontró que la morfología de los carbonizados depende del rango del carbón y de su composición maceral. Características morfológicas tales como alta porosidad, menor espesor de pared y morfología tipo red, adecuadas para una mejor combustión, se encontraron en los carbones de menor rango y ricos en vitrinita y liptinita. Se halló que los carbonizados de carbones beneficiados poseen mejores características morfológicas en comparación con los carbonizados de carbones originales.

Palabras clave: caracterización morfológica, carbonizados, desvolatilización, beneficio, análisis de imagen.

Received: October 31th 2011 Accepted: November 9th 2012

Introduction

Pulverised coal combustion is widely used for generating electricity; coal is crushed, pulverised and injected into a boiler by pressurised air. Pulverised coal has a vast surface area; this facilitates its combustion in the burners (Lawrence, 1998). Such combustion consists of two stages. The first stage comprises rapid pyrolysis in which gases, volatile material and non-volatile tar products are produced and a solid called char forms; this undergoes morphological determinant changes for its later reactivity. After this stage, a series of homogeneous gas-gas reaction and heterogeneous gas-liquid and gas-solid reactions are produced amongst the products generated in the first stage, including char oxidation which represents the dominant stage of the overall combustion process (Rojas and Barraza, 2007).

Char morphology depends on the original coal's characteristics, e.g. maceral type, rank, particle size, content and mineral matter type and on process variables, such as formation temperature, heating velocity, gaseous atmosphere and residence time. Yu (2007) and Cloke (2000) showed that char structure depends on coal rank and is linked to its thermoplastic properties during its heating. Low-rank chars produce network-type structures. An increase in its aromaticity and fusibility takes place as it increases its rank; the network-type char becomes reduced and then a spherical-type char is formed.

It is known that liptinite and vitrinite maceral (which are highly reactive) produce highly porous chars, whereas inertinite produces a high concentration of thick-walled, slightly porous and solid type chars (Barranco, 2001).Knowing how such coal characteristics work and ascertaining the effect of the operating conditions allows combustion optimisation regarding designing burners and improving processes. This leads to knowing which coal is most reactive, the time necessary to reduce the quantity of unburned-coal and energy loss due to ash heating (Rojas and Barraza, 2008). A possible strategy for achieving the previously inferred concept could lie in using beneficiated coal which has a high concentration of reactive maceral, such as liptinite or vitrinite.

The char morphology of four Colombian coals having different ranks and their maceral compositions with and without being beneficiated were determined in this work.

Experimental

Colombian coals from El Cerrejón (Guajira), La Jagua (César), Guachinte (Valle), and Nechí (Antioquia) were used in the experiment. Column flotation was used to obtain beneficiated coals (Piñeres, 2008). These coals were characterised by proximate analysis in line with standard ASTM D5142 (2005). Coal samples having less than 76 µm particle size were used.

Chars were obtained in a tubular reactor. An original coal and a nitrogen-oxygen mixture fed the reactor where devolatilisation took place. An amount of 1% and 2% oxygen was used for facilitating tar oxidation and avoiding char particle condensation. Coal particle residence time in the reactor was 100 ms, at 1,000oC and 104oC/s heating velocity. These conditions were in line with average operation conditions used in industrial pulverised-coal combustion systems.

A liquid resin and its respective hardener were used for preparing a char probe. The solid made up of coal-resin-hardener was smoothed with water sandpaper and polished using 0.5, 0.3 and 0.05 µm alumina suspensions.

A metallographic microscope was used for char image analysis in a room lit with white light; 20x resolution was used. The microscope had a chamber which captures an image and digitises it in a 1,600x1,200-pixel matrix. LUCIA G software (5.3-version) was used for capturing and editing images. Around 200 images were captured to obtain 500 individual particles from these chars.

Software called module for processing char images (MPCI) was used for automatic analysis of the char images; it identified char particles and characterised them regarding their external area: Feret's minimal and maximum diameter, the number of pores, percentage wall thickness bigger than 5 µm, average wall thickness, porosity and sphericity. The software classified every char particle according to the codification proposed by Alvarez and Lester (2010).

Results and Discussion

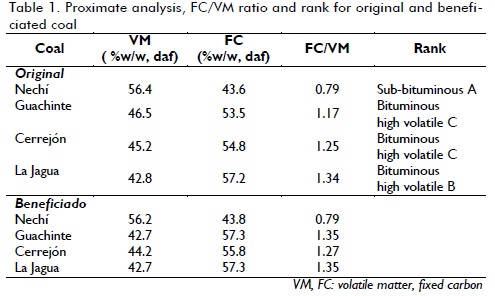

Table 1 shows the proximate analysis and fixed carbon/volatile matter (FC/VM) fuel ratio results for the four coals (both beneficiated and original), dry ash free (daf). It was observed that Nechí coal had the highest volatile matter content in both the original and beneficiated coal, and La Jagua coal had the lowest content. El Cerrejón and La Jagua coals had similar fixed carbon values, having the highest content of the four coals.

The FC/VM ratio had its lowest value in Nechí coal, followed by Guachinte, El Cerrejón and La Jagua coals; this trend was also observed in the beneficiated coals. Coal having a low FC/VM ratio could be considered to be more reactive to combustion because they were characterised by having high oxygen content helping ignition and improving both combustion and flame stability, which depends on volatile matter content (Lawrence, 1998).

Table 1 also shows the original coal's rank classification according to ASTM D388-09 standards (2005). It was observed that Nechí coal represented the lowest ranking coal, whereas La Jagua coal had the highest rank.

Char characterisation

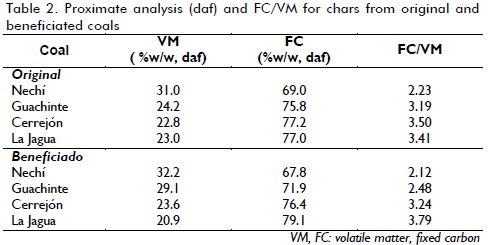

Table 2 presents the proximate analysis (daf) for the chars obtained from the original and beneficiated coal. It can be observed that the chars were not entirely devolatilised. Nechí coal had a considerable quantity of volatile remains in its chars, as well as beneficiated coal chars, which had more remaining volatile matter than char from original coals.

Such volatile remains play a significant role in coal combustion, especially when the remaining volatile char matter ignites, thereby helping flame stability. Rojas (2005) found that the chars' maximum reactivity (value of reactivity at maximum velocity regarding weight loss at a certain temperature) was greater at low devolatilisation times since char particles having higher volatile-remaining content were obtained. The control stage is determined by char oxidation during combustion; this stage takes place in a few seconds, by comparison with the milliseconds taken by devolatilisation.

The CF/MV ratio for chars from all coals was higher than that of original and beneficiated coals. Nevertheless, the trend was conserved as Nechí coal could be more reactive for having the lowest CF/MV ratio, whereas La Jagua and El Cerrejón coals were the least reactive.

Image analysis

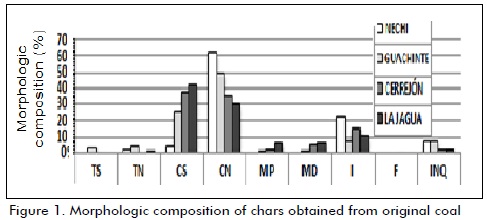

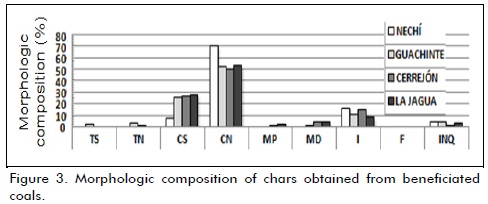

According to the morphologic classification proposed by Alvarez and Lester (2010), the chars were classified as tenuisphere (TS, spherical, thin wall), tenuinetwork (TN, pore network, thin wall), crassisphere (CS, spherical, thick wall), crassinetwork (CN, pore network of thick wall), mixed porous (MP, pore-dense mixture with pore predominance), mixed dense (pore-dense mixture with dense part predominance), inertoid (I, Inertoids), fusinoide (F, solids) and unburned (INQ, coal fragments not devolatilised).

The morphology of chars from original coals

Figure 1 shows the morphologic composition of chars obtained from original coal. It was observed that all 4 coals developed a high proportion of thick-wall morphology (CS and CN char type), followed by inertoid type.

Thin wall morphology was almost void in the chars. Nechí coal had a high percentage of network-type, thick wall CN (62.9%) chars and remarkably low spherical-type CS (4.2%) chars, whereas La Jagua coal had a high percentage of CS and the lowest CN percentage for the four coals.

Figure 1 also shows that CS, MP and MD increased with coal rank as well as a decrease in CN. This was possibly due to the fact that as rank increased, aromaticity and fusibility increased as well, this being reflected in larger particle swelling during pyrolysis. This modified char morphology to spherical shapes. Similar results were obtained in Rojas' work (2005). However, thin-wall TS and TN char production was low for all coals; low rank coals (Nechi and Guachinte) had the highest values (3.7% and 2.0%, respectively).

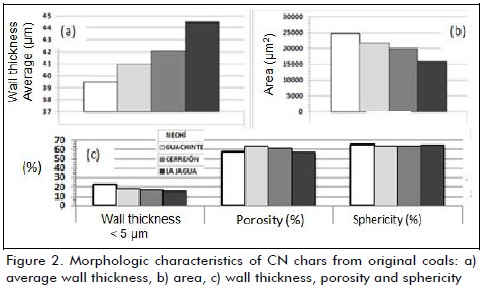

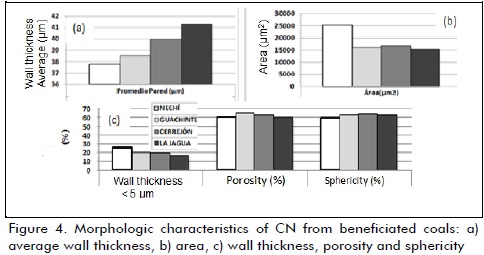

Figure 2 shows properties such as wall thickness, porosity, area and sphericity of char having CN morphology from original coal. Both wall thickness and char percentage with wall thickness larger than 5 µm was lower in Nechí coal, followed by Guachinte, Cerrejón and La Jagua coal. Porosity and surface area tended to decrease with rank. Char porosity has significant importance in coal combustion; chars having high porosity are usually more reactive. Besides, wall thickness affects oxygen transport inside the char structure, allowing better diffusion inside a particle and increasing the area available for the reaction.

Network-type morphology (associated with large surface area) has more reactivity to combustion compared to reactivity in cenospheric chars. This is probably due to accessible surface area variation and the release or retention of volatiles during the plastic stage (Rojas, 2005). Zhu et al., (2008) found out that the effect of particle-size on coal production was related to particle heating speed and volatiles' secondary reactions inside coal particles.

Taking into account that all such morphologic characteristics influence coal reactivity, it is believed that the most reactive particles are those which have a thinner walls, high porosity, network-type morphology and a large surface area. Following these parameters in an ascending order, the combustion reactivity of the four coals was Nechí>Guachinte>Cerrejón>La Jagua. These results agreed with those obtained from the CF/MV index as well as the coal rank they represented.

The morphology of char from beneficiated coals

Figure 3 shows the morphologic composition of chars from beneficiated coals. Once again, a high proportion of CN and CS chars occurred. The percentage of CS, MD and MP chars tended to increase with coal rank, whereas CN and I morphologies tended to become reduced. It can be observed in Figure 4 that both wall thickness and the percentage of chars having wall thickness higher than 5 µm of CN was lower in Nechí coal followed by Guachinte, Cerrejón and La Jagua. Porosity and surface area tended to become reduced with coal rank.

Comparing original and beneficiated char morphologies

The four coals had high CN and CS percentage in chars obtained from original and beneficiated coal. MP, MD and I solid-type morphologies became reduced in line with unburned percentage. Increased CS and CN morphology (considered the most reactive) and the decrease of solid-type chars (less reactive due to their higher non-fusible material content) made beneficiated chars more appropriate for combustion than their original coals.

There was an unburned-morphology reduction in all cases, suggesting that devolatilisation was more efficient.

A decrease in average wall thickness and an increase in low wall thickness percentage up to 5 µm, as well as in beneficiated coal porosity, was observed by comparing the morphologic characteristics of chars obtained from coals with and without being beneficiated, suggesting that they were more reactive than their respective original coals.

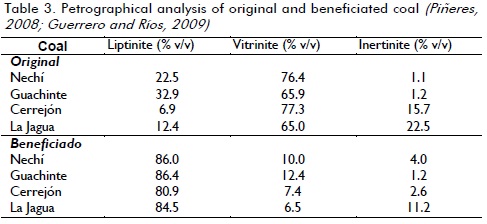

The relationship between char morphological properties and coal petrographical characteristics

Table 3 shows original and beneficiated petrographical analysis (Piñeres, 2008; Guerrero and Ríos, 2009) and chars obtained from each coal were also related. According to the petrographical analysis, Nechí coal had high vitrinite (76.4%) and liptinite (22.5%) content. Such high aliphatic group content suggested significant hydrogen and oxygen content, providing a considerable quantity of low-molecular-weight volatile matter.

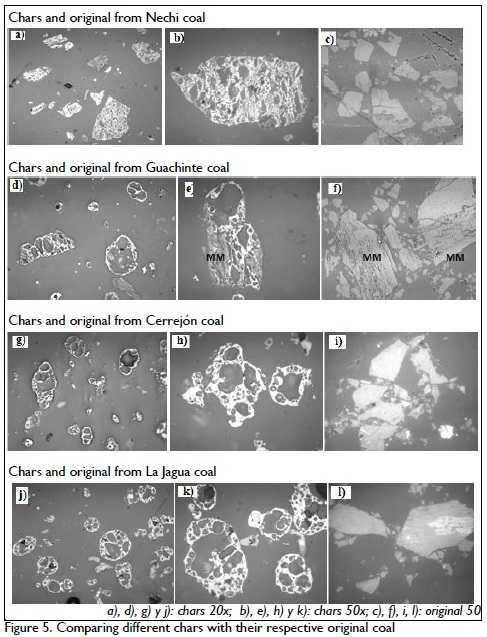

By comparing images (a) and (c) in Figure 5, it can be seen that Nechí coal char morphology did not undergo any change regarding its original coal, in spite of high release of volatile matter. This suggested that Nechí coal had low fusibility and degassed bubbles did not join or grow to produce particle swelling during the pyrolysis plastic stage. By contrast, they went out directly to the particle surface. The chars thus had material degasified in a small-bubble shape caused by a large quantity of low-molecular-weight volatile matter, as can be observed in Figure 5, images (a) and (b).

Coal from the Guachinte mine had the highest liptinite content (32.9%). Nevertheless, it had a considerable quantity of organic matter mixed with mineral matter. As shown in Figure 5 (e) and (f), mineral material formed part of original coal and char. Unlike Nechí coal, and despite them almost belonging to the same rank, Guachinte coal char morphology was different from its original coal. This shows that during the pyrolysis plastic stage, molten coal fluency allowed bubble formation in the coal and led to particle swelling.

The Cerrejón coal had the highest vitrinite content and one of the highest inertinite contents, along with La Jagua. Inertinite presence significantly reduced coal thermo-plasticity during heating, causing cenosphere thick-wall formation. Comparing images (g) and (h) with (i), Figure 5, a great change in coal's morphological structure was noticed after devolatilisation, showing a great fusibility of coal during the plastic stage. It was also observed that char wall thickness from Cerrejon and La Jagua coals was thicker than that of char from Nechí and Guachinte coal.

La Jagua coal had the highest inertinite content, which explains the large quantity of chars having solid-type morphology (MP, MD and I). Inertinite is aromatic and does not release sufficient quantities of volatile fuels, which leads to obtaining thicker walled and less porous chars by contrast with chars obtained from other chars. Comparing images (j) and (k) which show char images to image (I) showing coal without its original, a morphological change in the plastic stage throughout cenosphere formation was observed.

Conclusions

The FC/VM ratio increased according to the rank of the coals used in this study: Nechi<Guachinte<Cerrejón<LaJagua. Many thin-wall char morphologies (TN and CN) were developed in low-rank coals; by contrast, thick-wall and solid-type morphologies were favoured in high-rank coals. It was also found that the network-type char percentage decreased whereas CS increased along with coal rank. The most reactive particles had thinner walls, high porosity and network-type morphology. Accordingly, coals in an increasing reactivity order were: Nechí>Guachinte>Cerrejón>La Jagua, showing a direct relationship with coal rank. By contrast, beneficiated coals were more reactive than non-beneficiated coals since they had low-thickness walls, higher porosity and higher network-type morphology percentage.

Coal petrographical analysis suggested the different characteristics that chars would develop during devolatilisation because of the variation in their maceral composition. Such variations might determine the char type, how porosity would develop and average wall-thickness.

References

Alvarez, D., Lester, E., The procedure used to develop a coal char classification -Commission III Combustion Working Group of the International Committee for Coal and Organic Petrology., International Journal of Coal Geology, Vol. 81, 2010, pp. 333-342. [ Links ]

Barranco, R., The characterisation and combustion of South-American coals. PhD thesis, University of Nottingham, Nottingham, England, 2001. [ Links ]

Cloke, M., Wu, T., Barranco, R., Lester, E., Char characterization and its application in a coal burnout model., Fuel, Vol. 82, 2000, pp. 1989 - 2000. [ Links ]

Guerrero, J., Ríos, H., Desarrollo metodológico para analizar macerales de carbón., Thesis Universidad del Valle, Santiago de Cali, Colombia, 2009. [ Links ]

Lawrence, R., Advanced Pulverized Coal Combustion. Proceedings of the Conference on Advanced Coal-Based Power and Environmental Systems., 1998, pp. 21-23. [ Links ] [ Links ]

Rojas, A., Estudio cinético de la combustión del char de carbón pulverizado. Thesis Ph.D., Universidad del Valle, Santiago de Cali, Colombia, 2005. [ Links ]

Rojas, A., Barraza, J., Efecto de las condiciones de desvolatilización de carbones pulverizados sobre las características físicas de carbonizados., Ingeniería e Investigación, Vol. 27, 2007, pp. 32 - 40. [ Links ]

Rojas, A., Barraza, J., Caracterización morfológica de carbones pulverizados: Determinación experimental., Rev. Fac. Ing. Univ. Antioquia, Vol. 43, 2008, pp. 42-58. [ Links ]

Yu, J., Wall, T., Formation of the structure of chars during devolatilization of pulverized coal and its thermo properties: A review., Progress in Energy and Combustion Science, Vol. 33, 2007, pp. 135-170. [ Links ] [ Links ]